Processing technology of triticale whole-wheat roll convenient food

A technology of convenience food and processing technology, which is applied in food preparation, food science, application, etc. It can solve problems such as promoting premium nutritional grains, adjusting prenatal structure, and improving processing methods, etc., to achieve small viscosity and uniform thickness , Easy to brew and eat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

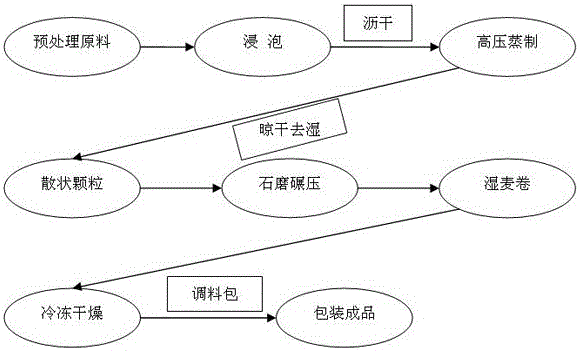

Image

Examples

Embodiment 1

[0028] The Hedong Wumai series bred by the Cotton Research Institute of Shanxi Academy of Agricultural Sciences were selected: Yunhei 28 blue-grained wheat and purple-grained wheat strains. After the above raw materials are sieved to remove stones and impurities, some of the raw materials are removed from the skin to make wheat kernels for later use, and the raw materials are marked as blue wheat, blue wheat kernels, purple wheat kernels and purple kernels;

[0029] Soaking: Take 3 kg of the marked raw materials and soak them in water according to the ratio of material to liquid of 0.5:2 (weight ratio). The soaking time of blue wheat, blue wheat kernels, purple wheat kernels and purple wheat kernels is 5 hours respectively. 2 hours, 8 hours, 2 hours, stir once every 30 minutes, along the same direction while stirring, check the water content and hardness of the raw materials every 30 minutes, when the water content of each raw material reaches 65%, and the hardness is 7 N, quic...

Embodiment 2

[0036] The Hedong Wumai series bred by the Cotton Research Institute of Shanxi Academy of Agricultural Sciences were selected: Yunhei 28 blue-grained wheat and purple-grained wheat strains. After the above raw materials are sieved to remove stones and impurities, some of the raw materials are removed from the skin to make wheat kernels for later use, and the raw materials are marked as blue wheat, blue wheat kernels, purple wheat kernels and purple kernels;

[0037] Soaking: Take 4 kg of marked raw materials and soak them in water according to the ratio of solid to liquid at 1:3 (weight ratio). 3.5 hours, 10 hours, 3.5 hours, stir once every 30 minutes, along the same direction while stirring, check the water content and hardness of the raw materials every 30 minutes, when the water content of each raw material reaches 75% and the hardness is 8 N, quickly drain Dry excess water and steam in a pressure cooker;

[0038]High-pressure steaming: adopt the single-factor measurement...

Embodiment 3

[0044] The Hedong Wumai series bred by the Cotton Research Institute of Shanxi Academy of Agricultural Sciences were selected: Yunhei 28 blue-grained wheat and purple-grained wheat strains. After the above raw materials are sieved to remove stones and impurities, some of the raw materials are removed from the skin to make wheat kernels for later use, and the raw materials are marked as blue wheat, blue wheat kernels, purple wheat kernels and purple kernels;

[0045] Soaking: Take 4 kg of marked raw materials and soak them in water according to the ratio of material to liquid of 1.5:4 (weight ratio). 3 hours, 10 hours, 6 hours, stir once every 30 minutes, along the same direction while stirring, check the water content and hardness of the raw materials every 30 minutes, when the water content of each raw material reaches 76%, and the hardness is 9 N, quickly drain Dry excess water and steam in a pressure cooker;

[0046] High-pressure steaming: adopt the single factor measurem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com