Wide-load efficient turbine generator set with switchable partial cylinders

A technology of steam turbine generator set and steam turbine set, which is applied in the direction of steam engine device, machine/engine, mechanical equipment, etc. It can solve the problems of decreased cycle efficiency, increased throttling loss, increased coal consumption rate of power supply, etc., so as to improve the operation economy performance, increase the main steam pressure, and promote the effect of energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

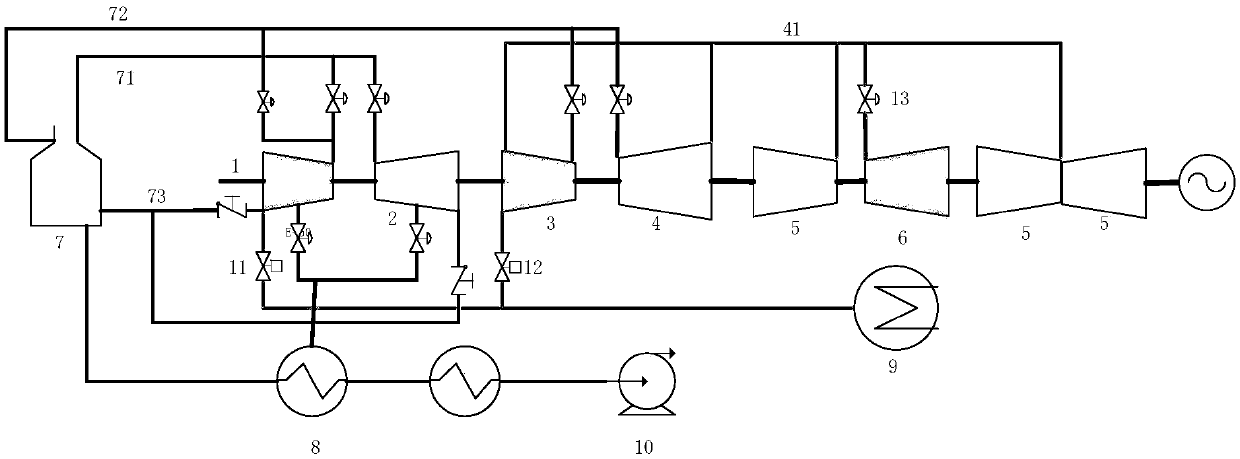

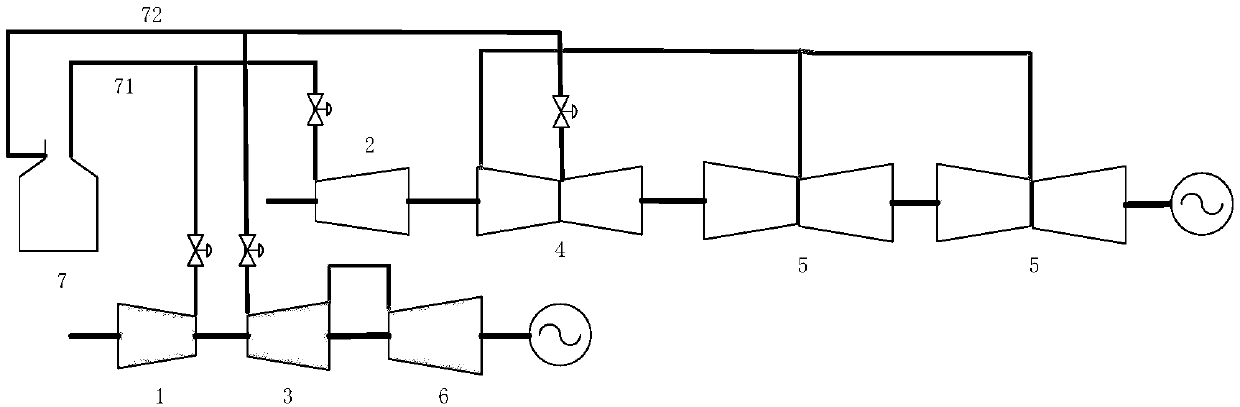

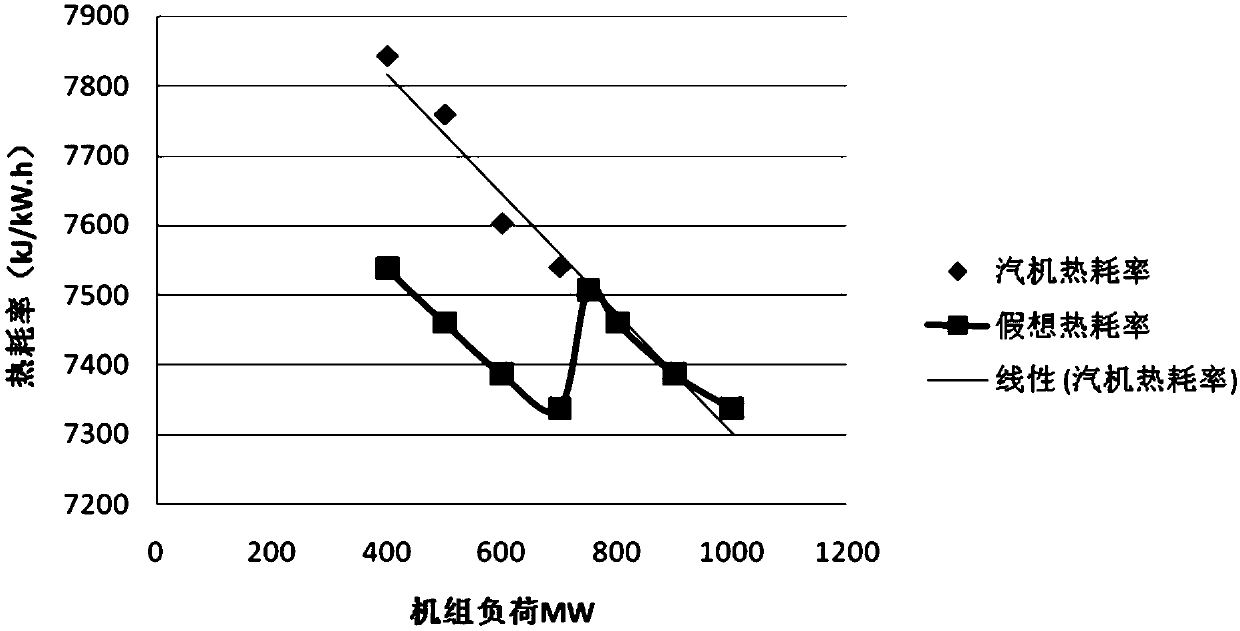

[0041] Taking a super (super) critical 1000MW primary reheat unit as an example, the steam turbine adopts throttling steam distribution mode, and the high-pressure valve is fully opened to slide pressure operation. The main steam pressure is low under medium and low loads, which affects the economy of the unit. For this reason, the layout of high, medium and low pressure cylinders is partially cut off. Considering the high pressure cylinder block set series and the peak load requirements of the unit, the high pressure cylinder of the original 1000MW unit is divided into two high pressure cylinders, which are the original 660MW unit and the 350MW unit respectively. The high-pressure cylinder corresponding to the unit, the work and flow capacity of the two high-pressure cylinders are basically set according to the relationship of 2:1. In addition, the capacity of the original two medium-pressure cylinders is the same, and now the capacity is adjusted according to the relationship...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com