Cement grinding aid

A cement grinding aid and cement technology, which are applied in the field of cement grinding aids, can solve the problems of restricting the promotion and application of cement grinding aids, affecting the enhanced performance of grinding aids, and excavating modification effects, and achieve good economic and social benefits. , Good grinding effect and simplified production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

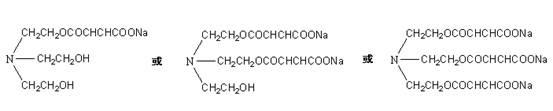

Image

Examples

Embodiment 1

[0028] Add 100kg triethanolamine to the reactor, then add 40kg acetic acid, adjust the solution to neutral, then add 60kg maleic anhydride, stir and heat up to 60°C, react for 5h, cool to room temperature, and then use 500kg 20% sodium hydroxide Adjust the pH of the solution to neutral to obtain the cement grinding aid.

Embodiment 2

[0030] Add 100kg of triethanolamine to the reactor, then add 40kg of acetic acid, adjust the solution to neutral, then add 70kg of maleic anhydride, stir and heat up to 80°C, react for 4.5h, cool to room temperature, and then use 535kg of 20% hydrogen to oxidize Sodium solution adjusts pH to neutral to obtain cement grinding aid.

Embodiment 3

[0032] Add 100kg triethanolamine to the reactor, then add 40kg acetic acid, adjust the solution to neutral, then add 75kg maleic acid, stir and heat up to 85°C, react for 4h, cool to room temperature, and then use 550kg 20% sodium hydroxide Adjust the pH of the solution to neutral to obtain the cement grinding aid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com