Method for handling (meth) acrylic ester-containing solution

A technology of acrylate and methyl, applied in the field of treating acrylate-containing solutions, can solve the problems of sludge formation and unsatisfactory continuous and stable operation of the system, and achieve the effect of inhibiting sludge formation and ensuring long-term stable and continuous operation

Active Publication Date: 2010-11-10

MITSUBISHI RAYON CO LTD

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention provides a method for handling a (meth)acrylic ester-containing solution in which the (meth)acrylic ester-containing solution is treated by at least one process selected from washing, neutralization and extraction, the said method being capable of ensuring a stable continuous operation of the treating system for a long period of time without deteriorating a liquid-liquid separation efficiency and a distillation efficiency in subsequent steps while inhibiting the formation of sludge, when waste water or a waste aqueous solution obtained by recovering effective ingredientsfrom the (meth)acrylic ester-containing solution treated by said at least one process is recycled to the previous process and reused therein. The above waste water or waste aqueous solution is previously cooled to a temperature of 10 to 50 DEG C and then solids are removed therefrom prior to recycling the waste water or waste aqueous solution to the previous process and reusing the same therein.

Description

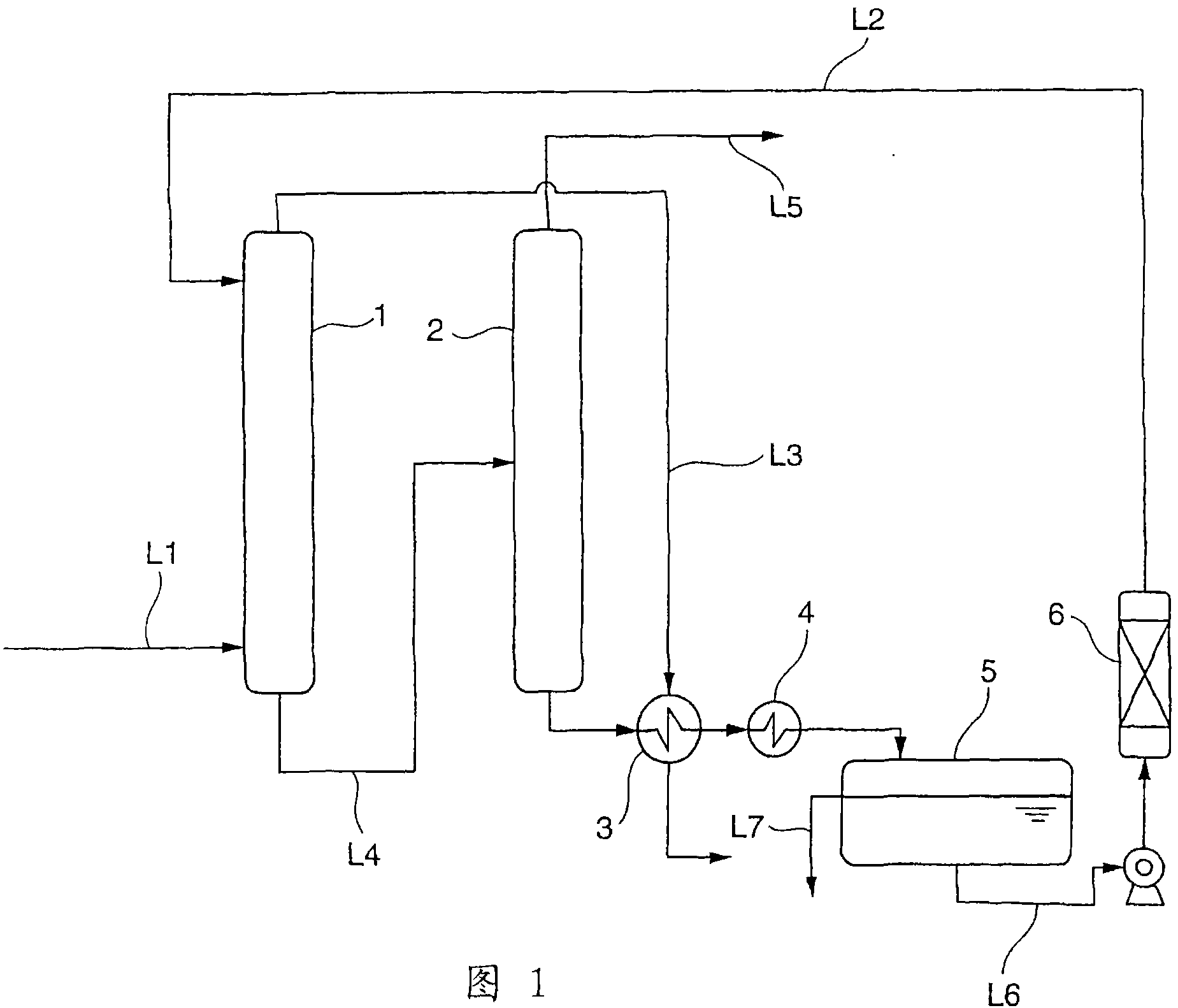

Process for treating solutions containing (meth)acrylates technical field The present invention relates to a method for treating a (meth)acrylate-containing solution, more particularly, the present invention relates to a method for treating a (meth)acrylate-containing solution treated by at least one process selected from washing, neutralization and extraction . Background technique (Meth)acrylates are produced by esterification of (meth)acrylic acid and alcohols in the presence of a homogeneous acid catalyst or a heterogeneous solid acid catalyst. When a homogeneous acid catalyst is used, the resulting esterification reaction solution is washed and / or neutralized with an aqueous base solution after completion of the reaction, thereby separating and removing the acid catalyst and unreacted (meth)acrylic acid from the reaction product. Whereas when a heterogeneous solid acid catalyst is used, the resulting esterification reaction solution is extracted with water or an aque...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C07C69/54C07C67/58C02F1/52B01D9/02B01D11/04C02F1/00C02F1/58C02F1/66C07C67/56

CPCC07C67/56C02F2103/36C07C67/58C02F1/52B01D11/0488C02F1/66C02F1/26B01D11/0492C07C69/54

Inventor 矢田修平高崎研二铃木芳郎小川宁之

Owner MITSUBISHI RAYON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com