Full-automatic coffee capsule packing machine

A technology for coffee capsules and packaging machines, which is applied in the directions of packaging, transportation and packaging, and types of packaging items, can solve problems such as large volume, complex mechanism structure, and troublesome operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation of the fully automatic coffee capsule packaging machine of the present invention will be further described below in conjunction with the accompanying drawings.

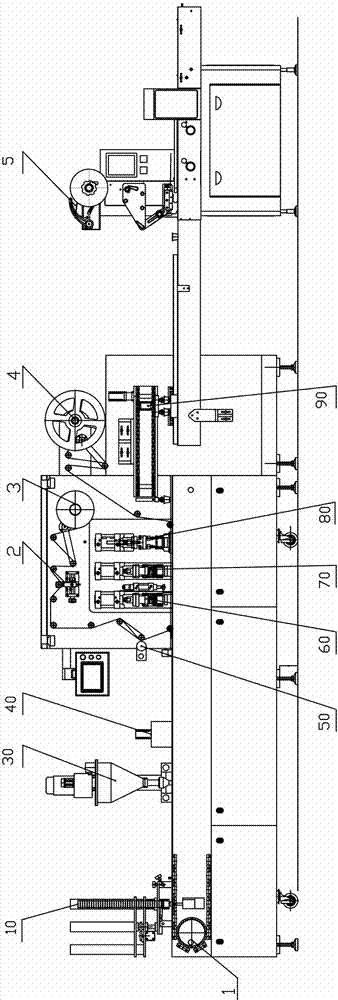

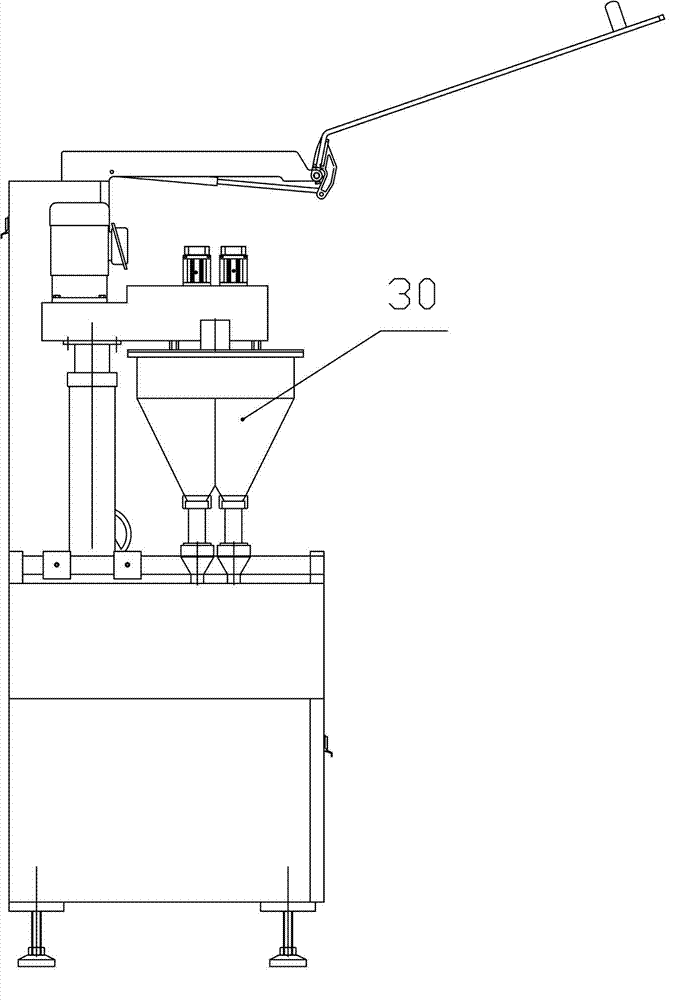

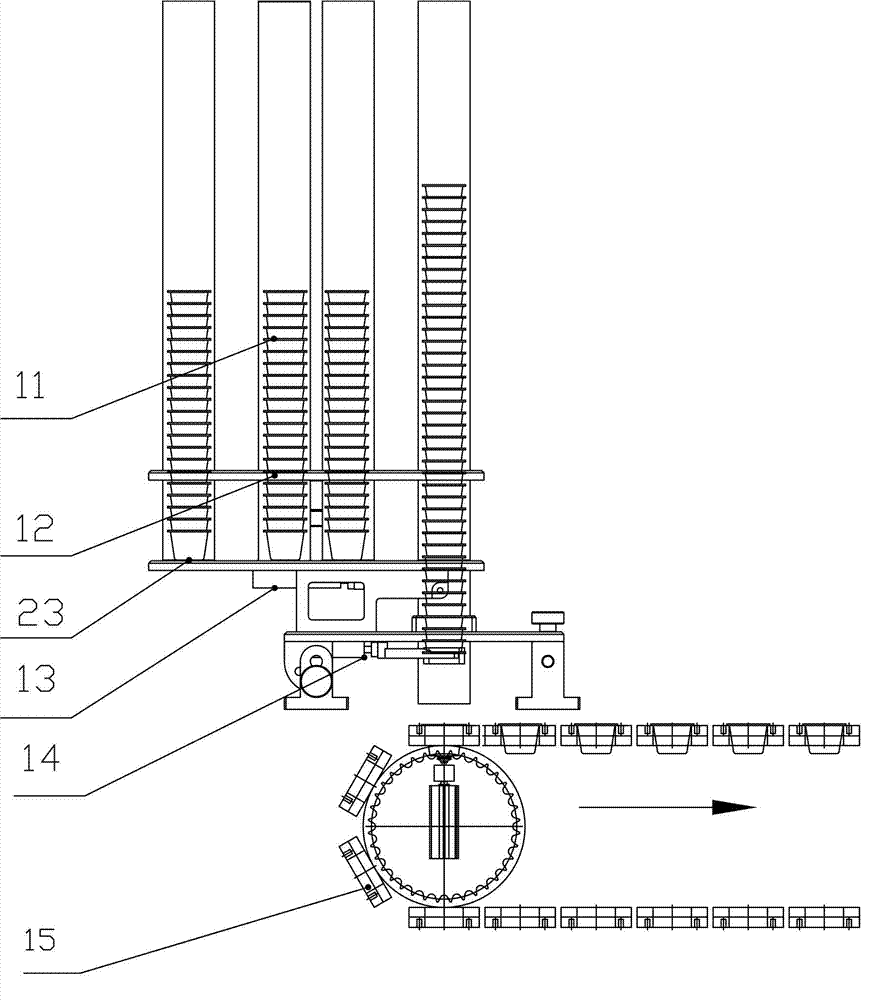

[0042] like Figure 1-Figure 2 (The direction of the arrow is the running direction of the main system), according to the fully automatic coffee capsule packaging machine of the present invention, it includes a main drive system 1, a feeding system 30, a sealing film heat-sealing mechanism, and a sealing film punching mechanism 80. System 1 controls the material cup 11 in the cup dropping system 10 to pass through the feeding system 30 , sealing film heat-sealing mechanism, sealing film punching mechanism 80 , robot automatic delivery system 90 , and finally to the automatic packaging mechanism 5 for outer packaging. The main transmission system 1 is driven by a chain, which can stably transport the material cups 11 without causing accumulation or shortage of the material cups 11 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com