Integrally-assembled cantilever-type retaining wall and construction method thereof

A retaining wall and monolithic technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of slow construction speed and a large amount of labor, and achieve the effects of fast construction speed, low project cost and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

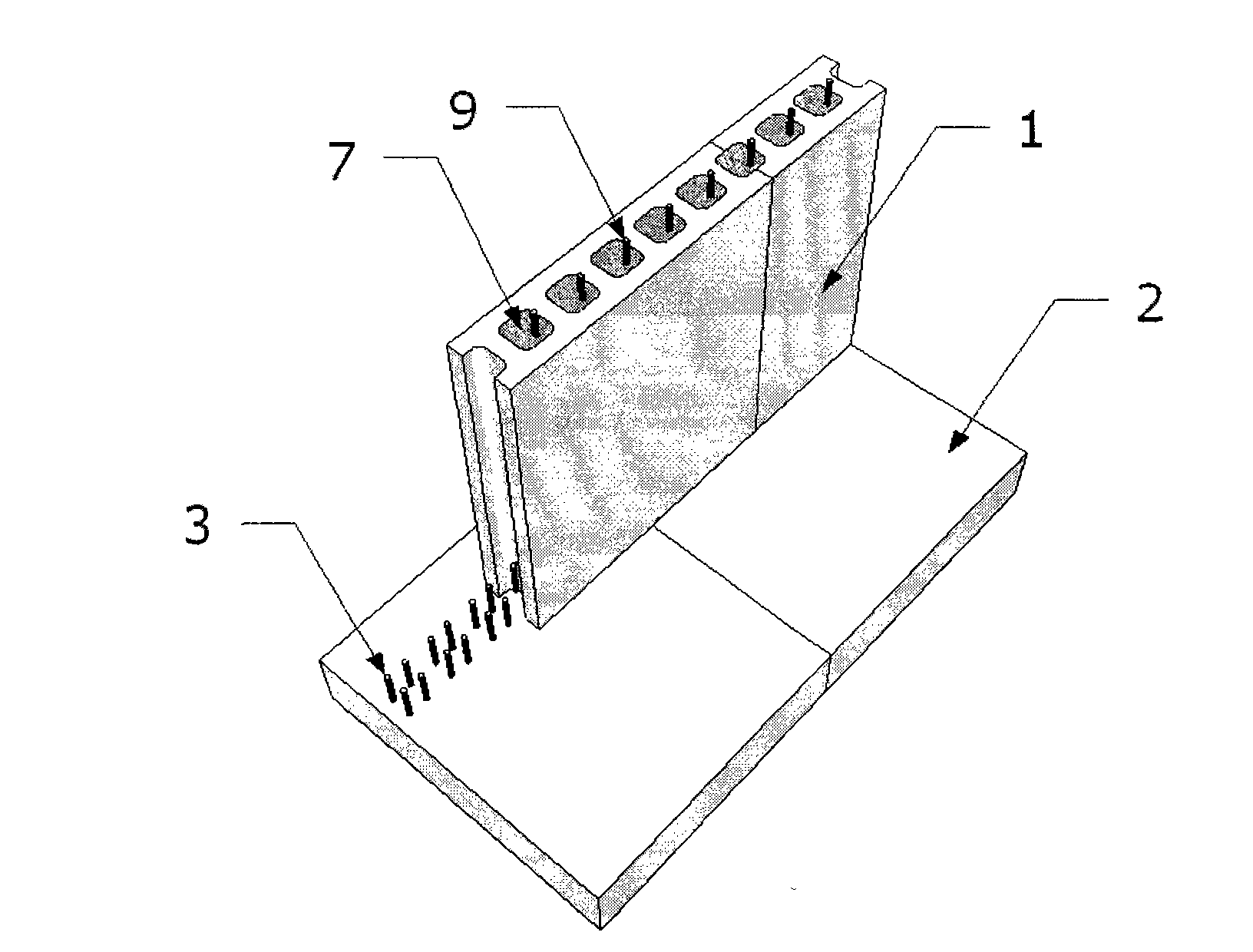

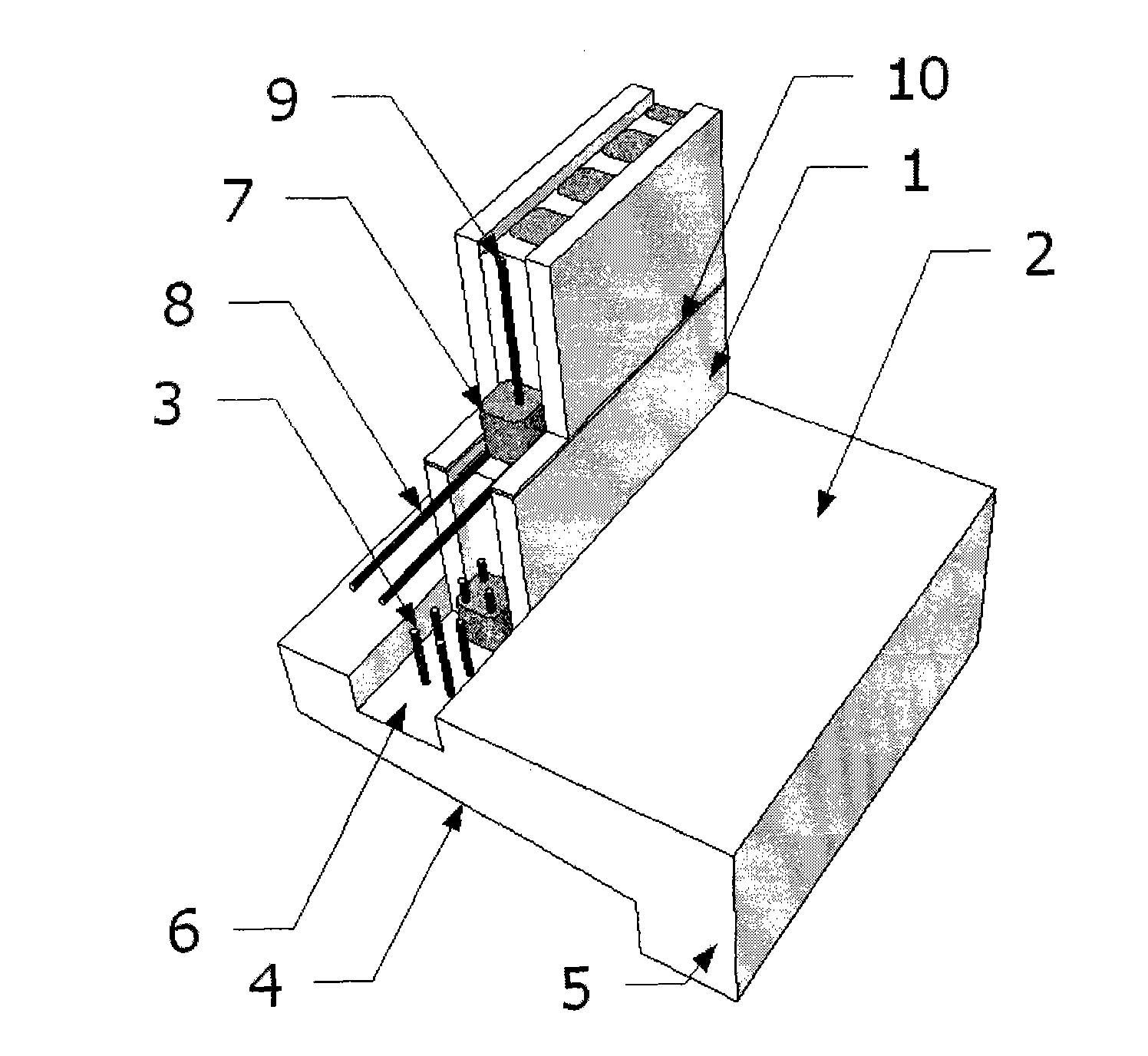

[0026] see figure 1 , an assembled integral cantilever retaining wall, comprising a prefabricated concrete hollow wall panel 1 and a prefabricated reinforced concrete bottom slab 2 with vertically lapped reinforcement bars 3 on one side of the prefabricated reinforced concrete bottom slab 2 . When assembling the prefabricated concrete hollow wall panel 1, the vertical lap steel bars 3 of the prefabricated reinforced concrete bottom slab 2 are extended into the holes in the prefabricated concrete hollow wall panel 1, and the vertical receiving bars are inserted into the holes of the prefabricated concrete hollow wall panel 1 Reinforcing reinforcement and pouring concrete to form an assembled integral cantilever retaining wall.

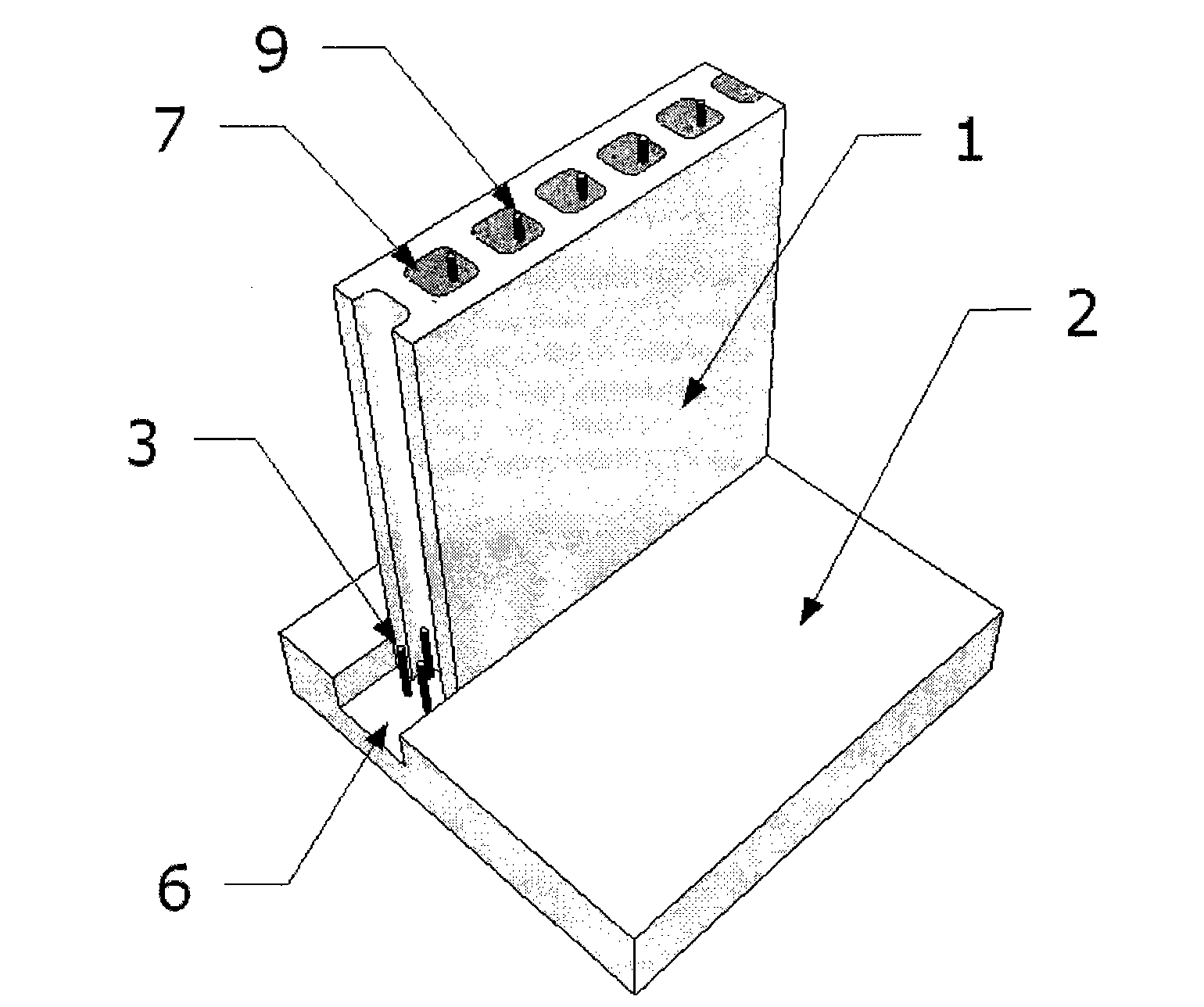

[0027] see figure 2 , if the prefabricated reinforced concrete base plate 2 has a groove 6, then the prefabricated concrete hollow wall panel 1 must be stuck in the groove 6.

[0028] Construction of the assembled monolithic cantilever retaining wall...

Embodiment 2

[0035] see Figure 7 , is also an assembled integral cantilever retaining wall, but the wall panel adopts the form of variable cross-section, and the prefabricated concrete hollow wall panel 1 is used to build staggered holes to form two wall panels with different heights. Connect them with U-shaped ribs 12 (see Figure 8 ), the interlayer between the two wall panels is filled with concrete 11 to form variable section wall panels.

[0036] Construction of the above-mentioned assembled integral cantilever retaining wall (variable section wall panel):

[0037] (a) Preparatory work: including the prefabrication preparation work of the concrete hollow wall panel 1 and the reinforced concrete floor 2 and the preparation work on the construction site. The prefabrication preparation work is carried out in the prefabrication factory. According to the design drawings, the concrete hollow wall panel 1 and the reinforced concrete bottom slab 2 with vertically lapped reinforcement bars ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com