Marine oil-resistant and paint-aging-resistant independent shielding power cable and manufacturing method thereof

A power cable and paint-resistant technology, applied in the direction of power cables with shielding layer/conductive layer, power cables, cable/conductor manufacturing, etc., can solve the problems of shortened life of marine cables, cable pollution, hidden safety hazards, etc., to achieve Guarantee unimpeded flow, overcome flame retardant performance, good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

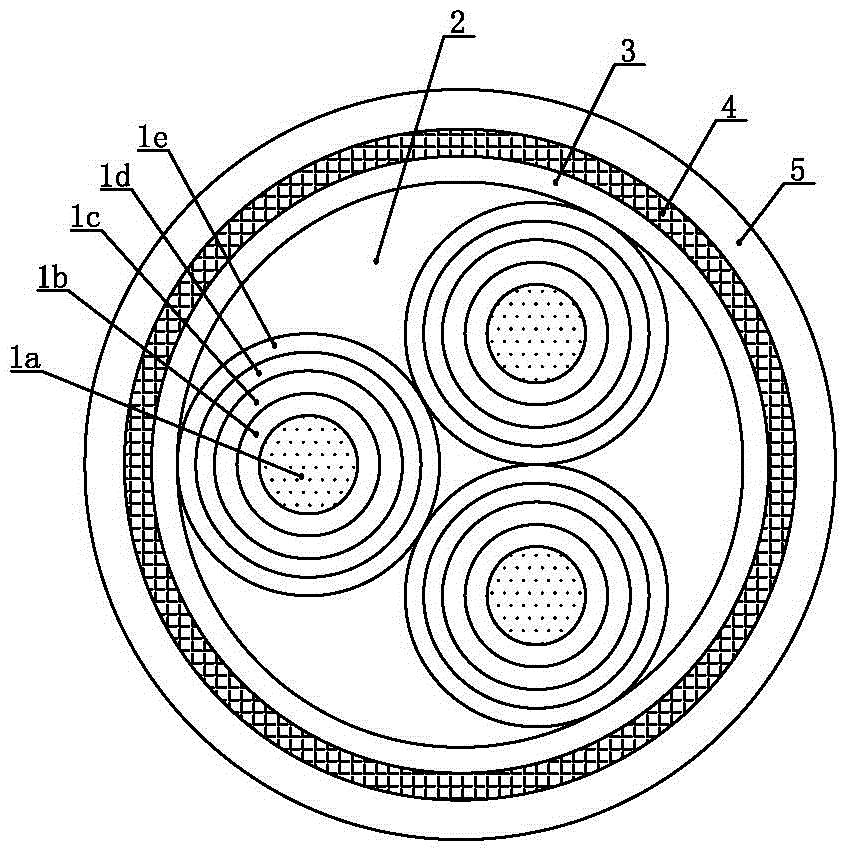

[0019] Such as figure 1 As shown, the marine oil-resistant, paint-resistant and aging-resistant independent shielded power cable of the present invention includes the following steps in turn: uniformly extrude the insulating layer 1b on the outer periphery of the stranded copper conductor 1a, and wrap the inner wrapping tape around the outer periphery of the insulating layer 1b 1c, the outer circumference of the shielding inner wrapping tape 1c is covered with an independent shielding layer 1d, and the outer circumference of the independent shielding layer 1d is wrapped with a shielding outer wrapping tape 1e to form a power cable core, and the gap between multiple power cable cores After filling the flame-retardant polypropylene fiber core 2, it is integrally twisted to form a power cable core. The outer periphery of the power cable core is wrapped with a high thermal resistance coefficient flame-retardant fire-resistant longitudinal tape 3, and the high thermal resistance coe...

Embodiment 2

[0024] Such as figure 1 As shown, the marine oil-resistant, paint-resistant and aging-resistant independent shielded power cable of the present invention includes the following steps in turn: uniformly extrude the insulating layer 1b on the outer periphery of the stranded copper conductor 1a, and wrap the inner wrapping tape around the outer periphery of the insulating layer 1b 1c, the outer circumference of the shielding inner wrapping tape 1c is covered with an independent shielding layer 1d, and the outer circumference of the independent shielding layer 1d is wrapped with a shielding outer wrapping tape 1e to form a power cable core, and the gap between multiple power cable cores After filling the flame-retardant polypropylene fiber core 2, it is integrally twisted to form a power cable core. The outer periphery of the power cable core is wrapped with a high thermal resistance coefficient flame-retardant fire-resistant longitudinal tape 3, and the high thermal resistance coe...

Embodiment 3

[0029] Such as figure 1 As shown, the marine oil-resistant, paint-resistant and aging-resistant independent shielded power cable of the present invention includes the following steps in turn: uniformly extrude the insulating layer 1b on the outer periphery of the stranded copper conductor 1a, and wrap the inner wrapping tape around the outer periphery of the insulating layer 1b 1c, the outer circumference of the shielding inner wrapping tape 1c is covered with an independent shielding layer 1d, and the outer circumference of the independent shielding layer 1d is wrapped with a shielding outer wrapping tape 1e to form a power cable core, and the gap between multiple power cable cores After filling the flame-retardant polypropylene fiber core 2, it is integrally twisted to form a power cable core. The outer periphery of the power cable core is wrapped with a high thermal resistance coefficient flame-retardant fire-resistant longitudinal tape 3, and the high thermal resistance coe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com