Heat pipe

A heat pipe, one-end technology is applied in the field of heat exchange equipment, which can solve problems such as affecting heat exchange efficiency, and achieve the effect of improving heat transfer efficiency and improving heat transfer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

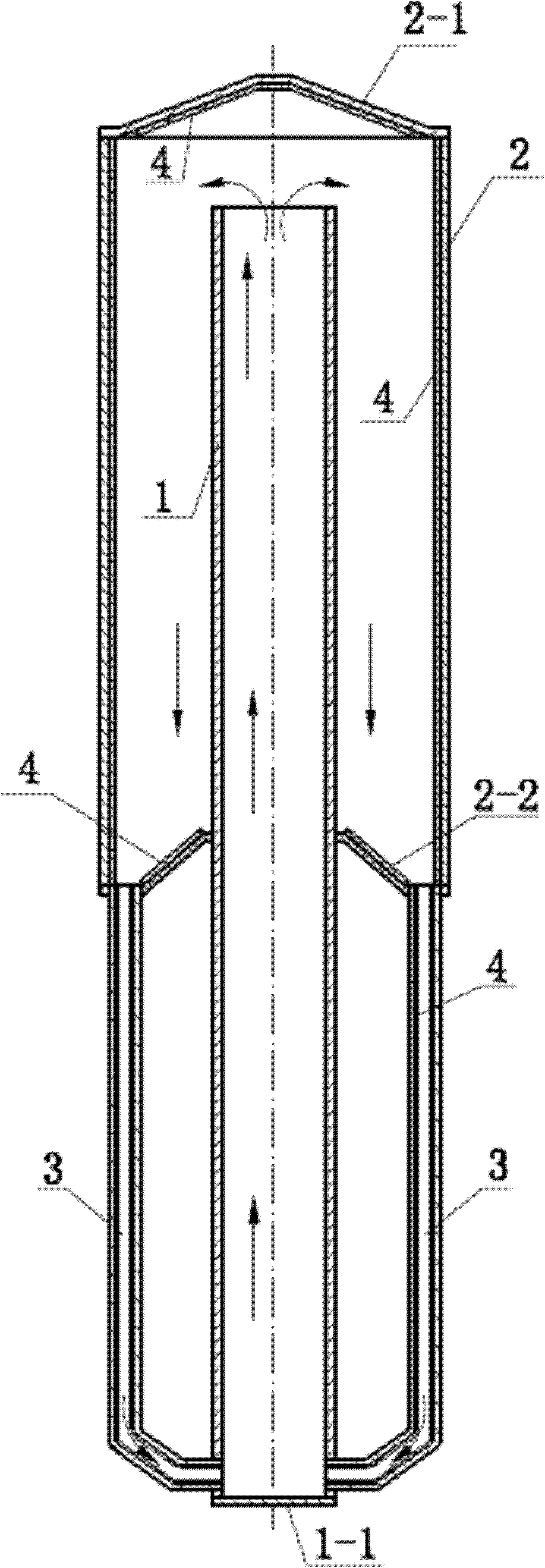

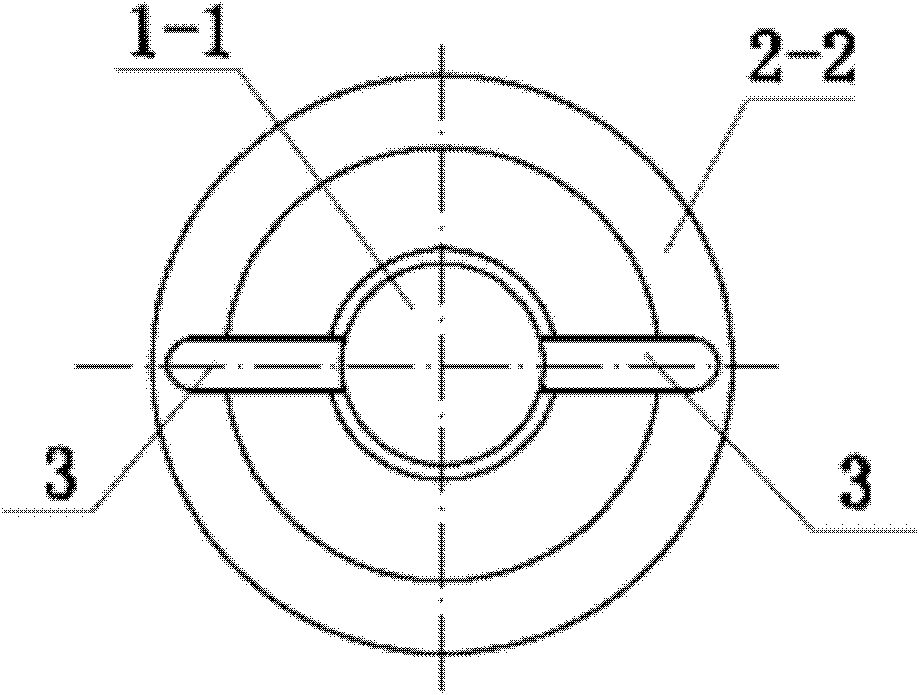

[0016] see Figure 1 to Figure 4 , the inner tube 1 is a cylindrical straight tube, the upper end of which is open, and the lower end is closed by the thermal end cap 1-1. The outer tube 2 is also a cylindrical straight tube, the closed end of the upper end is a conical condensation end cap 2-1, and the lower end is open. The inner tube 1 is coaxially inserted into the outer tube 2 , its open end extends to close to the condensation end cap 2 - 1 of the outer tube 2 , and the other end extends out of the outer tube 2 . The above-mentioned outer pipe 2 forms the condensation section of the heat pipe, and the part of the inner pipe 1 protruding from the outer pipe 2 forms the condensation section of the heat pipe. The open end of the outer tube 2 is provided with a sealing ring 2-2 which closes the annular opening between the outer tube 2 and the inner tube 1. The middle part of the sealing ring 2-2 is conical, and the upper and lower parts are radially inward and downward resp...

Embodiment 2

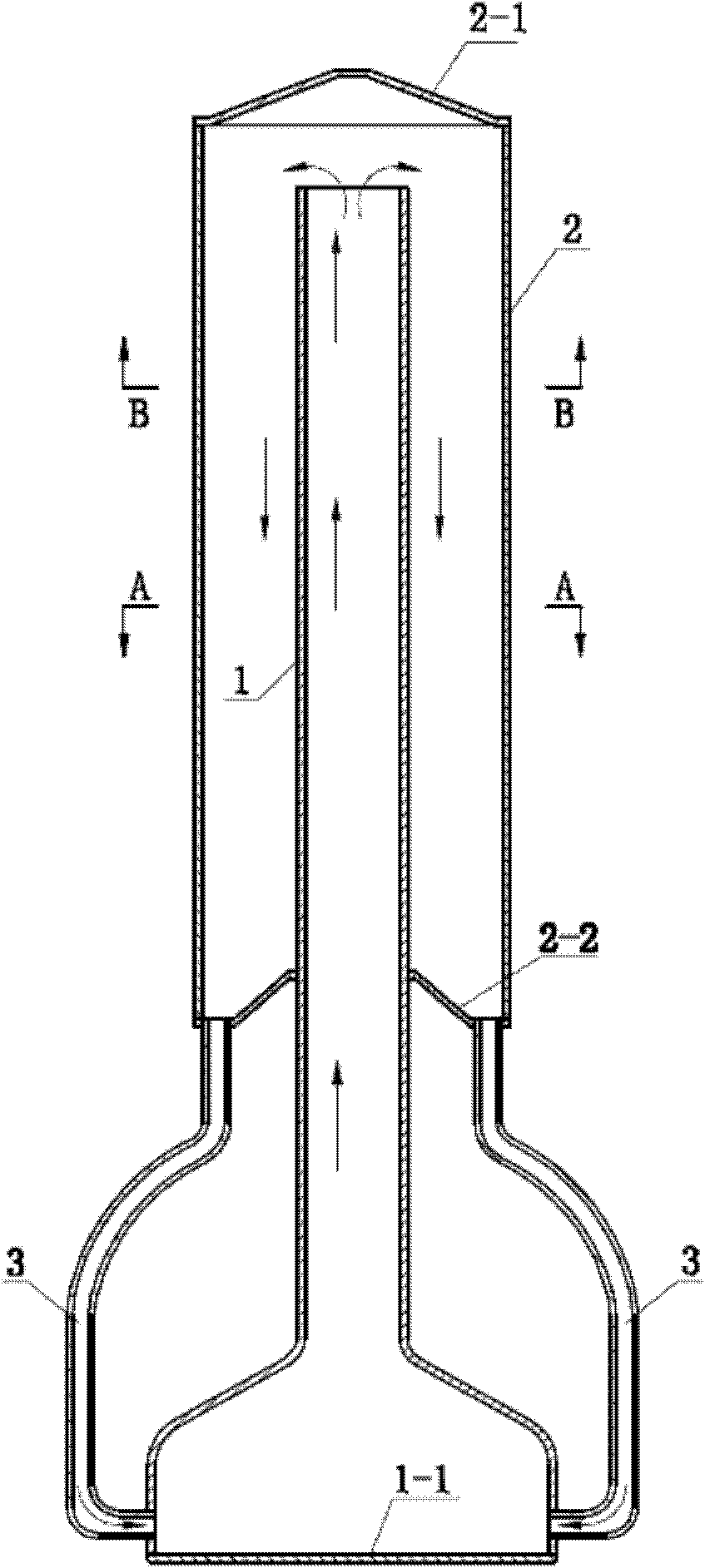

[0020] see Figure 3 ~ Figure 6 , the inner tube 1 of this embodiment radially expands into a convex shape at one end close to the closure, so that the area of the closed end of the inner tube 1 increases. When in use, the end surface is close to the heat source, which is suitable for occasions where the heat source is distributed in a planar form, such as a computer CPU cooling. The inner wall of the outer pipe 2 and the return pipe 3 and the lower surface of the condensation end cover 2-1 and the upper surface of the sealing ring 2-2 are all provided with a capillary liquid-absorbing core 4, and the capillary liquid-absorbing core 4 is provided on the outer pipe 2. And the inner wall of the return pipe 3, the lower surface of the condensation end cover 2-1 and the upper surface of the sealing ring 2-2 are provided with a micro-groove structure 5 coated with a layer of hydrophilic material on the surface. Four return pipes 3 are evenly distributed on the sealing ring 2-2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com