Fully-degradable antibacterial food packaging film and preparation method thereof

A food packaging film, fully degradable technology, applied in the field of food packaging and food packaging materials, can solve the problems of increased production costs, complicated preparation methods, difficult commercial production, etc., and achieve the effects of saving costs, ensuring antibacterial activity, and optimizing formulas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

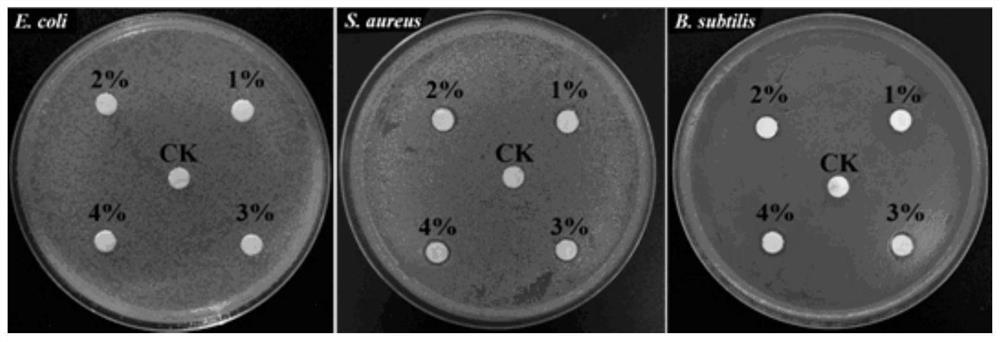

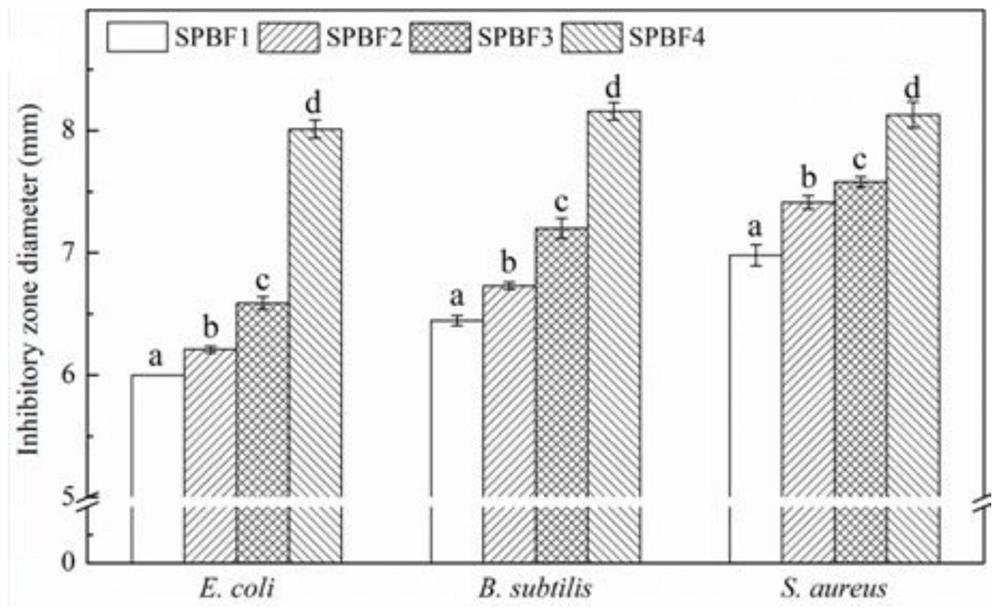

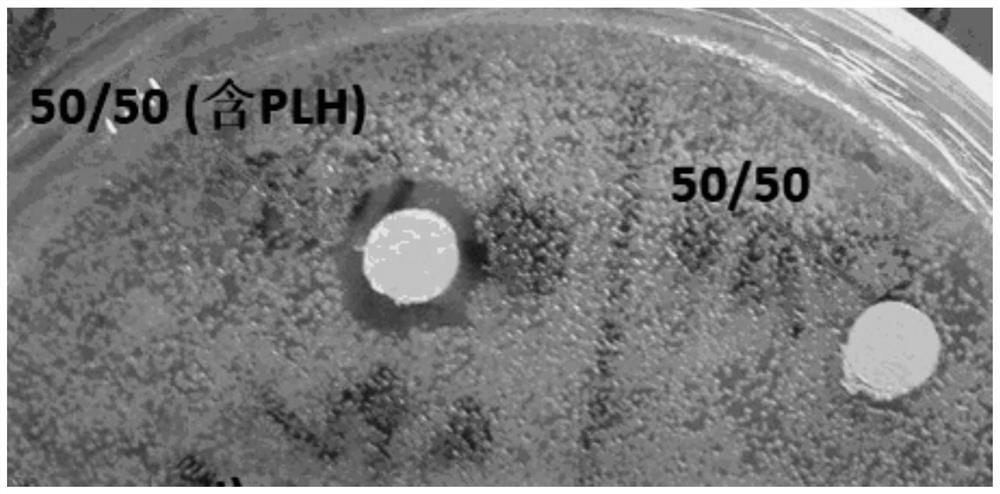

Method used

Image

Examples

Embodiment 1

[0044] The preparation process of the fully degradable antibacterial food packaging film of the present embodiment is as follows:

[0045] (1) Hydroxypropyl cross-linked starch (4kg), polybutylene terephthalate / adipate (16kg), citric acid (0.2kg), glyceryl monostearate (0.3kg), organic Modified montmorillonite (2kg) and ε-polylysine hydrochloride (0.8kg) were mixed in a high-speed mixer. During the mixing process, glycerin (1.6kg) was slowly added to the high-speed mixer through the auxiliary valve. In the machine, the mixing time is 6 minutes, and after mixing, it is placed at room temperature for 24 hours;

[0046] (2) Use a twin-screw extruder to extrude the mixture obtained in step (1) in one step. After the strip is air-cooled by the conveyor belt, it is made into uniform-sized blown film pellets by a pelletizer. The temperature in each zone of the extruder is The order is 105°C, 120°C, 125°C, 135°C, 125°C, head temperature 110°C, screw speed 150rpm;

[0047] (3) The bl...

Embodiment 2

[0051] The preparation method of the fully degradable antibacterial food packaging film of the present embodiment comprises the steps:

[0052] (1) Add ε-polylysine hydrochloride (0.6kg) into an appropriate amount of water, stir in a water bath at 40°C until dissolved, and obtain a clear liquid;

[0053] (2) Hydroxypropyl starch (8kg), polybutylene terephthalate / adipate (12kg), citric acid (0.4kg), stearic acid (0.6kg), organically modified montmorillonite (1.8kg) is placed in the high-speed mixer and mixed, and the ε-polylysine hydrochloride aqueous solution and glycerin (3kg) obtained in step (1) are slowly added to the high-speed mixer through the auxiliary valve during the mixing process. , the total mixing time is 6min, and then the resulting mixture is placed at room temperature for 24h;

[0054] (3) Use a twin-screw extruder to extrude the mixed material obtained in step (2) in one step. After the material strip is air-cooled by the conveyor belt, it is made into unifo...

Embodiment 3

[0059] Use the following steps to prepare the fully degradable antibacterial food packaging film described in this embodiment:

[0060] (1) Hydroxypropyl cross-linked starch (10kg), polybutylene terephthalate / adipate (9kg), polybutylene succinate (1kg), maleic anhydride (0.3kg) , benzoyl peroxide (0.03kg), stearic acid (0.6kg), organically modified montmorillonite (1kg), ε-polylysine hydrochloride (1kg) are placed in a high-speed mixer, and the mixing process Slowly add glycerin (3.5kg) into the high-speed mixer through the additive valve in the middle, the total mixing time is 6min, and then stand at room temperature for 24h;

[0061] (2) Use a twin-screw extruder to extrude the mixture obtained in step (1) in one step. After the strip is air-cooled by the conveyor belt, it is made into uniform-sized blown film pellets by a pelletizer. The temperature in each zone of the extruder is The order is 105°C, 120°C, 125°C, 135°C, 125°C, head temperature 110°C, screw speed 150rpm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com