Method for regenerating carbon fibers from carbon fiber-reinforced composite material wastes

A reinforced composite material, composite material technology, applied in the field of waste recycling of carbon fiber reinforced composite materials, can solve unavoidable problems and achieve the effect of low equipment cost, obvious economic benefits, and unified social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

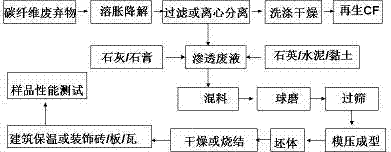

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Carbon Fiber Reinforced Epoxy Composite Recycling.

[0029] Put the carbon fiber reinforced epoxy resin composite tube into a glass tank of corresponding size, add a mixture of concentrated sulfuric acid, alkylphenol polyoxyethylene ether and tetrahydrofuran (9:1:1), and immerse the carbon fiber reinforced composite material at room temperature. After soaking for 24 hours under static or stirring conditions, filter or centrifuge to take out the carbon fiber, wash it with clean water for several times until it is clean, dry it naturally or heat it to get the regenerated carbon fiber, and store it for later use; the soaked waste liquid is distilled to remove tetrahydrofuran, and then add hydroxide After sodium neutralization, it can be used as an additive for adhesives or paints.

Embodiment 2

[0030] Example 2 Carbon Fiber Reinforced Epoxy Composite Recycling.

[0031] Put the carbon fiber-reinforced epoxy resin composite tube into a glass tank of corresponding size, add a mixture of concentrated sulfuric acid, petroleum ether and polyethylene glycol 400 (7:2:2) to immerse the carbon fiber-reinforced composite material, stand at room temperature or After soaking for 48 hours under stirring conditions, filter or centrifuge to take out the carbon fiber, wash it with clean water for several times until it is clean, dry it naturally or heat it to obtain the regenerated carbon fiber, and store it for later use; after the soaked waste liquid is distilled to remove petroleum ether, add hydroxide After calcium neutralization, it can be used as an additive for adhesives or coatings.

Embodiment 3

[0032] Example 3 Carbon Fiber Reinforced Epoxy Composite Recycling.

[0033] Put the carbon fiber reinforced epoxy resin composite tube into a glass tank of the corresponding size, add a mixture of concentrated sulfuric acid, fatty alcohol polyoxyethylene ether and dioxane (6:5:1), and immerse the carbon fiber reinforced composite material After soaking for 36 hours at room temperature or under stirring conditions, filter or centrifuge to take out the carbon fiber, wash it with clean water for several times until it is clean, dry it naturally or heat it to obtain the regenerated carbon fiber, and store it for later use; the soaked waste liquid is distilled to remove dioxane After ringing, add calcium oxide to neutralize and use it as an additive for adhesives or coatings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com