Ultrasonic composite electric resistance welding method for TC4 and 718 steel

A composite resistance and ultrasonic technology, which is applied in the field of ultrasonic composite resistance welding and ultrasonic composite resistance welding devices, can solve the problems of reduced joint performance and inclusion of welded joints, and achieves improved performance, reduced heat exposure, and reduced heat embrittlement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

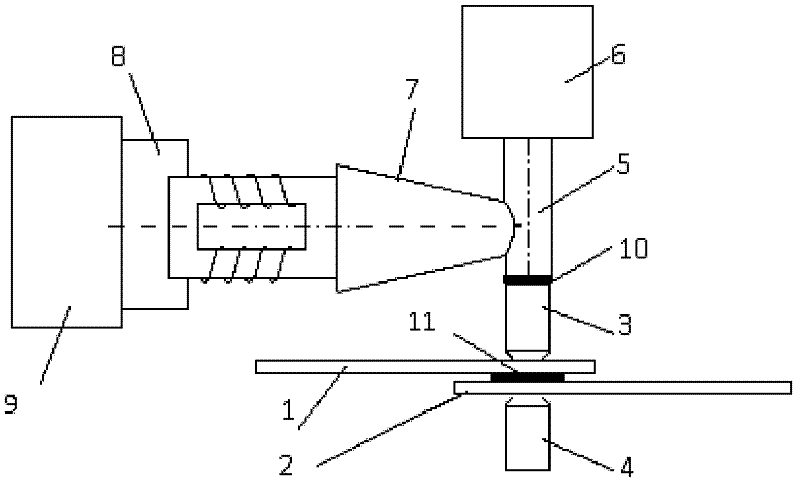

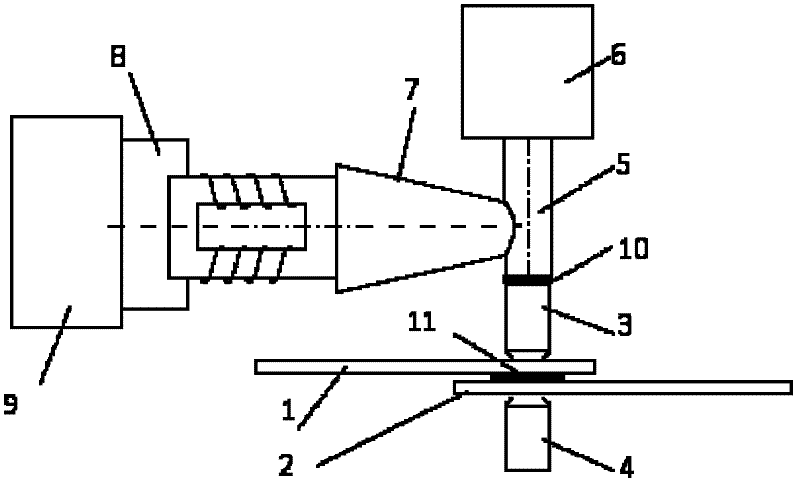

Embodiment 1

[0034] Set the working parameters of the ultrasonic generator 9: power P=80W, resonant frequency f=80kHz, amplitude A=0.1-5.0μm, duration t=120s; set the working parameters of the three-phase DC resistance welding machine: power W=120KW, welding Current I=18KA, welding pressure F=10KN, power-on time t=120s. By placing a V / Ni bimetal with a thickness of about 40-60 μm as an intermediate transition layer between the two weldments, the welding of the TC4 titanium alloy plate with a thickness of 2.0mm and the 718 steel plate is realized, and the shear strength of the joint reaches 381MPa.

Embodiment 2

[0036] Set the working parameters of the ultrasonic generator 9: power P=80W, resonant frequency f=100kHz, amplitude A=0.1-5.0μm, duration t=60s; set the working parameters of the three-phase DC resistance welding machine: power W=120KW, welding Current I=10KA, welding pressure F=15KN, power-on time t=180s. By placing a V / Ni bimetal with a thickness of about 40-60 μm as an intermediate transition layer between the two weldments, the welding of 3Cr2NiMo steel with a thickness of 2.0mm and Ti-6Al-4V titanium alloy is realized, and the shear strength of the joint is achieved. Up to 413MPa.

Embodiment 3

[0038] Set the working parameters of the ultrasonic generator 9: power P=80W, resonant frequency f=90kHz, amplitude A=0.1-5.0μm, duration t=40s; set the working parameters of the three-phase DC resistance welding machine: power W=120KW, welding Current I=8KA, welding pressure F=14KN, power-on time t=200s. By placing a V / Ni bimetal with a thickness of about 40-60 μm as an intermediate transition layer between the two weldments, the welding of the TC4 titanium alloy plate with a thickness of 1.5mm and the 718 steel plate is realized, and the shear strength of the joint reaches 403MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com