A manipulator sonic zipper cutting machine and cutting method

A cutting machine and manipulator technology, applied in clothing, textiles, papermaking, fasteners, etc., can solve the problems of zipper disorder, zipper arch, deformation, easy slanting of zipper lace, etc., and achieve the effect of neat zipper length and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

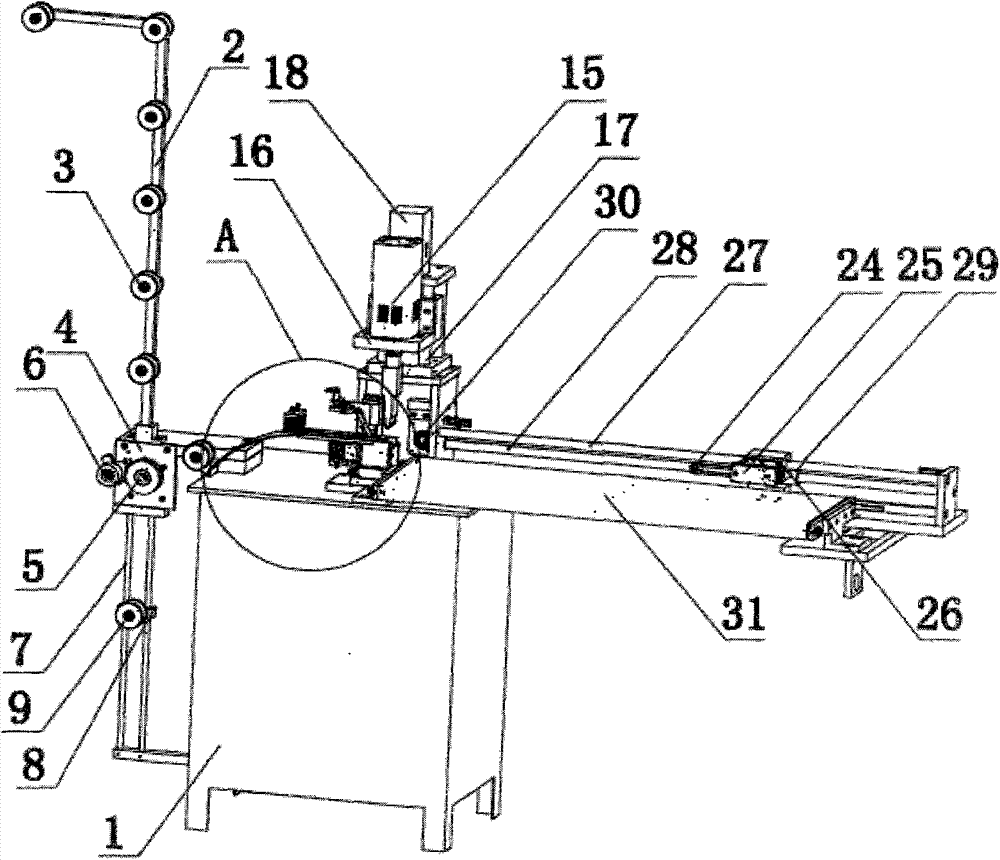

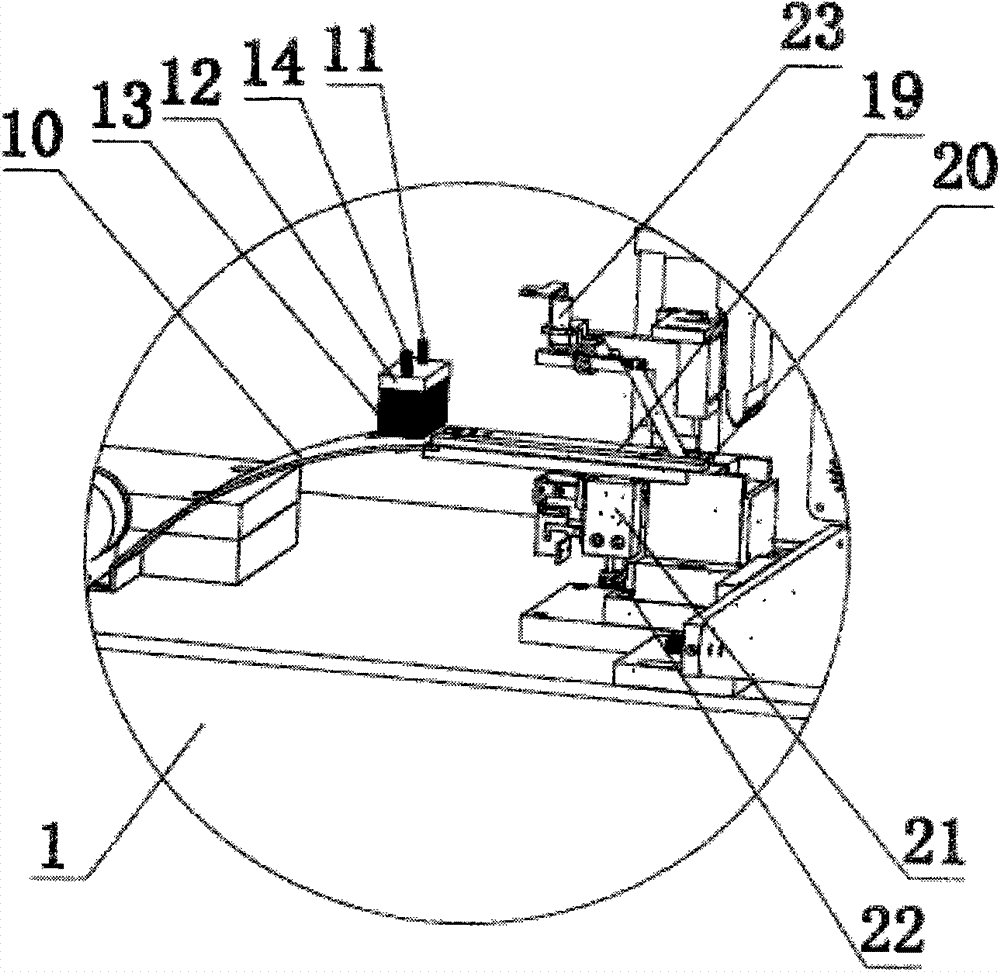

[0022] Example: such as figure 1 and figure 2 As shown, a manipulator sonic zipper cutting machine includes a frame 1, and a tape feeding device, a tape cutting device, a manipulator pulling tape device and a tape out device installed on the frame 1.

[0023] The belt feeding device includes a support rod 2, on which six guide pulleys 3 are arranged in sequence, and a support seat 4 is arranged at the lower end of the support rod 2, and a pair of driving wheels 5 and Pinching pulley 6, driving pulley 5 is connected with a transmission motor, and pinching pulley 6 is connected with a spring tensioning mechanism, and spring tensioning mechanism is exactly a spring and a positioning pin that spring is fixed on support seat 4; Support seat 4 A pair of load-bearing slide bars 7 are provided below the load-bearing slide bar 7, and a load-bearing sliding bearing 8 is set on the load-bearing sliding bar 7, and a load-bearing sliding bearing 8 is provided with a road wheel 9 on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com