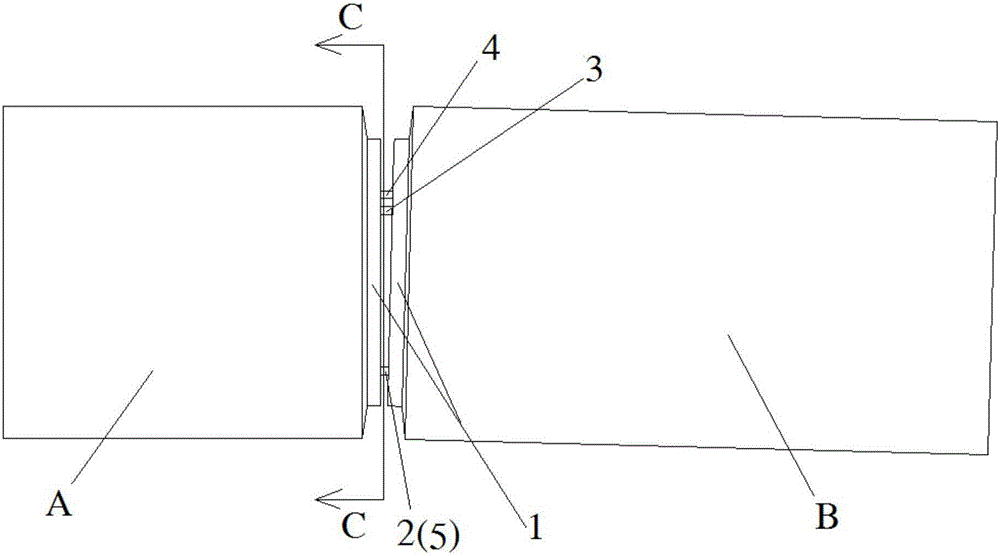

Method for welding butt joint of large thick wall pipelines in nuclear power station

A technology of butt joints and large and thick walls, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., and can solve the problems of large gap between groups, inability to complete welding of pipe sections, and burn-through of blunt edges of grooves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

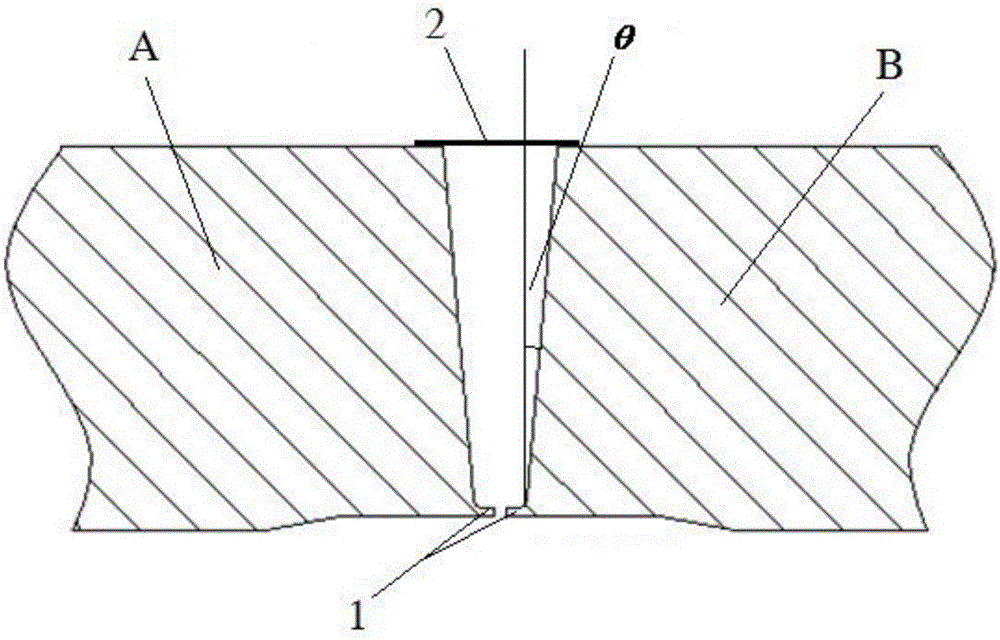

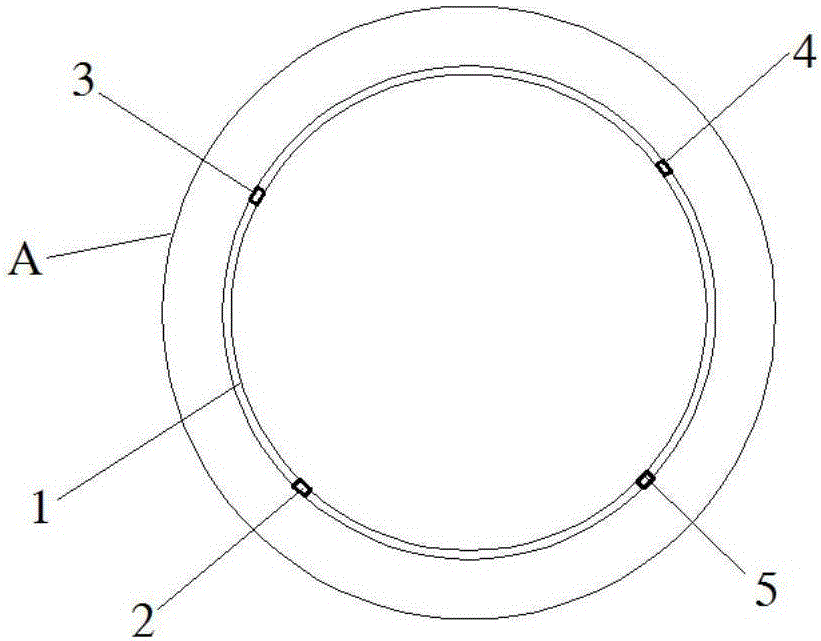

[0040] Example 1: Welding a welding test piece at the 5G position, the material is TP316LN stainless steel, φ952.5×82.6mm, and the thickness of the blunt edge of the groove is 2.16-2.41mm

[0041] The specification of the welded test piece is φ952.5×82.6mm, that is, the outer diameter of the pipe is 952.5mm, the wall thickness is 82.6mm, the material is TP316LN stainless steel, and the unilateral slope of the groove is 5°. When welding, the welding equipment is the GTVI all-position automatic welding machine from LIBURDI Company in Canada; the tungsten electrode adopts polished cerium tungsten electrode, and the diameter of the tungsten electrode is 4.0mm, the taper is 30°, and the platform diameter is 0.8-1.2mm; the welding wire adopts It is ER316L welding wire (stainless steel welding wire produced by Manchester, UK), and the diameter of the welding wire is 1.0mm; the shielding gas is 99.999% Ar.

[0042] The corresponding values of the pairing gap of the pipeline to be we...

Embodiment 2

[0049] Example 2: Welding a welding test piece at the 5G position, the material is TP316LN stainless steel, φ952.5×82.6mm, and the thickness of the blunt edge of the groove is 2.16-2.41mm

[0050] The specification of the welded test piece is φ952.5×82.6mm, that is, the outer diameter of the pipe is 952.5mm, the wall thickness is 82.6mm, the material is TP316LN stainless steel, and the unilateral slope of the groove is 5°. When welding, the welding equipment is the GTVI all-position automatic welding machine from LIBURDI Company in Canada; the tungsten electrode adopts polished cerium tungsten electrode, and the diameter of the tungsten electrode is 4.0mm, the taper is 30°, and the platform diameter is 0.8-1.2mm; the welding wire adopts It is ER316L (stainless steel welding wire produced by British Manchester Company), and the diameter of the welding wire is 1.0mm; the shielding gas is 99.999% Ar.

[0051] The corresponding values of the pairing gap of the pipe to be welded at...

Embodiment 3

[0058] Example 3: Welding a welding test piece at the 6G position, the material is TP316LN stainless steel, φ457×45mm, and the thickness of the blunt edge of the groove is 2.16-2.41mm

[0059] The specification of the welded test piece is φ457×45mm, that is, the outer diameter of the pipe is 457mm, the wall thickness is 45mm, the material is TP316LN stainless steel, and the unilateral slope of the groove is 6°. When welding, the welding equipment is the GTVI all-position automatic welding machine from LIBURDI Company in Canada; the tungsten electrode adopts polished cerium tungsten electrode, and the diameter of the tungsten electrode is 4.0mm, the taper is 30°, and the platform diameter is 0.8-1.2mm; the welding wire adopts It is ER316L (stainless steel welding wire produced by British Manchester Company), and the diameter of the welding wire is 1.0mm; the shielding gas is 99.999% Ar.

[0060] The values corresponding to the pair gaps of the pipes to be welded at different ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com