Method for manufacturing motor mounting bracket

A technology for mounting brackets and manufacturing methods, applied in the direction of manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve problems affecting the performance and service life of motor mounting brackets, low accuracy of welding dimensions, unfavorable motor support and fixation, etc. To achieve the effect of improving the firm performance of the installation, convenient and simple installation and disassembly, and ensuring the firmness of the installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

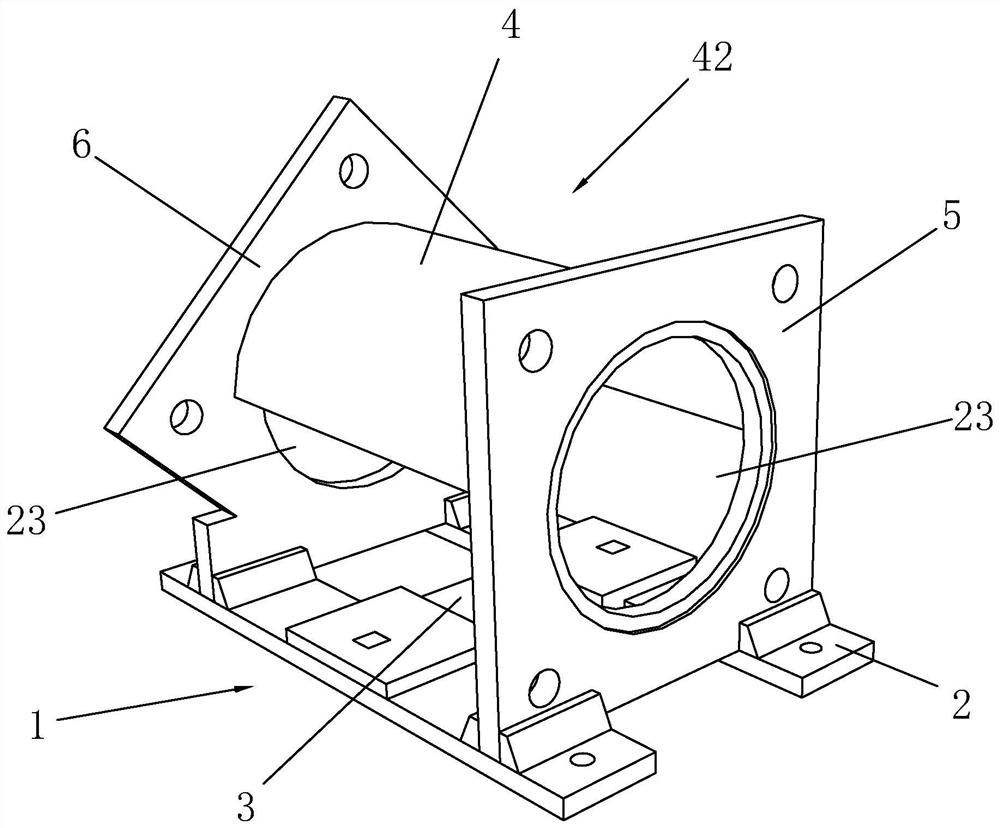

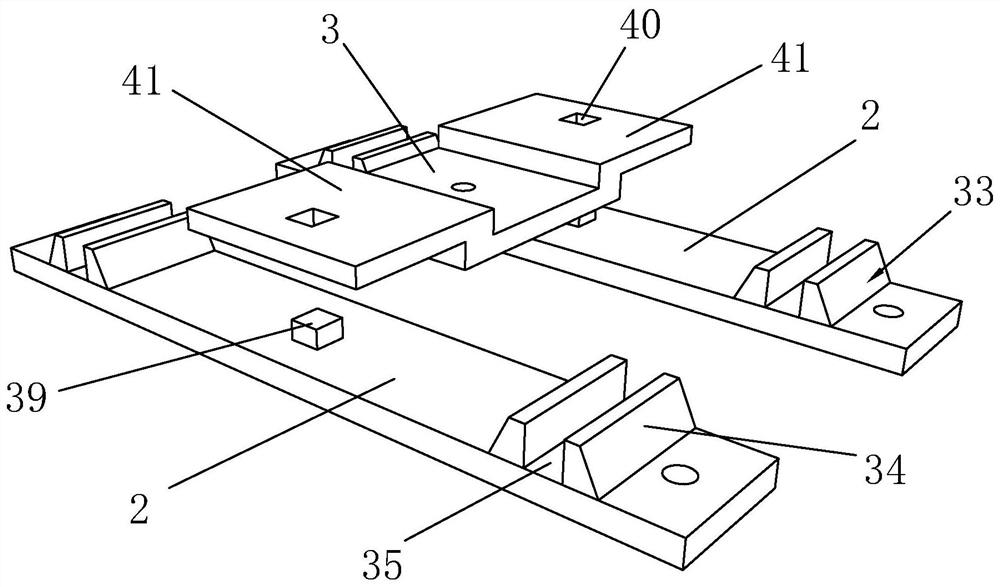

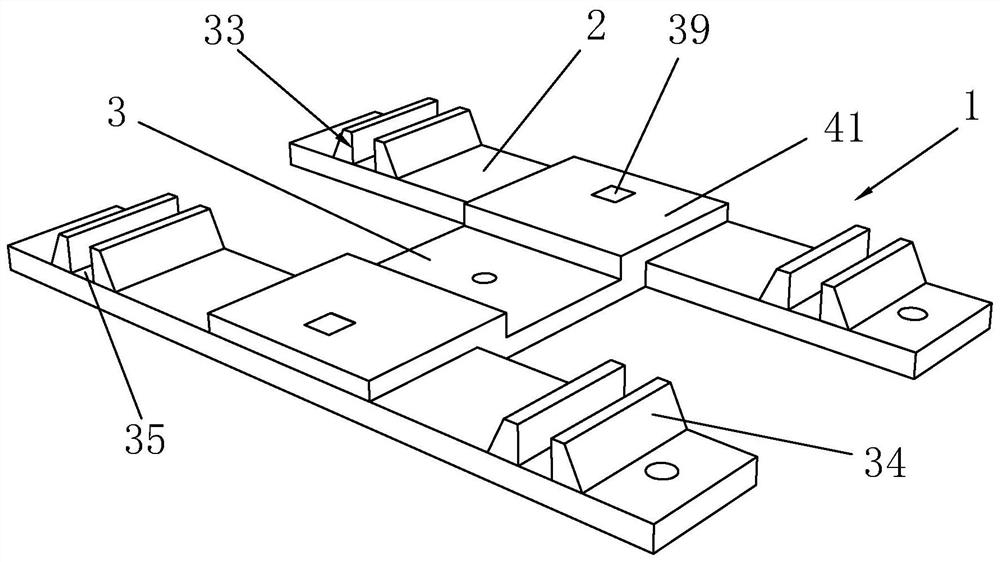

[0046] like Figure 1 to Figure 16 Shown, be the manufacture method of a kind of motor mounting bracket of the present invention, comprise the steps:

[0047] 1) Preparation of the supporting base plate 1: the supporting base plate 1 includes two supporting side plates 2 and a reinforcing connecting plate 3, and the supporting side plate 2 and the reinforcing connecting plate 3 are prepared according to the design size; the two supporting side plates 2 and a reinforcing connecting plate The plates 3 are combined to form a support base plate 1, and the reinforcement connecting plate 3 connects two support side plates 2, which effectively improves the structural strength of the entire support base plate 1. There are also preset fixing holes on the support base plate 2, through which the support base plate 1 and the installation The installation and fixation between the surfaces finally realizes the installation and fixation of the motor, which is convenient and simple to install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com