Large-load pressure and pulling force sensor

A tension sensor and large load technology, applied in the field of sensing systems, can solve the problems of integrated tension and pressure sensors, the deviation of the tension and pressure measurement range, and limit the application of piezoelectric sensors, etc., to achieve small structure size, large detection force range, The effect of simple and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

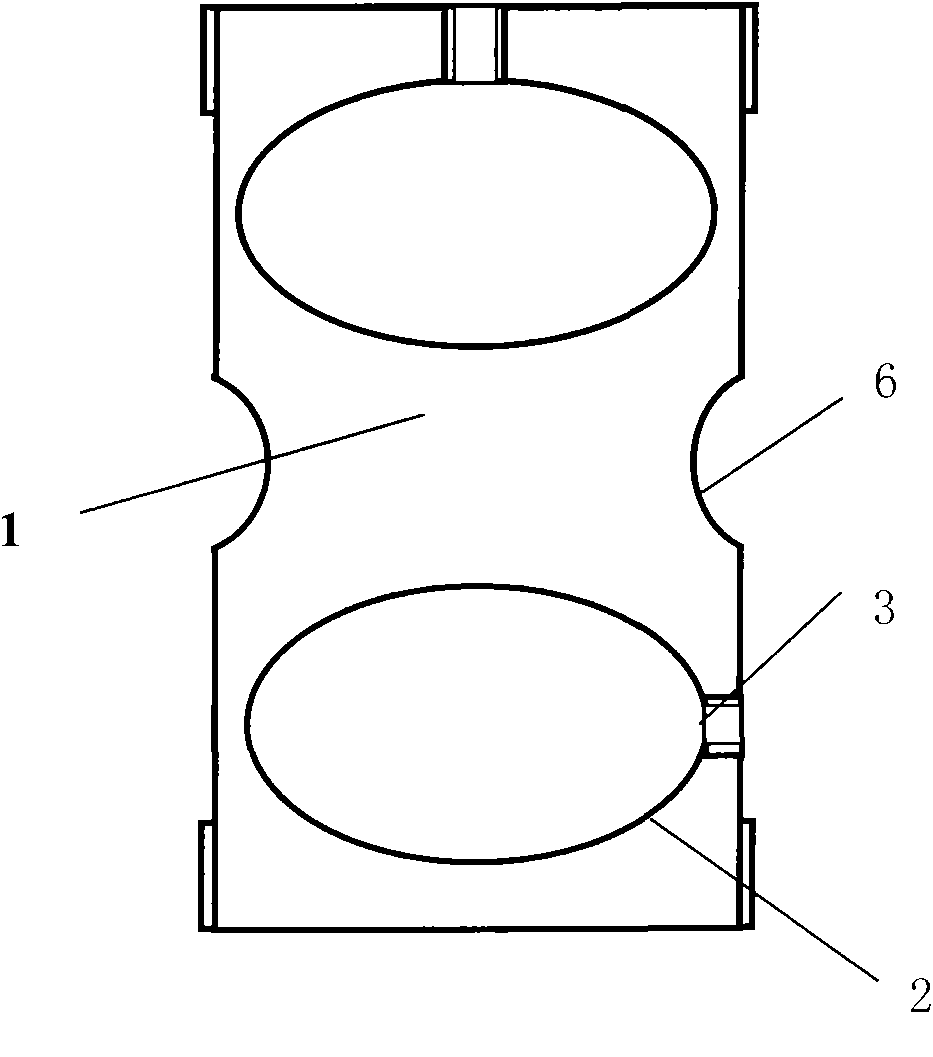

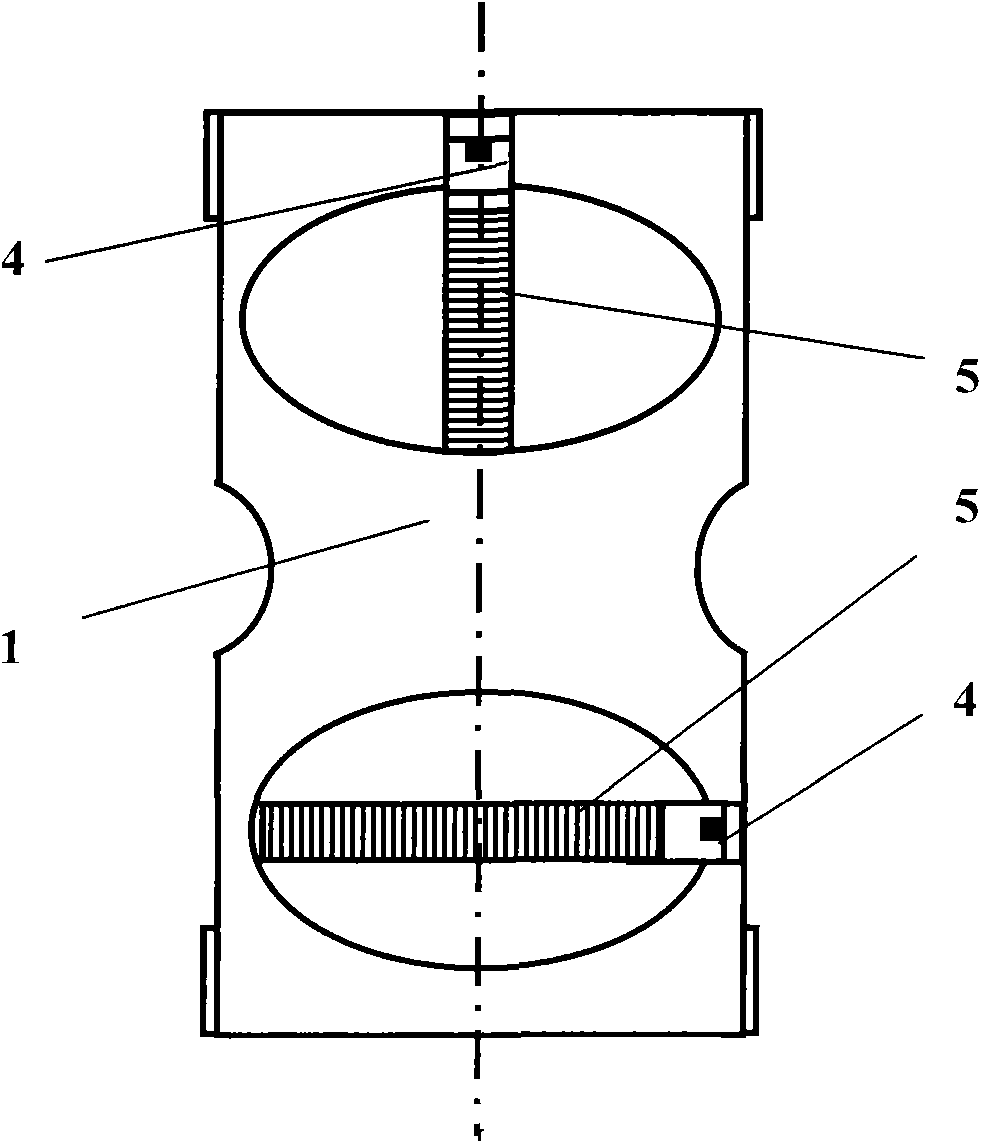

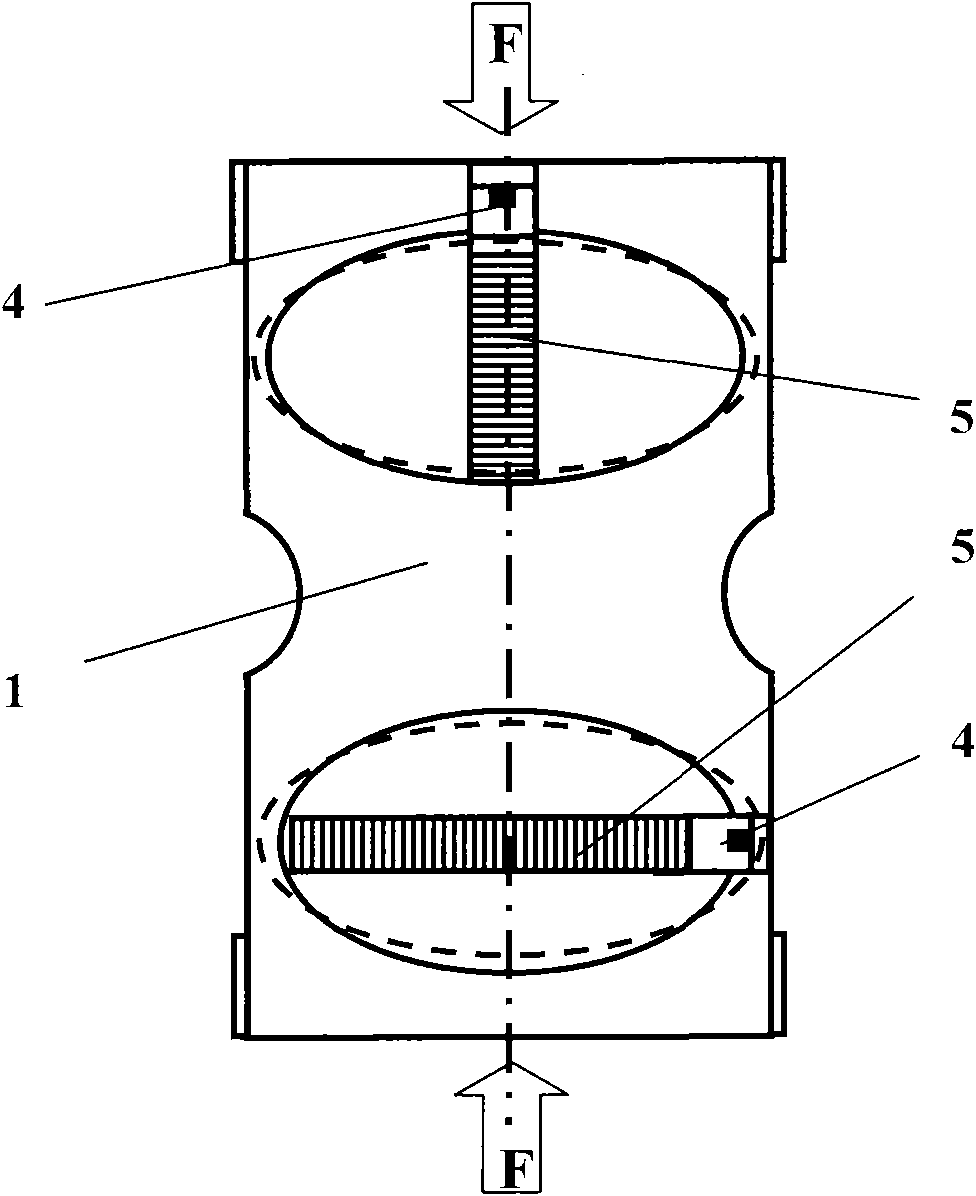

[0030] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the sensor of the present invention includes an elastic frame 1, two cavities 2 are provided at the upper and lower ends of the elastic frame 1, and a through hole 3 is provided on the side of the cavity 2, and the fastener 4 arranged on the elastic frame runs through port 3; the cavity 2 is provided with a piezoelectric body 5, one end of the piezoelectric body 5 is fixedly connected to the fastener 4, and the other end is in contact with the inner wall of the cavity opposite to the through hole, and the piezoelectric body 5 is a force-electric transmission Sensitive material body.

[0031] The cavity 2 is a closed ellipsoid, and each cavity 2 is provided with a through opening 3. The upper hole 2 is provided with a through opening 3 at the upper end, and the lower hole 2 is provided with a through opening 3 at the right end, that is, the upper and lower ends of the piezoelectric The body is arranged vertic...

Embodiment 2

[0038] like Figure 5 As shown, only one cavity 2 is provided on the upper end of the elastic frame 1, and the upper end of the cavity 2 is provided with a through opening 3. Others are with embodiment 1.

Embodiment 3

[0040] like Image 6 As shown, only one cavity 2 is provided at the lower end of the elastic frame 1, and a through opening 3 is provided at the left end of the cavity 2. Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com