High-strength sound absorption board

A sound-absorbing panel, high-strength technology, used in buildings, building structures, floors, etc., can solve the problems of high scrap rate, large pollution, poor structural strength, etc., and achieve improved sound absorption performance, excellent flame retardant performance, structural high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

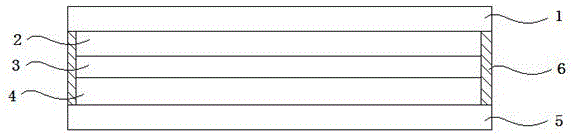

[0035] This case lists a high-strength sound-absorbing panel of an embodiment, which includes a first sound-absorbing layer 1, a first air layer 2, a second sound-absorbing layer 3, a second air layer 4, a third sound-absorbing layer 5 and The column 6, the column 6 is used to fix and support the first sound-absorbing layer 1, the second sound-absorbing layer 3 and the third sound-absorbing layer 5, and itself has no influence on the sound-absorbing performance of the sound-absorbing panel.

[0036] The thickness ratio between the first sound-absorbing layer 1, the first air layer 2, the second sound-absorbing layer 3, the second air layer 4 and the third sound-absorbing layer 5 is preferably 1: 0.75-0.78: 0.91-0.93: 0.86-0.88: 1.03-1.05; the total thickness of the sound-abso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com