Treatment system for bean vermicelli production wastewater

A technology for the production of wastewater and treatment systems, which is applied in the fields of food industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the waste of useful resources, high energy consumption, low efficiency of high-concentration wastewater, etc. problems, to achieve the effect of improving energy saving and emission reduction, ensuring up-to-standard emissions, and ensuring the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

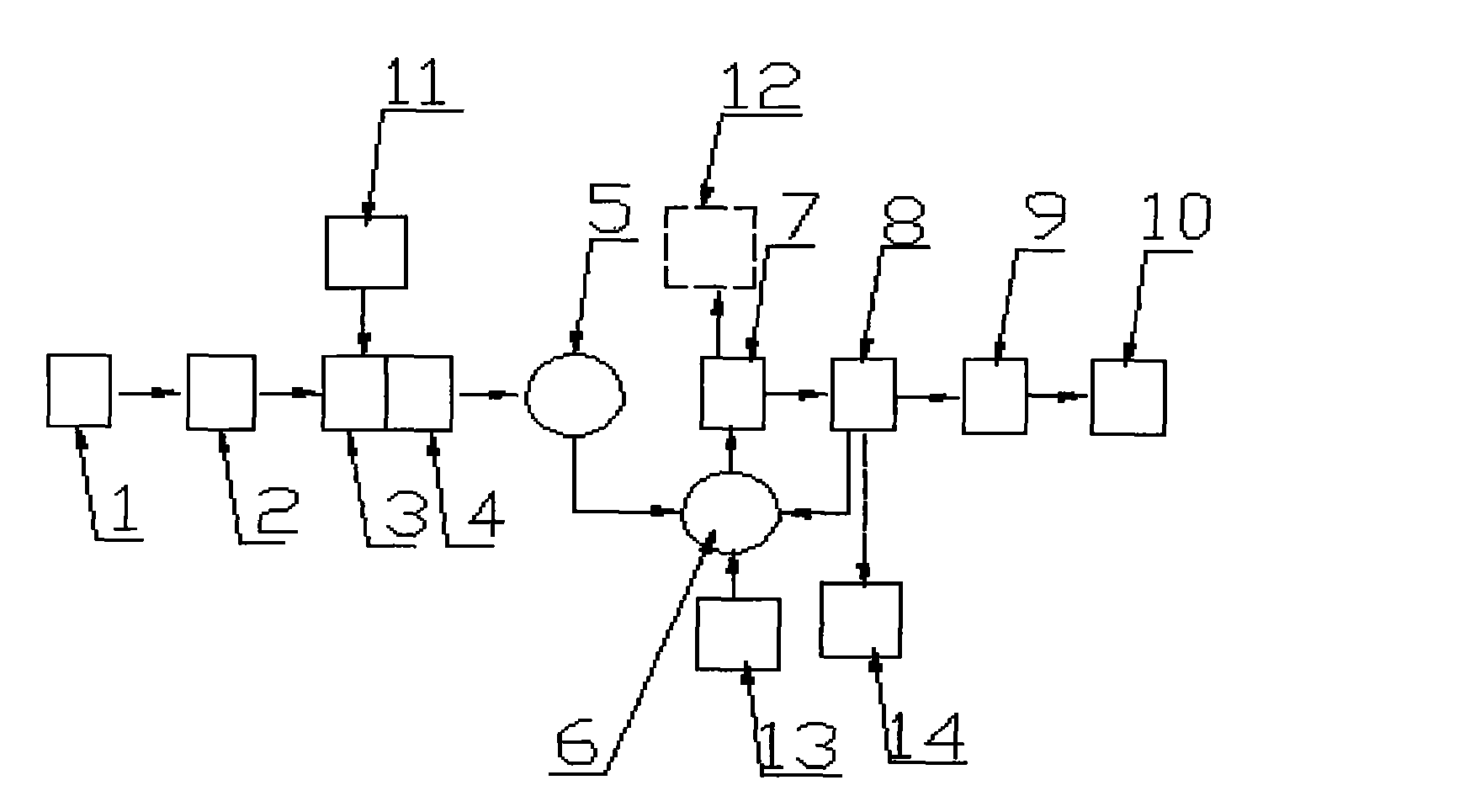

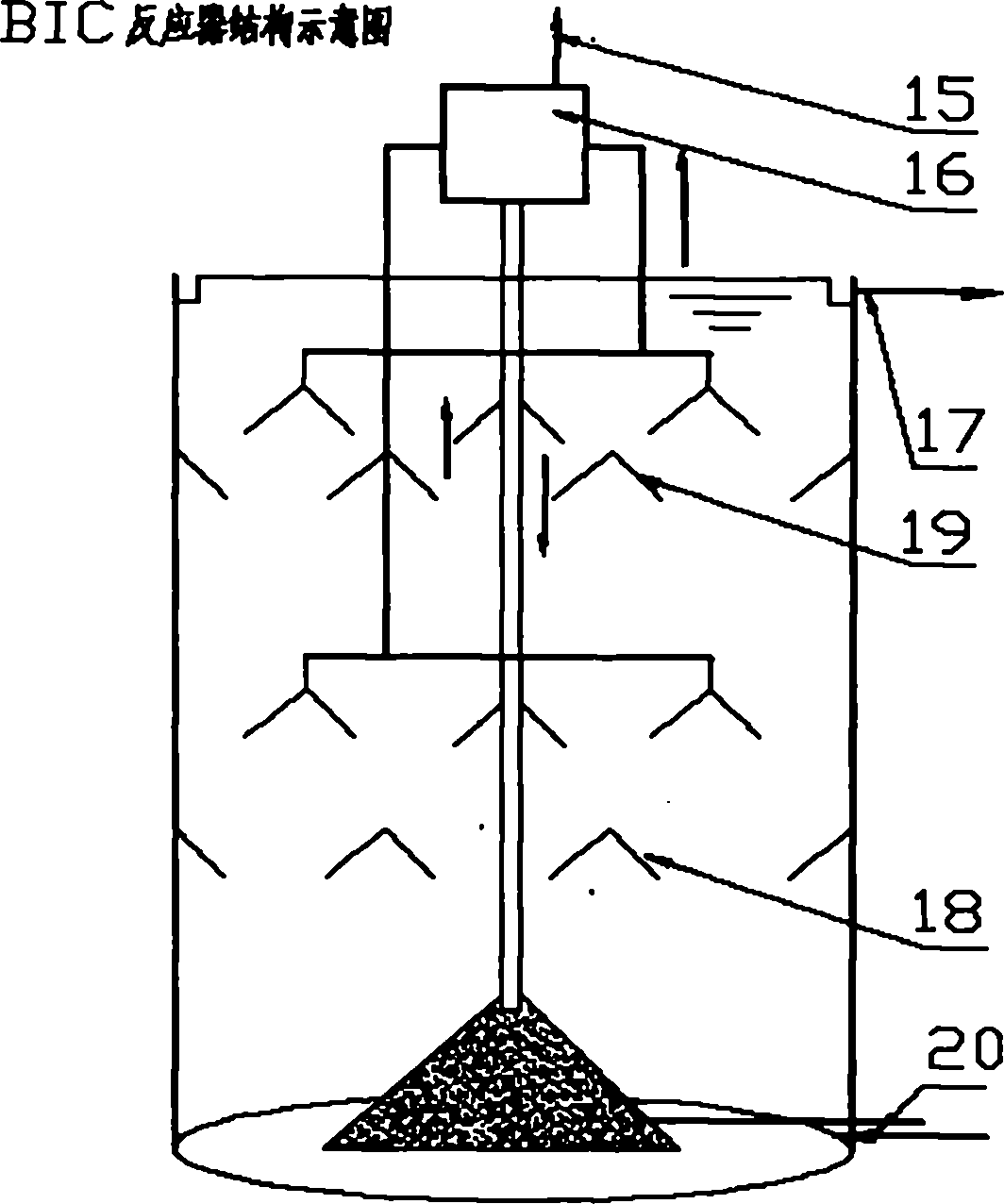

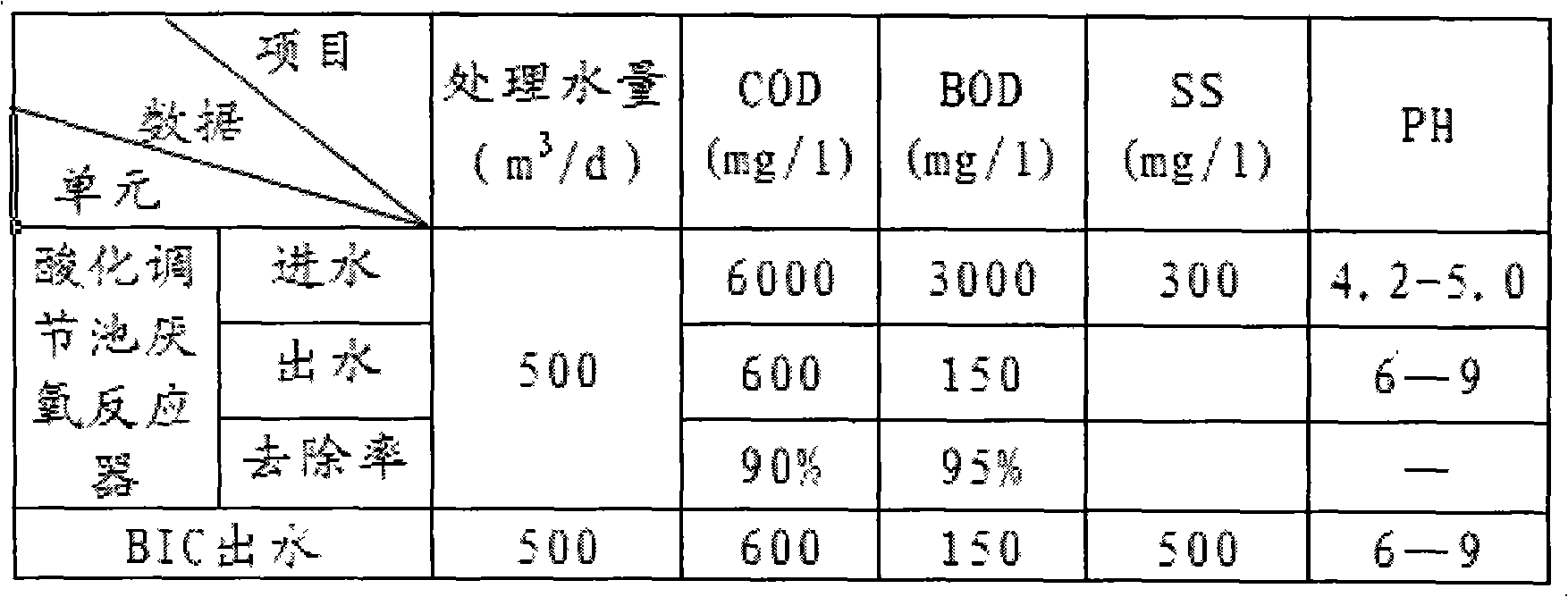

[0023] like figure 1 and figure 2 Shown, a kind of treatment system of vermicelli production waste water is characterized in that, comprises water inlet 1 and water outlet 10, is communicated with first settling tank 2, acidification by pipeline successively between described water inlet 1 and water outlet 10 Adjusting tank 3, lifting water pump, anaerobic reactor 7, second sedimentation tank 8 and aerobic treatment tank 9; the first sedimentation tank 2 is used for pre-sedimentation treatment of wastewater, and the acidification adjustment tank 3 is used for adjusting high The water quality and water quantity of concentrated wastewater, the anaerobic reactor 7 is used to perform anaerobic fermentation and generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com