Welding method and structure for motor end ring and conducting bars

A welding method and bar technology, applied in welding equipment, magnetic circuit shape/pattern/structure, workpiece edge, etc., can solve the problem that the vertical accuracy of the bar and the end face is difficult to guarantee, the interval is difficult to accurately control, and the welding quality needs to be improved, etc. problems, to achieve the effect of reducing the difficulty of welding operation, reducing difficulty, and positioning simple and clear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

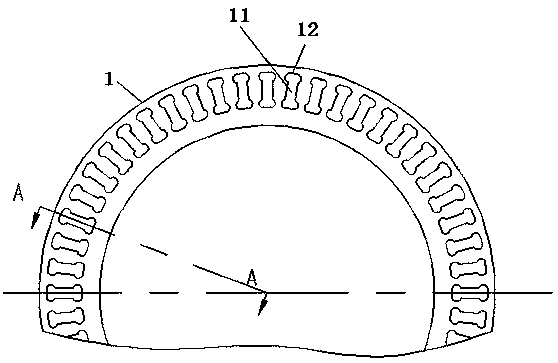

[0040] Attached below Figures 1 to 2 Embodiments of the present invention are described in detail.

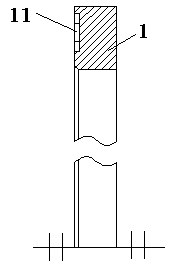

[0041] The welding method of the motor end ring and the guide bar, including the end ring 1 and the guide bar, is characterized in that according to the size of the end of the guide bar, a groove 11 corresponding to the guide bar is processed on the end surface of the end ring 1, and then the guide bar The bar and the groove 11 are welded on the end ring 1 correspondingly.

[0042] like figure 1 As shown, the groove on the end ring is a single groove that corresponds to the guide bar one by one, rather than a full circle of annular grooves.

[0043] One guide bar is welded in one groove, the area of the groove on the end ring is reduced, and the solder is limited in a single groove during welding, ensuring that the melting and solidification of the solder is always limited in a single groove during the welding process, which can Effectively reduce the amount of silver sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com