Foaming ceramic based on phosphate tailings and coal gangue and preparation method thereof

A technology of foamed ceramics and coal gangue, which is applied in the field of phosphorus tailings and coal gangue resource utilization, can solve the problems of large influence on the quality stability of porous ceramics, increase the difficulty of pore regulation, increase the complexity of the process, etc., and achieve low cost , low production cost, and the effect of reducing liquid viscosity and surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

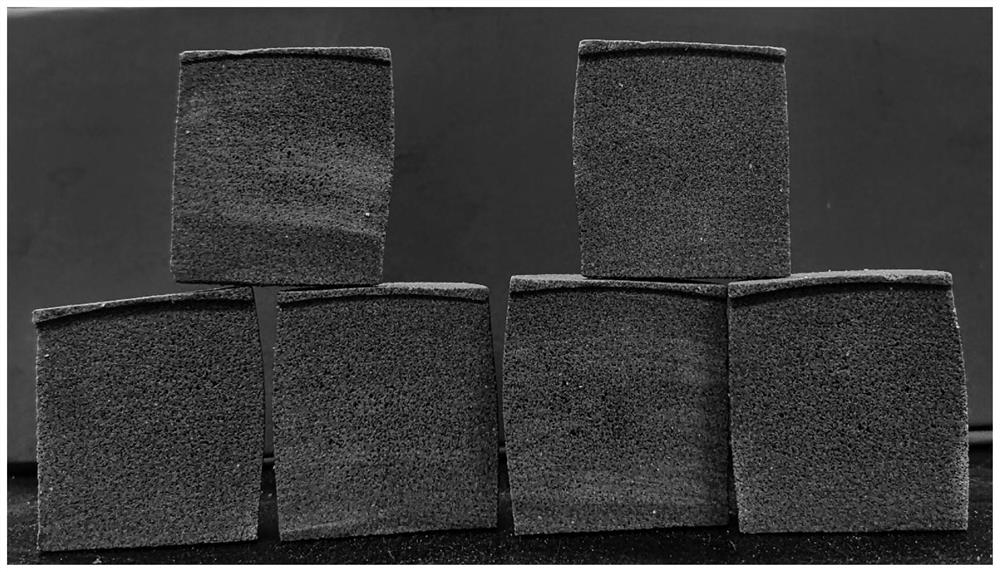

Image

Examples

Embodiment 1

[0047] A foamed ceramic based on phosphorus tailings and coal gangue and a preparation method thereof. The steps of the preparation method are:

[0048] Step 1. Mix 60wt% phosphorus tailings and 40wt% coal gangue as raw materials to obtain a mixture. in:

[0049] The SiO of the phosphorous tailings 2 The content is 74.42wt%;

[0050] The chemical composition of the gangue: Al 2 o 3 The content is 35.01wt%, and the C content is 9.48wt%;

[0051] Among the raw materials: CaO+MgO is 3.168wt%, K 2 O+Na 2 O is 2.352wt%, Fe 2 o 3 +C is 5.796 wt%.

[0052] Step 2: Stir the mixture for 16 minutes, then add 5wt% of the binder and 5wt% water of the mixture, continue to stir for 18 minutes, press to form, and dry at 105°C for 24 hours to obtain a billet body.

[0053] Step 3: The green body is heated up to 600°C at a rate of 9°C / min, then to 950°C at a rate of 3°C / min, then to 1200°C at a rate of 2°C / min, kept for 75 minutes, and then The furnace was cooled to room temperatu...

Embodiment 2

[0058] A foamed ceramic based on phosphorus tailings and coal gangue and a preparation method thereof. The steps of the preparation method are:

[0059] Step 1. Mix 65wt% phosphorous tailings and 35wt% coal gangue as raw materials to obtain a mixture. in:

[0060] The SiO of the phosphorous tailings 2 The content is 78.36wt%;

[0061] The chemical composition of the gangue: Al 2 o 3 The content is 37.25wt%, and the C content is 10.23wt%;

[0062] Among the raw materials: CaO+MgO is 3.5555wt%, K 2 O+Na 2 O is 2.6745wt%, Fe 2 o 3 +C is 5.9295 wt%.

[0063] Step 2: Stir the mixture for 17 minutes, then add 3 wt% of the binder and 7 wt% of water, continue to stir for 17 minutes, machine press, and dry at 110°C for 28 hours to obtain a billet body.

[0064] Step 3, the green body is heated up to 630°C at a rate of 8°C / min, then to 900°C at a rate of 4°C / min, and then to 1180°C at a rate of 2°C / min, kept for 90 minutes, and then The furnace was cooled to room temperatur...

Embodiment 3

[0069] A foamed ceramic based on phosphorus tailings and coal gangue and a preparation method thereof. The steps of the preparation method are:

[0070] Step 1. Mix 70wt% phosphorous tailings and 30wt% coal gangue as raw materials to obtain a mixture. in:

[0071] The SiO of the phosphorous tailings 2 The content is 78.33wt%;

[0072] The chemical composition of the gangue: Al 2 o 3 The content is 39.21wt%, and the C content is 9.74wt%;

[0073] Among the raw materials: CaO+MgO is 3.699wt%, K 2 O+Na 2 O is 2.837wt%, Fe 2 o 3 +C is 6.067 wt%.

[0074] Step 2. Stir the mixture for 20 minutes, then add 5wt% of the binder and 6wt% water of the mixture, continue to stir for 15 minutes, press to form, and dry at 106°C for 26 hours to obtain a billet body.

[0075] Step 3, the body is heated up to 650°C at a rate of 5°C / min, then to 930°C at a rate of 3°C / min, then to 1190°C at a rate of 1°C / min, kept for 45 minutes, and then The furnace was cooled to room temperature to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com