Biomass continuous pyrolysis charing apparatus with flexible spiral conveying apparatus

A screw conveying device, pyrolysis carbonization technology, applied in carbonization furnaces, biofuels, special forms of dry distillation, etc., can solve the problems of high operating costs, material transportation restrictions, complex equipment structure, etc., to achieve good safety, stable operation, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

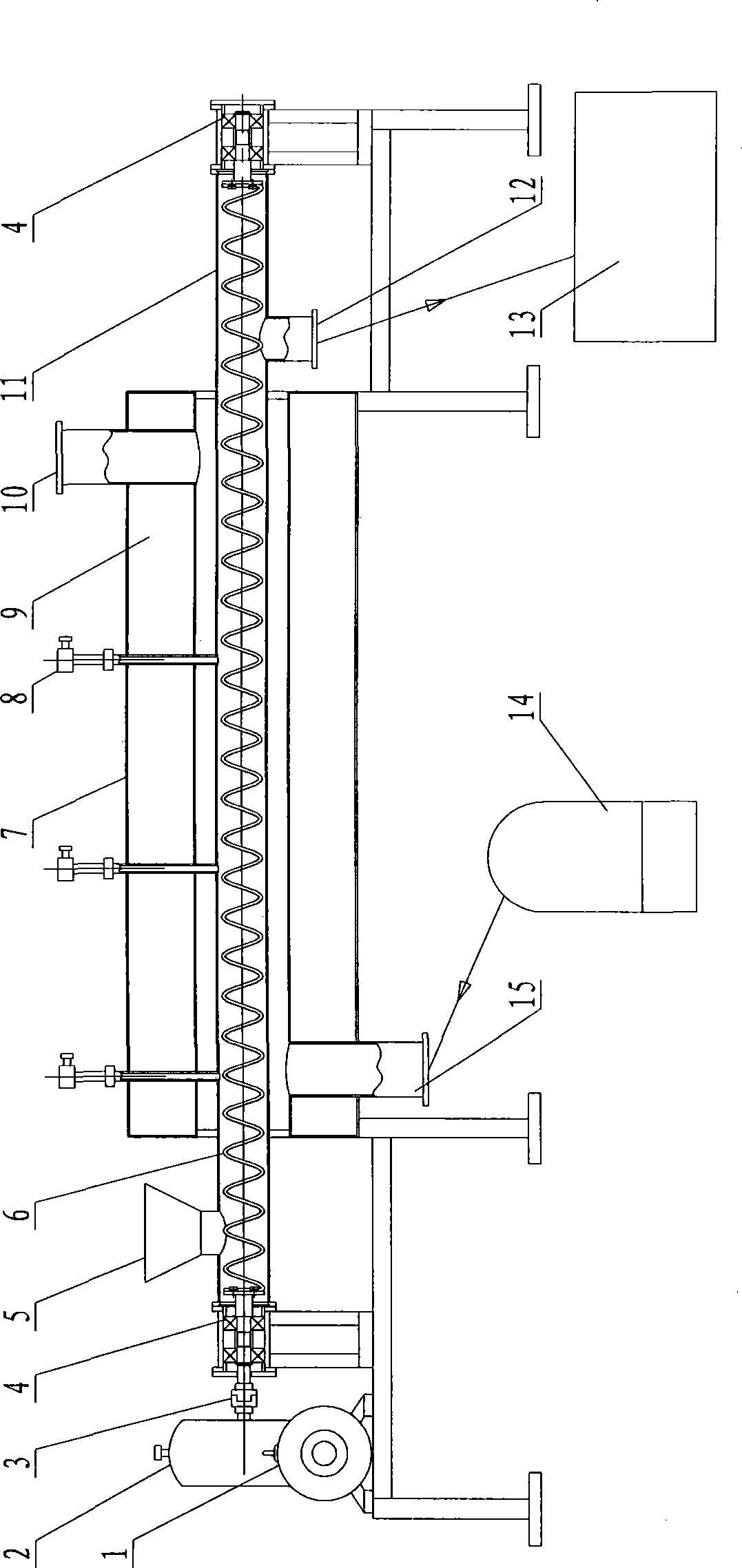

[0020] Such as figure 1 As shown, a biomass continuous pyrolysis and carbonization device with a flexible screw conveying device includes a motor 1, a coupling 3, a bearing 4, a flexible coil spring 6, a pyrolysis tube 11, a feed port 5, and a charcoal outlet Port 12 and heating device;

[0021] One end of the pyrolysis tube 11 is provided with a feed port 5 communicated with the inner cavity of the pyrolysis tube 11, and the other end is provided with a charcoal outlet 12 communicated with the inner cavity of the pyrolysis tube 11. A flexible helical spring 6 is plugged in, one end of the flexible helical spring 6 is connected to the output shaft of the motor 1 through the first bearing 4 and the coupling 3, and the other end is supported by the second bearing 4, and the outer side of the pyrolysis tube 11 is arranged There is a heating device for heating the pyrolysis tube 11 . The feed inlet 5 is set on the upper surface of the pyrolysis tube 11 , and the char outlet 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com