Method and device for semi-molten ingot casting of polycrystalline silicon

A polysilicon and ingot casting technology is applied in the field of polysilicon semi-melting ingot casting methods and devices, which can solve problems such as affecting the conversion efficiency of solar cells, and achieve the effects of prolonging the service life of a thermal field, reducing shadows, and smoothing the crystal growth interface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1) Evenly lay polysilicon fragments with a diameter of 3 mm and a thickness of 8 mm on the bottom of the quartz crucible so that the thickness of the fragment layer reaches 8 mm, and then vacuumize and heat in sequence to obtain a heated fragment layer;

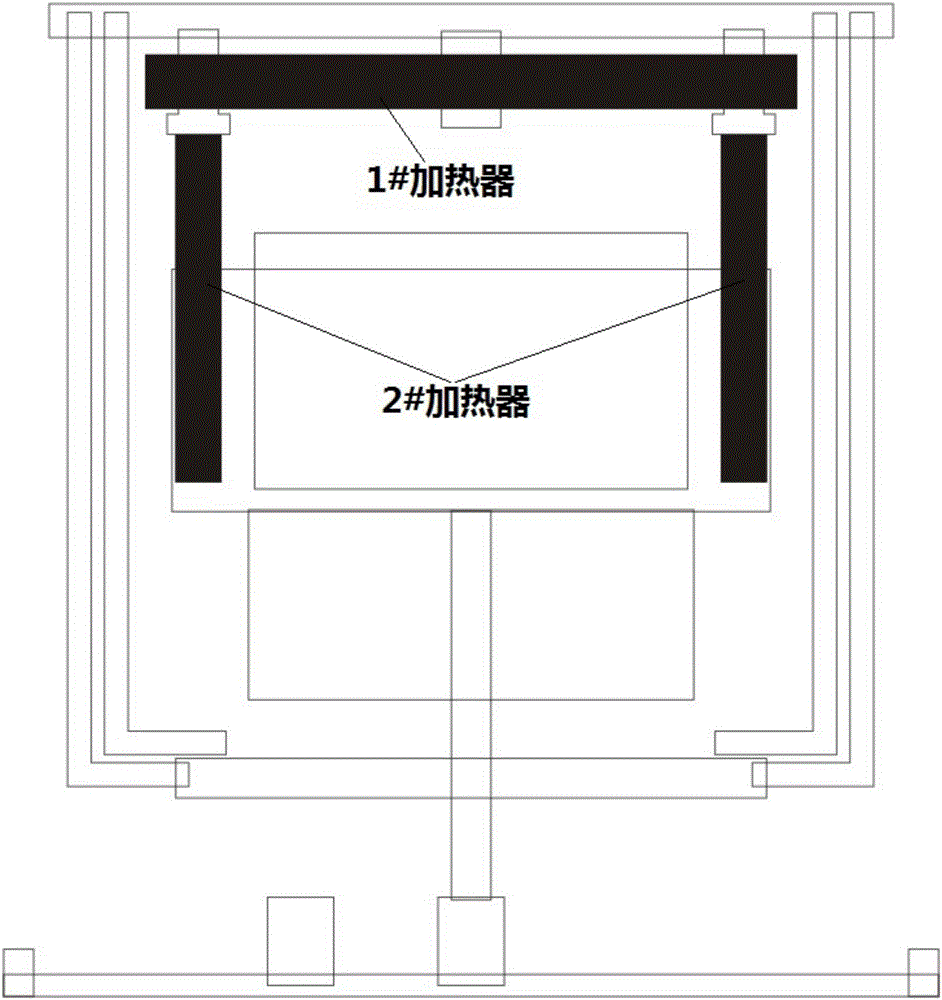

[0048] 2) Raise the temperature of the heater of the ingot furnace to 1550°C, and then adjust the power ratio of the top heater and the side heater to 1:0.2, so that there is continuous cooling at the bottom to ensure that the seed crystal is not melted; when the seed crystal When the remaining thickness is 10mm, the cooling air flow rate at the bottom is 20ml / s, and after the temperature gradually drops to 1430°C, adjust the power ratio of the top heater and the side heater to 0.5:0.8 at the same time, and keep the temperature constant, and grow the crystal for 20 minutes;

[0049] 3) The cooling air flow rate at the bottom is 20ml / s, continue to reduce the temperature of the ingot furnace heater to 1400°C, the power r...

Embodiment 2

[0054] 1) Evenly lay polysilicon fragments with a diameter of 5 mm and a thickness of 10 mm on the bottom of the quartz crucible so that the thickness of the fragment layer reaches 20 mm, and then vacuumize and heat in sequence to obtain a heated fragment layer;

[0055] 2) Raise the temperature of the ingot furnace heater to 1552°C, and then adjust the power ratio of the top heater and the side heater to 1:0.2, so that there is continuous cooling at the bottom to ensure that the seed crystal is not melted; when the seed crystal When the remaining thickness is 10mm, the cooling air flow rate at the bottom is 40ml / s, and after the temperature gradually drops to 1435°C, adjust the power ratio of the top heater and side heater to 0.5:0.8 at the same time, keep the temperature constant, and grow crystals for 30 minutes;

[0056] 3) The cooling air flow rate at the bottom is 40ml / s, continue to reduce the temperature of the ingot furnace heater to 1404°C, the power ratio coefficient...

Embodiment 3

[0061] 1) Evenly lay polysilicon fragments with a diameter of 10 mm and a thickness of 30 mm on the bottom of the quartz crucible, so that the thickness of the fragment layer reaches 30 mm, and then vacuumize and heat in sequence to obtain a heated fragment layer;

[0062] 2) Raise the temperature of the heater of the ingot furnace to 1555°C, and then adjust the power ratio of the top heater and the side heater to 1:0.2, so that there is continuous cooling at the bottom to ensure that the seed crystal is not melted; when the seed crystal When the remaining thickness is 10mm, the cooling air flow rate at the bottom is 50ml / s, and after the temperature gradually drops to 1440°C, adjust the power ratio of the top heater and the side heater to 0.5:0.8 at the same time, and keep the temperature constant, and grow the crystal for 40 minutes;

[0063] 3) The cooling air flow rate at the bottom is 50ml / s, continue to reduce the temperature of the ingot furnace heater to 1410°C, the pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com