Paper container product detection machine and detection method thereof

A quality inspection machine and paper container technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of missed inspection, high probability of wrong inspection, high labor cost, unreasonable structural design of the quality inspection machine, etc., to reduce missed inspections. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

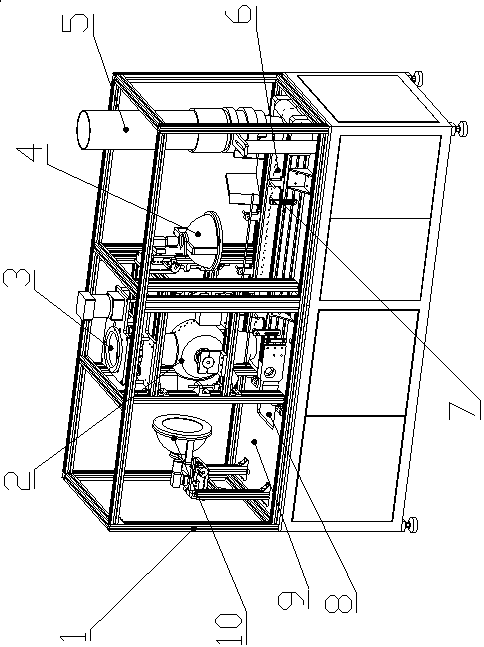

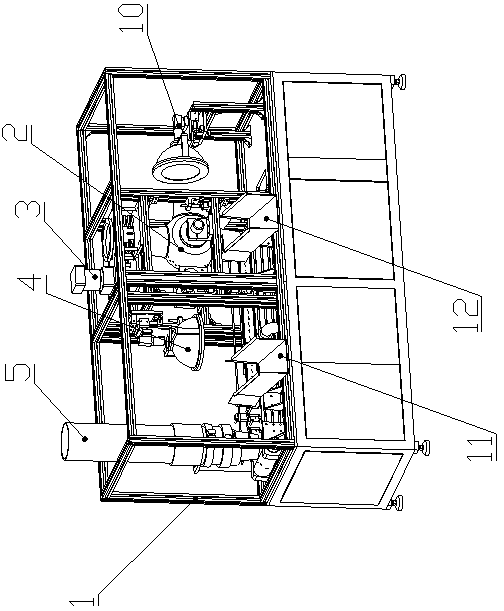

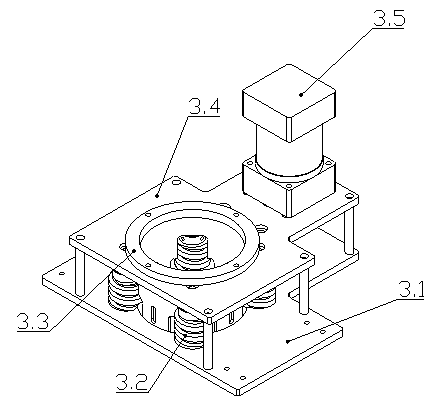

[0029] As shown in the figure, the paper container quality inspection machine according to the present invention includes a frame 1, a screw cup lowering device 3, a drum type suction cup turning device 2, a camera detection device, a vacuum conveying device 6 and a cup discharging device 5, the The inside of the frame 1 is provided with a workbench 9, the vacuum conveying device 6 is arranged on the right part of the workbench 9, and the drum type suction cup turning device 2 is arranged above the left end of the vacuum conveying device 6 , the screw lower cup device 3 is located above the drum type suction cup turning device 2, the camera detection device includes a first camera detection device 10 and a second camera detection device 4, the first camera The detection device 10 is arranged on the left side of the drum type suction cup turning device 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com