Ball grid array (BGA) balling single-point repair method

A technology of rework and reballing, which is applied to electrical components, circuits, manufacturing tools, etc. It can solve the problems of low success rate of rework, missing solder balls, damaged devices, etc., so as to improve the pass rate of rework and reduce soldering time , The effect of reducing the influence of device life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

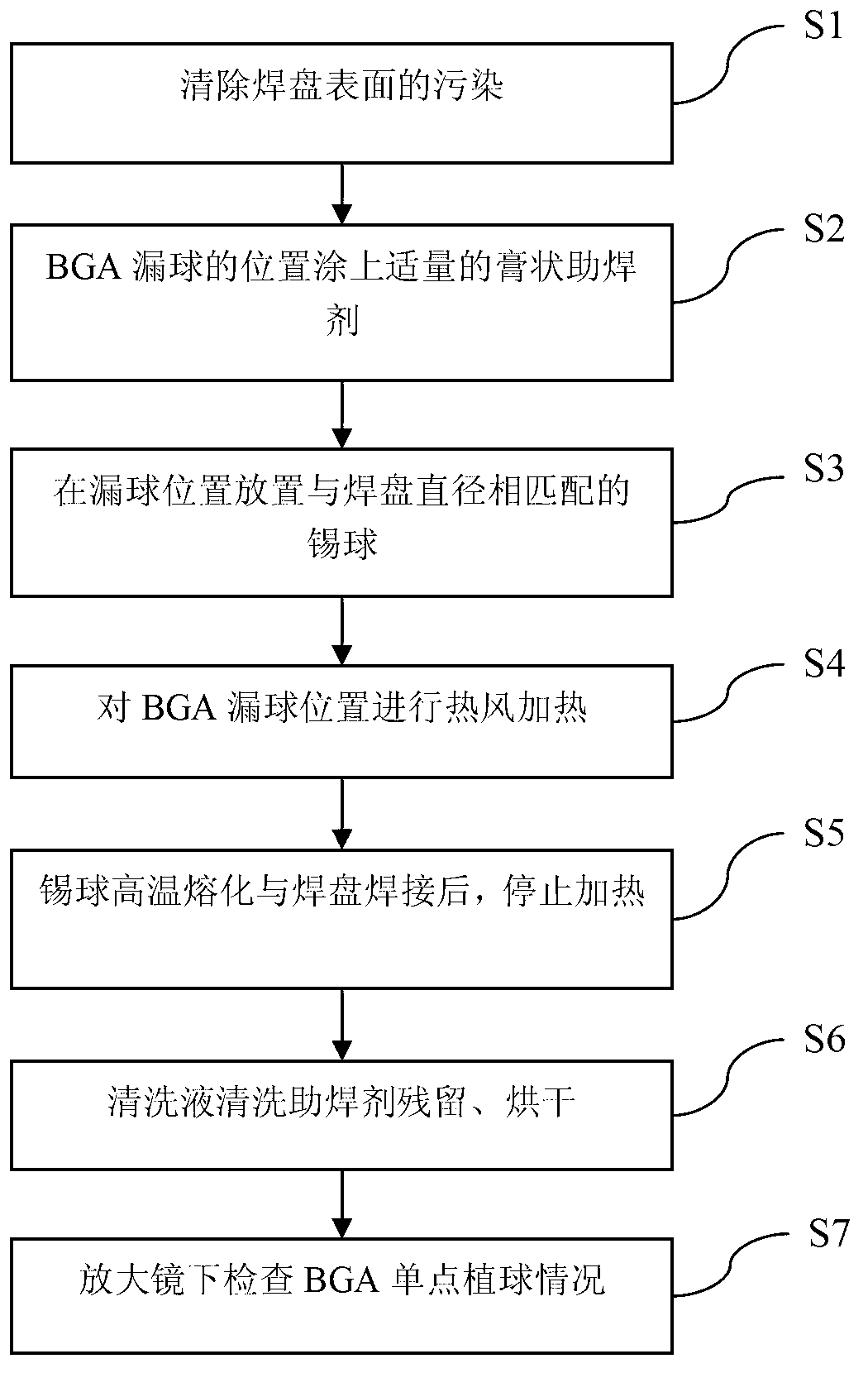

[0030] image 3 A flow chart of a BGA single-point rework method for ball planting according to a preferred embodiment of the present invention is schematically shown.

[0031] Specifically, as image 3 As shown, the BGA ball planting single-point repair method according to a preferred embodiment of the present invention includes:

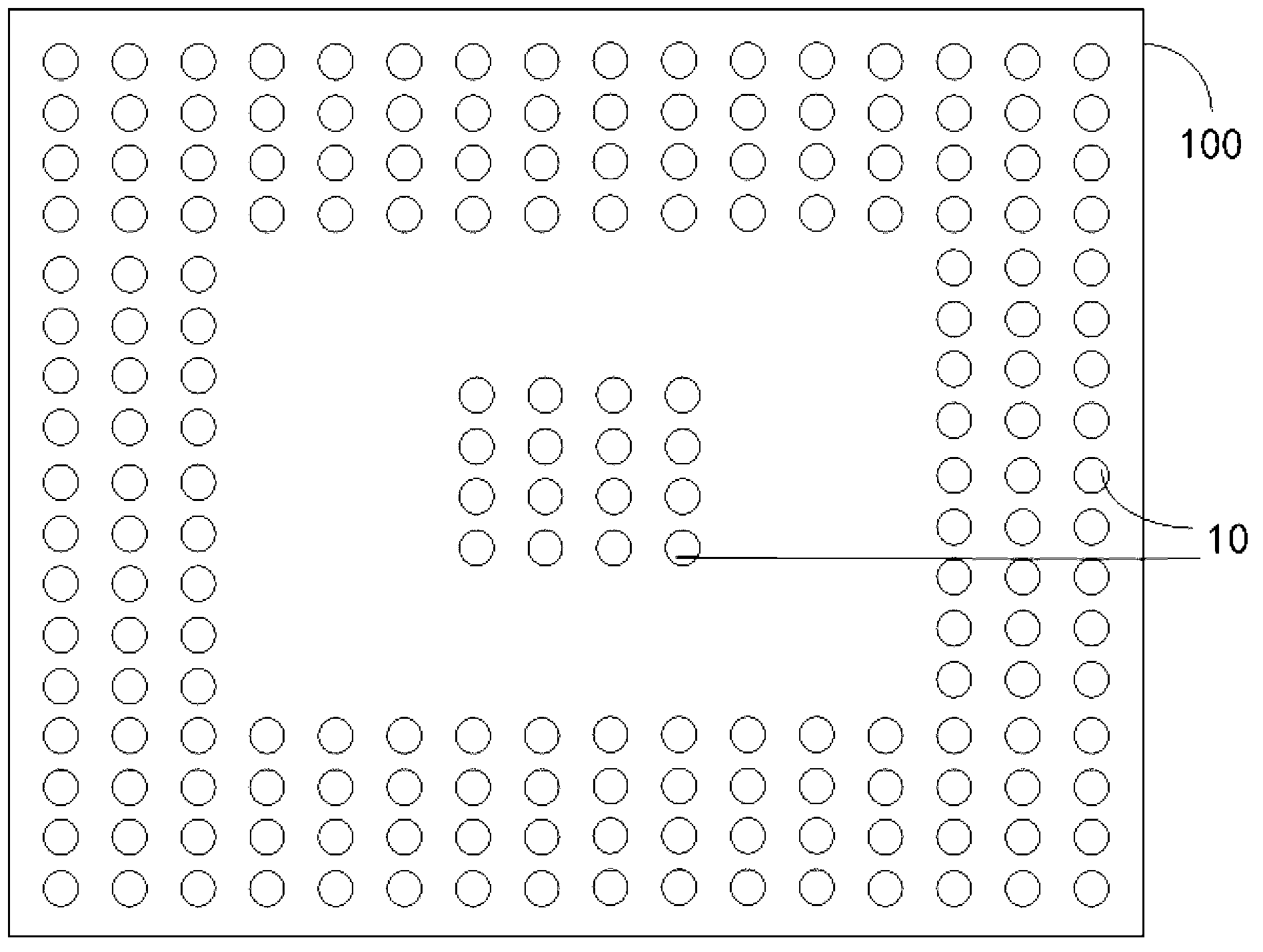

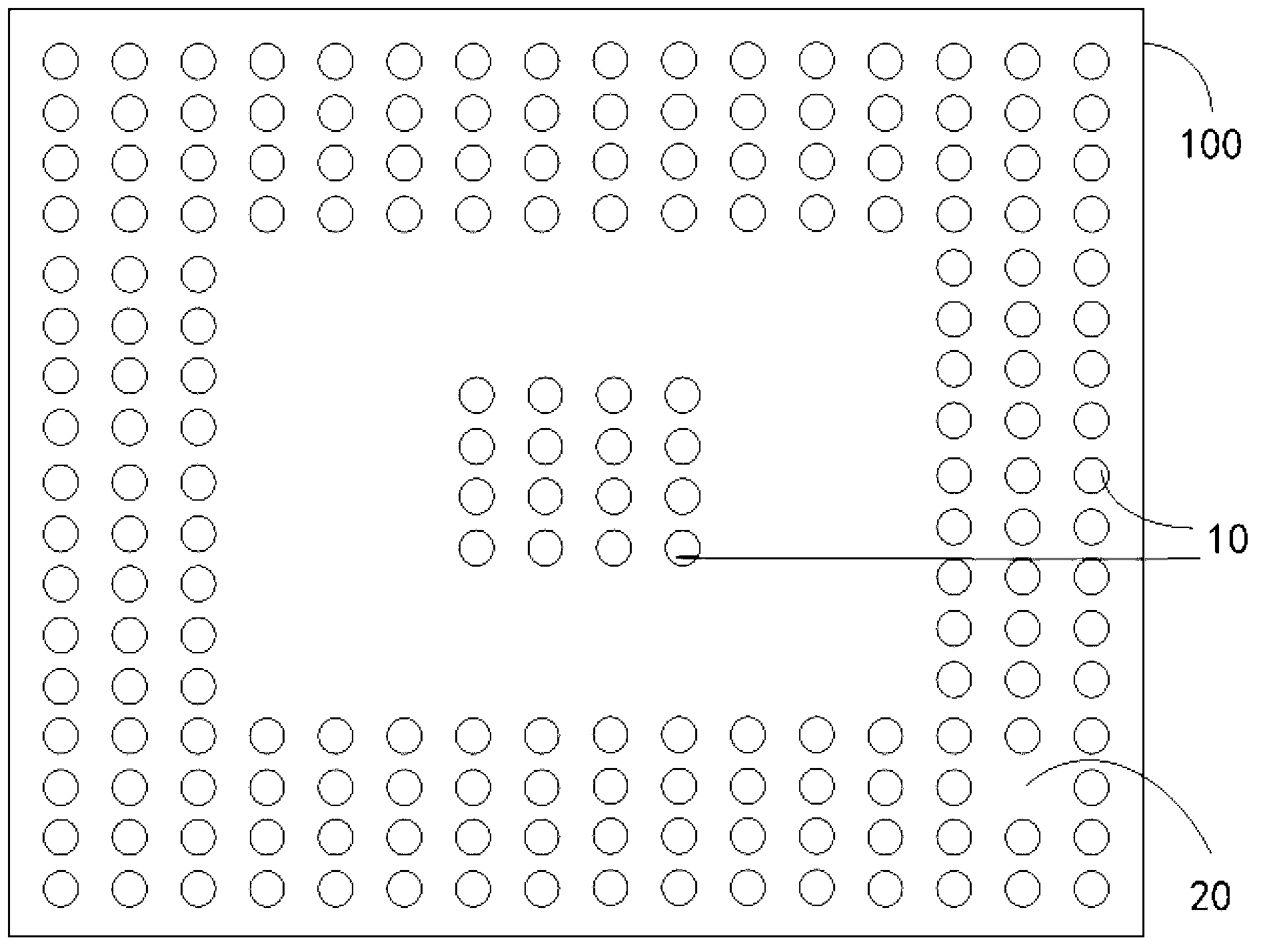

[0032] The first step S1 : removing the oxide layer and pollutants on the surface of the BGA pad of the drain ball (referred to as the “drain ball pad” in this specification) on the bottom surface 100 of the BGA chip. For example, pollutants include dust.

[0033] Second step S2: Take paste flux and apply it on a single drain ball pad. For example, use a needle to dip a small amount of cream flux into the cream s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com