Building plate with gold tailing granules and making method of building plate

A technology for gold tailings and building boards, applied in clay products, ceramic products, other household appliances, etc., can solve problems such as poor utilization of gold tailings, and achieve excellent fire performance, low process energy consumption, and good product performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 prepares gold tailings particle

[0040] A kind of processing method of gold tailings of the present invention, comprises the steps:

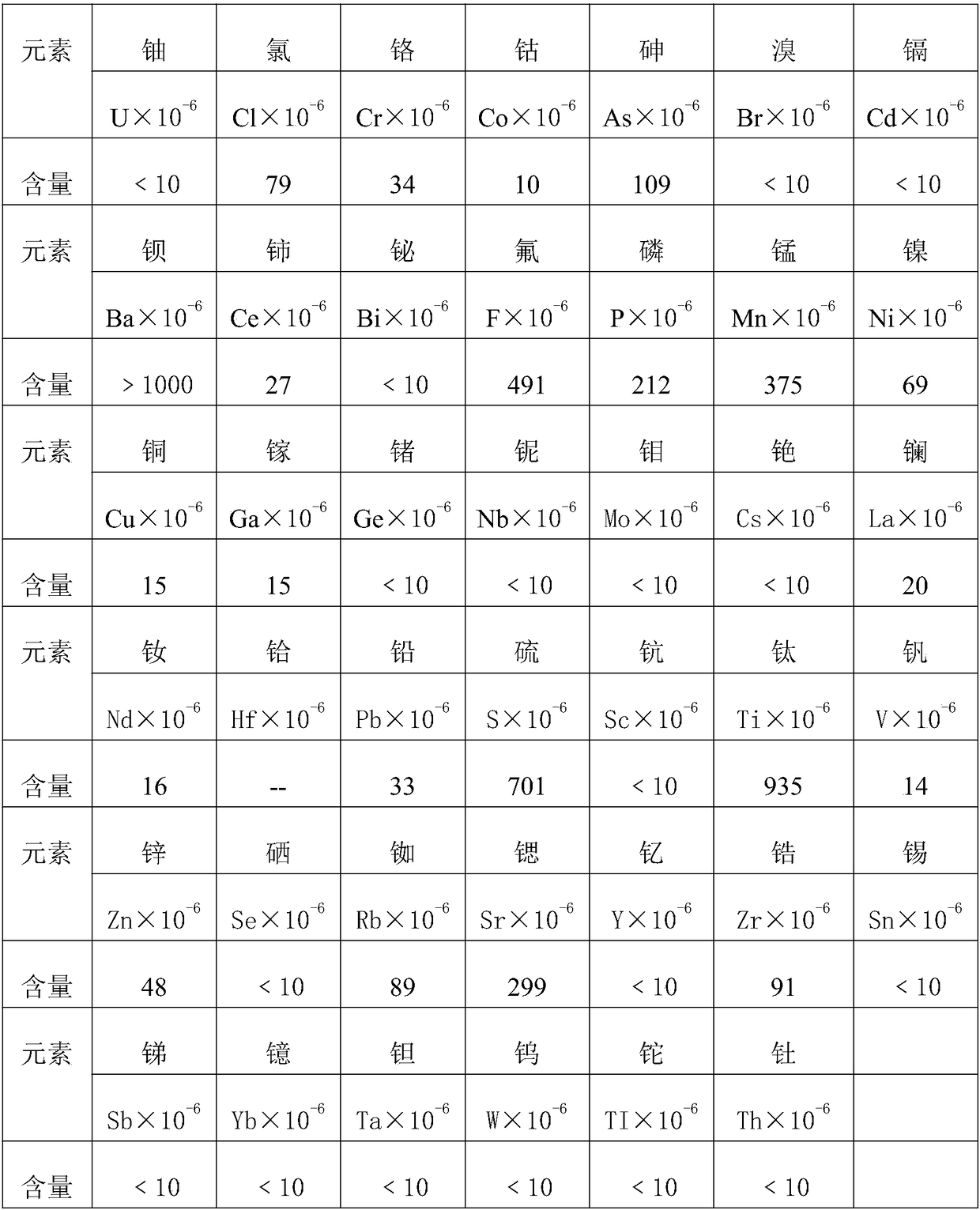

[0041] (1) Take the gold tailings, pass through a 800-1250 mesh sieve after multiple screenings, and add a magnetic separator to screen out the fine iron ore, so that the iron ore content in the remaining tailings is lower than 0.5wt%;

[0042] (2) Add water to the remaining tailings to make tailings slurry, the amount of water added is twice the amount of tailings; then adjust the pH of the tailings slurry with dilute HCL solution or dilute NaOH solution according to the pH value of the tailings slurry Value to neutral, spare;

[0043] (3) adding talcum powder accounting for 2wt% of the tailings solids to the above tailings slurry for modification;

[0044] (4) Add a coupling agent (calcium carbonate and titanate coupling agent TMC-201 mixed at 1:1) accounting for 5wt% of the tailings solids to the tailings slurry after t...

Embodiment 2

[0047] Embodiment 2 prepares gold tailings particle

[0048] A kind of processing method of gold tailings of the present invention, comprises the steps:

[0049] (1) Take the gold tailings, pass through a 800-1250 mesh sieve after multiple screenings, and add a magnetic separator to screen out the fine iron ore, so that the iron ore content in the remaining tailings is lower than 0.5wt%;

[0050] (2) Add water to the remaining tailings to make tailings slurry, the amount of water added is 3 times the amount of tailings; then adjust the pH of the tailings slurry with dilute HCL solution or dilute NaOH solution according to the pH value of the tailings slurry Value to neutral, spare;

[0051] (3) adding talc powder accounting for 10wt% of the tailings solids to the above tailings slurry for modification;

[0052] (4) Add a coupling agent (calcium carbonate and titanate coupling agent TMC-201 mixed at 1:1) accounting for 3wt% of the tailings solids to the tailings slurry after ...

Embodiment 3

[0055] Embodiment 3 prepares gold tailings particle

[0056] A kind of processing method of gold tailings of the present invention, comprises the steps:

[0057] (1) Take the gold tailings, pass through a 800-1250 mesh sieve after multiple screenings, and add a magnetic separator to screen out the fine iron ore, so that the iron ore content in the remaining tailings is lower than 0.5wt%;

[0058] (2) Add water to the remaining tailings to make tailings slurry, the amount of water added is twice the amount of tailings; then adjust the pH of the tailings slurry with dilute HCL solution or dilute NaOH solution according to the pH value of the tailings slurry Value to neutral, spare;

[0059] (3) adding talc powder accounting for 6wt% of the tailings solids to the above tailings slurry for modification;

[0060] (4) Add a coupling agent (calcium carbonate and titanate coupling agent TMC-201 mixed at 1:1) accounting for 4wt% of the tailings solids to the tailings slurry after the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com