Modular assembly integrated valve block applied to hydraulic motor side

A hydraulic motor, modular technology, applied in the direction of servo motor components, servo motors, fluid pressure actuators, etc., can solve the problems of high manufacturing cost, long design cycle, and lack of modular and standardized design, and achieve manufacturing cost The effect of reducing and shortening the design cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

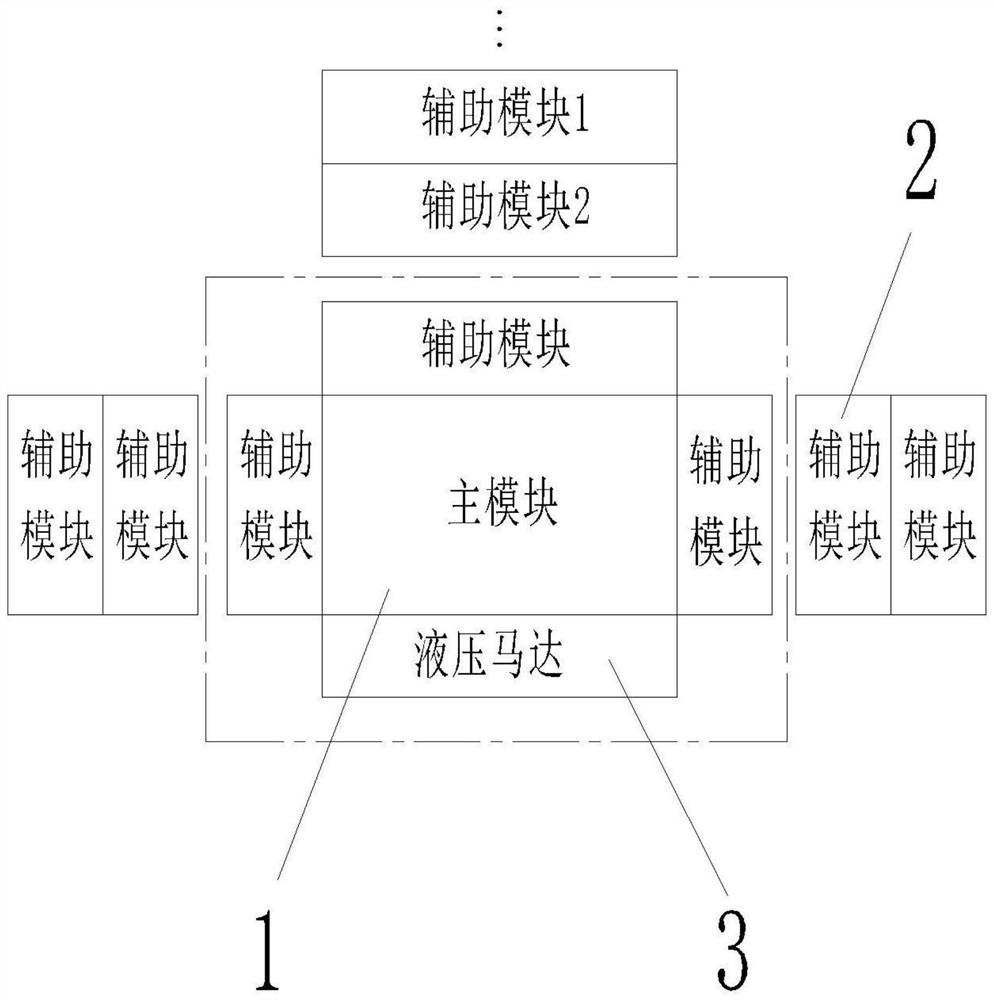

[0026] Such as figure 1 As shown, a modular assembly integrated valve block applied to the hydraulic motor side, it includes a main module 1 with fixed functions, and multiple auxiliary modules 2 whose functions can be canceled, replaced or combined. Module 1 and each auxiliary module 2 are equipped with standardized interfaces, and each auxiliary module 2 realizes oil circuit communication with the main module 1 through the standardized interface, between the main module 1 and the auxiliary modules 2, and between different auxiliary modules 2 All can be detachably installed together.

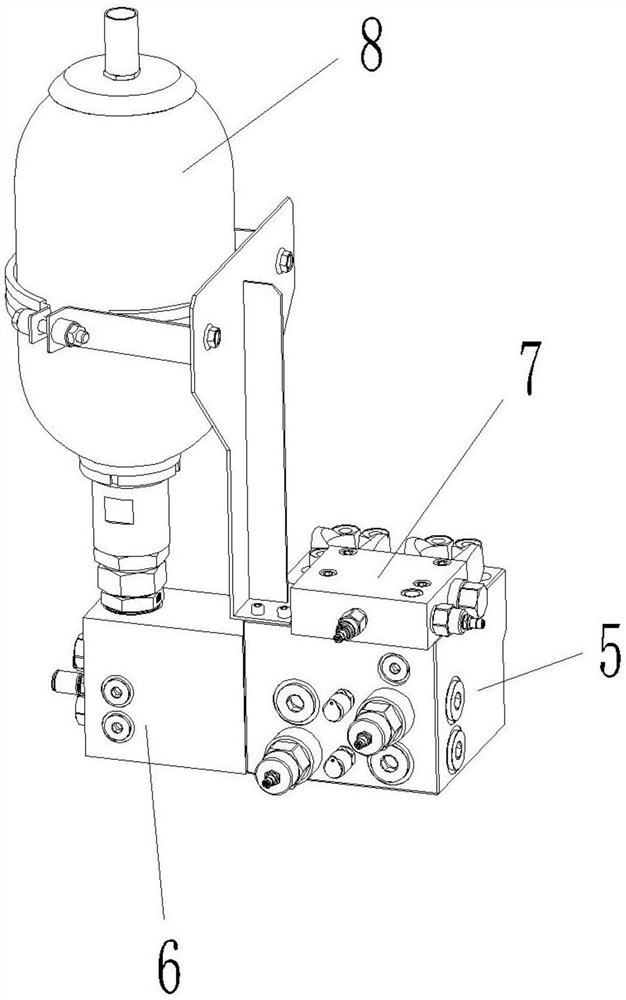

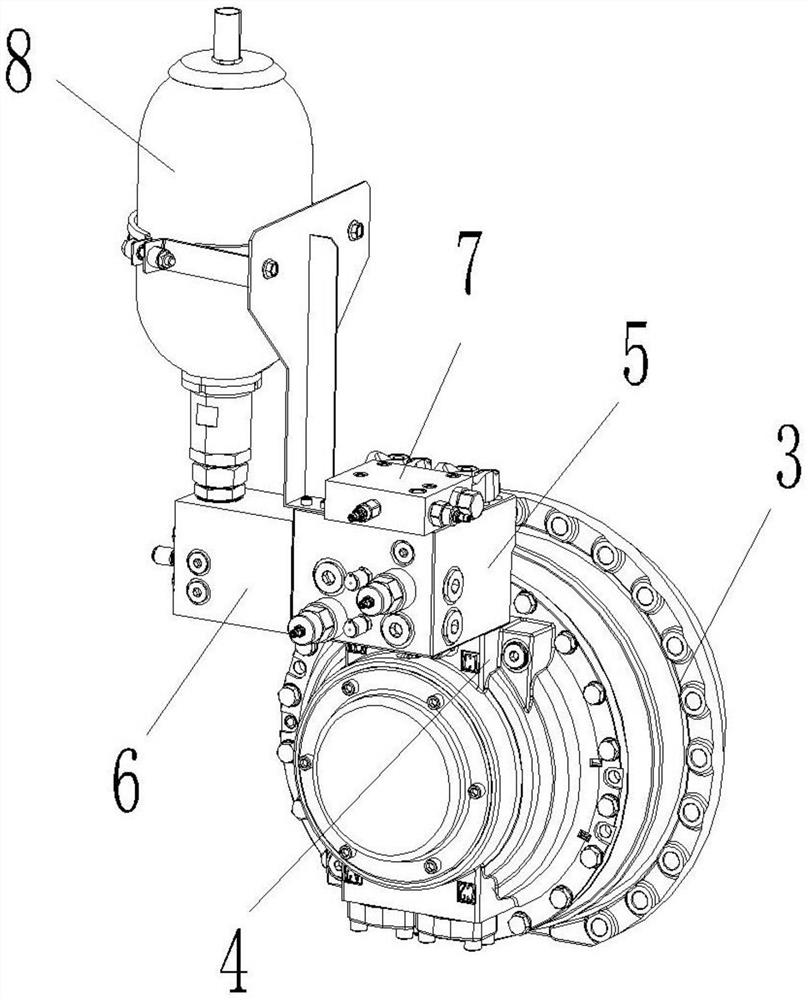

[0027] In this embodiment, the main module 1 includes an overflow module 5; the auxiliary module 2 includes an oil supply module 6 and a flushing module 7; the main module 1 is installed at the oil port 4 of the motor 3, and the main module 1 and The installation structure of the motor 3 and the installation structure between the modules are as follows: Figure 2-4 shown.

[0028] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com