Automatic speed servo adjusting filling and sealing packaging machine

A fully automatic, packaging machine technology, applied in the direction of packaging, transportation packaging, transportation and packaging, etc., can solve the problems that affect the production and processing speed, backward processing methods, waste of working hours, etc., to save production manpower, improve production efficiency, reduce The effect of energy consumption

Active Publication Date: 2014-11-19

汕头市中冠机械有限公司

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The current sealing machine can only seal a cup with the same aperture. If a cup with a smaller aperture needs to be processed, the cup placement sleeve on the conveyor belt needs to be replaced. The process is cumbersome and requires a lot of waste. Large working hours affect the production and processing speed, and the processing method is backward

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

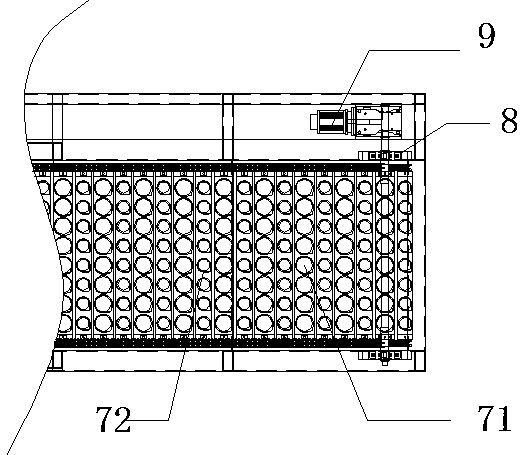

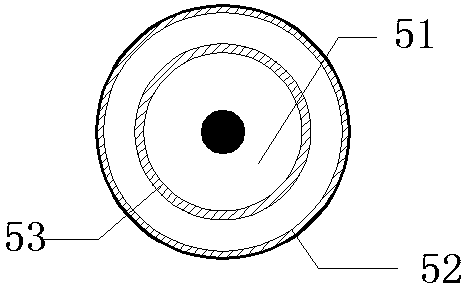

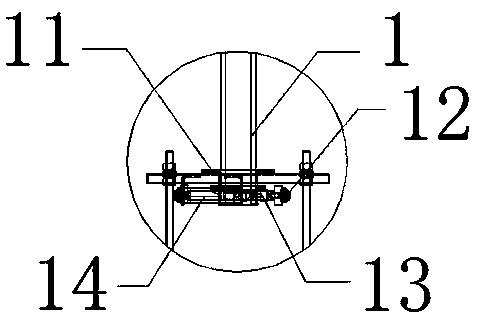

The invention relates to the technical field of packing and sealing machine, in particular to an automatic speed servo adjusting filling and sealing packaging machine comprising a cup placing mechanism, a fruit grain filling device, a filling machine, a film uncoiling mechanism, a sealing machine, a covering device and a speed servo adjusting cup feeding device. The speed servo adjusting cup feeding device comprises a cup conveying chain connected to a speed adjusting servo motor through a servo gear, the cup conveying chain is provided with cup dies with large diameters and cup dies with small diameters at intervals in an adjacent manner, the speed adjusting servo motor controls the operating speed of the cup conveying chain through a PLC, large and small cup mouth sealing switch is implemented, and a large pressing head and a small pressing head are arranged at the sealing pressing port of the bottom of the sealing machine. The machine has the advantages that sealing manners can be adjusted rapidly according to the production requirements, producing efficiency is improved, the design of a production line is integrated, production labor can be saved, purpose of reducing the production cost is achieved, energy consumption is reduced, and the requirements of energy saving and environment protecting are met.

Description

technical field The invention relates to the technical field of packaging and sealing machines, in particular to a fully automatic servo speed-regulating filling and sealing packaging machine. Background technique The current sealing machine can only seal a cup with the same aperture. If a cup with a smaller aperture needs to be processed, the cup placement sleeve on the conveyor belt needs to be replaced. The process is cumbersome and requires a lot of waste. Large working hours affect the production and processing speed, and the processing method is backward. The applicant sees the shortcomings of the above-mentioned conventional filling and sealing machines, adheres to the spirit of research, innovation and excellence, combines production practice, and uses professional and scientific methods to propose a practical solution, so he proposes this application. Contents of the invention The purpose of the present invention is to provide a simple structure, easy to use,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B65B51/10

Inventor 钱泽坤

Owner 汕头市中冠机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com