Equipment and preparation method for preparing environment-friendly plastic alloy new material from garbage and sludge in full-dose mode

A technology of environmentally friendly plastics and new materials, applied in the field of environmental protection, can solve the problems of large land occupation, high investment and operating costs, and long time anaerobic production of biogas, reducing the number of constructions, high resource utilization, and realizing waste regeneration. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

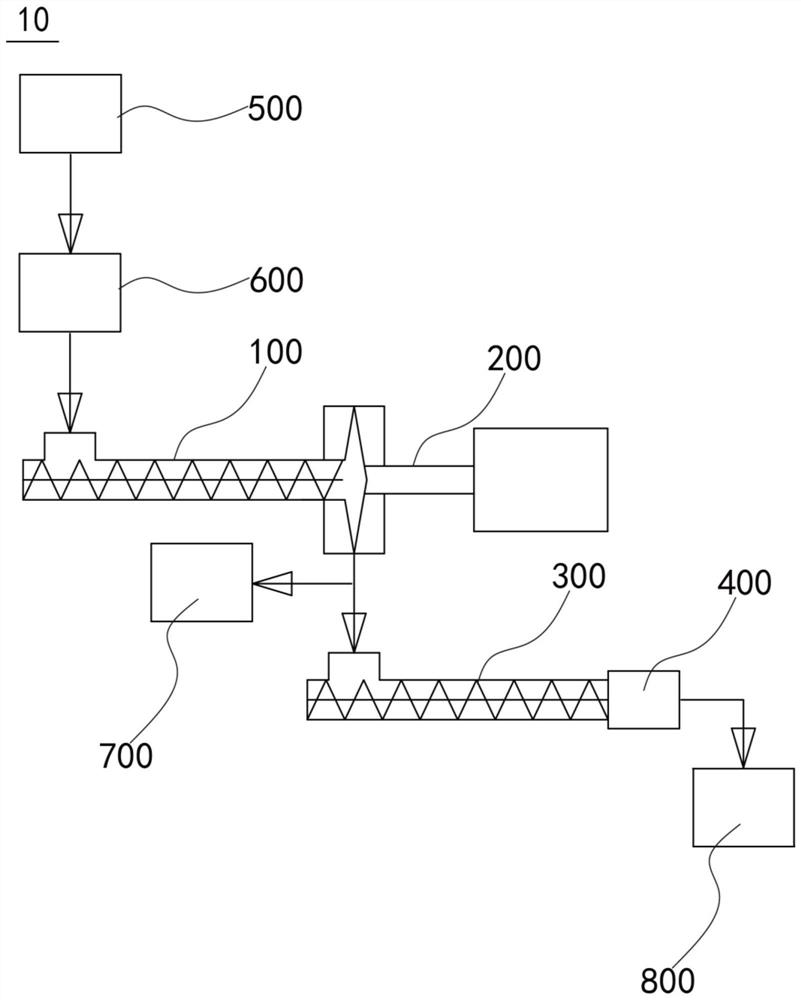

[0048] A method for preparing a new environmentally friendly plastic alloy material made from garbage and sludge, comprising the following steps:

[0049] The rubbish is sent to the crushing mechanism 500 for crushing treatment to obtain crushed rubbish. When the garbage is crushed, the combustibles (such as plastics, fabrics, bamboo, wood, leather, rubber, paper, etc.) become smaller than 30 mm, and the inorganic substances (such as glass, ceramics, masonry, shells, metals, etc.) It becomes less than 0.2 mm, and perishables (such as vegetables, meat, bones, shells, waste oil, etc.) become muddy.

[0050] The pulverized garbage, or the pulverized garbage mixed with the mixed sludge is sent to the extruding mechanism 600 for extrusion dehydration treatment to obtain the dehydration intermediate.

[0051] The dehydrated intermediate enters the first screw heater 100 for drying and melting to obtain a melt. The heating temperature of the first screw heater 100 is 100°C-230°C. ...

Embodiment 1

[0059] This embodiment provides a method for preparing a new environmentally friendly plastic alloy material produced from garbage and sludge.

[0060] A method for preparing new environmentally friendly plastic alloy materials made from garbage and sludge, comprising the following steps:

[0061] The household garbage is sent to the shredding mechanism 500 for shredding treatment to obtain shredded garbage. When the garbage is crushed, the combustibles (such as plastics, fabrics, bamboo, wood, leather, rubber, paper, etc.) become smaller than 30 mm, and the inorganic substances (such as glass, ceramics, masonry, shells, metals, etc.) It becomes less than 0.2 mm, and perishables (such as vegetables, meat, bones, shells, waste oil, etc.) become muddy.

[0062] The crushed garbage is sent to the extrusion mechanism 600 for extrusion dehydration treatment to obtain dehydration intermediates.

[0063] The dehydrated intermediate enters the first screw heater 100 for drying and m...

Embodiment 2

[0069] This embodiment provides a method for preparing a new environmentally friendly plastic alloy material produced from garbage and sludge.

[0070] A method for preparing new environmentally friendly plastic alloy materials made from garbage and sludge, comprising the following steps:

[0071] The household garbage is sent to the shredding mechanism 500 for shredding treatment to obtain shredded garbage. When the garbage is crushed, the combustibles (such as plastics, fabrics, bamboo, wood, leather, rubber, paper, etc.) become smaller than 30 mm, and the inorganic substances (such as glass, ceramics, masonry, shells, metals, etc.) It becomes less than 0.2 mm, and perishables (such as vegetables, meat, bones, shells, waste oil, etc.) become muddy.

[0072] The pulverized garbage and sludge are mixed and sent to the extrusion mechanism 600 for extrusion dehydration treatment to obtain dehydration intermediates.

[0073] The dehydrated intermediate enters the first screw he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com