Wheel cover assembly clamp

An assembly and wheel cover technology, applied in the field of wheel cover assembly fixtures, can solve problems such as complex structure and insufficient welding space, achieve large welding space, reduce welding operation difficulty, and solve the effect of insufficient substrate space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

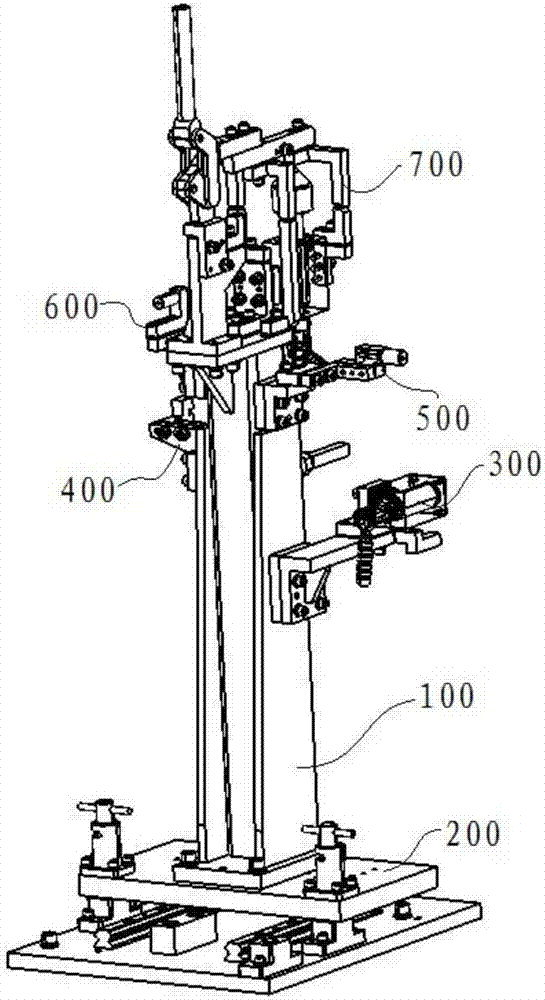

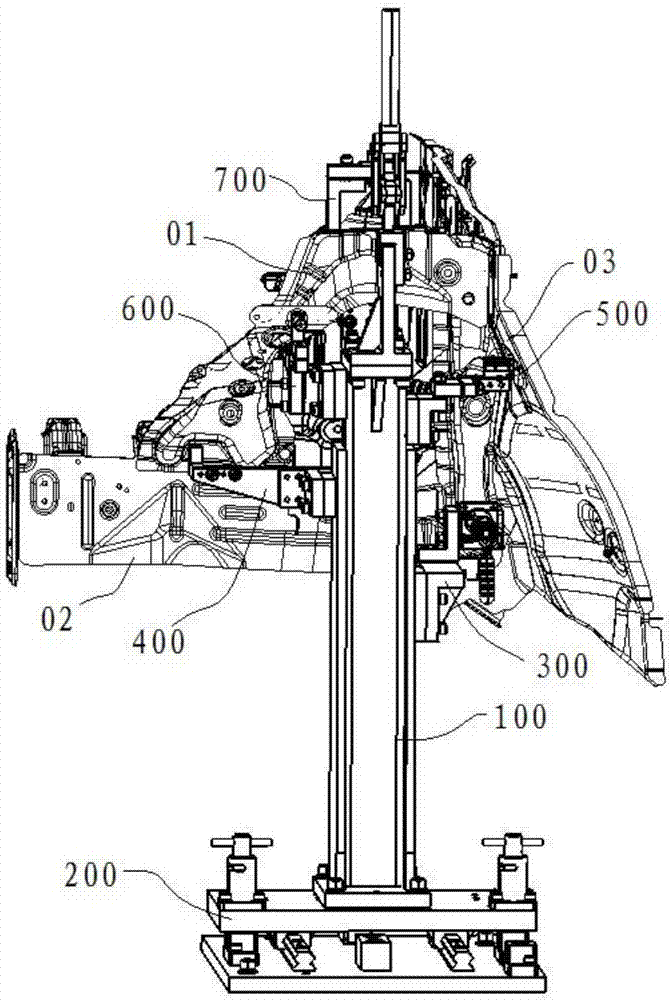

[0040] Embodiments of the present invention: as figure 1 and figure 2 As shown, the present invention provides a wheel cover assembly clamp, comprising:

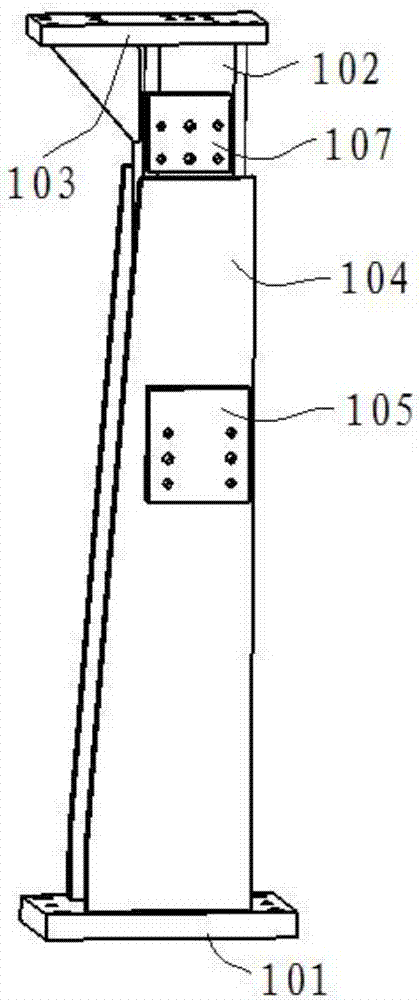

[0041] A support 100, the support 100 is connected with a sliding unit 200, the sliding unit 200 is used to guide the support 100 to move toward or away from the wheel cover assembly 01, the support 100 is fixed on the base plate (the base plate is not show);

[0042]The lower positioning unit 300, the lower positioning unit 300 is fixed on the support 100 to position and compress the lower part of the wheel cover assembly 01;

[0043] The side pressing unit 400, the side pressing unit 400 is fixed on the support 100, so as to press the overlapping part of the wheel house assembly 01 and the longitudinal beam assembly 02;

[0044] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com