Fireproof high-temperature-resistant power cable

A power cable and high-temperature-resistant technology, which is applied in the field of fire-resistant and high-temperature-resistant power cables, can solve the problems of low temperature resistance and poor fireproof performance, and achieve the effects of good high temperature resistance, high fireproof performance level, and long power supply cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. are intended only and not to limit the scope of the invention.

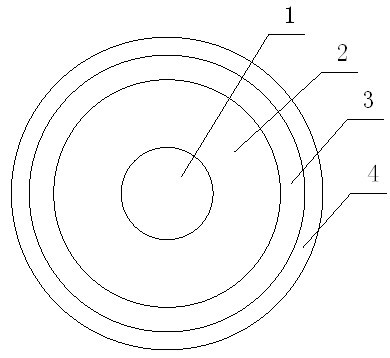

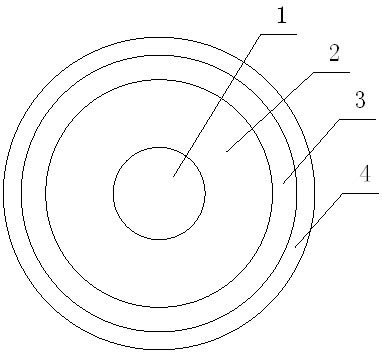

[0015] Such as figure 1 , a fire-proof and high-temperature-resistant power cable of the present invention, wherein the center of the cable is an alloy copper conductor 1, and the alloy copper conductor 1 is extruded with a silicon carbide insulating layer 2, and the silicon carbide insulating layer 2 is sequentially provided with a welded copper tube inner sheath Sheath 3 and PP copolymer extruded outer sheath 4.

[0016] The maximum service temperature of silicon carbide fiber is 1200℃, its heat resistance and oxidation resistance are better than carbon fiber, its strength is 1960-4410MPa, its strength retention rate is over 80% at the maximum service temperature, and its modulus is 176.4-294GPa. Chemical stability is also good. Silicon carbide fibers are mainly used as high te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com