Construction method of stainless steel cladding top plate of building water tank and building water tank

A construction method and stainless steel technology, applied in the configuration of water supply pool, construction, building components, etc., can solve the problems of difficult control of the quality of stainless steel cladding welds, great impact on human health, and high technical requirements for welders, so as to shorten the construction period, The effect of reducing the difficulty of welding operations and improving the quality of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

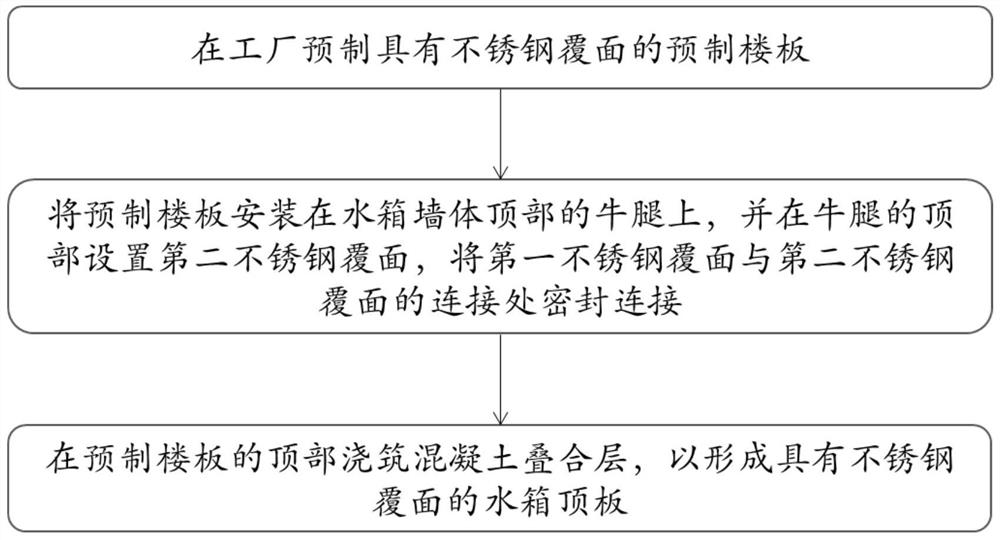

[0048] Such as figure 1 , figure 2 , image 3 As shown, this embodiment discloses a construction method for a stainless steel cladding roof of a water tank of a structure, including:

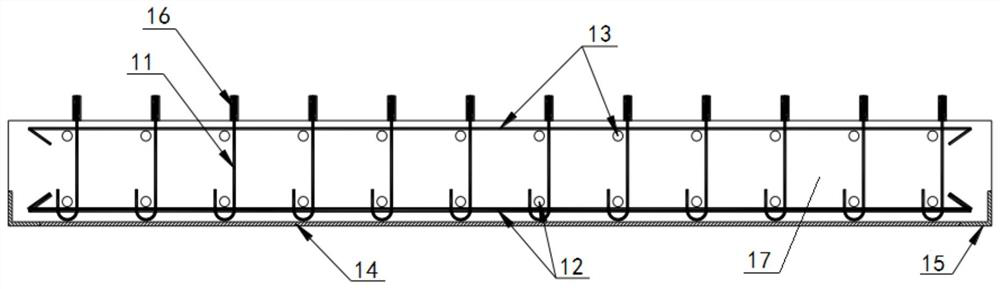

[0049] S1, prefabricated a prefabricated floor slab 10 with a first stainless steel cladding 14 .

[0050] This step can be done in the factory before being shipped to the site.

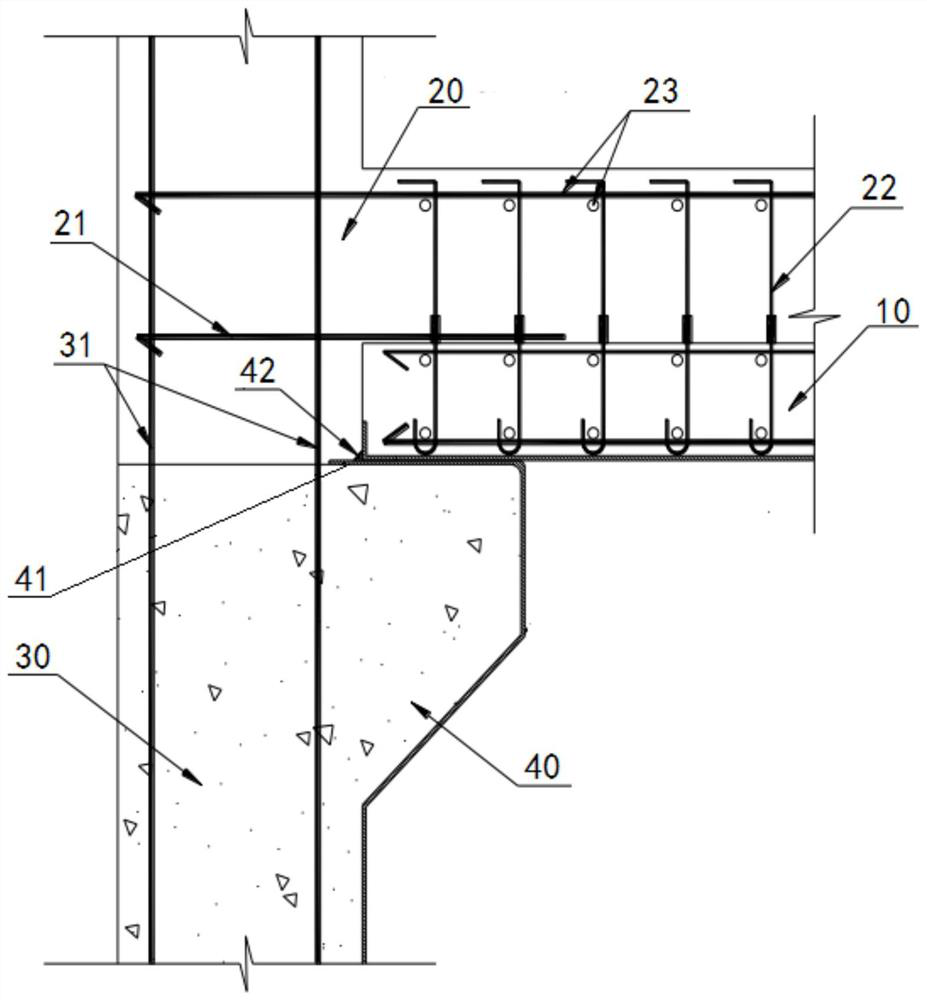

[0051] S2, hoisting and installing the prefabricated floor slab 10 on the corbel 40 at the top of the water tank wall 30, and welding the connection between the two for sealing.

[0052] Specifically, a second stainless steel cladding 41 is provided on the top of the corbel, and the connection between the first stainless steel cladding 14 and the second stainless steel cladding 41 is welded.

[0053] S3, pouring a concrete laminated layer 20 on top of the prefabricated floor 10 to form a water tank roof with stainless steel cladding.

[0054] In some embodiments, step S1 includes the following steps:

[0055] (1...

Embodiment 2

[0071] Such as figure 2 , image 3 As shown, the present embodiment discloses a structure water tank, comprising a water tank wall 30 and a water tank roof, the water tank wall 30 is provided with a corbel 40, the water tank roof is arranged on the corbel 40, and the water tank roof includes a prefabricated floor 10 and a concrete stack Composite layer 20, prefabricated floor slab 10 includes prefabricated floor slab concrete 17 and first stainless steel cladding 14, concrete lamination layer 20 is poured on the prefabricated floor slab concrete 17, the first stainless steel cladding is covered on the bottom of prefabricated floor slab concrete 17, between the two Secured by stainless steel anchor connections. The top of the corbel 40 is provided with a second stainless steel cladding 41 , and the top of the second stainless steel cladding 41 is in sealing connection with the bottom of the first stainless steel cladding 14 .

[0072] In some embodiments, the prefabricated f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com