A method for electrical cascading of aerospace optical fiber inertial groups

An electrical grade, optical fiber technology, applied in the field of inertial measurement, can solve problems such as easy errors in the position of welding wires, failure of welding operations, and reduced product reliability, so as to prevent wires from being easily broken above the solder joints, and the difficulty of welding and repairing is low. , The effect of neat and orderly flexible wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

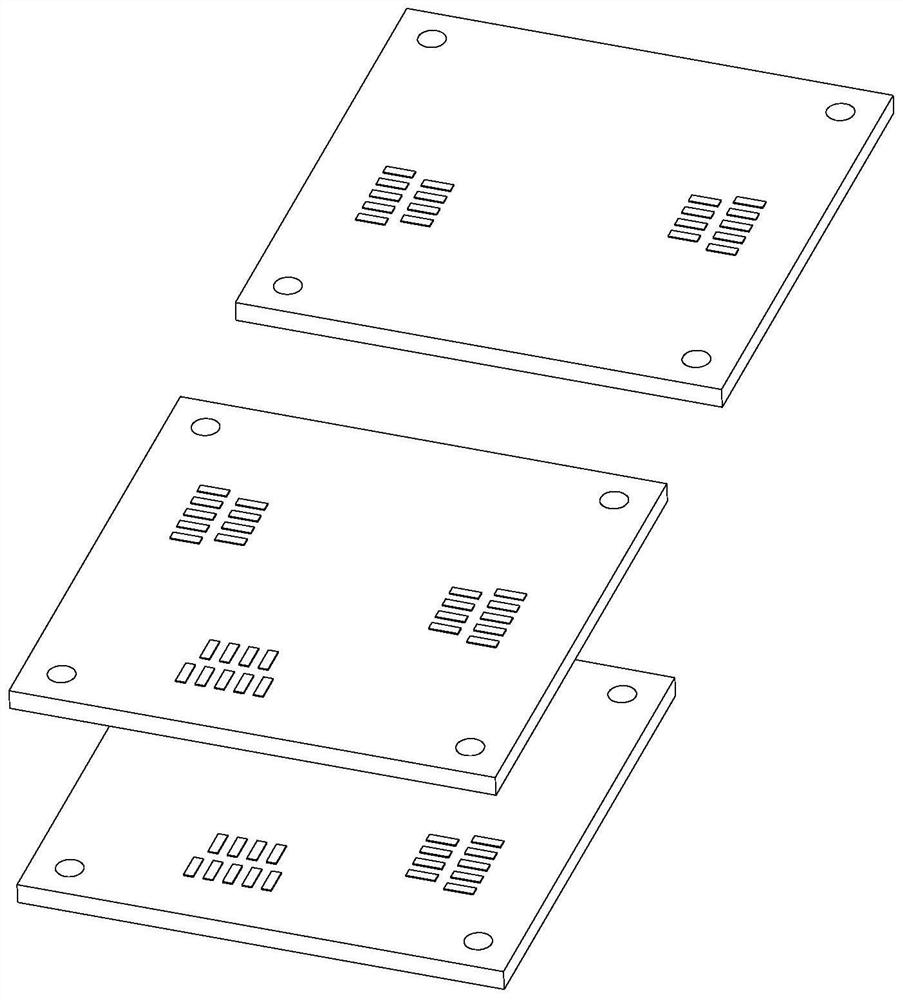

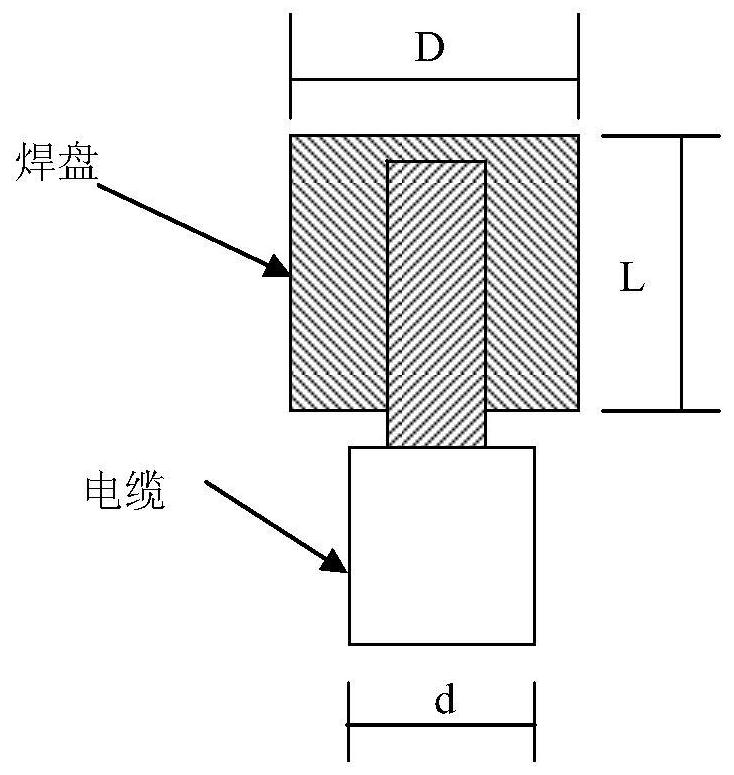

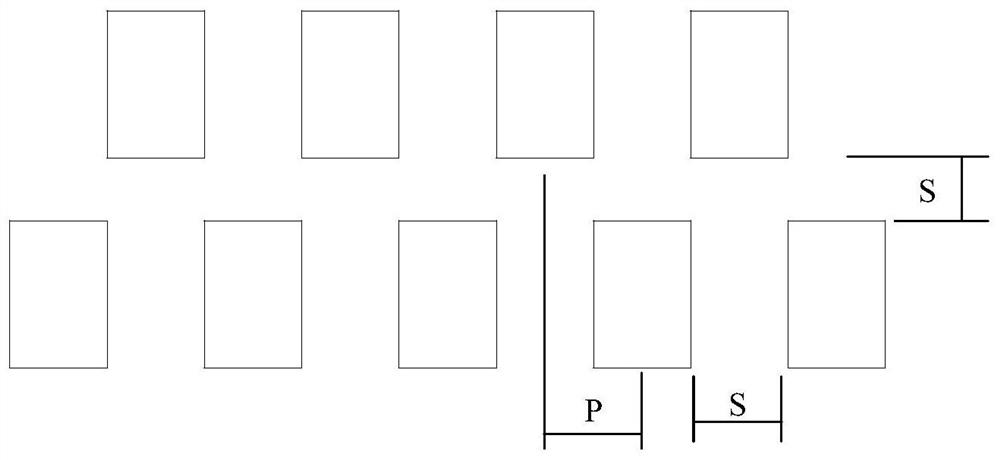

[0041] The aerospace fiber optic inertial group is used in space vehicles such as satellites, and the aerospace fiber optic inertial group is required to be small in size, light in weight, radiation resistance, and high reliability. There is almost no installation space for wires in the structural design, and the wire insulation is often squeezed and damaged. , The insulation performance of the whole machine is reduced, and the reliability is reduced due to the difficulty of repairing. By using the present invention, the disorder and disorder existing in the current electrical interconnection using a single wire, and the wire ends are welded in the through-hole pads can be effectively solved. It is difficult to repair, and the wires are easy t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com