Repair treatment method of mine

A mine and mountain technology, applied in the field of ecological restoration construction, can solve problems such as hillside regreening, achieve the effects of reducing the degree of impact, increasing germination rate and survival rate, and promoting early germination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

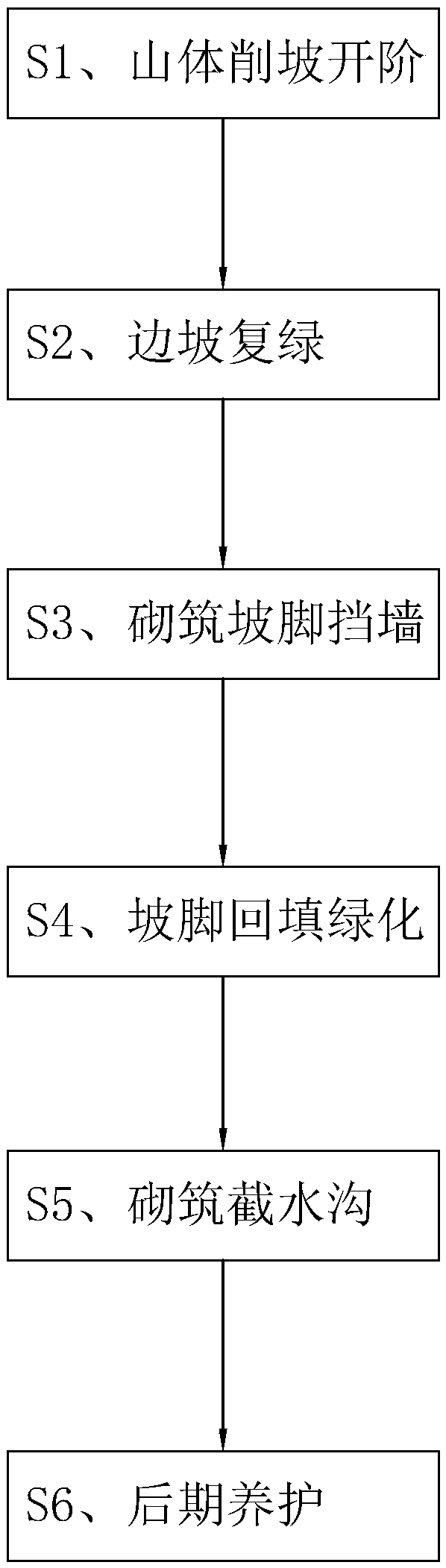

[0042]Embodiment 1: a kind of restoration management method of mine, comprises the following steps:

[0043] S1, the slope of the mountain is cut and the steps are opened. For mountains with a slope greater than or equal to 60°, slope cutting must be carried out, and the slope should be cut according to the slope ratio of 1:1. Of course, the slope ratio can be between 1:1 and 1:0.75 according to the actual construction needs or soil conditions. Make appropriate adjustments between the slopes, and carry out step-opening operations at equal intervals after the slope is cut to increase the roughness of the slope after the slope is cut.

[0044] S2, slope regreening. After the mountain is slope-cut, the waste stones obtained from the mining are transported to the temporary storage yard, and then the entire slope is cleaned, and the sundries and loose rocks are cleaned up, and grooves are made horizontally on the local smooth slope Or nail wooden strips to increase the roughness ...

Embodiment 2

[0062] Embodiment 2: A method for repairing and controlling a mine. The difference from Embodiment 1 is that the components contained in the spray-mixed vegetation and their corresponding contents are: 12 parts of peat soil; 68 parts of sieved humus soil; 3 parts of fiber; 0.1 part of chaff; 0.1 part of sawdust; 15 parts of water retaining agent; 0.3 parts of compound slow-release fertilizer; 10 parts of adhesive; 15 parts of water;

Embodiment 3

[0063] Embodiment 3: A method for repairing and controlling mines. The difference from Example 1 is that the components contained in the spray-mixed vegetation and their corresponding contents are: 18 parts of peat soil; 85 parts of sieved humus soil; 8 parts of fiber; 0.5 parts of chaff; 0.5 parts of sawdust; 30 parts of water-retaining agent; 1 part of compound slow-release fertilizer; 20 parts of adhesive; 55 parts of water;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com