Patents

Literature

131results about How to "Reduced material requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

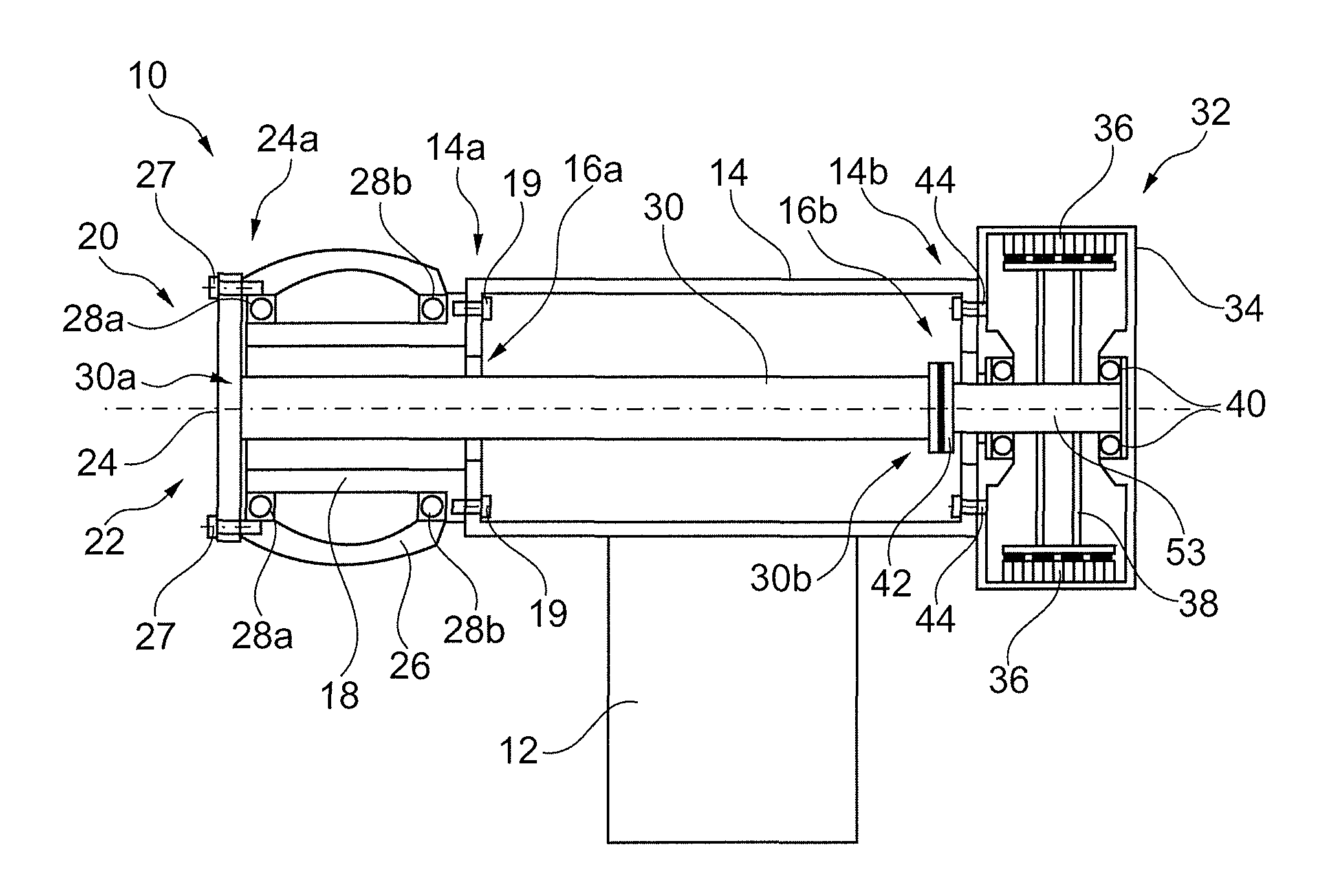

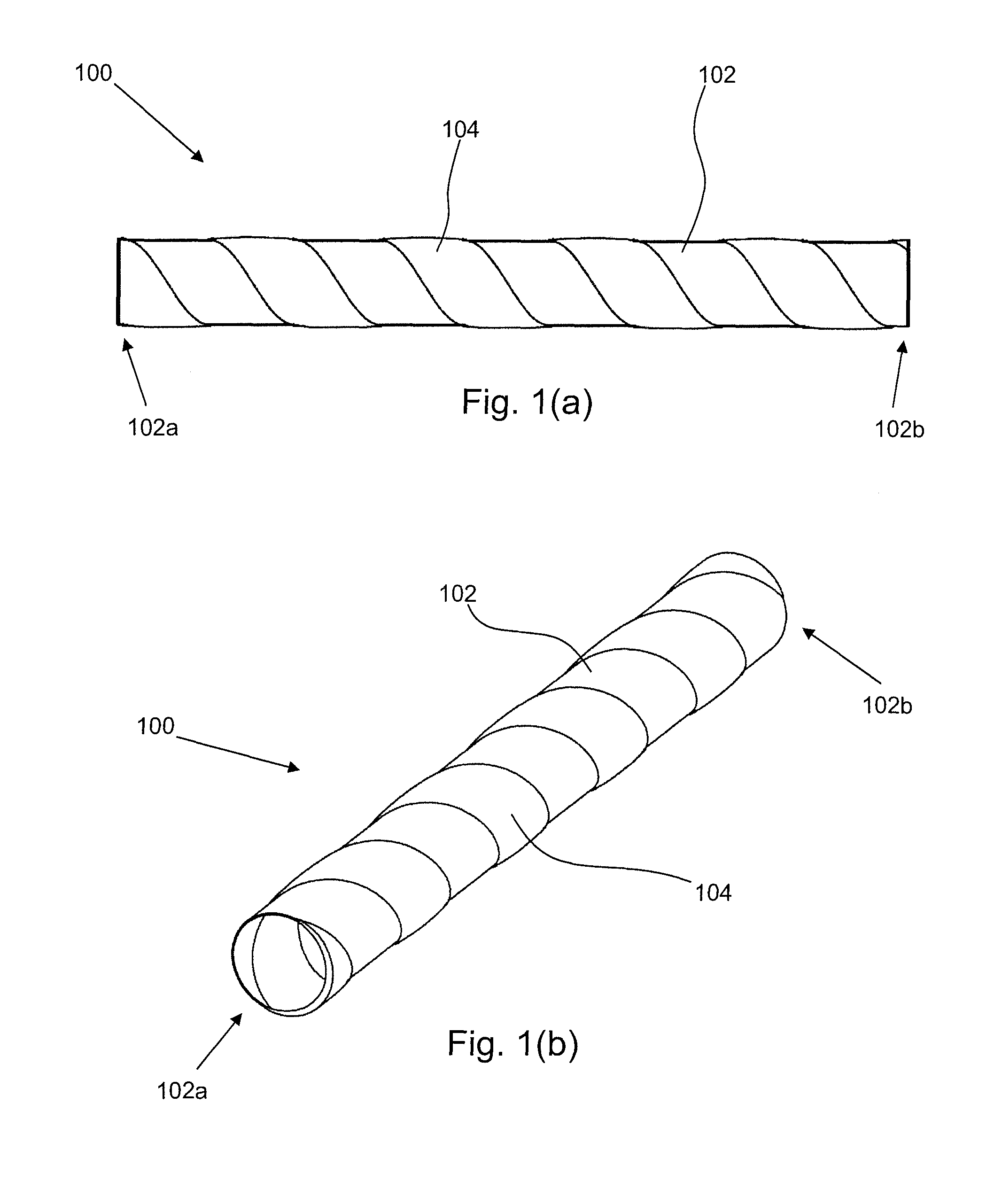

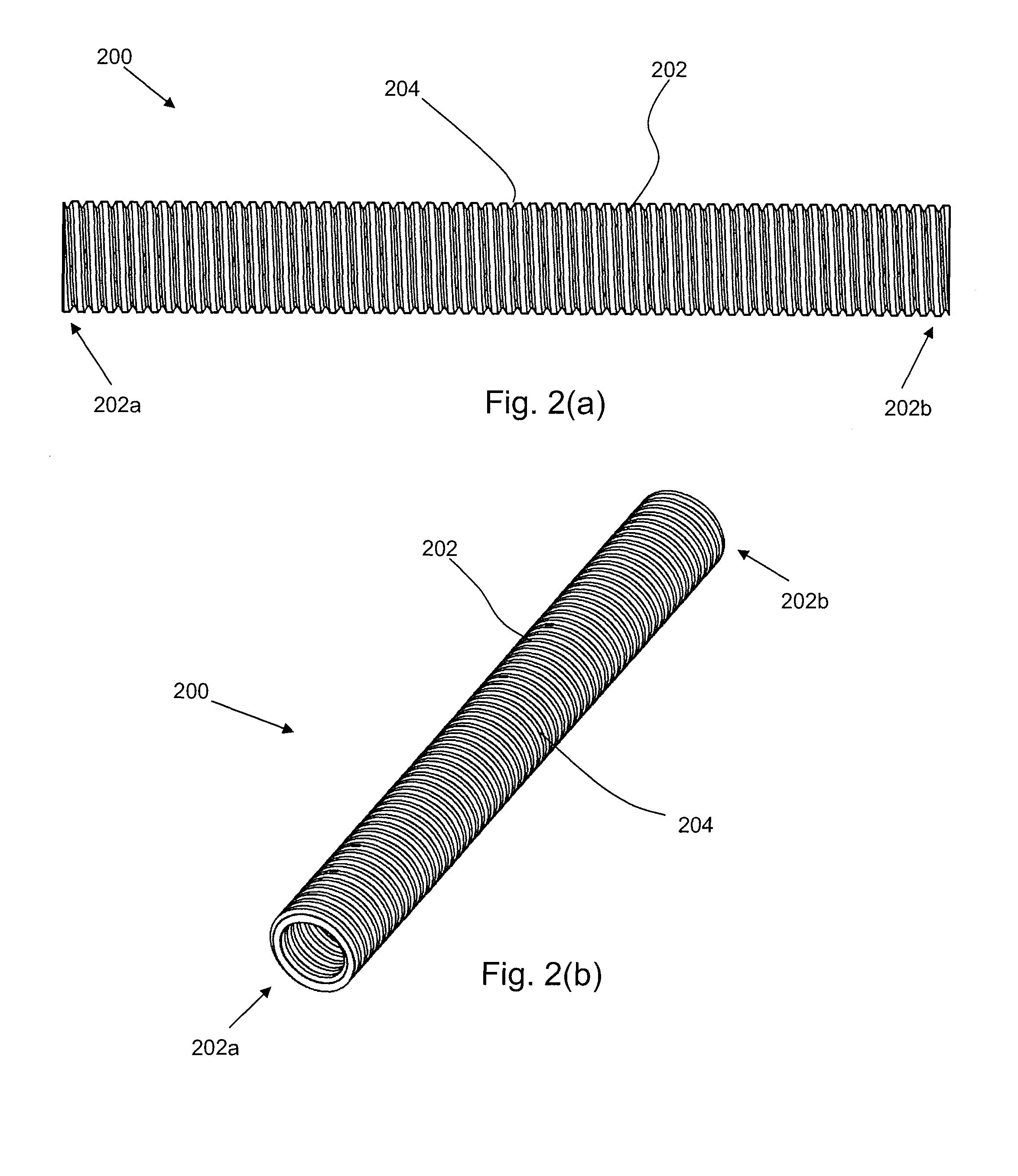

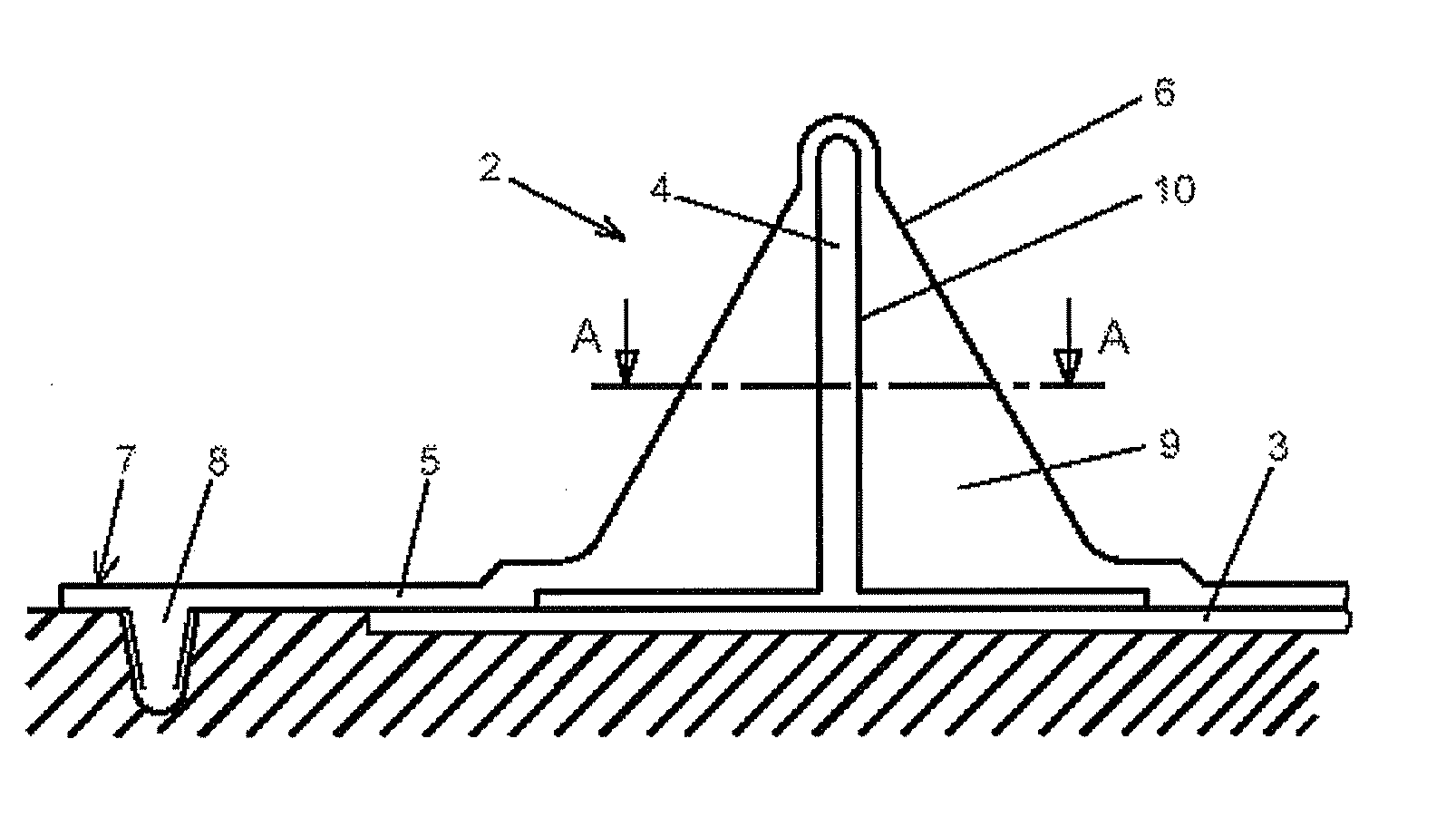

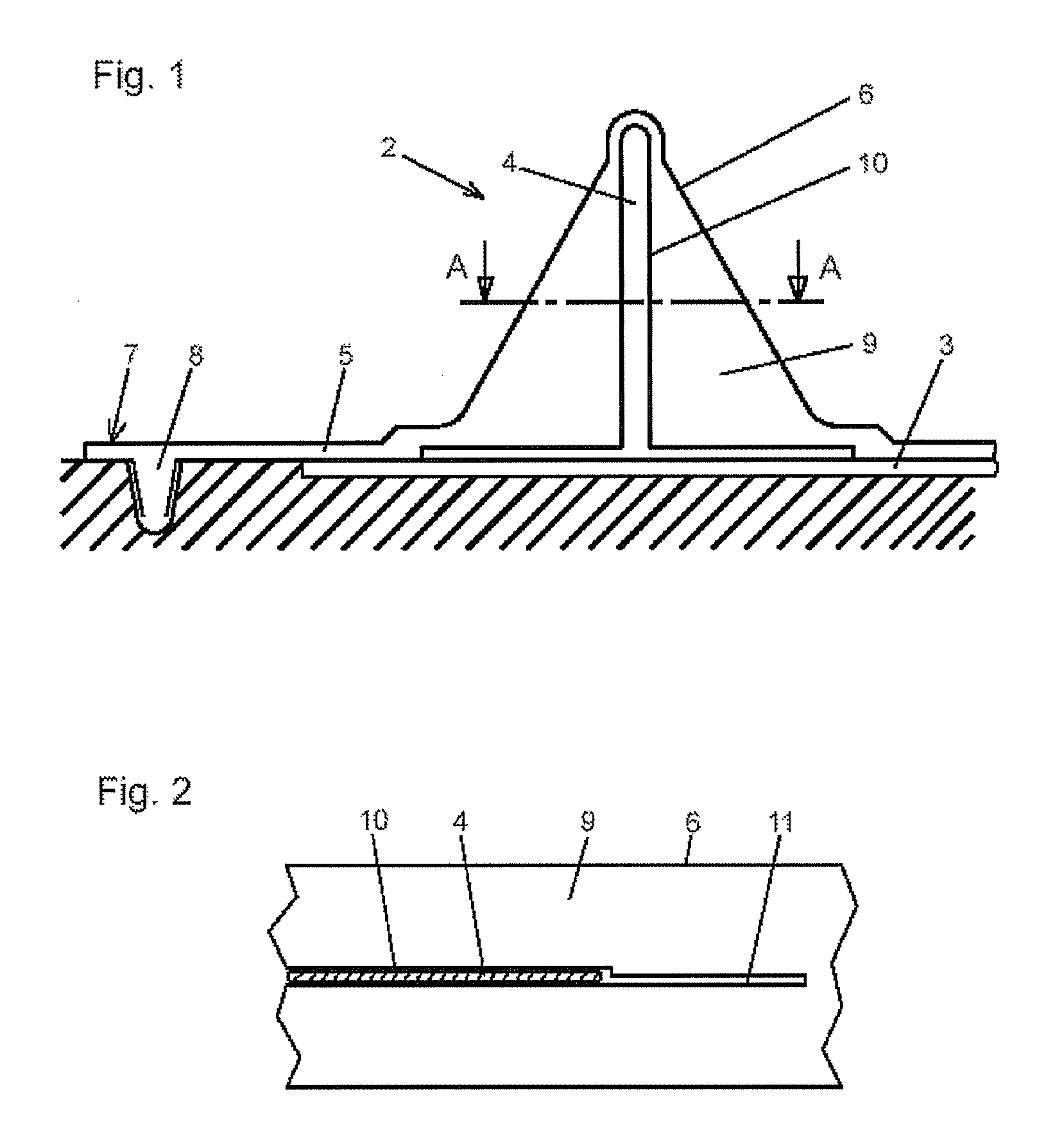

Wind turbine and a shaft for a wind turbine

InactiveUS8664792B2Little strengthImproves buckling stabilityEngine fuctionsFinal product manufactureDrive shaftTurbine

A drive shaft for a wind turbine is shaped so as to allow for increased bending of the shaft, while being suitable for transferring torque in a wind turbine system. An example of such a shaping is a drive shaft having a helical rib defined on the surface of the shaft. A wind turbine incorporating such a shaft, and a method of manufacture of such a shaft are also described.

Owner:ENVISION ENERGY DENMARK

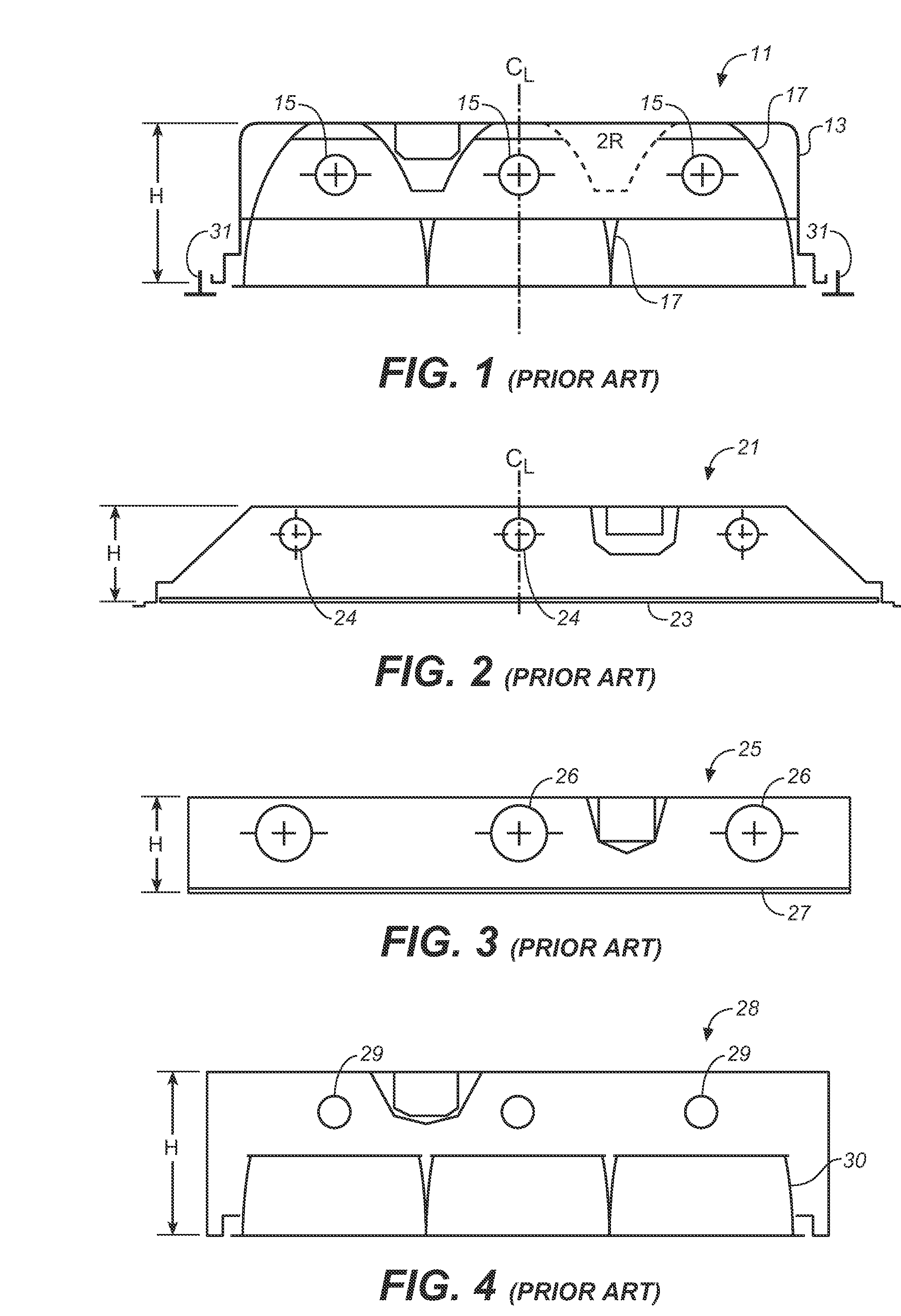

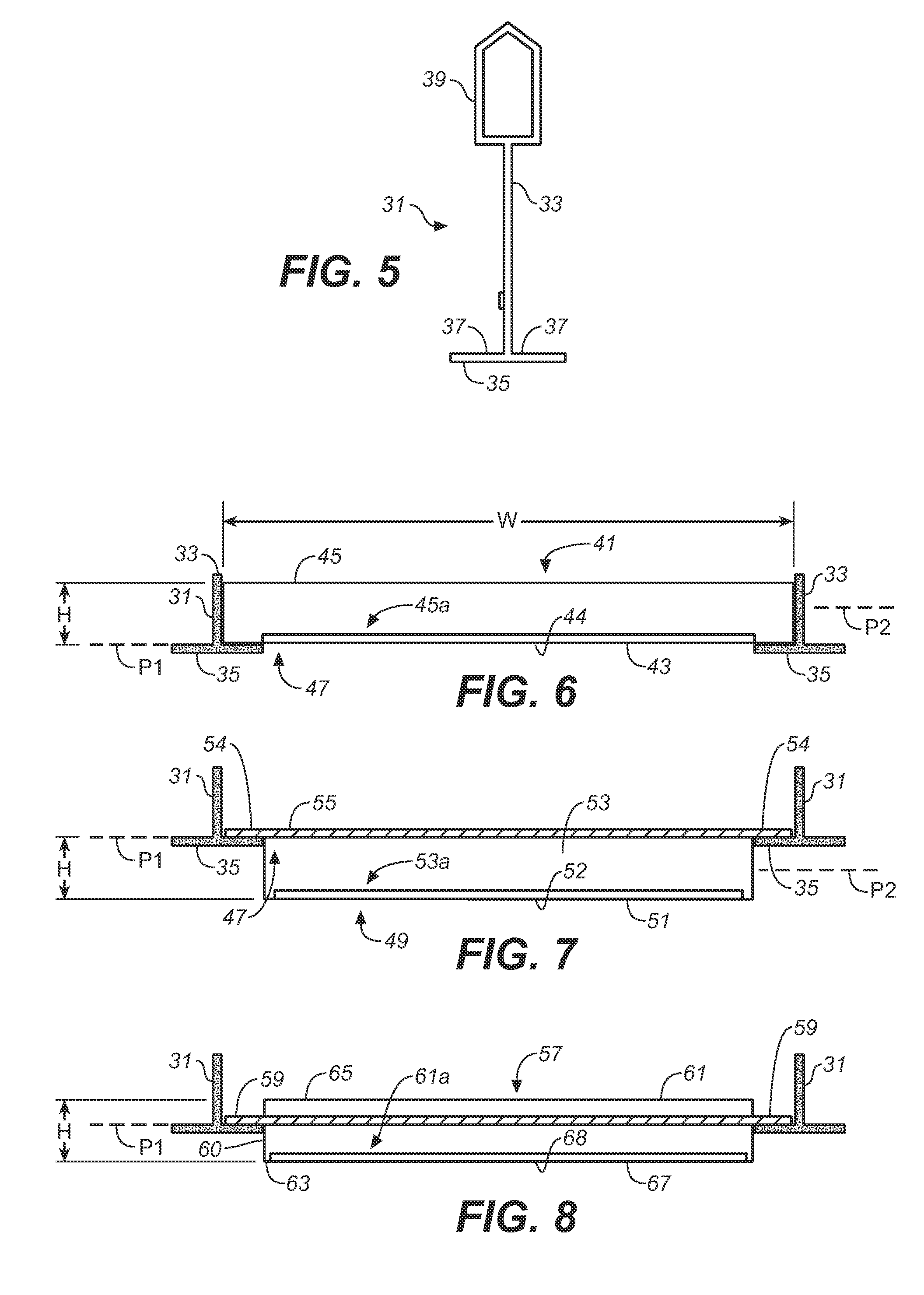

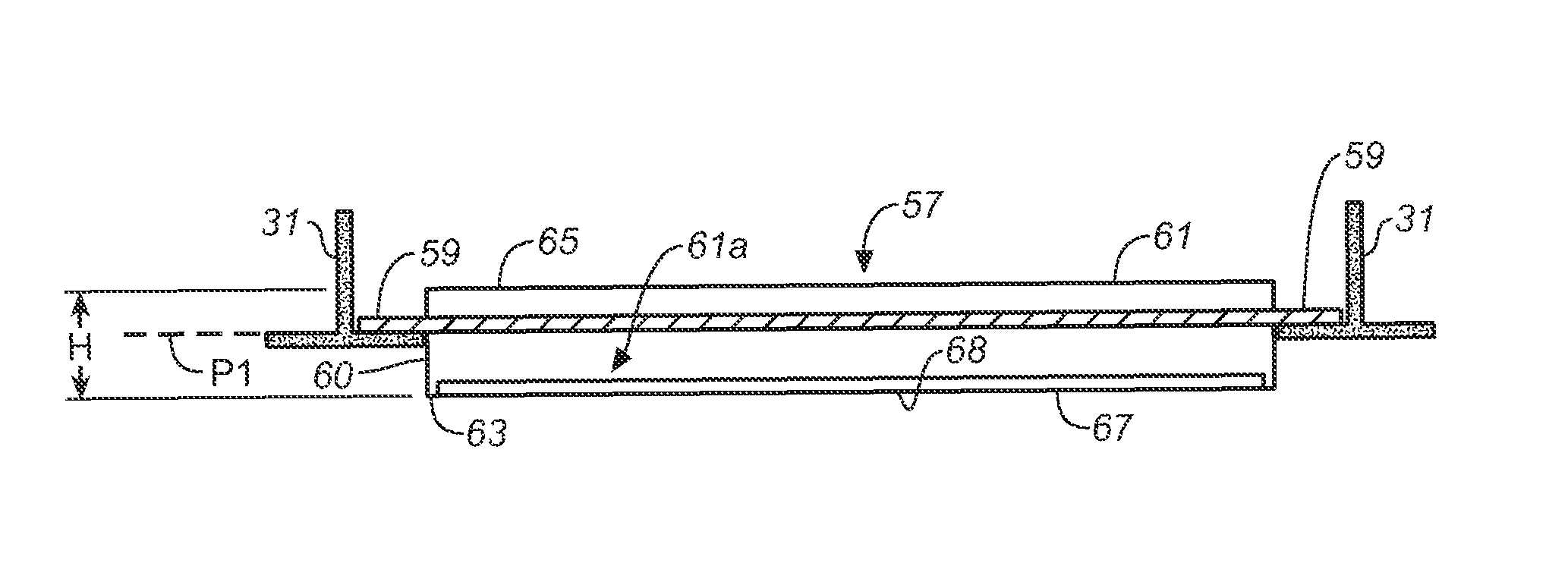

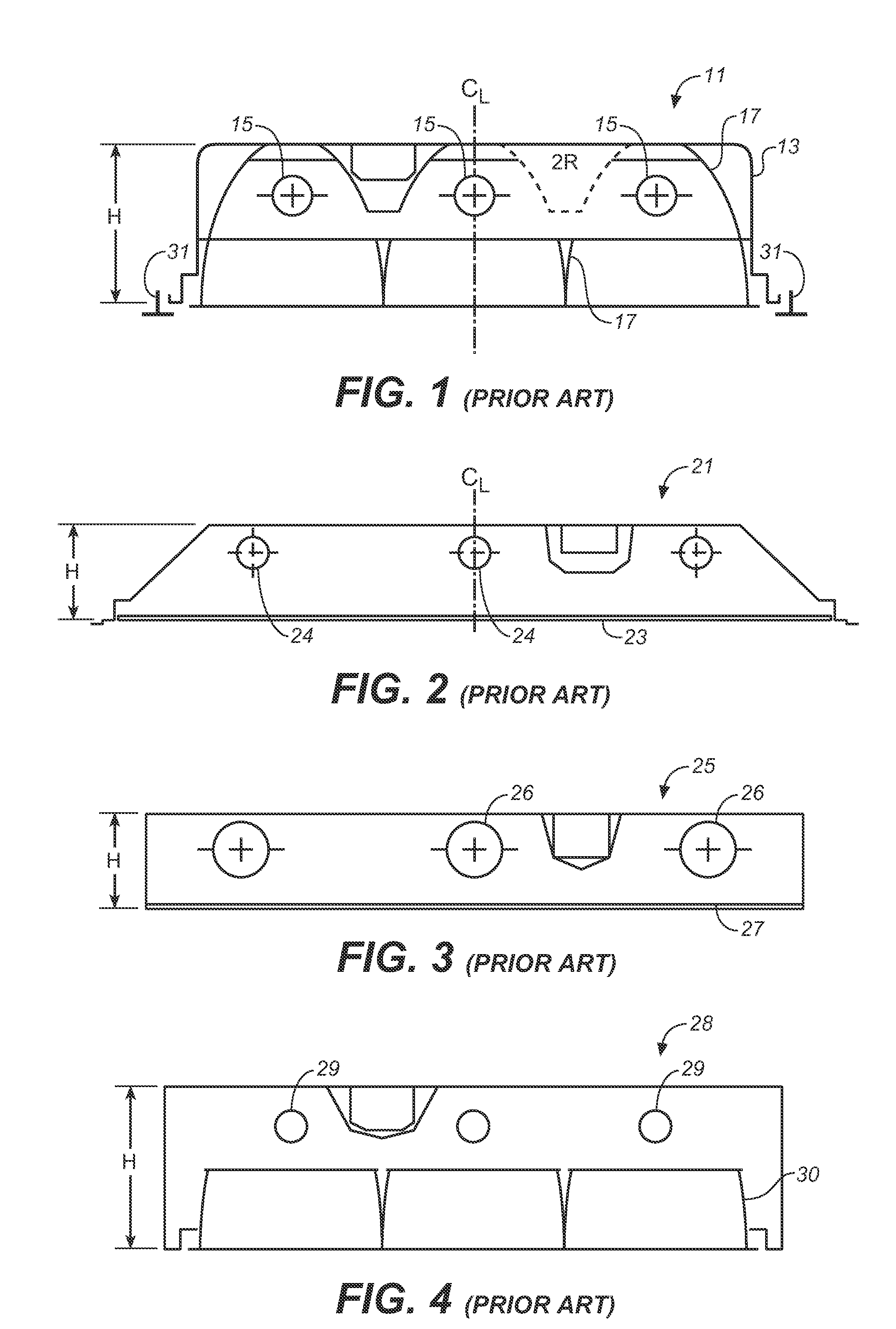

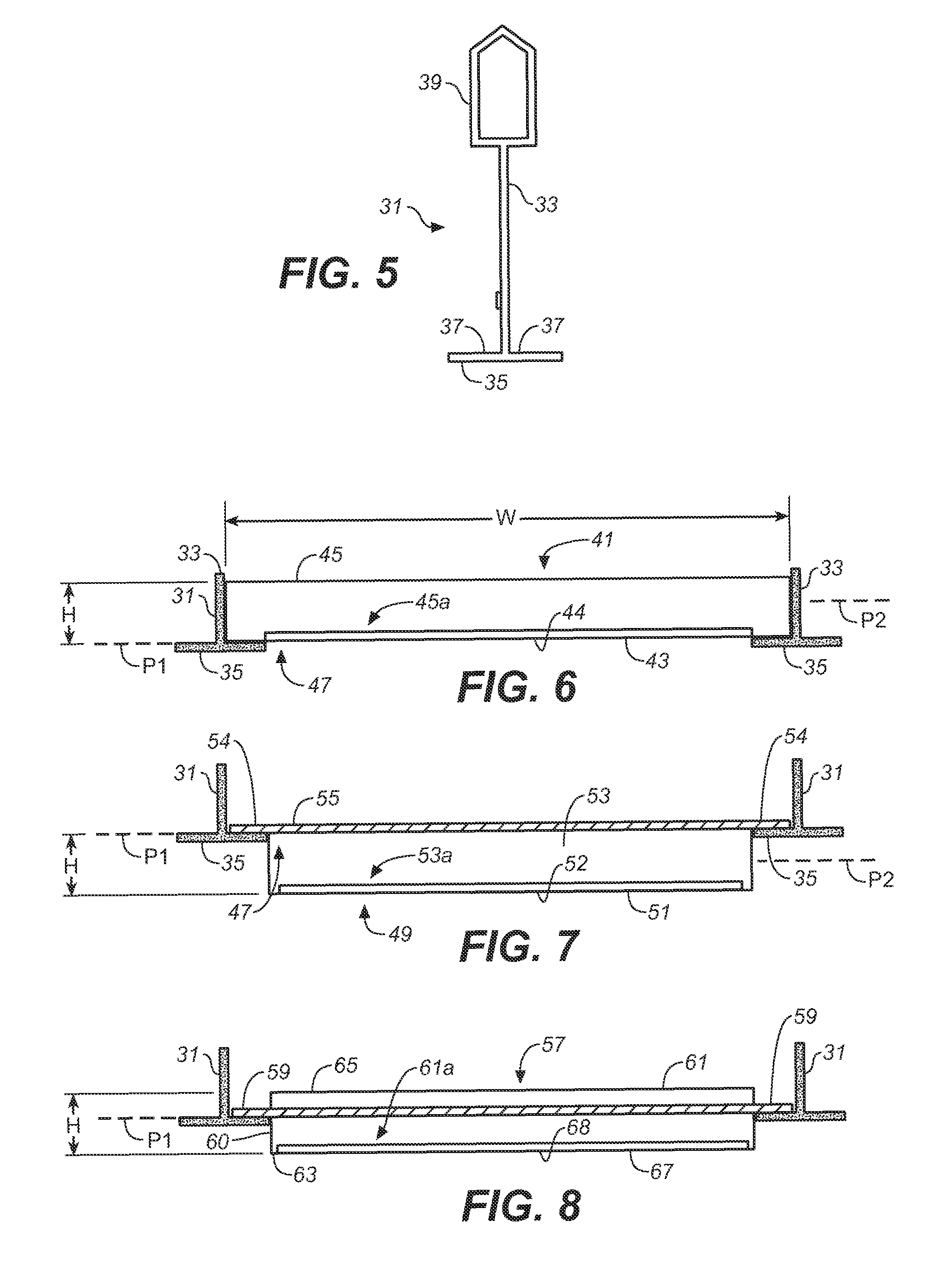

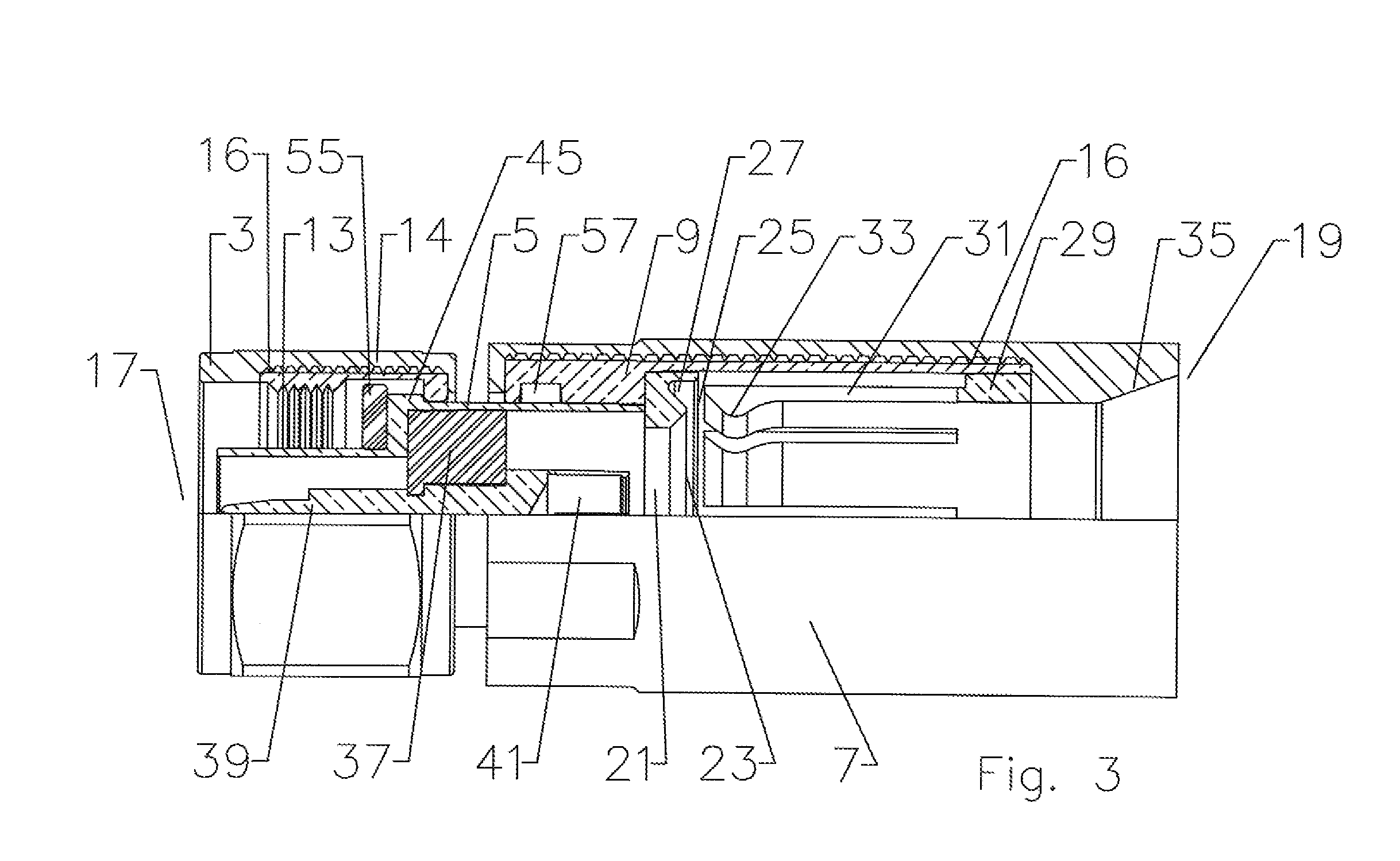

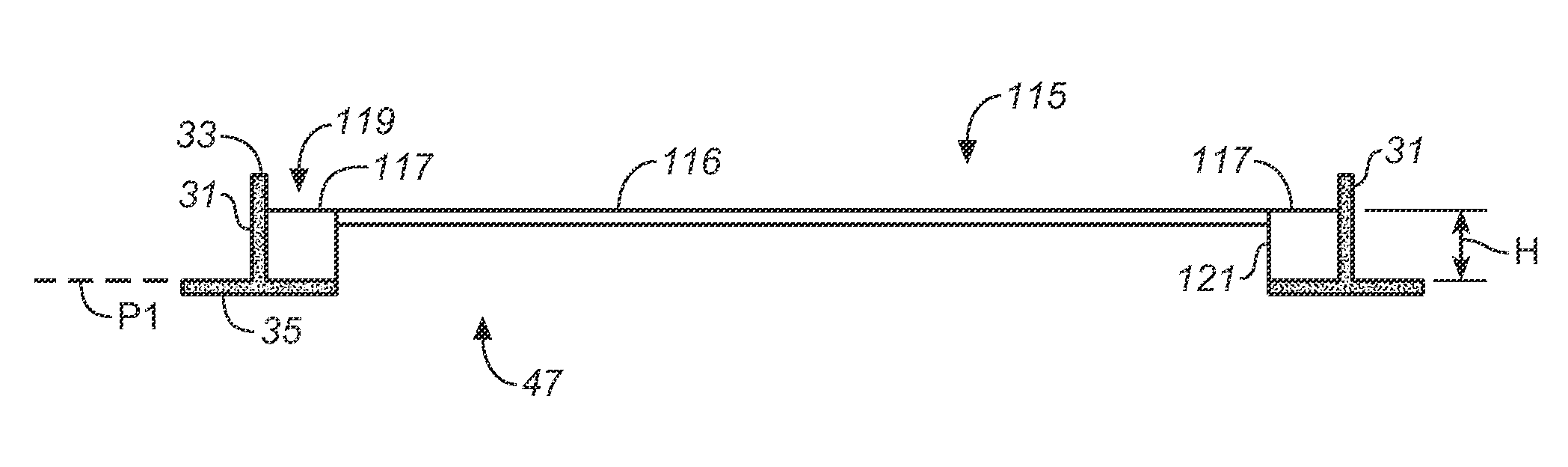

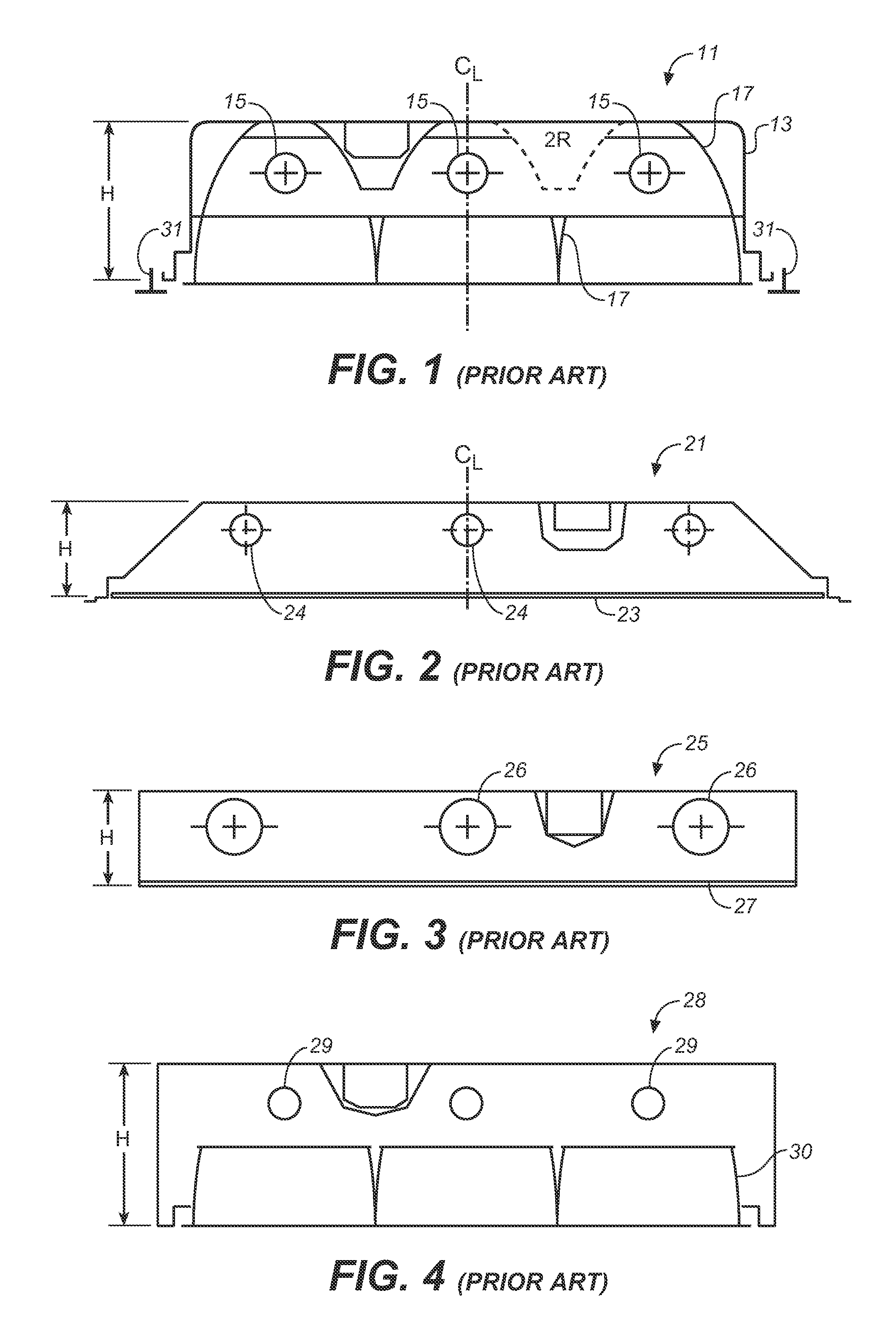

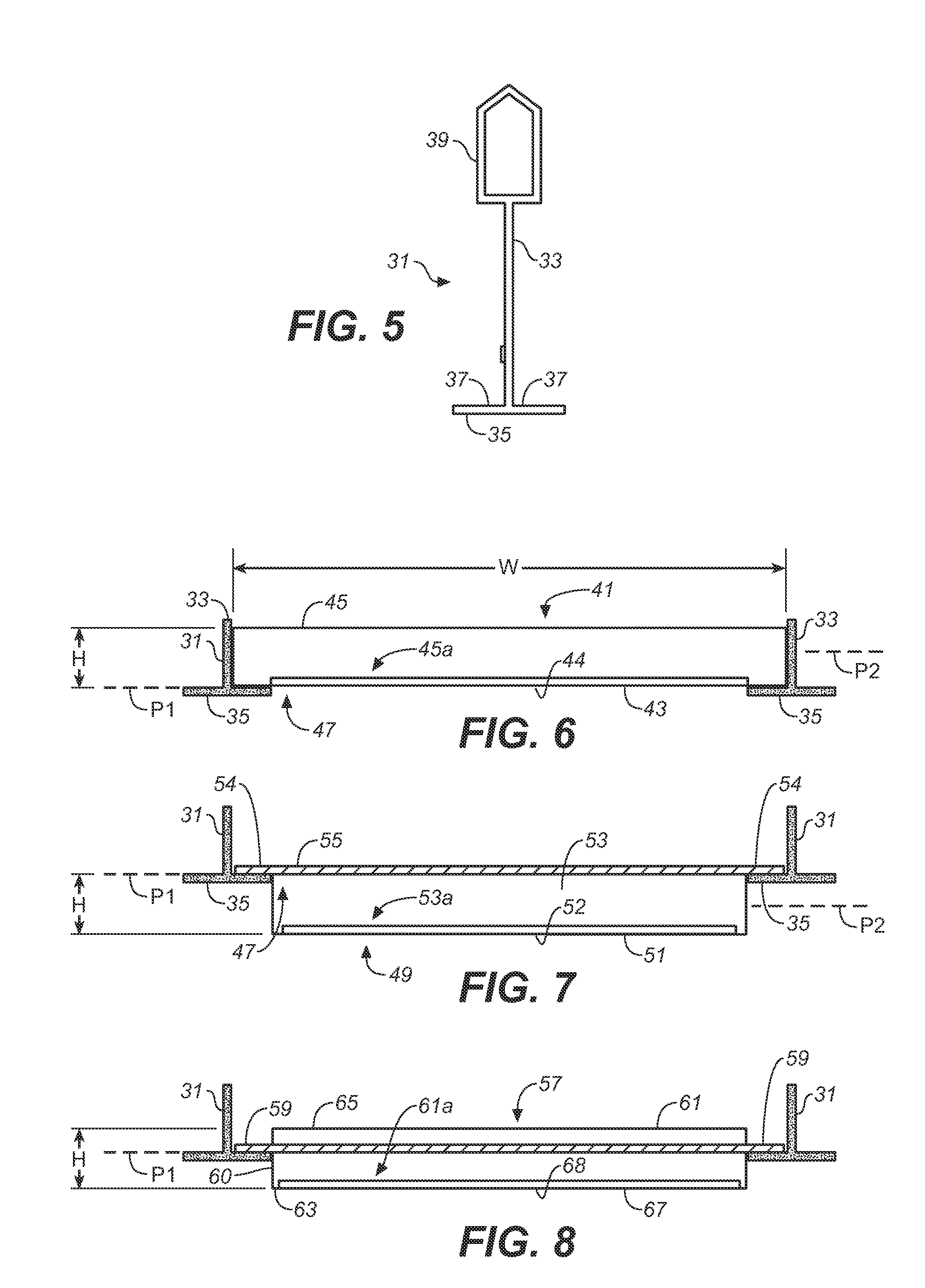

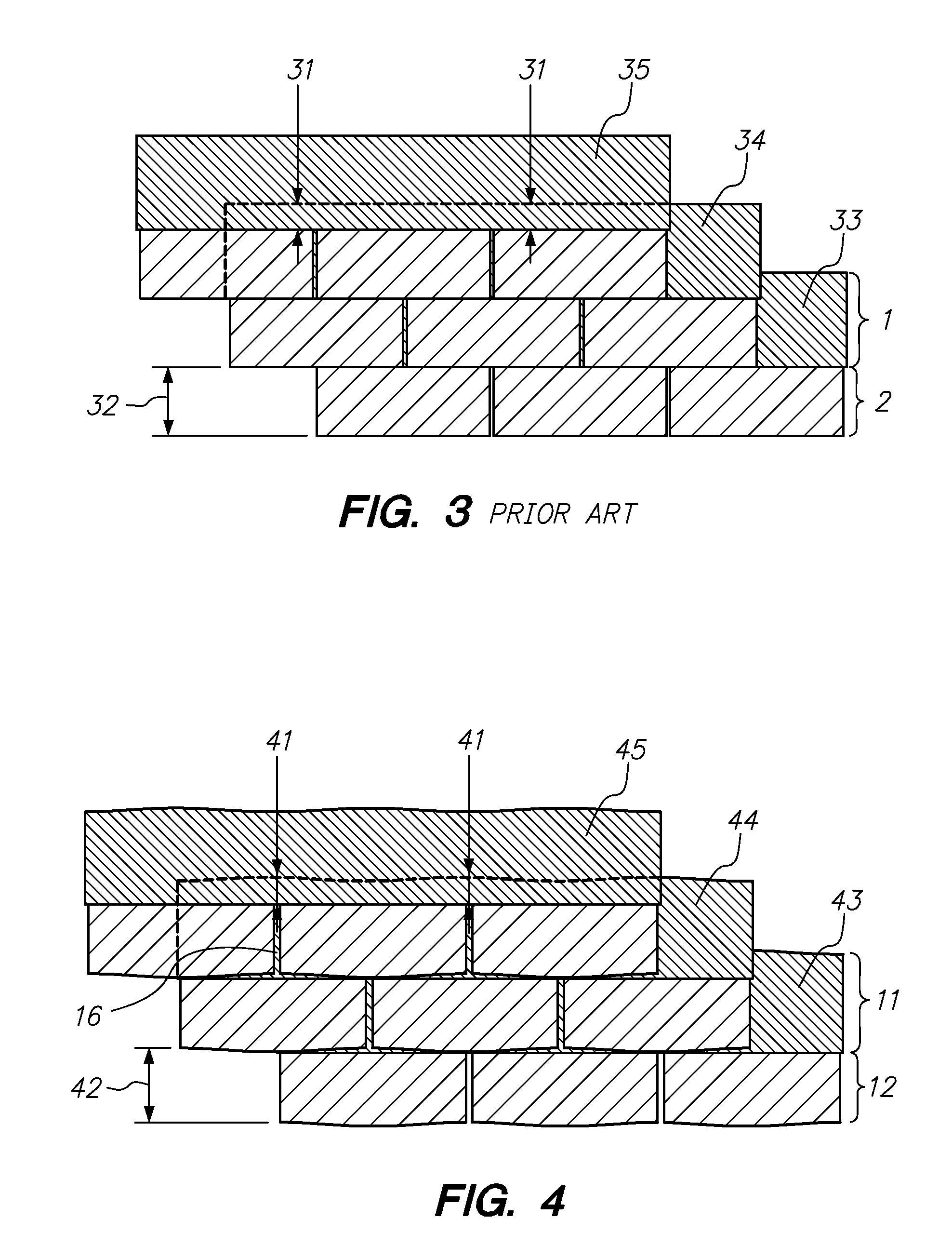

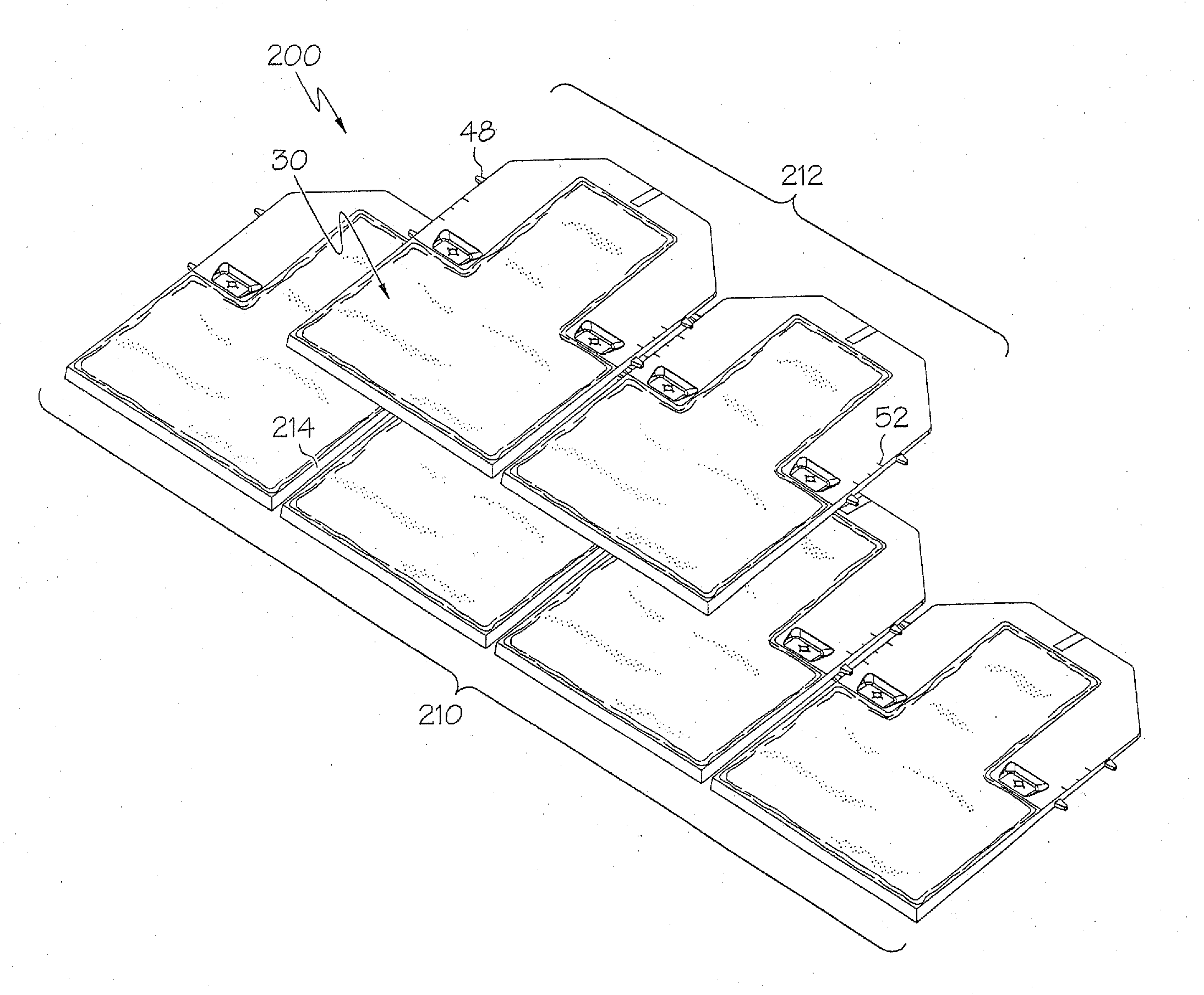

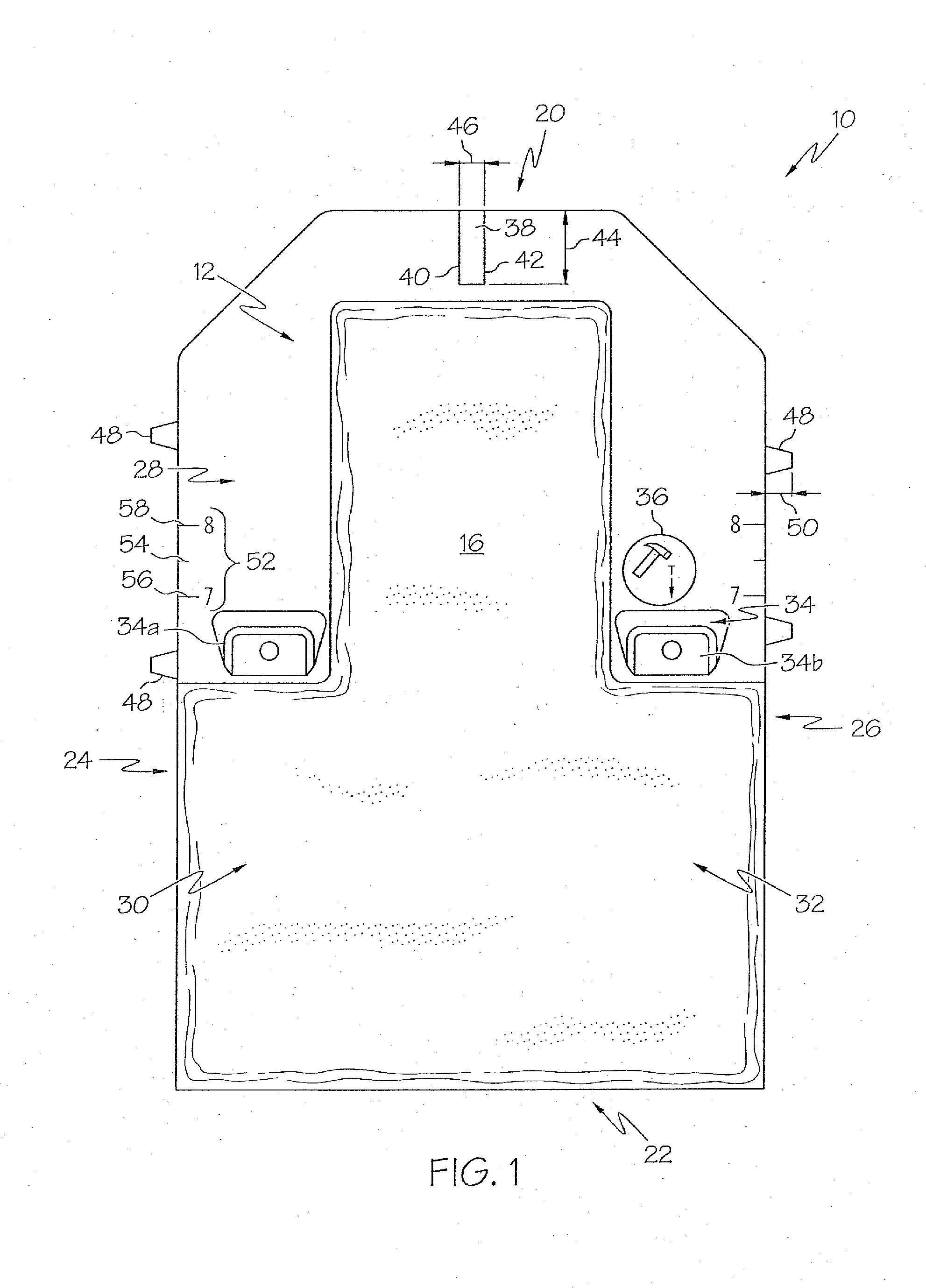

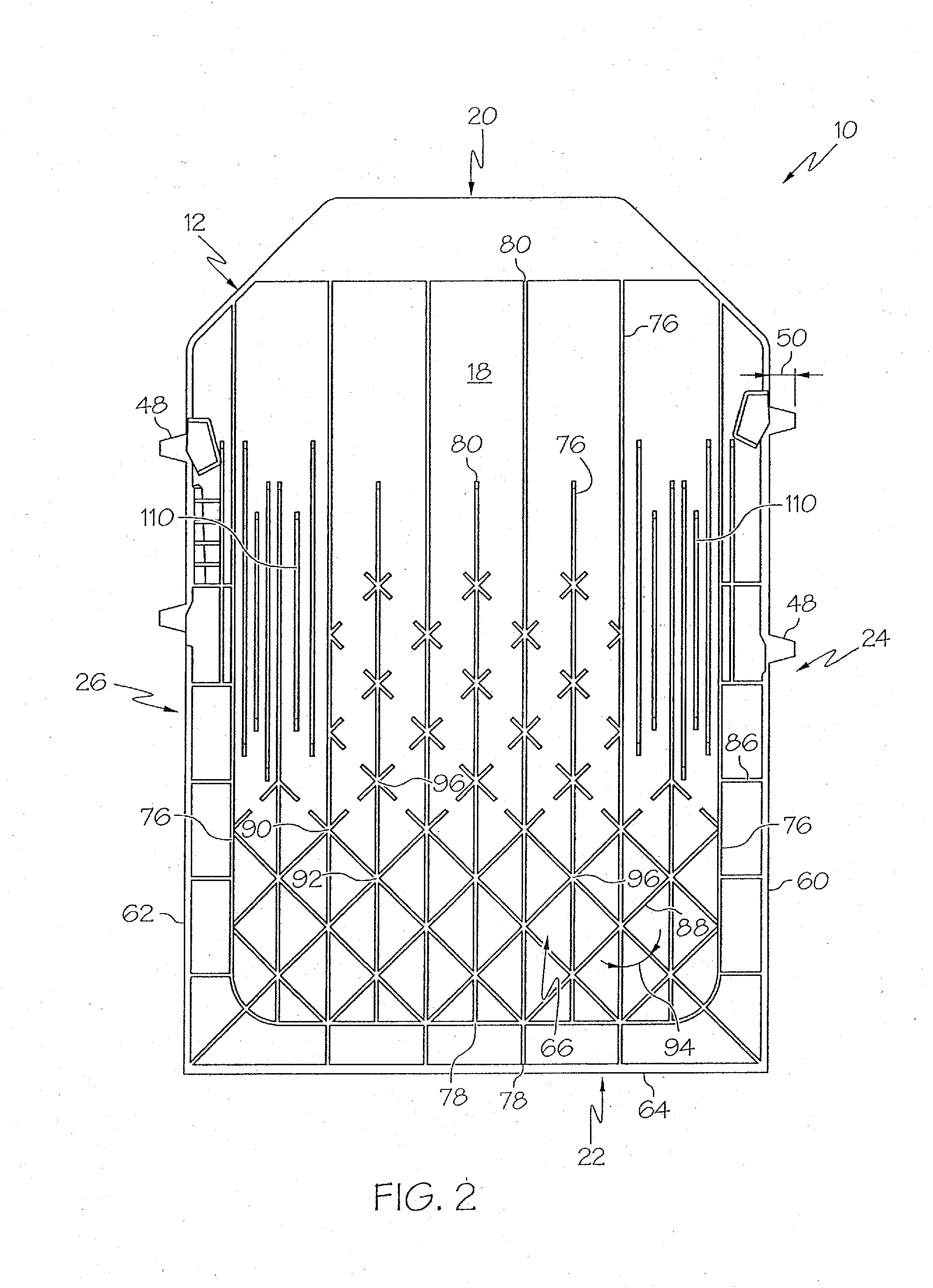

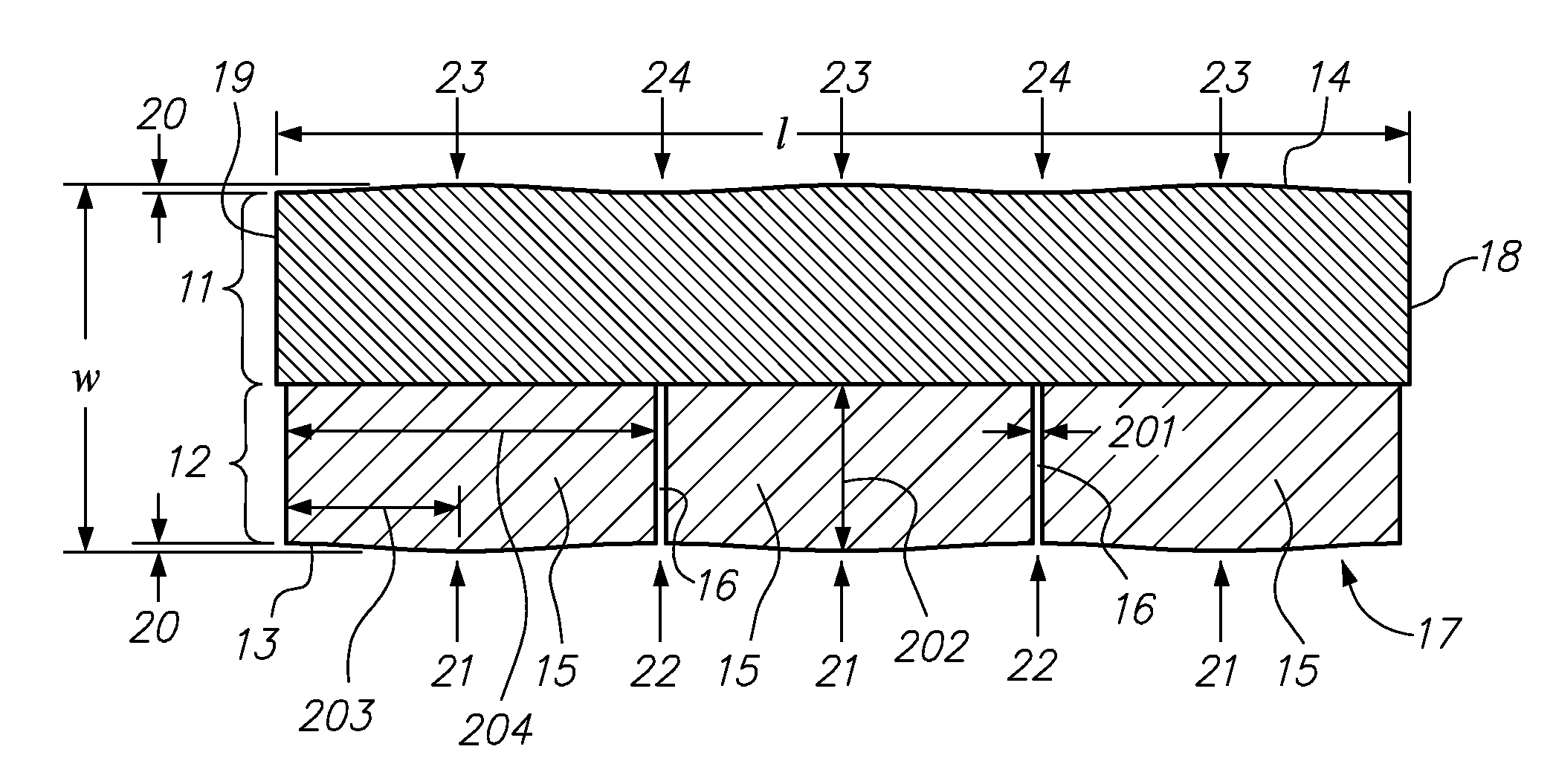

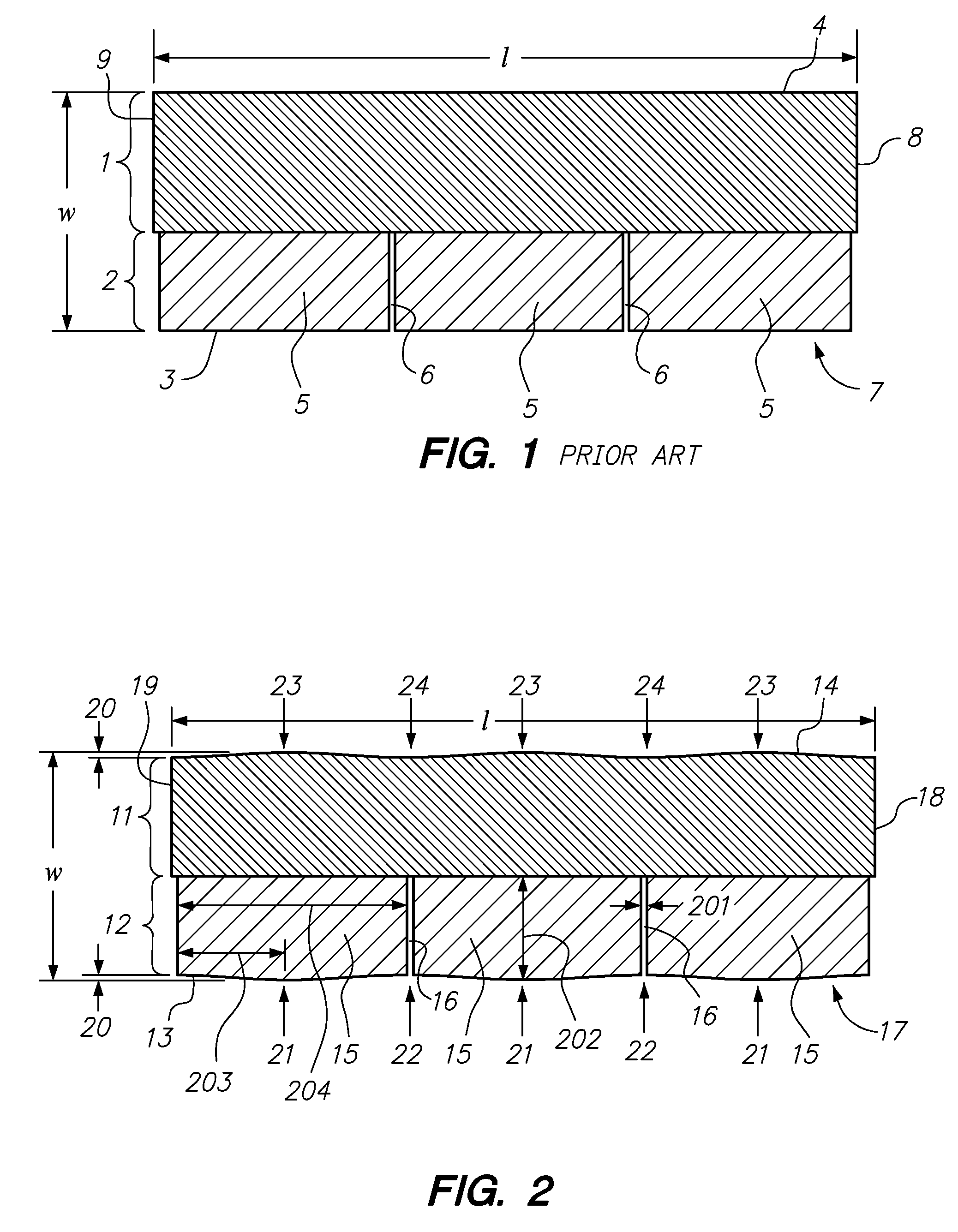

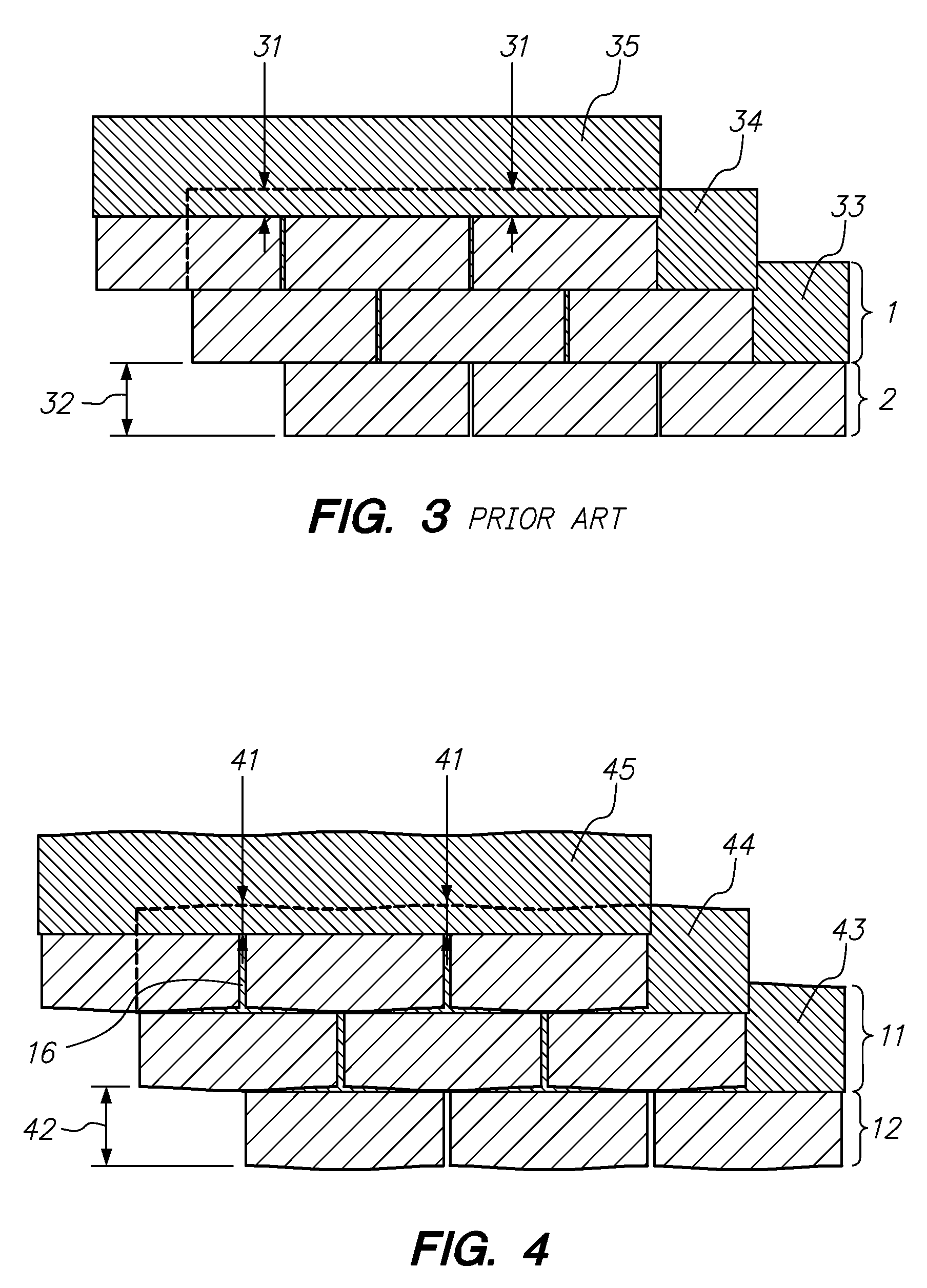

Low profile OLED luminaire for grid ceilings

ActiveUS20100284185A1Reduction in material requireReduce weightPlanar light sourcesNon-electric lightingMesh gridEngineering

A low-profile luminaire has a planar light source comprised of one or more planar organic light emitting diodes (OLEDs). The OLED light source is supported by a low-profile OLED support structure that lies in a plane. The support structure has a maximum height (H) of about two inches and preferably a height of about one inch or less. It also has perimeter dimensions that allow the luminaire to fit within and to be supported by the T-bar grid of a grid ceiling system. Electrical components for driving and controlling the OLED light source can be provided within the support structure or externally of this structure.

Owner:ABL IP HLDG

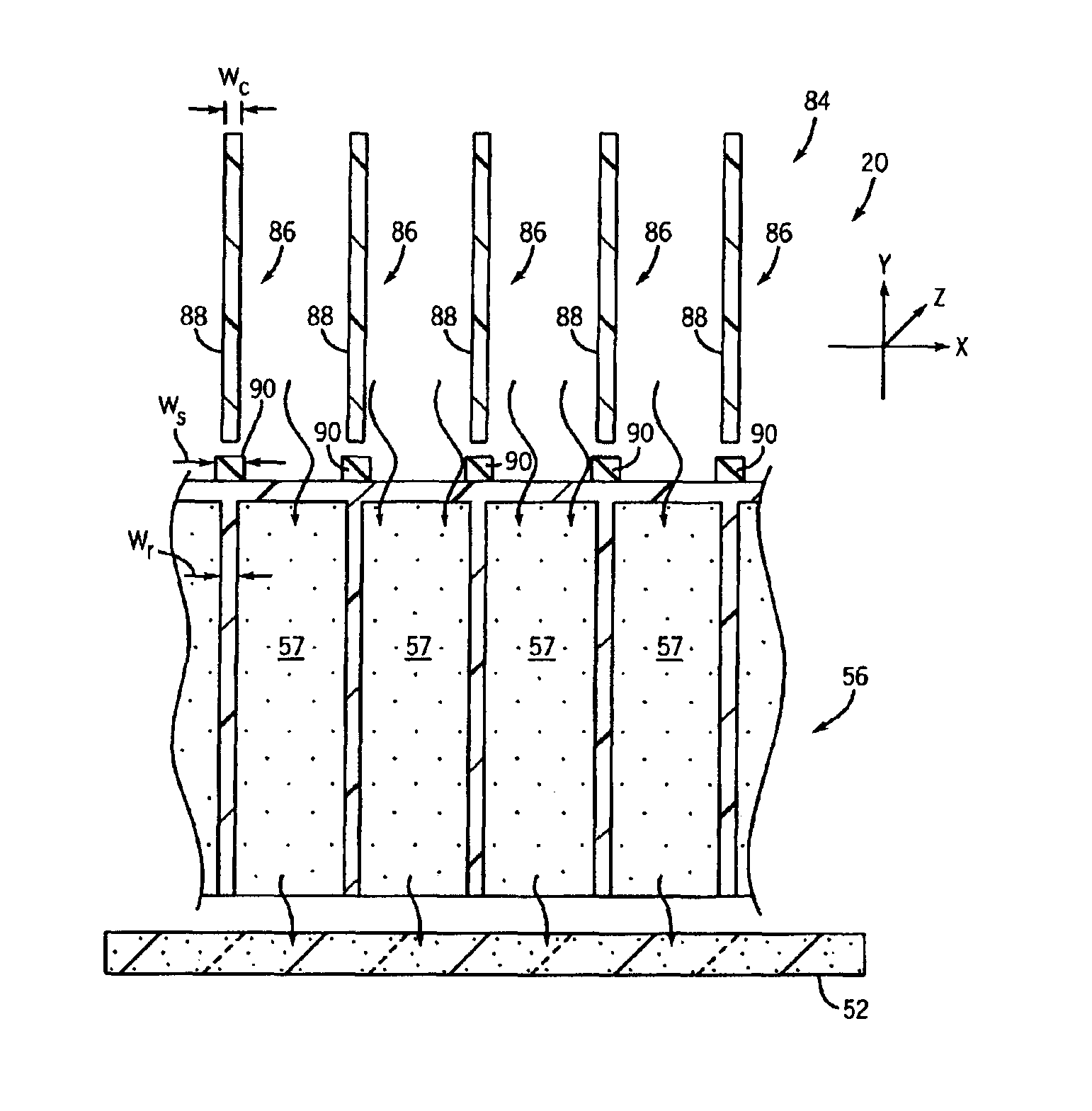

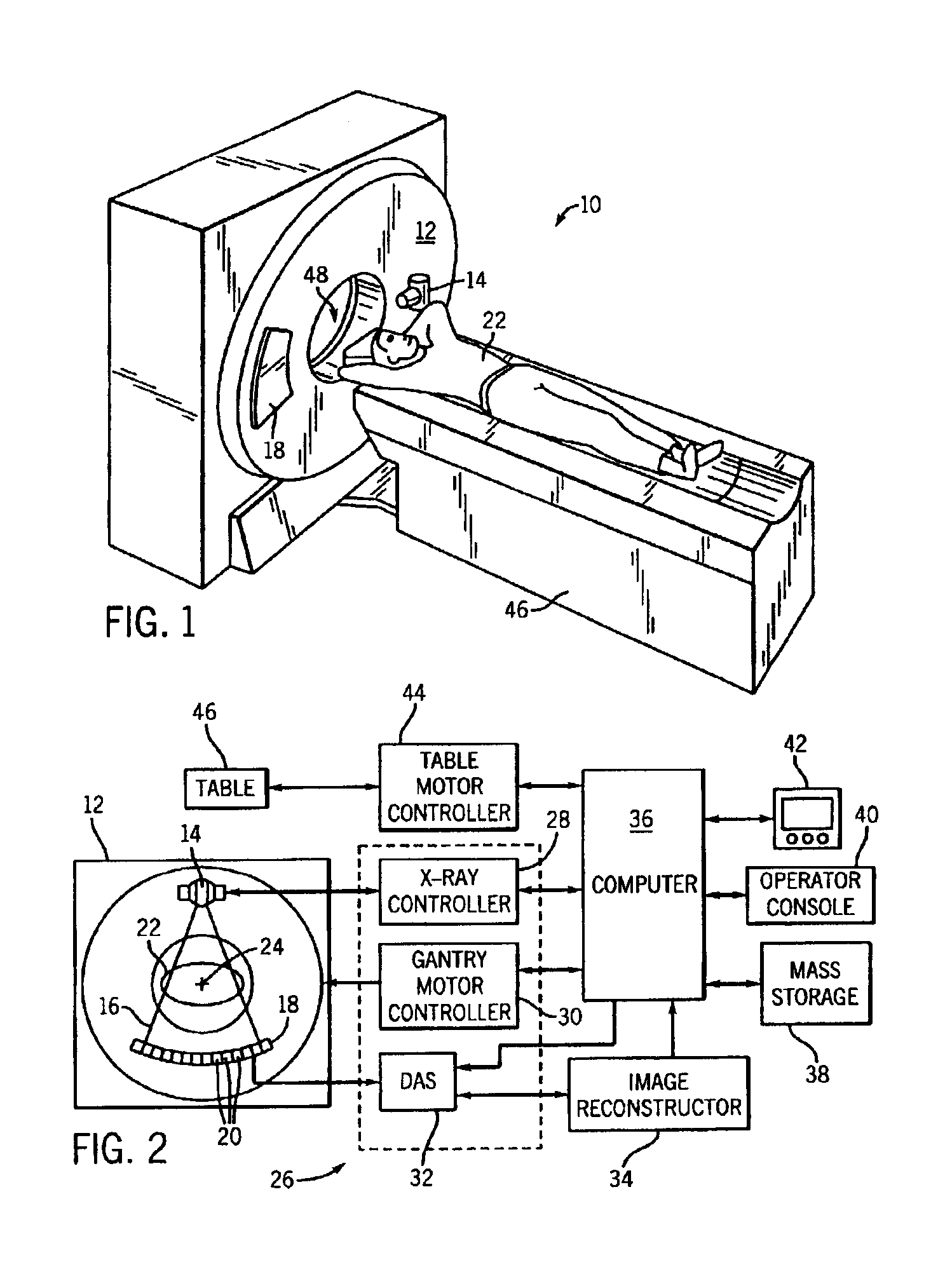

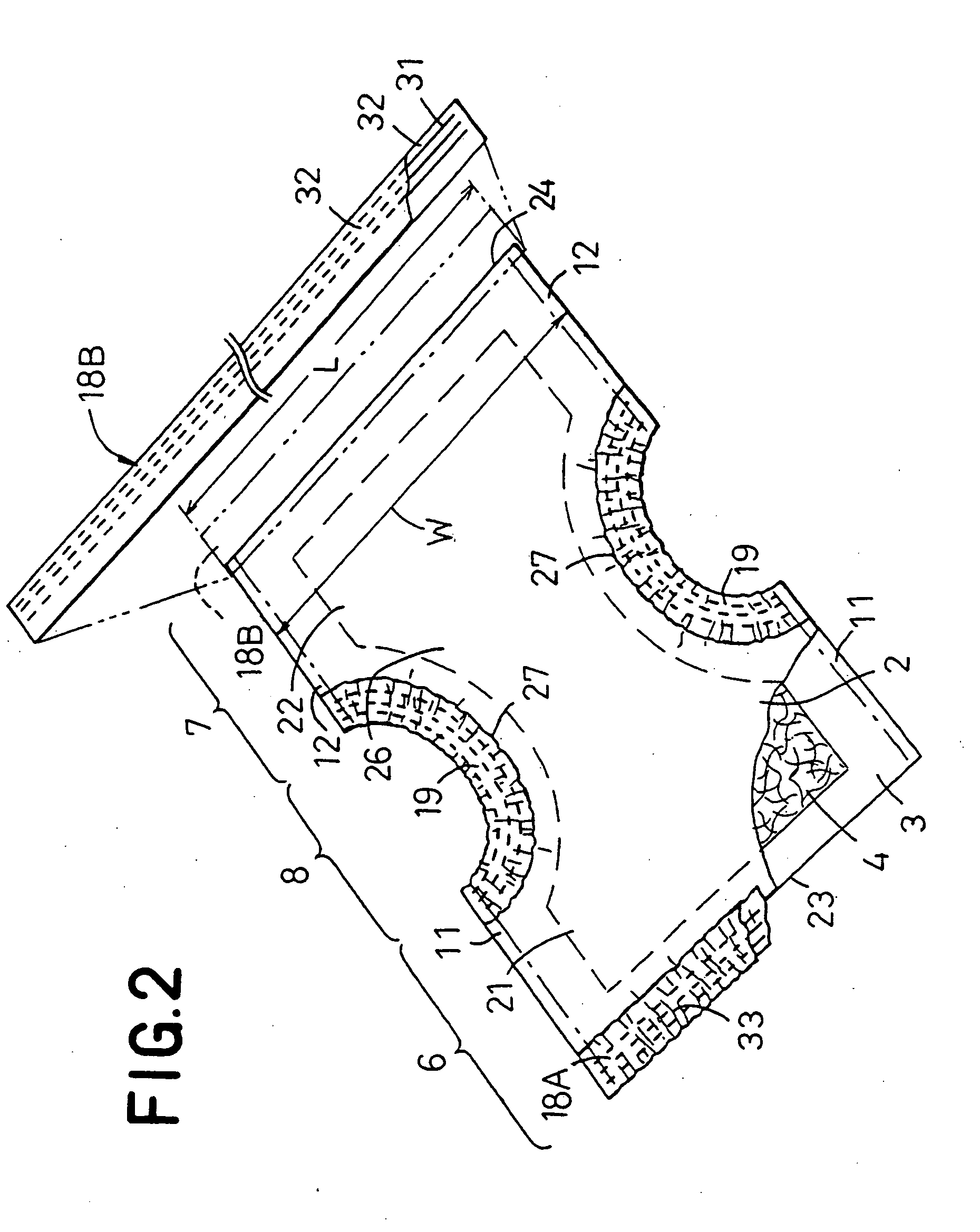

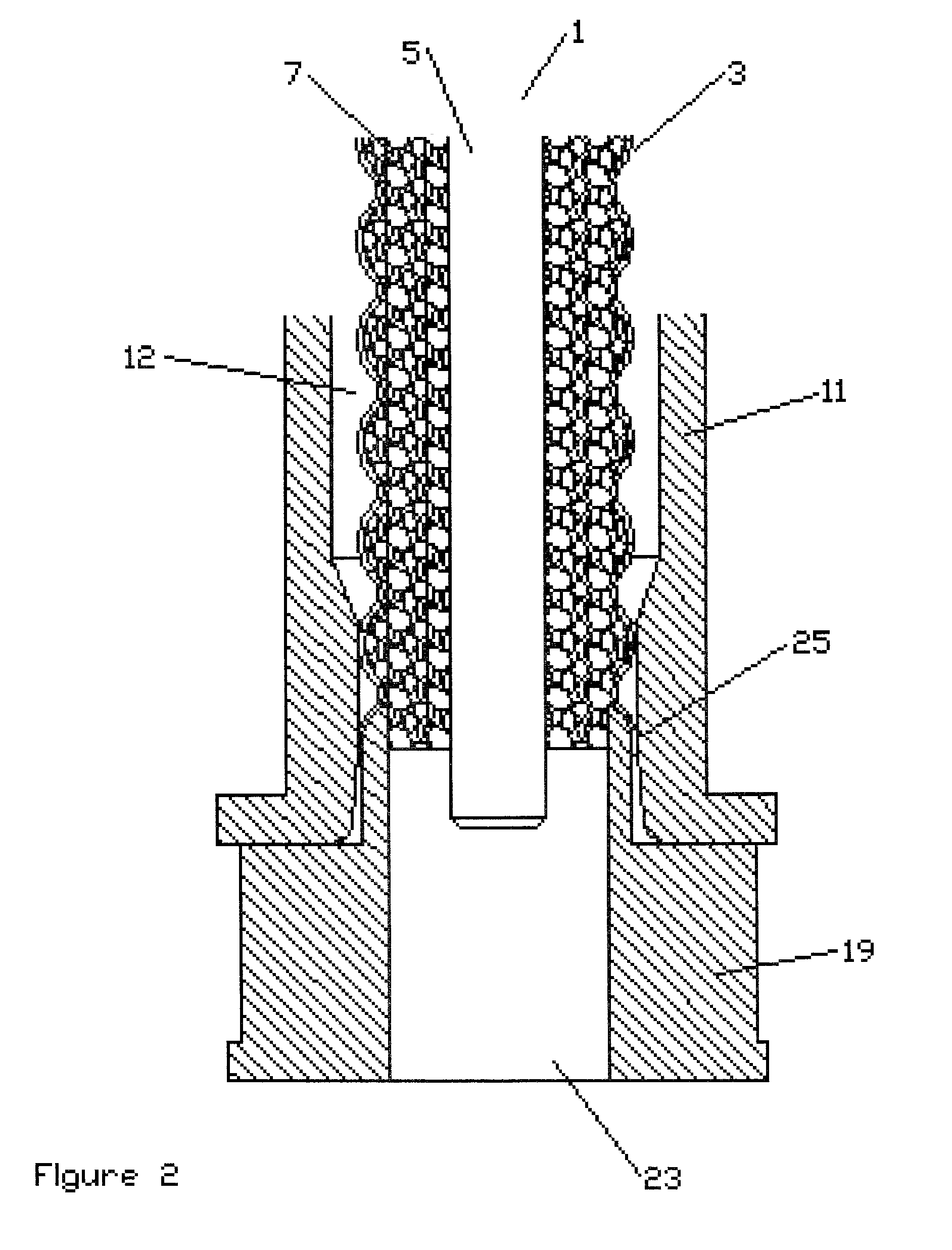

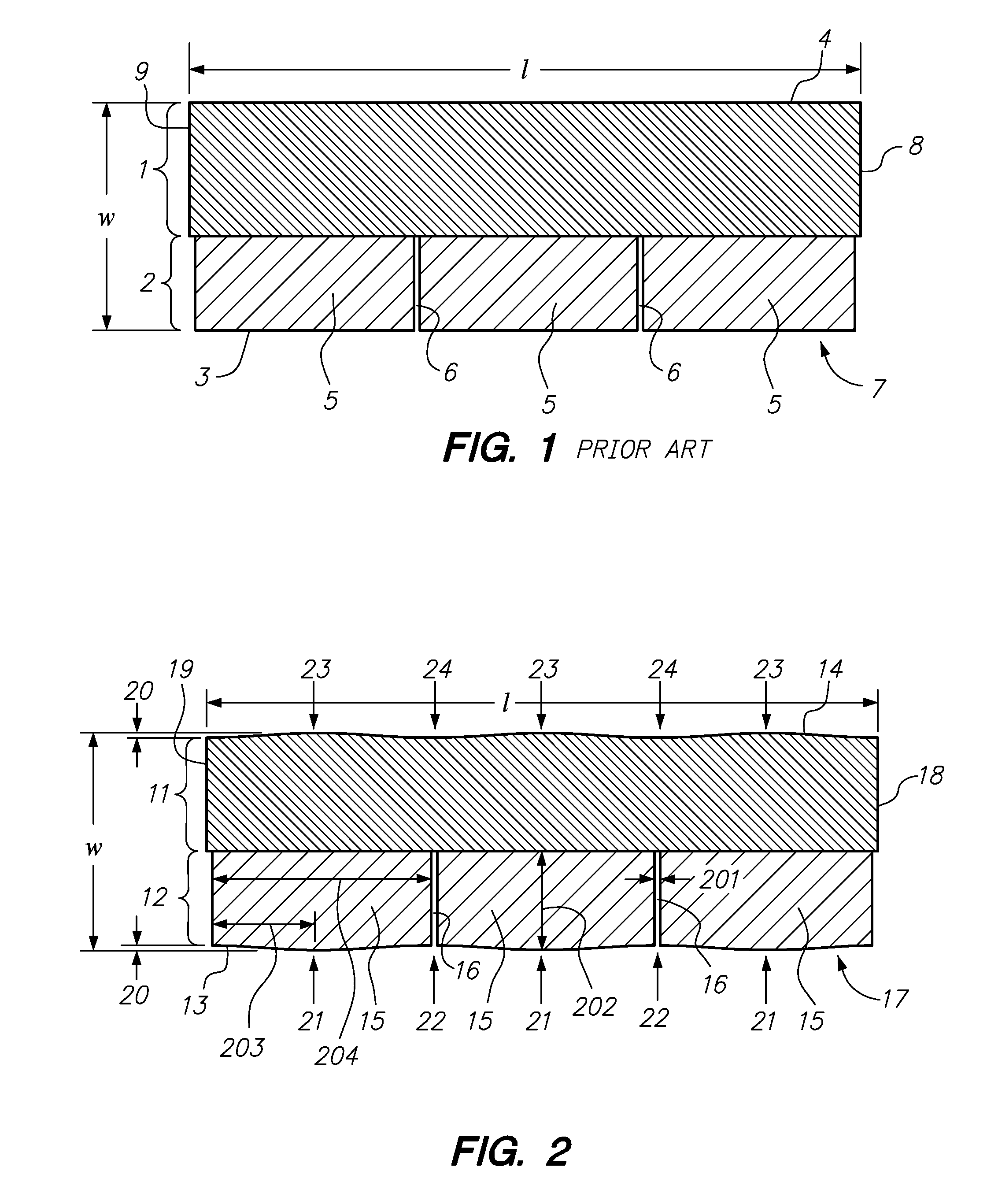

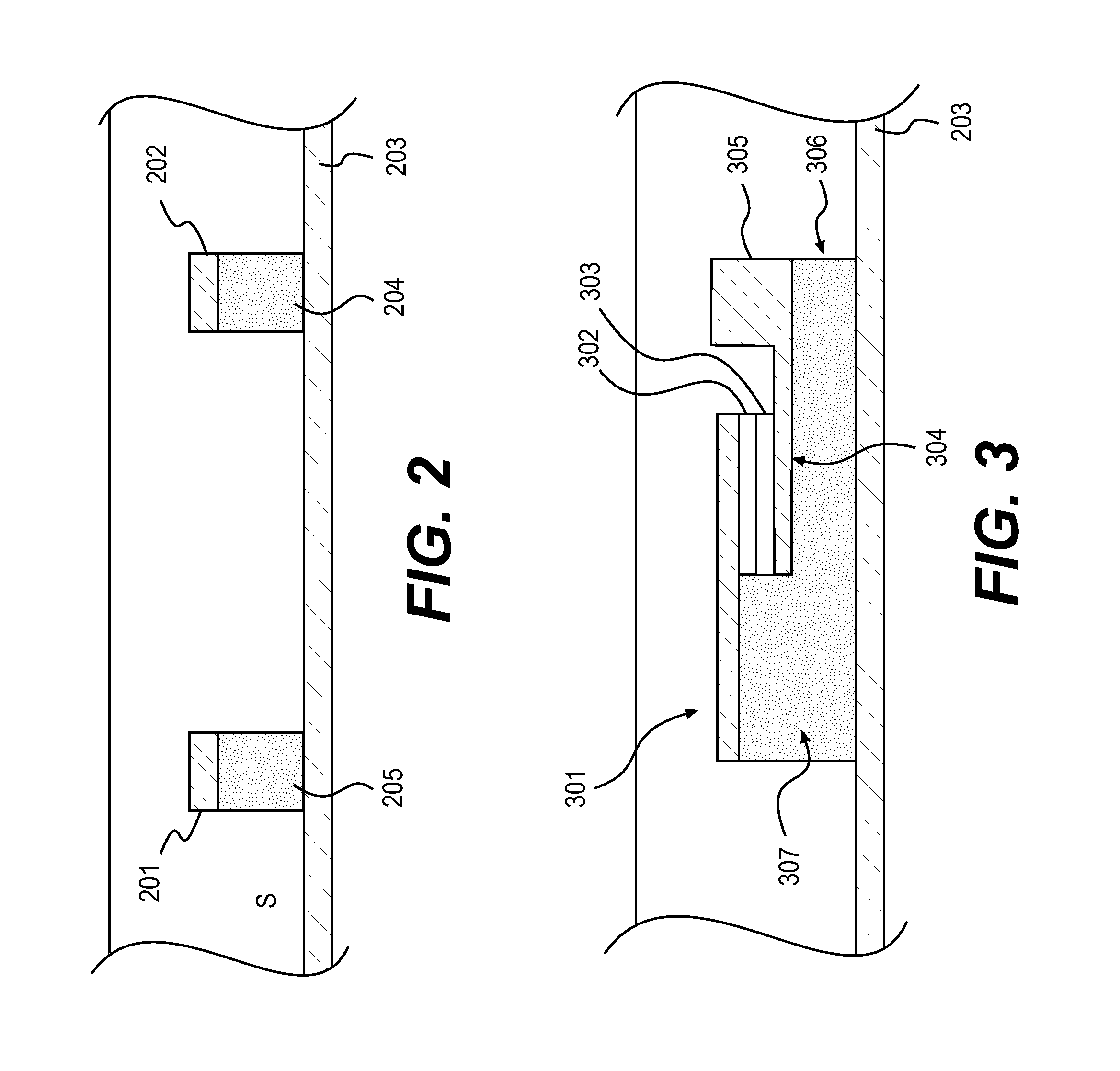

Collimator assembly having multi-piece components

InactiveUS6934354B2Convenient heightReduced material requirementsHandling using diaphragms/collimetersComputerised tomographsEngineeringMaterial requirements

The present invention is directed to a collimator assembly defined by a series of multi-piece collimator elements or plates that extend along at least one dimension of a scintillator pack. Each collimator element has a collimating component and a shielding component that are structurally independent from one another. The collimating components may be connected to the shielding components or separated by a small air gap. The shielding components are wider than the collimating components but the collimating components have a greater height. With this construction, the collimator assembly optimizes collimation and shielding with lower material requirements and reduced overall size.

Owner:GENERAL ELECTRIC CO

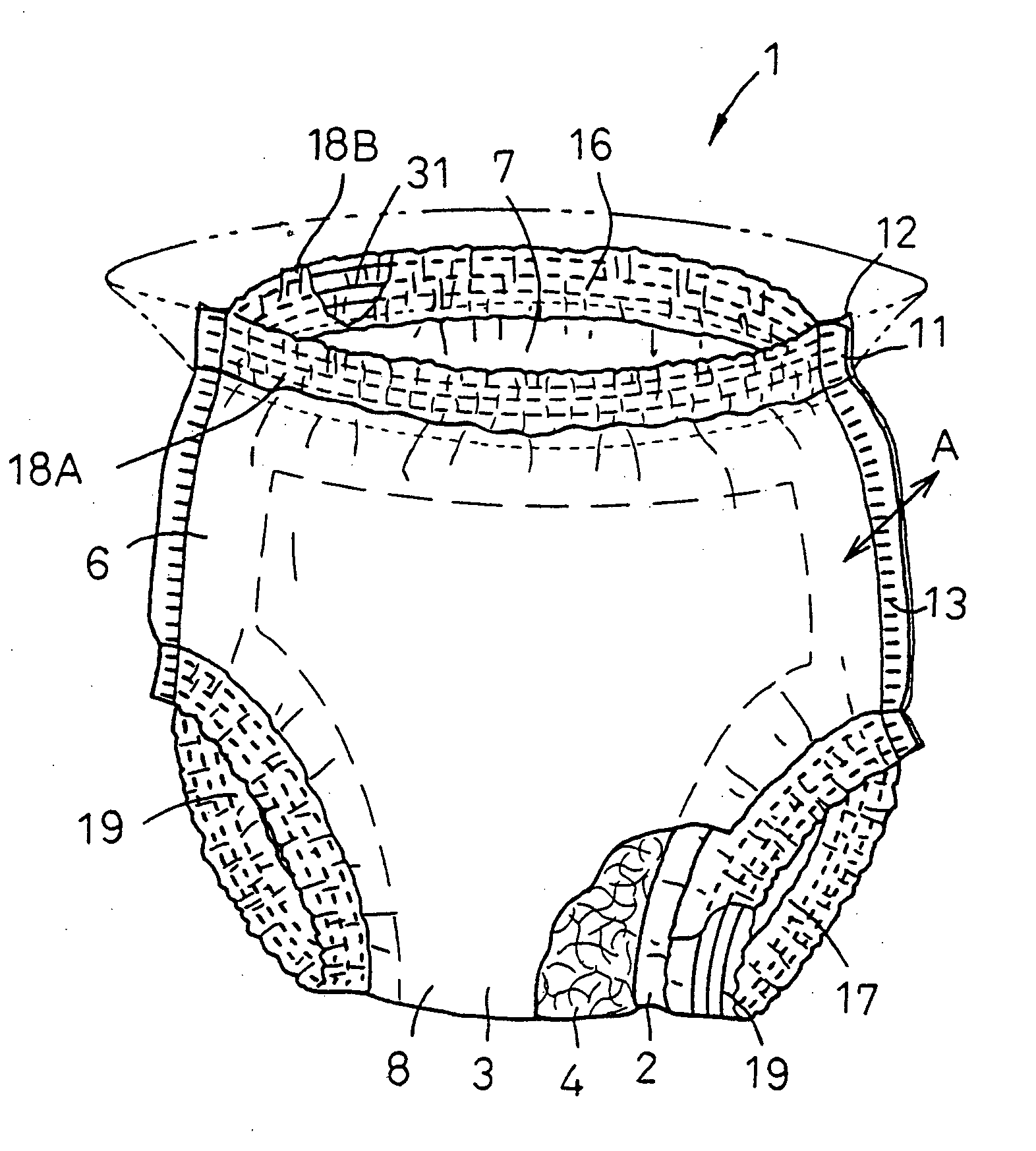

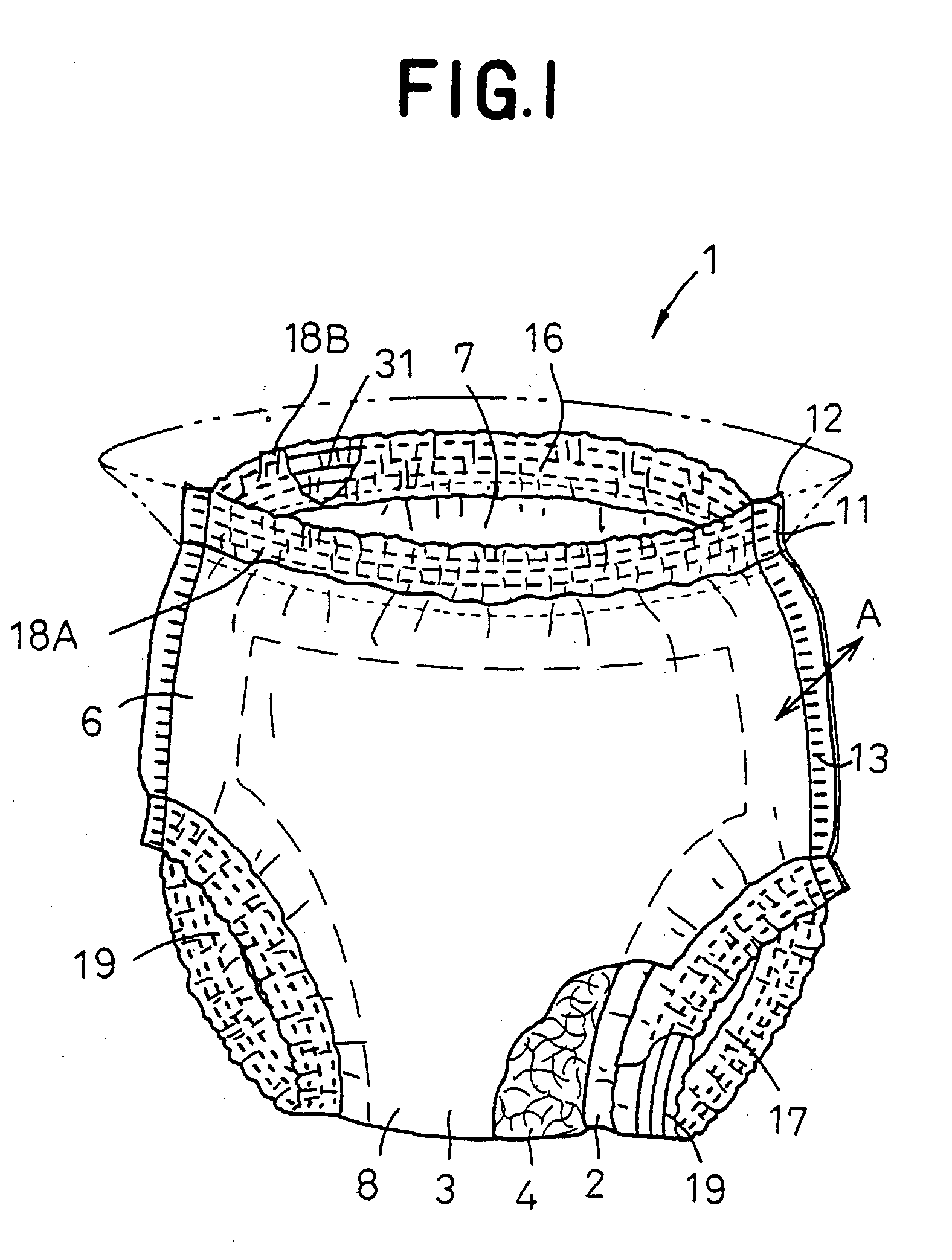

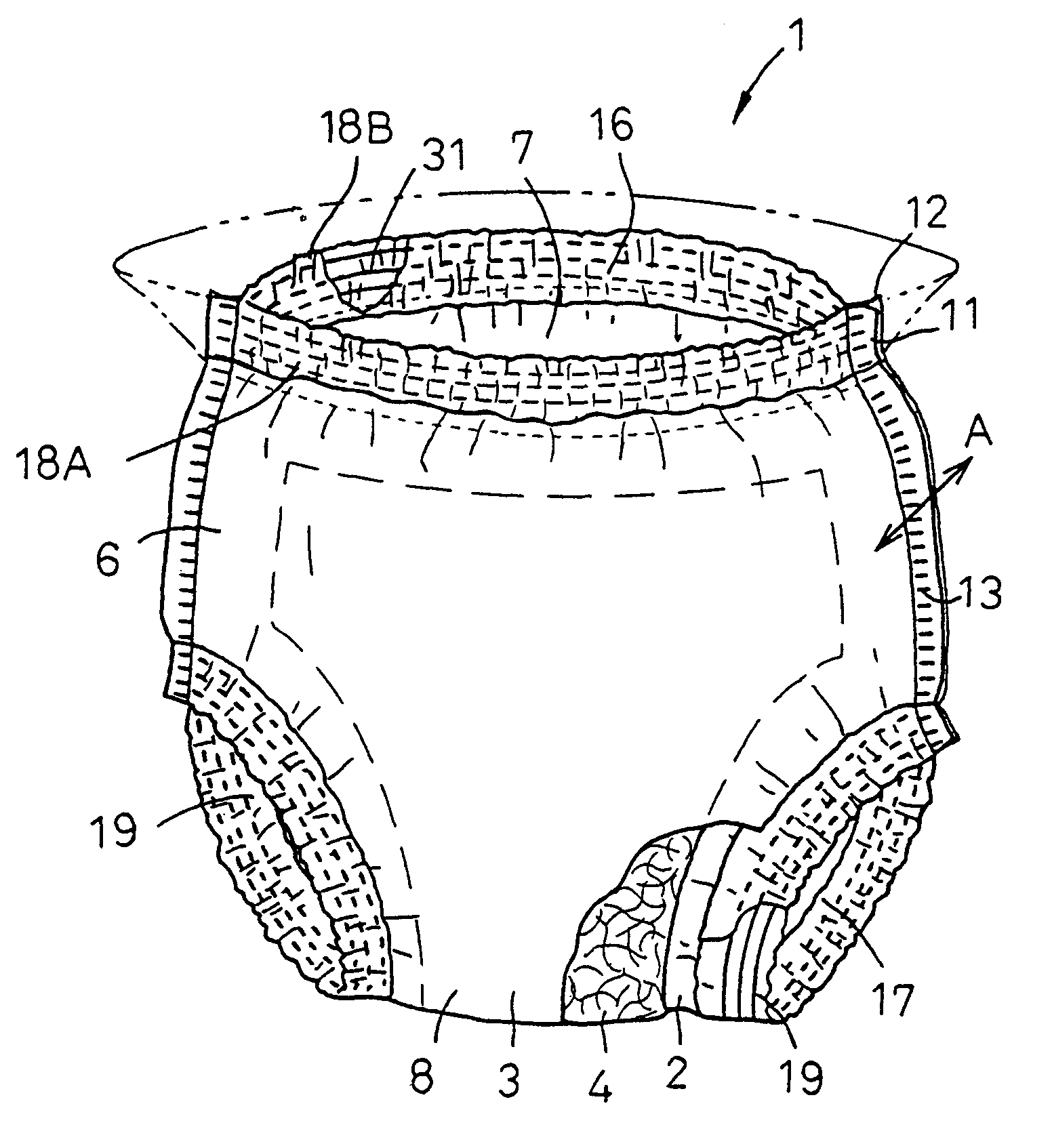

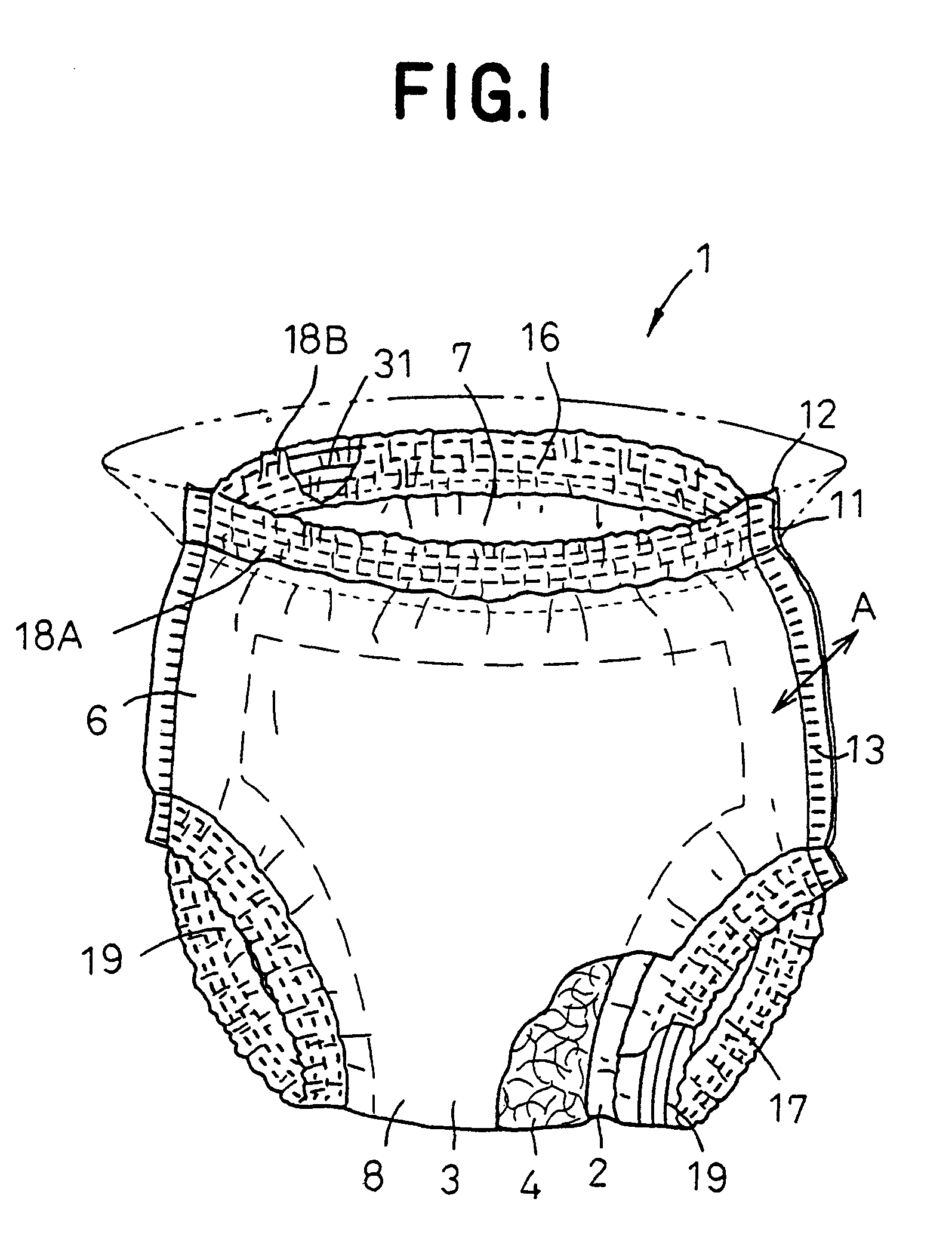

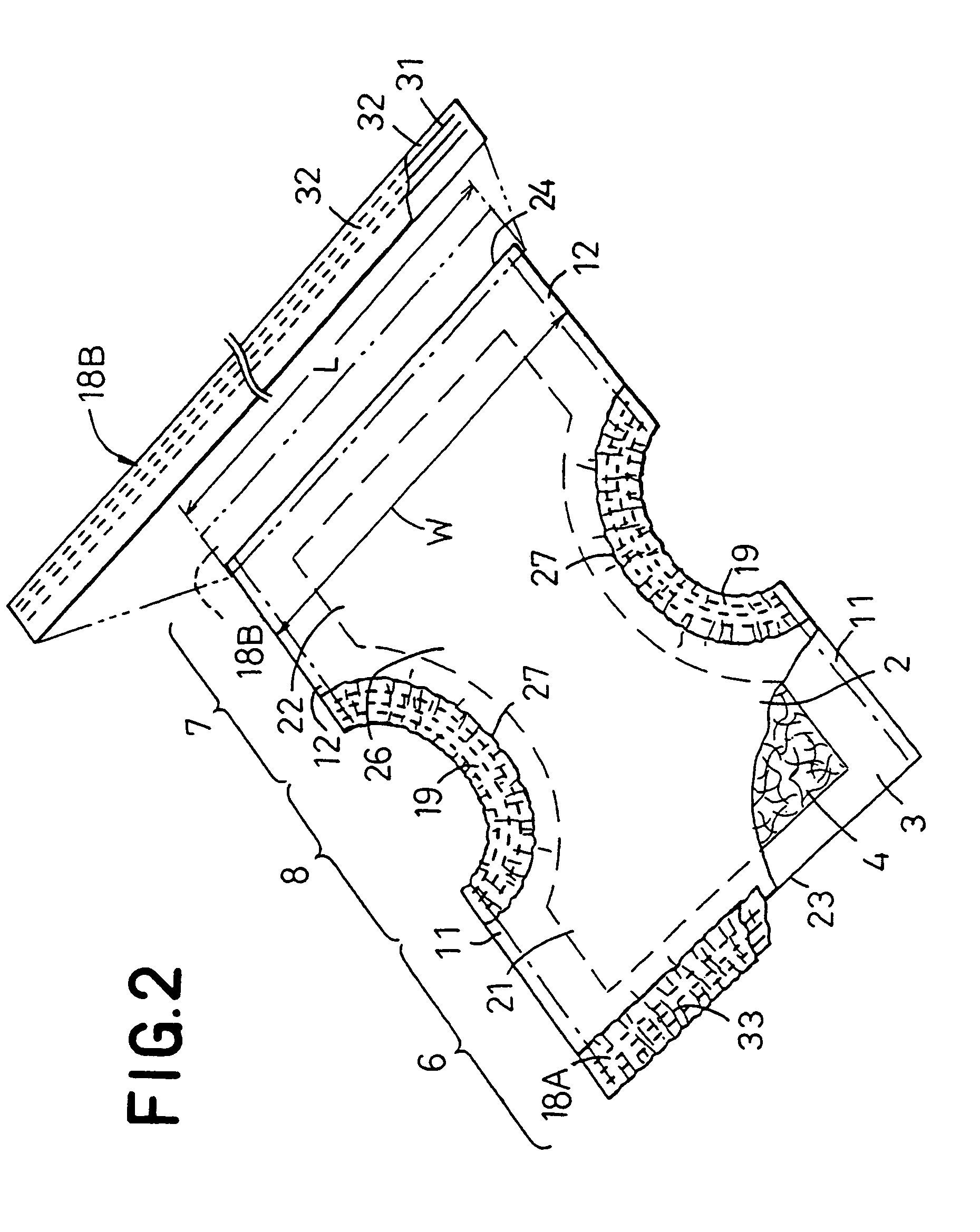

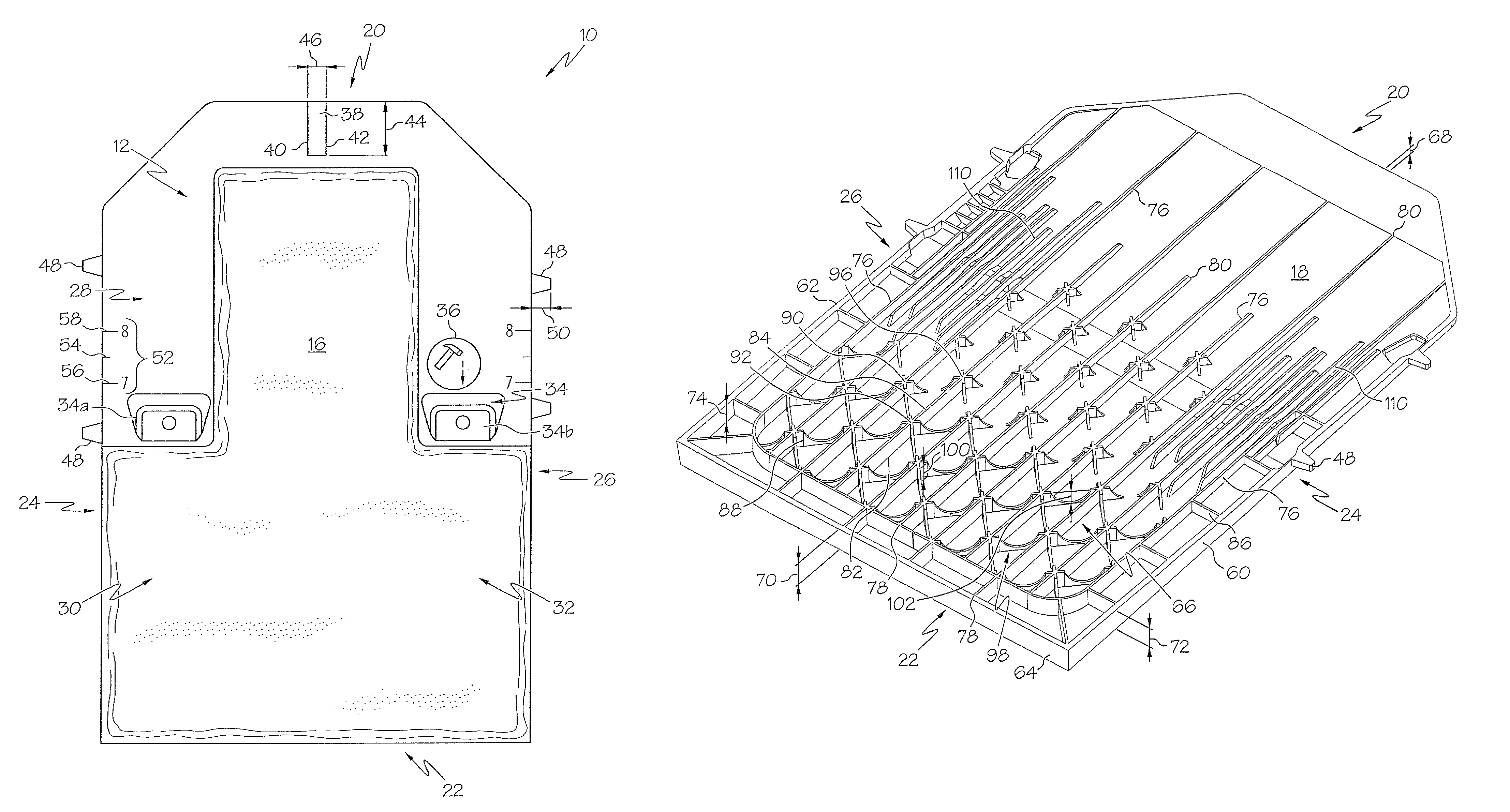

Disposable diaper

InactiveUS20090182298A1Reduced material requirementsUnnecessary coverageSkirtsGirdlesEngineeringMechanical engineering

Front and rear waist regions of a diaper having a waist-hole of which a peripheral edge is elastically stretchable in a circumferential direction respectively include covering zones and elastic zones adapted to be stretchable beyond lengths of the covering zones in the circumferential direction.

Owner:UNI CHARM CORP

Method for preparation of anion exchange resins

InactiveUS6756462B2Reduce environmental impactReduced material requirementsCation exchanger materialsIon-exchanger regenerationPhysical chemistryIon-exchange resin

An improved process for preparing anion exchange resins based on the use of a non-agitated plug-flow quench procedure followed by recycle of a portion of the recovered chloromethylation reaction fluids into subsequent chloromethylation reactions is disclosed. The combination of plug-flow hydration, providing highly concentrated recovered sulfuric acid, together with the recycle or reuse of the recovered concentrated sulfuric acid, allows for reduced raw material requirements during anion exchange resin manufacture and reduces the environmental impact of waste sulfuric acid processing.

Owner:ROHM & HAAS CO

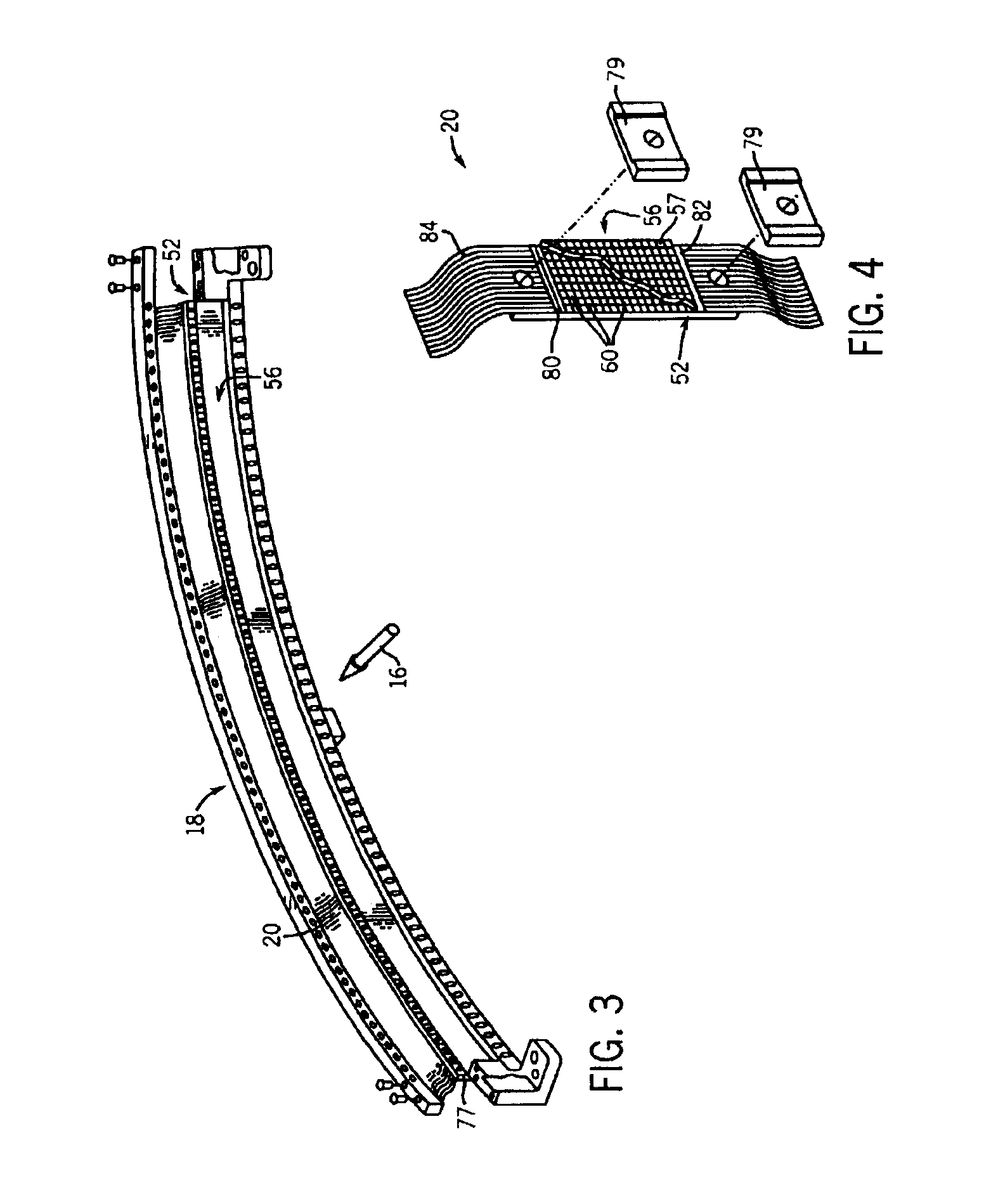

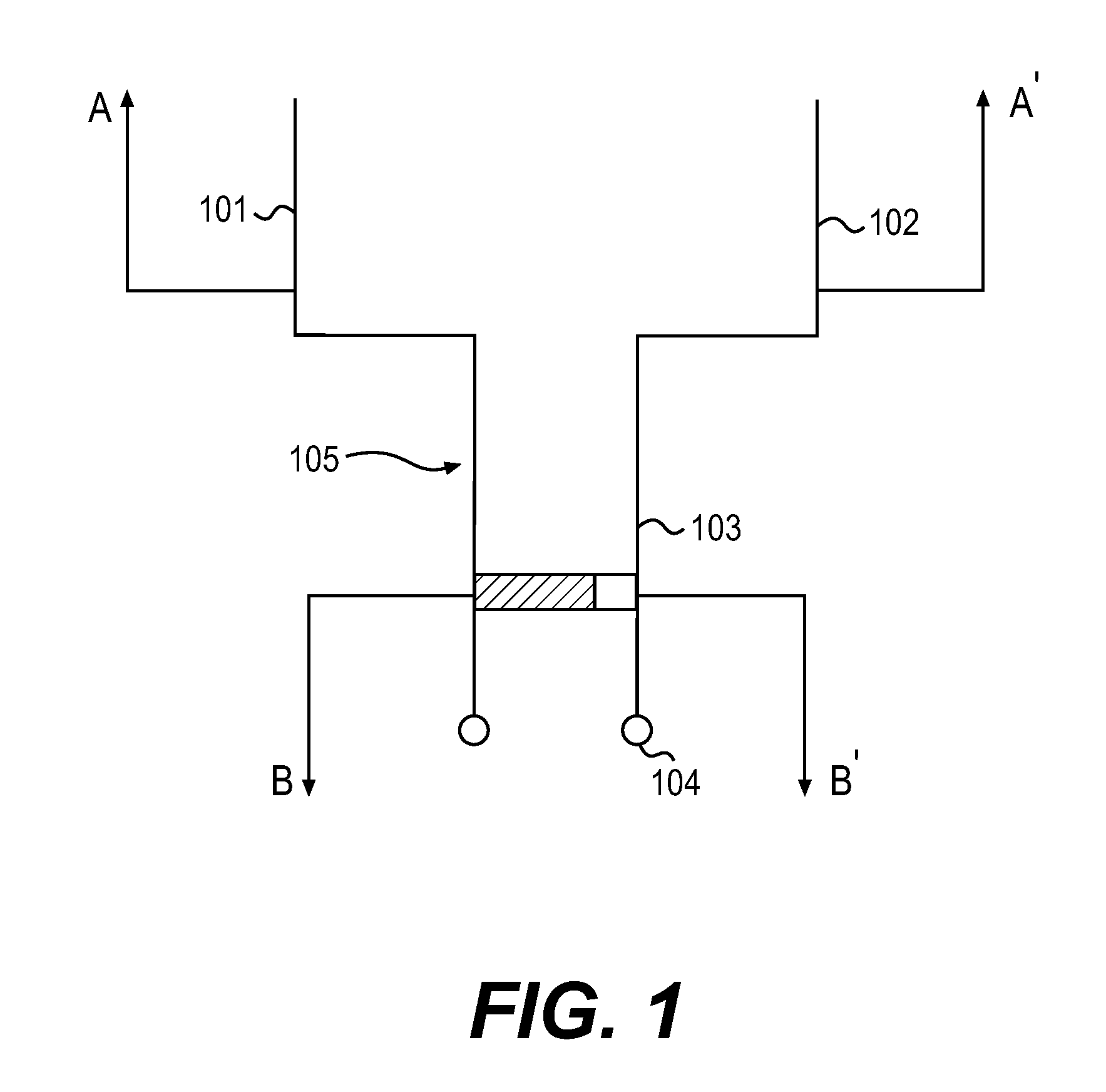

Panel antenna with variable phase shifter

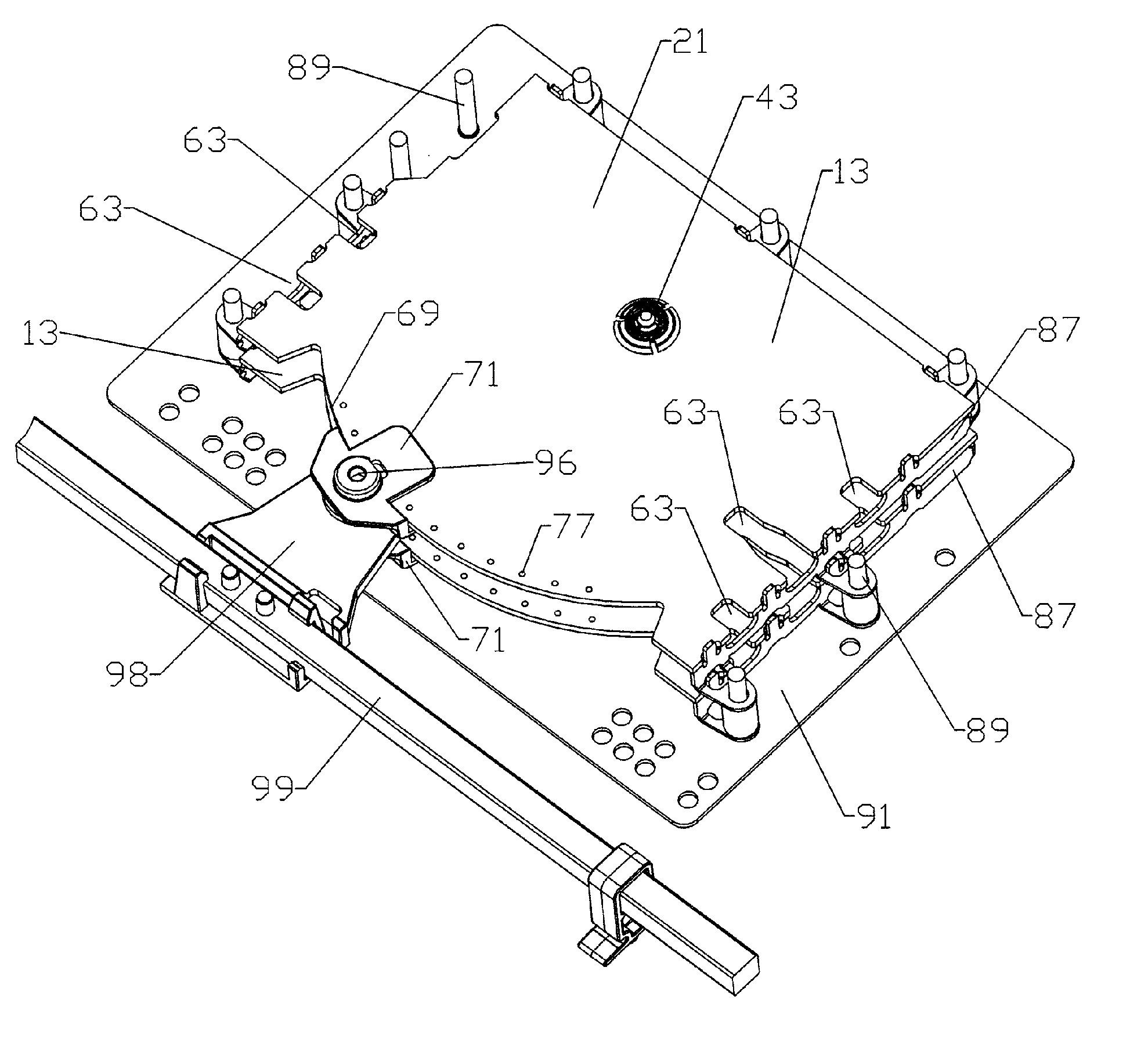

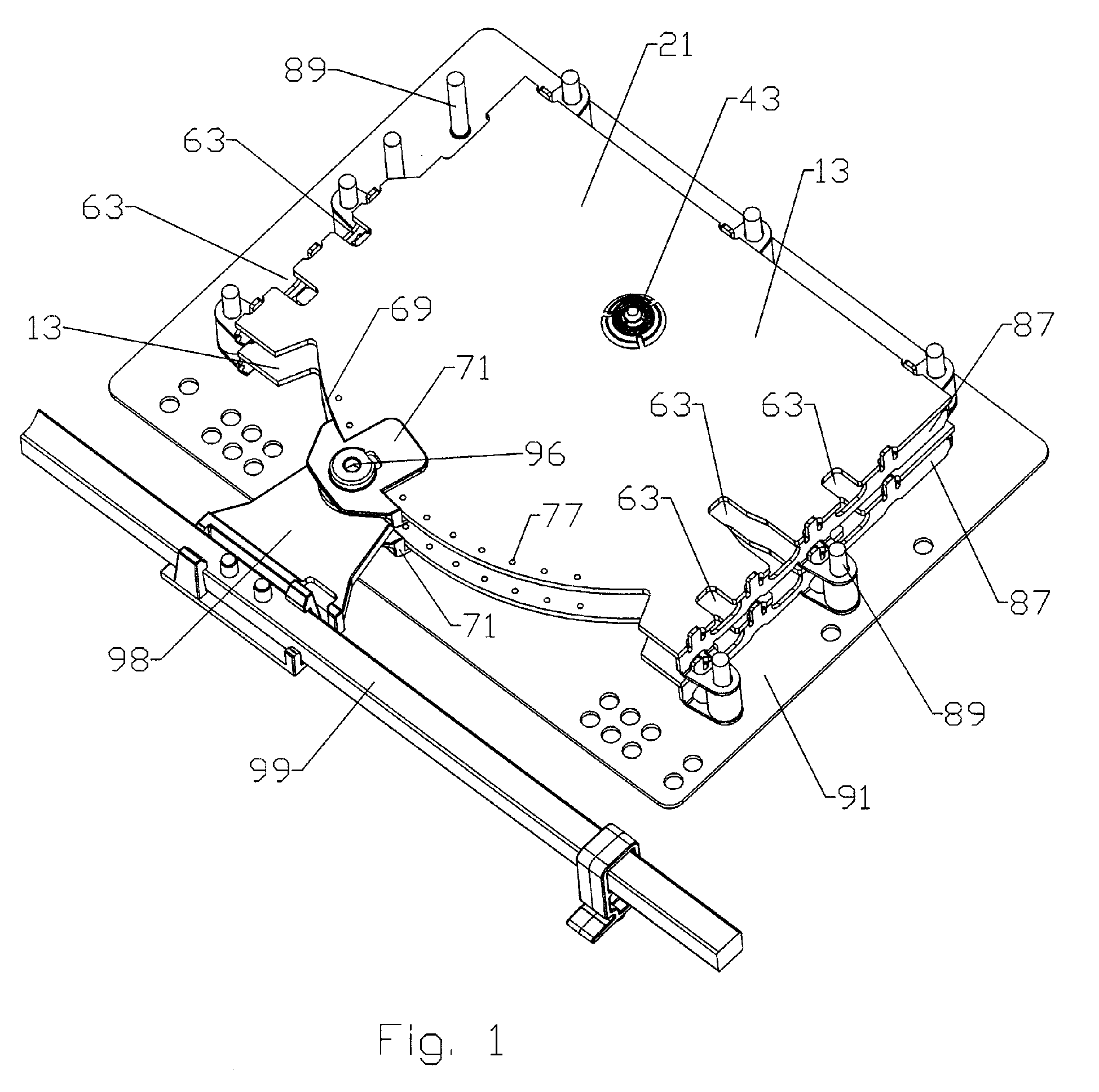

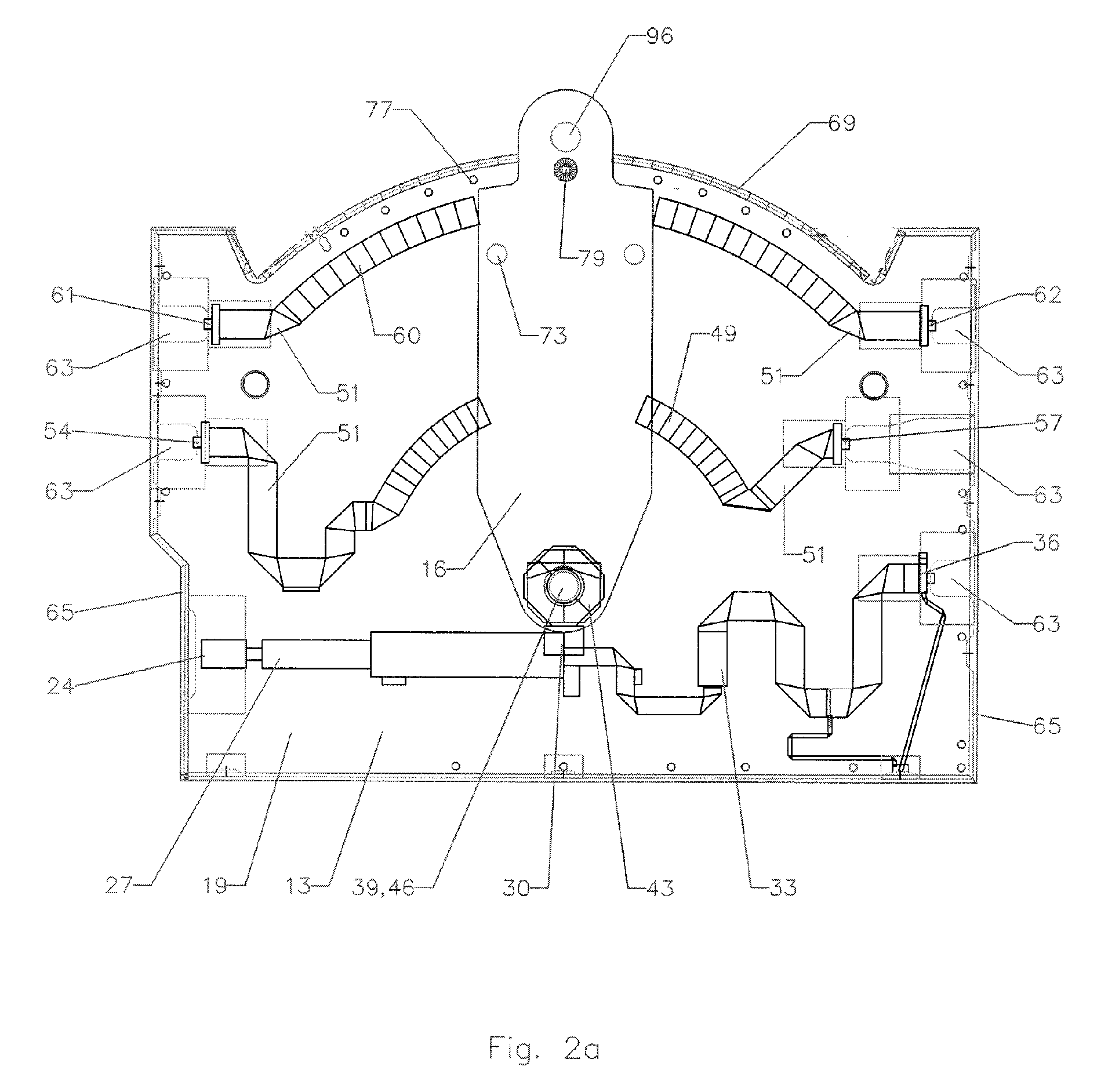

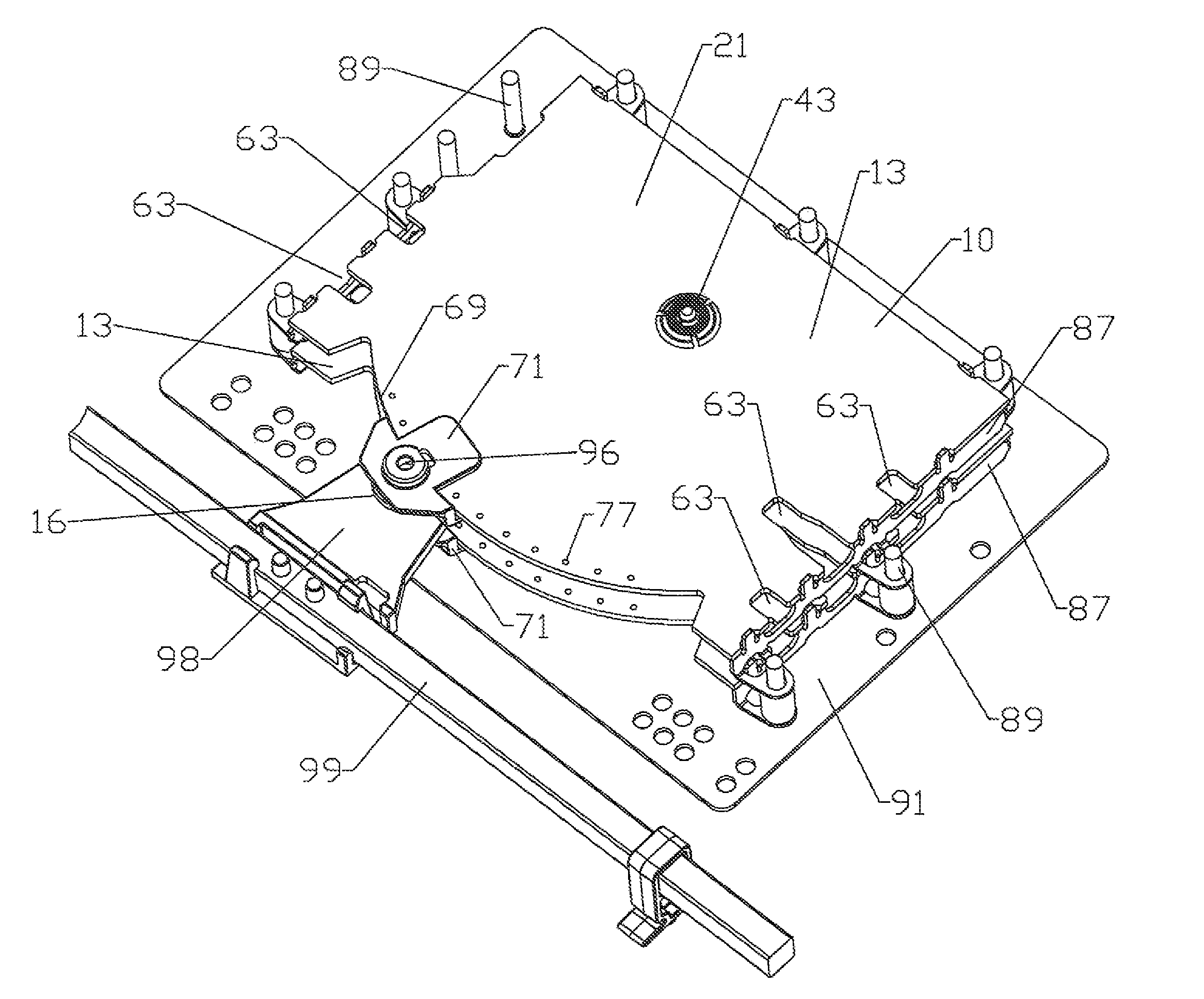

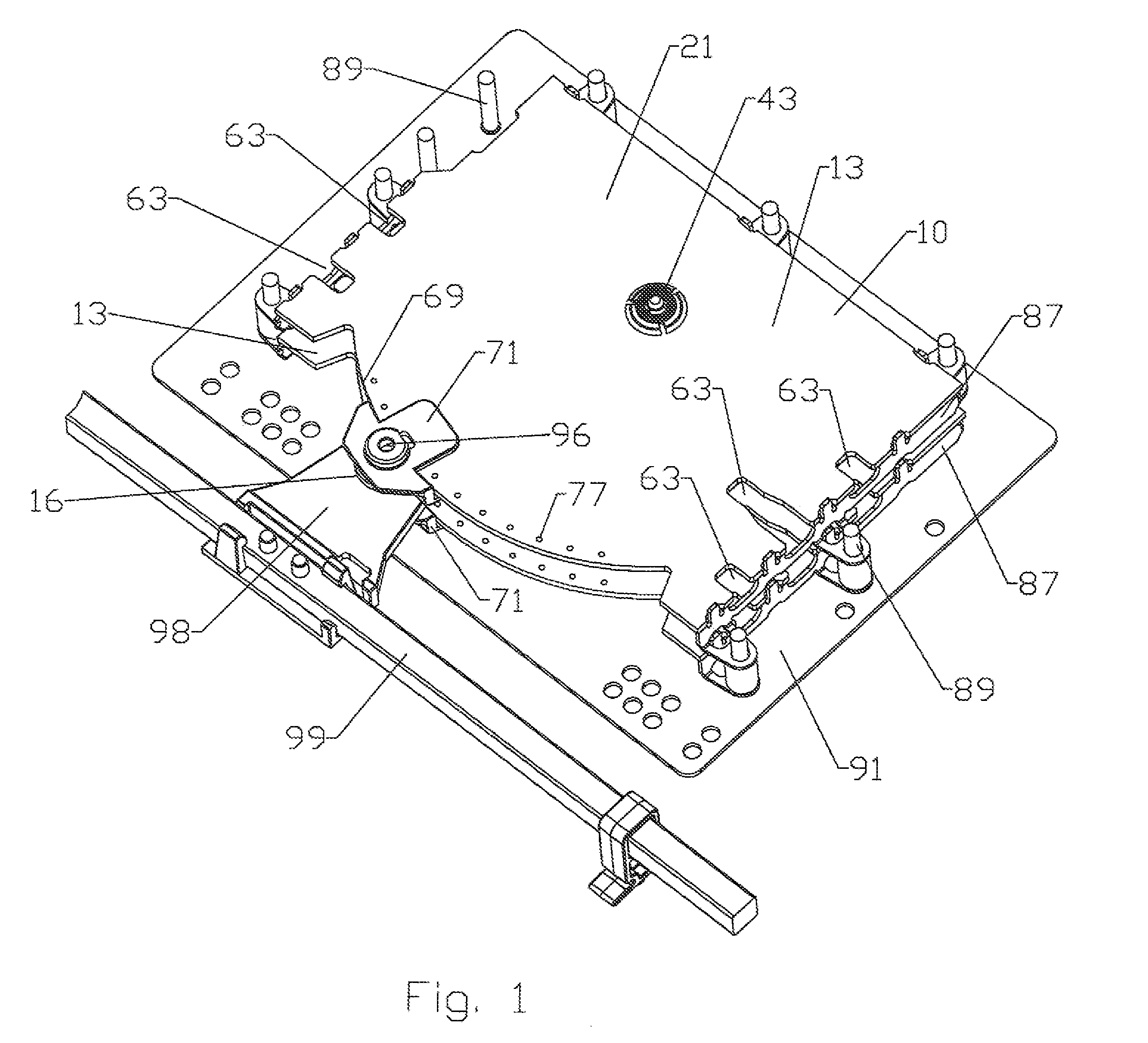

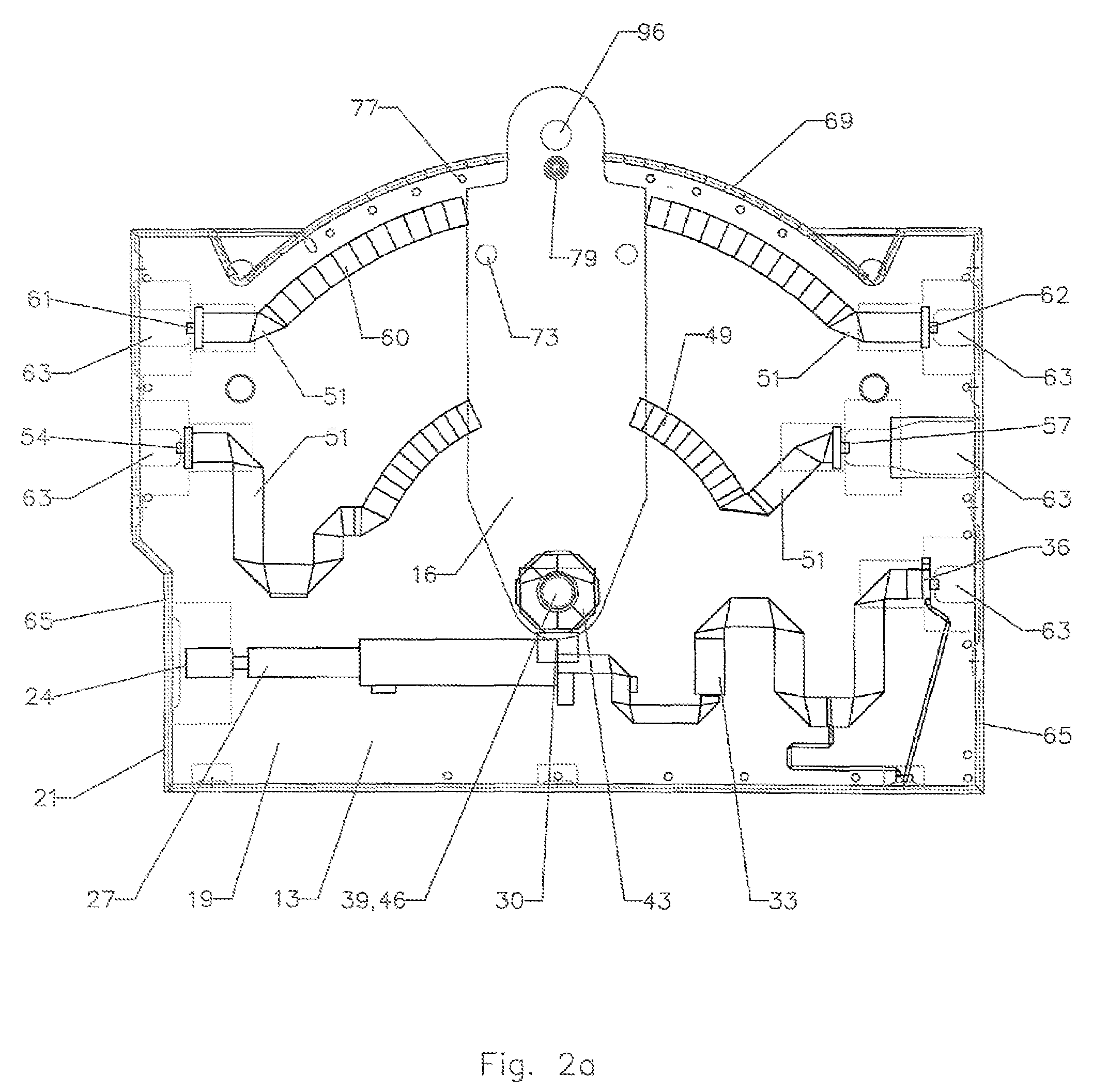

ActiveUS20060077098A1Low costSmall sizeAntenna feed intermediatesDelay linesControl theoryMechanical engineering

A panel antenna having a variable phase shifter module with at least one main-PCB having an input trace coupled to a wiper junction. An arcuate trace on the main-PCB extending between a first output trace and a second output trace, the arcuate trace having an arc center proximate the wiper junction. A wiper-PCB having a linking trace thereon; the wiper-PCB rotatably coupled to the main-PCB proximate the wiper junction with the linking trace facing the first main-PCB. Because the linking trace faces the main-PCB, the wiper-PCB may be formed from inexpensive and structurally resilient substrate material. The linking trace coupling the wiper junction with the arcuate trace. Multiple arcuate traces may be linked to further output traces to add additional outputs, each having variable phase shift between them, depending upon the position of the wiper-PCB. Multiple main-PCBs may be stacked upon each other and the wiper-PCBs of each controlled by a common linkage.

Owner:COMMSCOPE TECH LLC

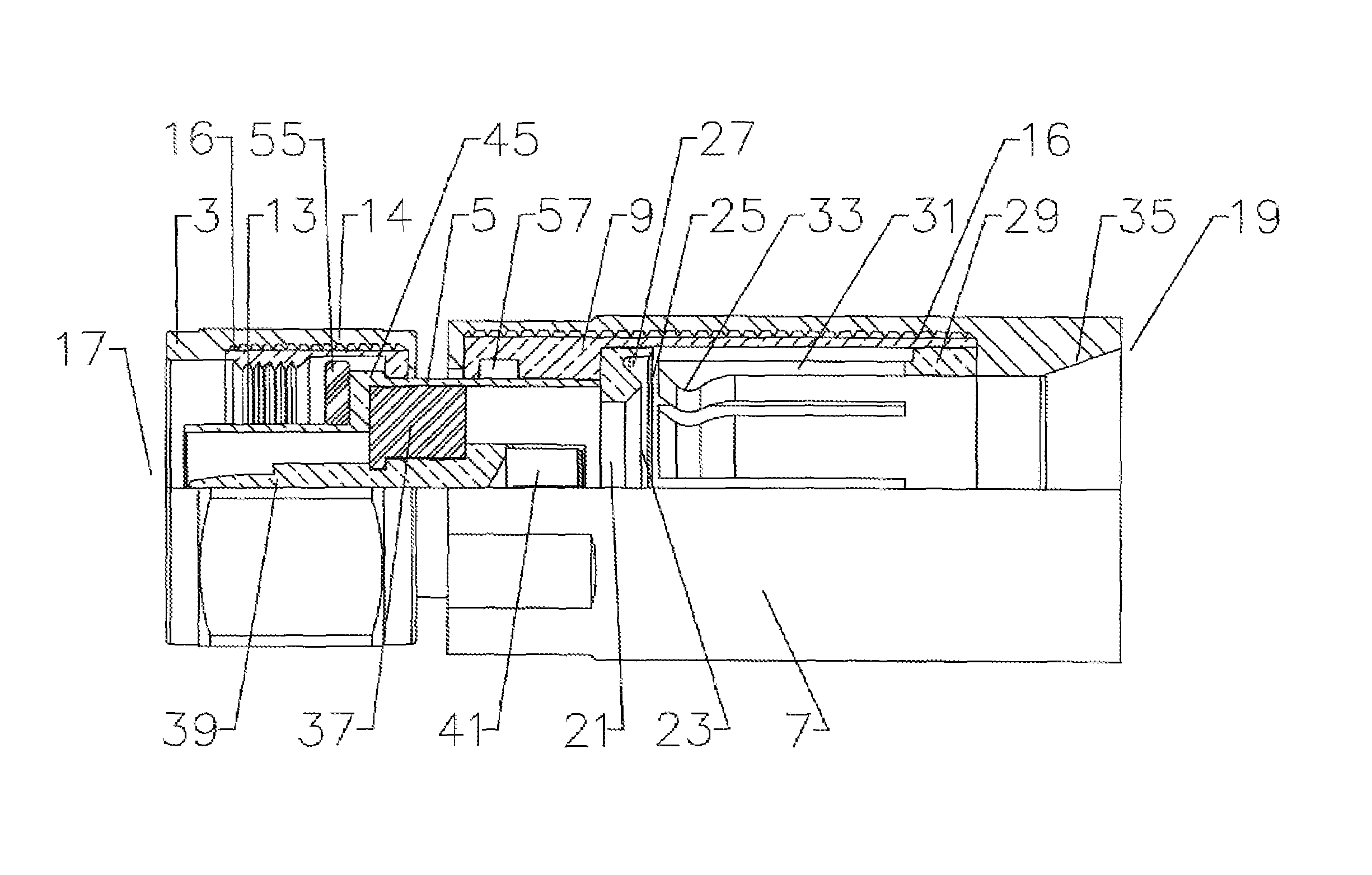

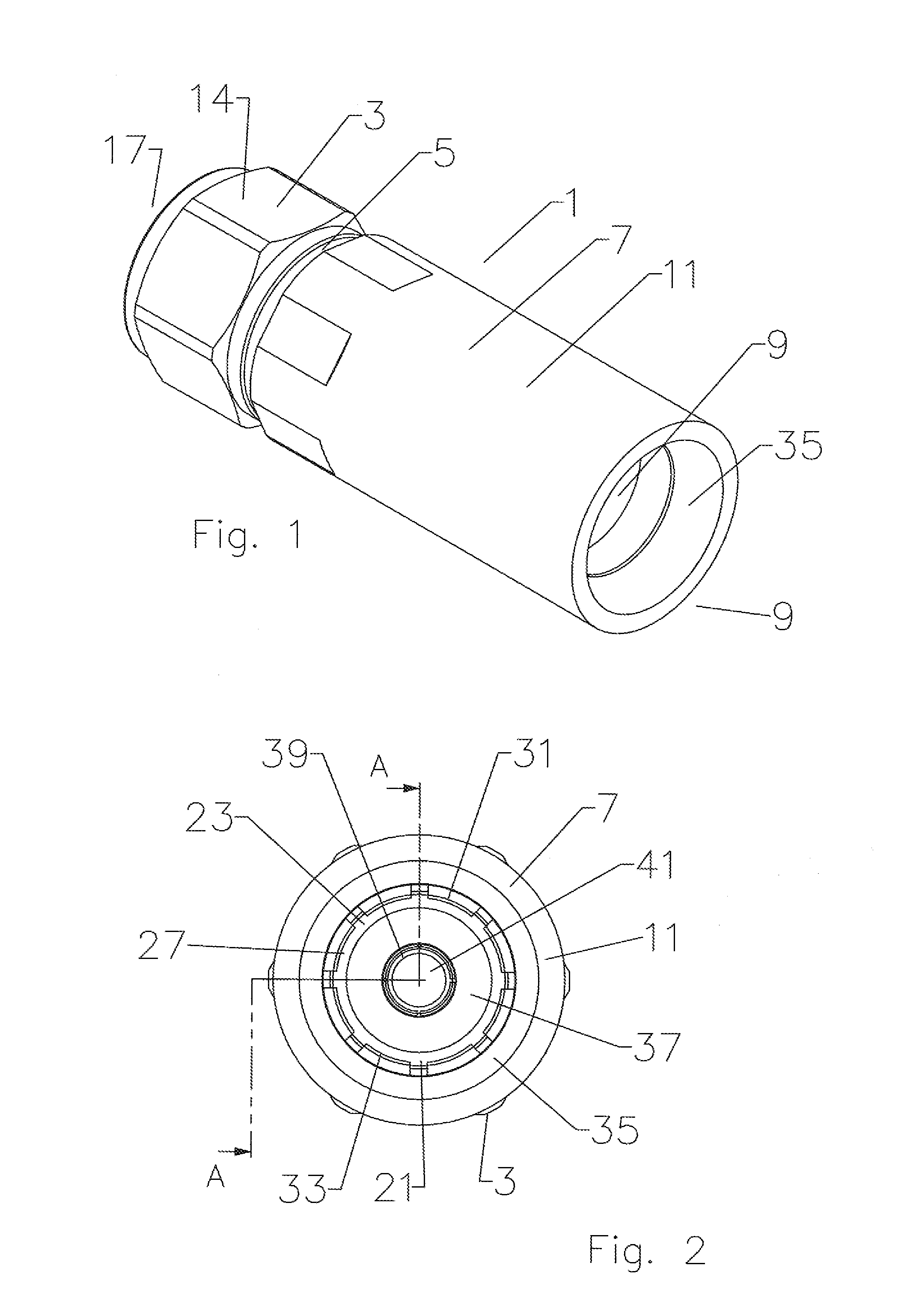

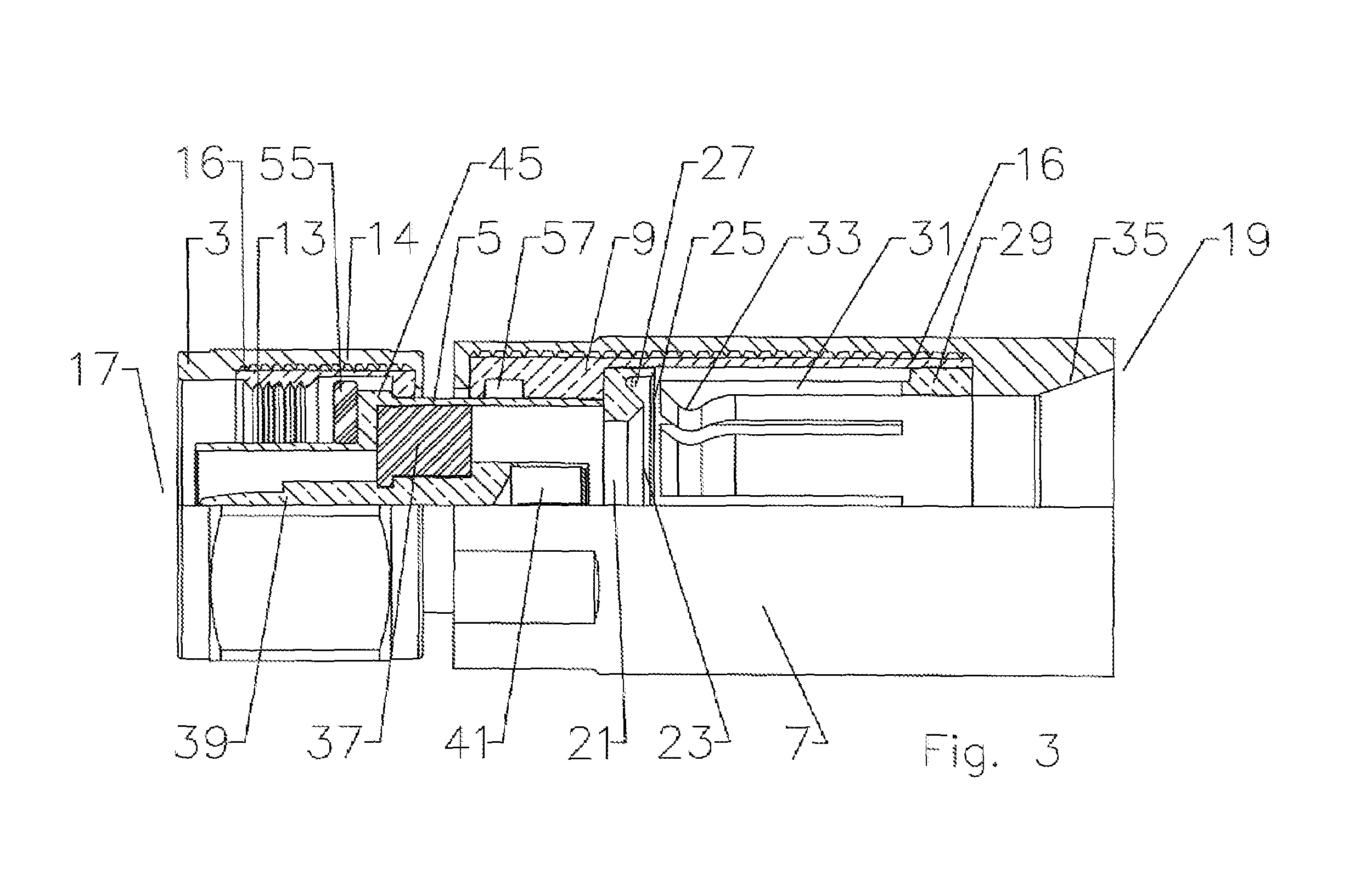

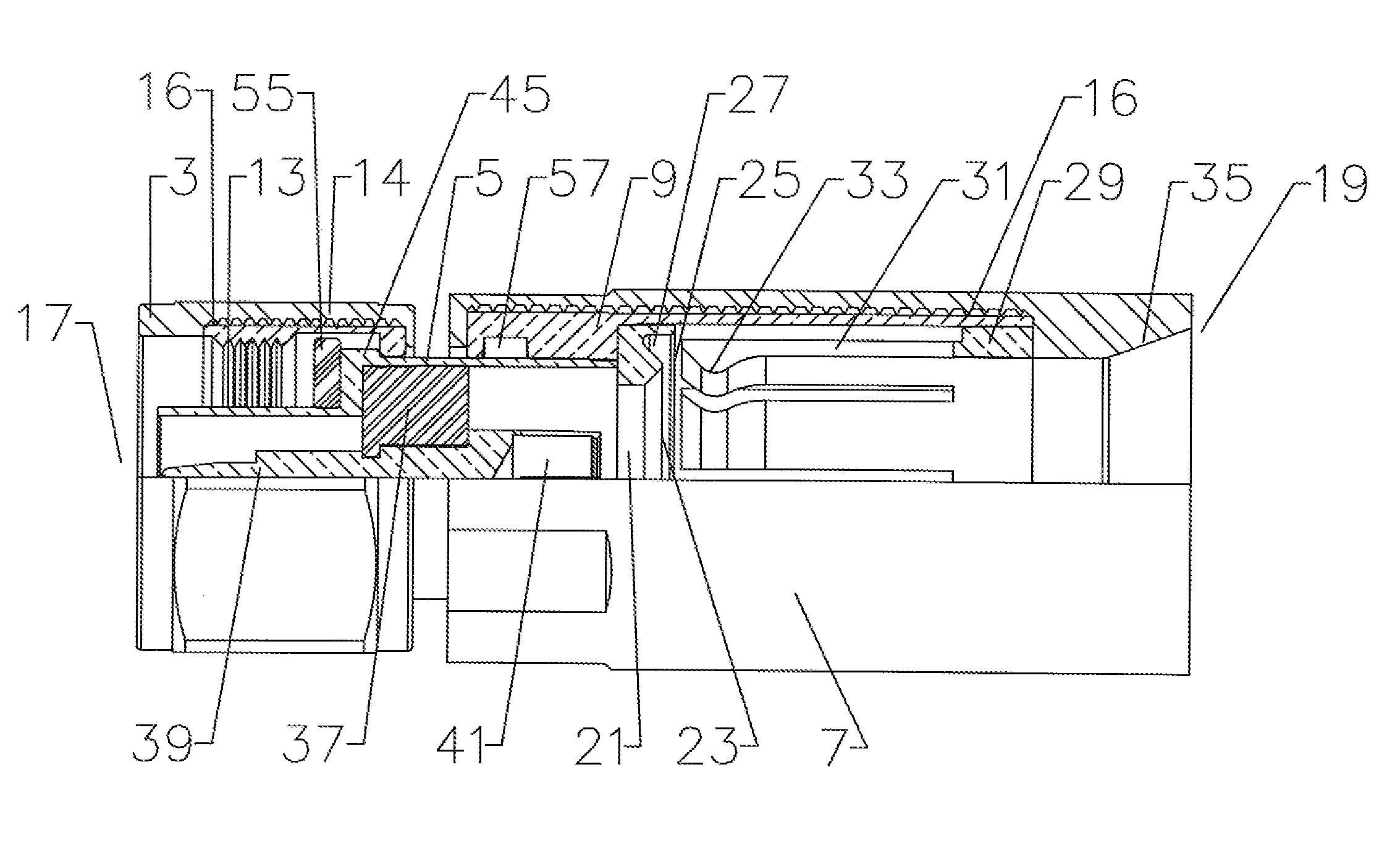

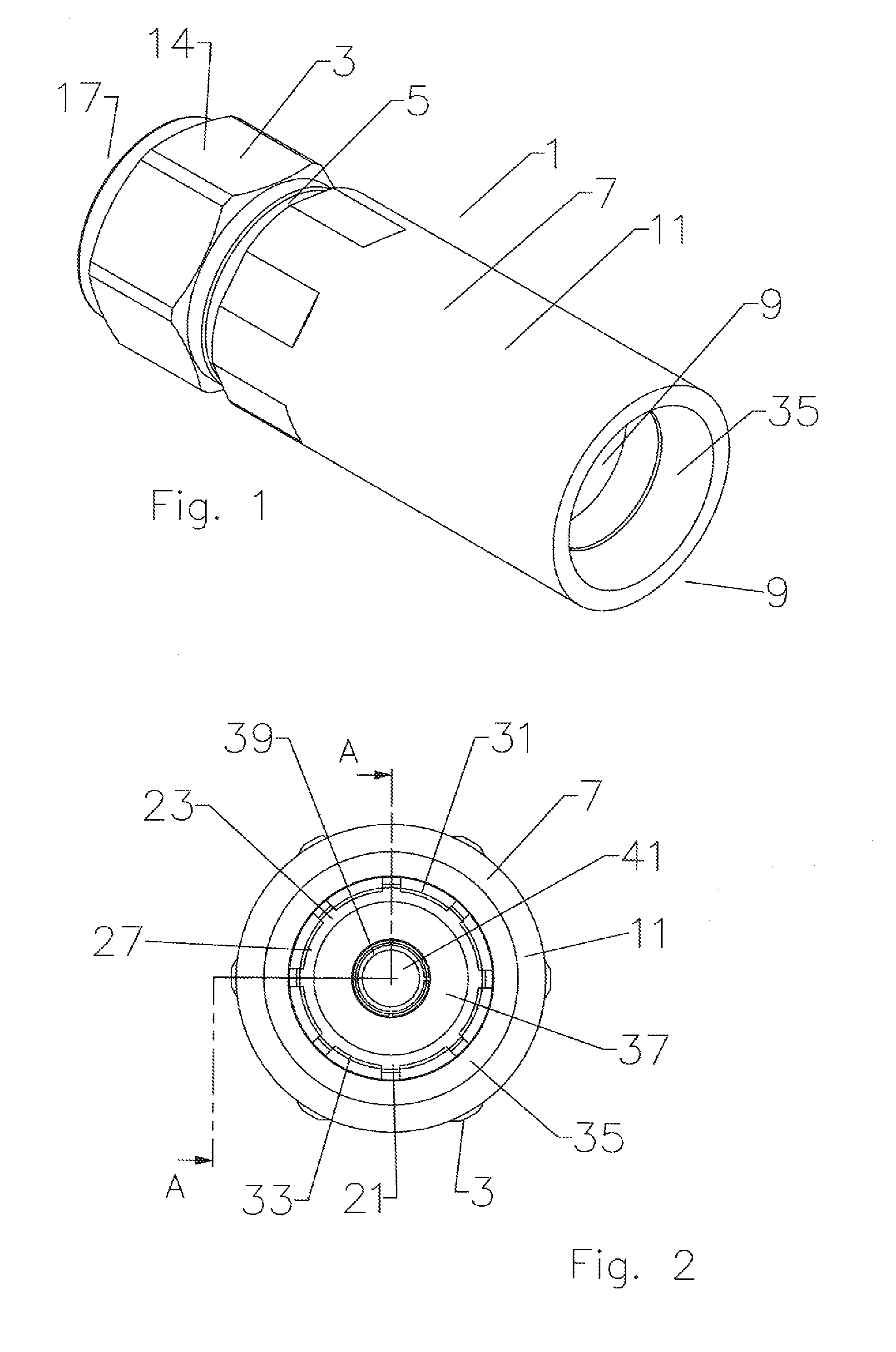

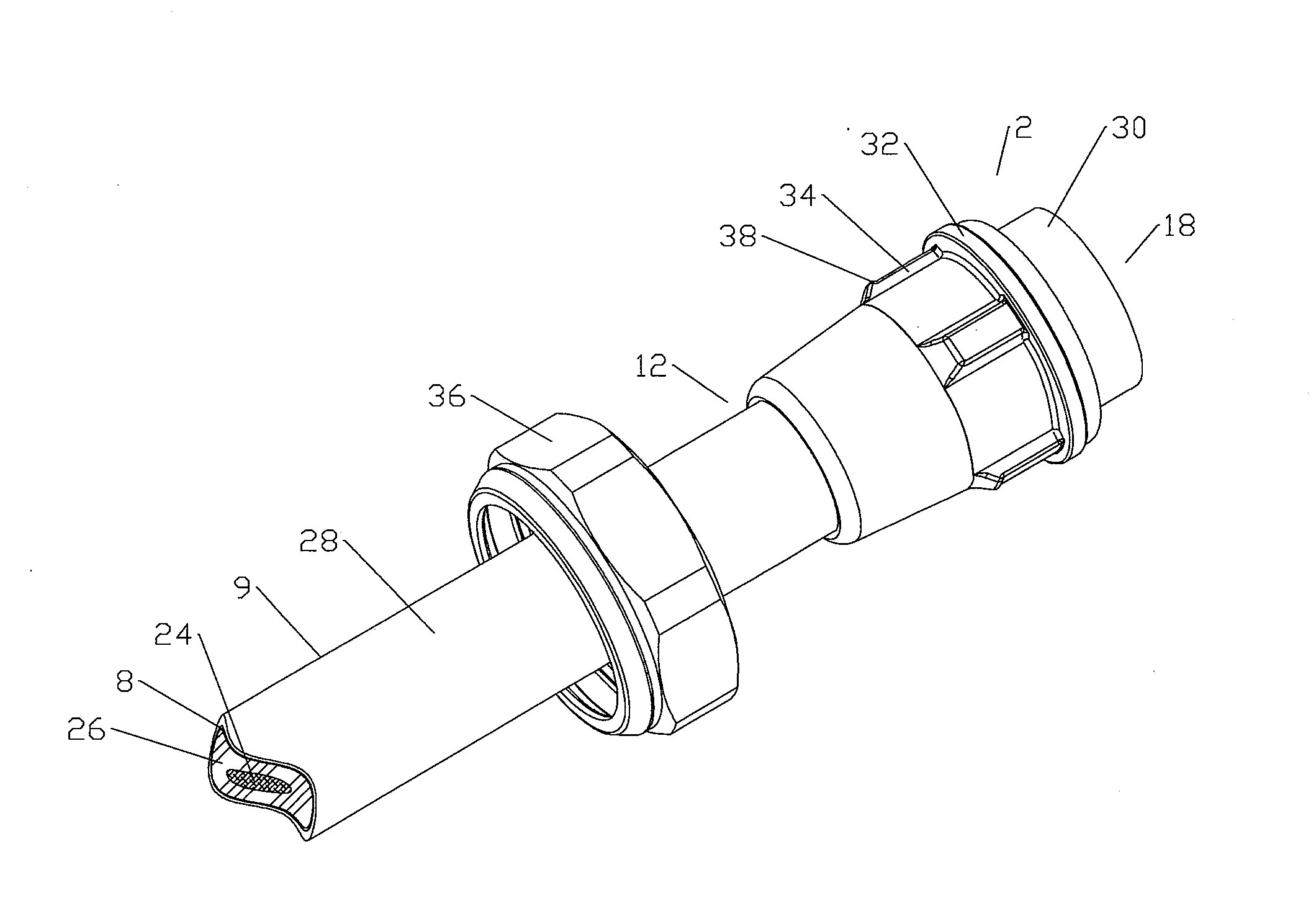

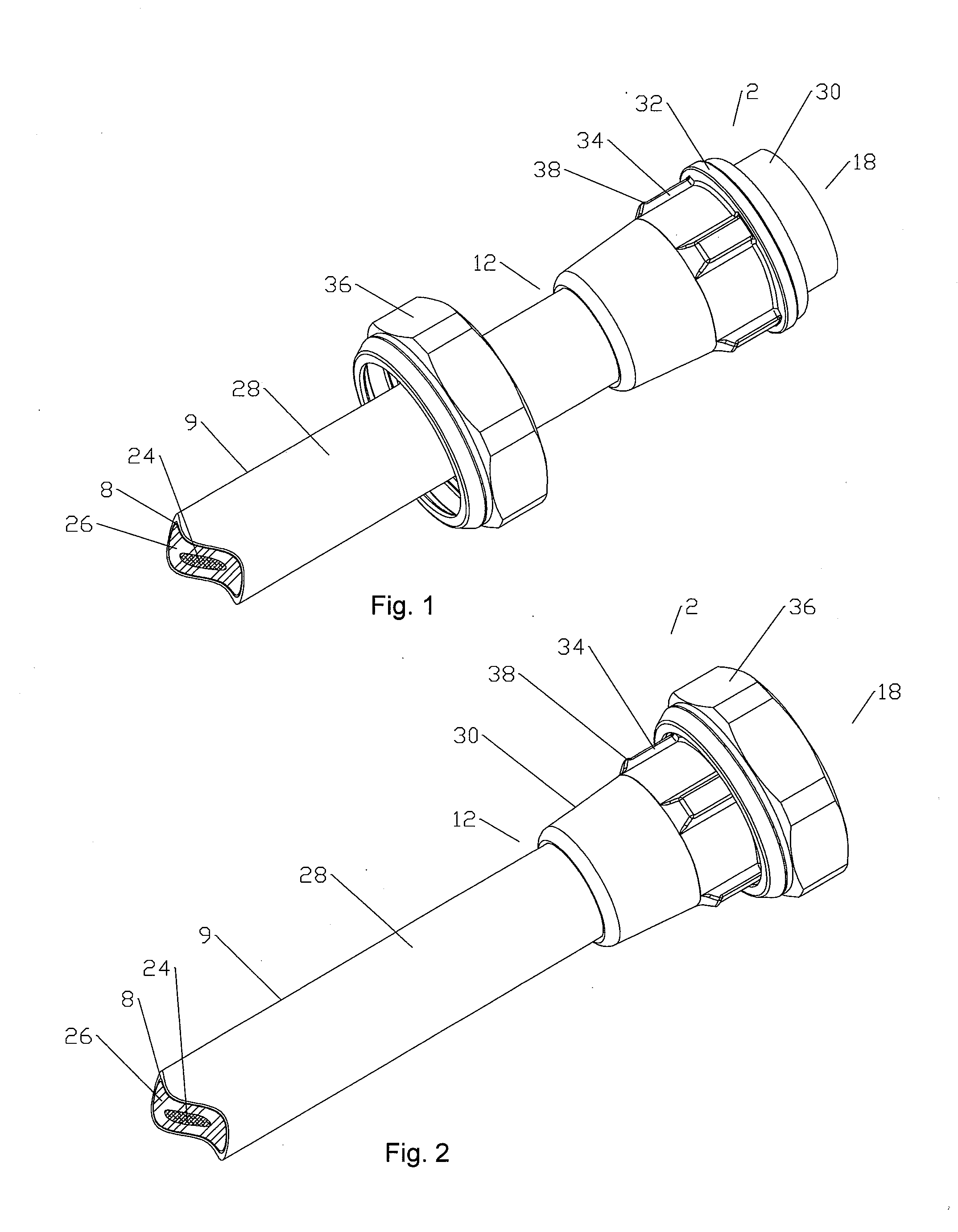

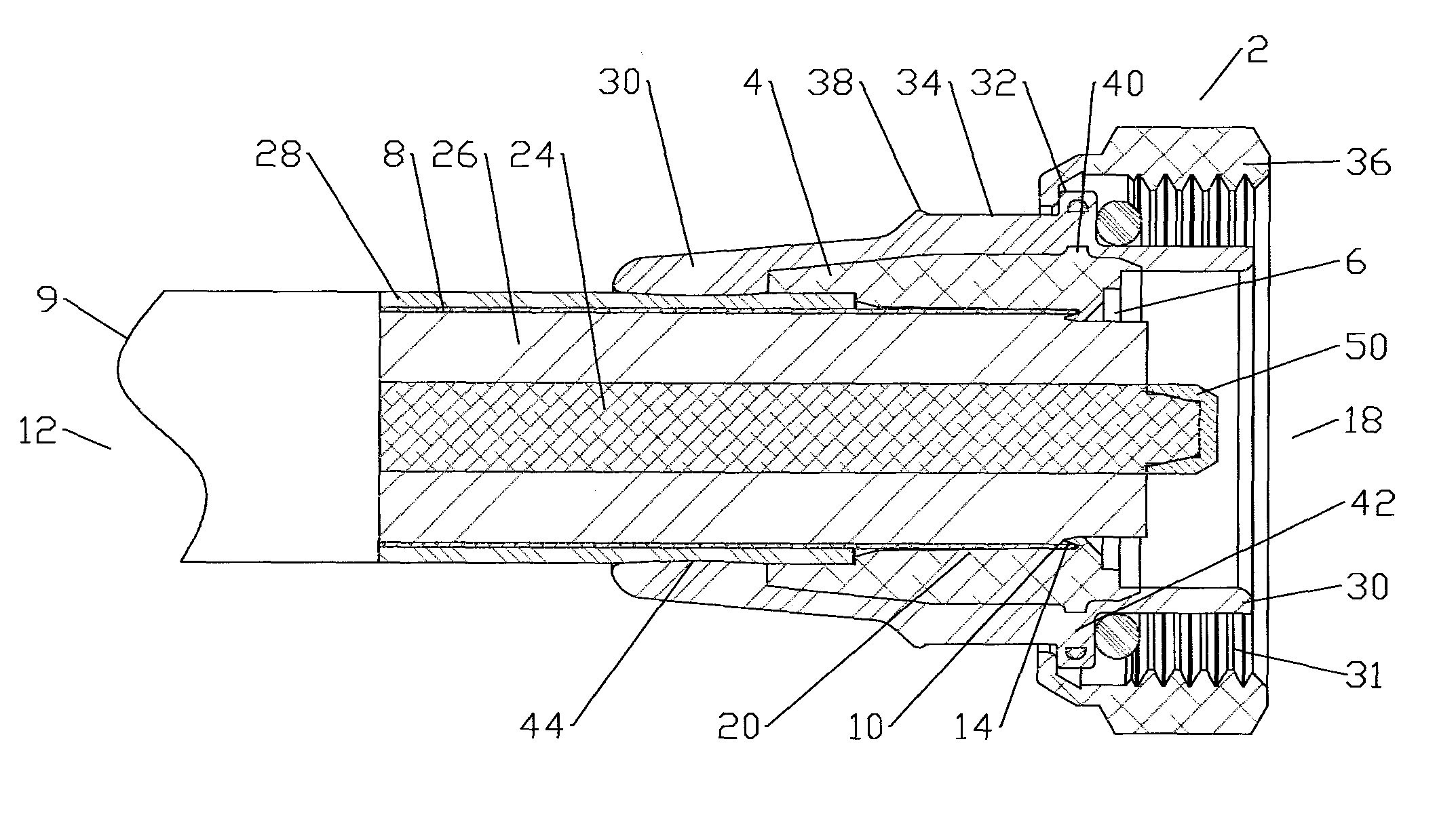

Axial compression electrical connector for annular corrugated coaxial cable

InactiveUS7275957B1Reduced material requirementsReduce weightElectrically conductive connectionsTwo pole connectionsInterference fitElectrical conductor

An electrical connector having a longitudinal axis with interface and cable ends for coaxial cable having an annular corrugated solid outer conductor. The connector having a body and an interface joined in an interference fit along the longitudinal axis of the connector. A spring finger ring within a bore of the body is rigidly connected to the body. The spring finger ring having a plurality of spring fingers extending towards an connector end; the spring fingers having an inward projecting bead at the connector end. The spring fingers positioned opposite an outer conductor groove open to the cable end, the outer conductor groove proximate the cable end of the interface.

Owner:ANDREW LLC

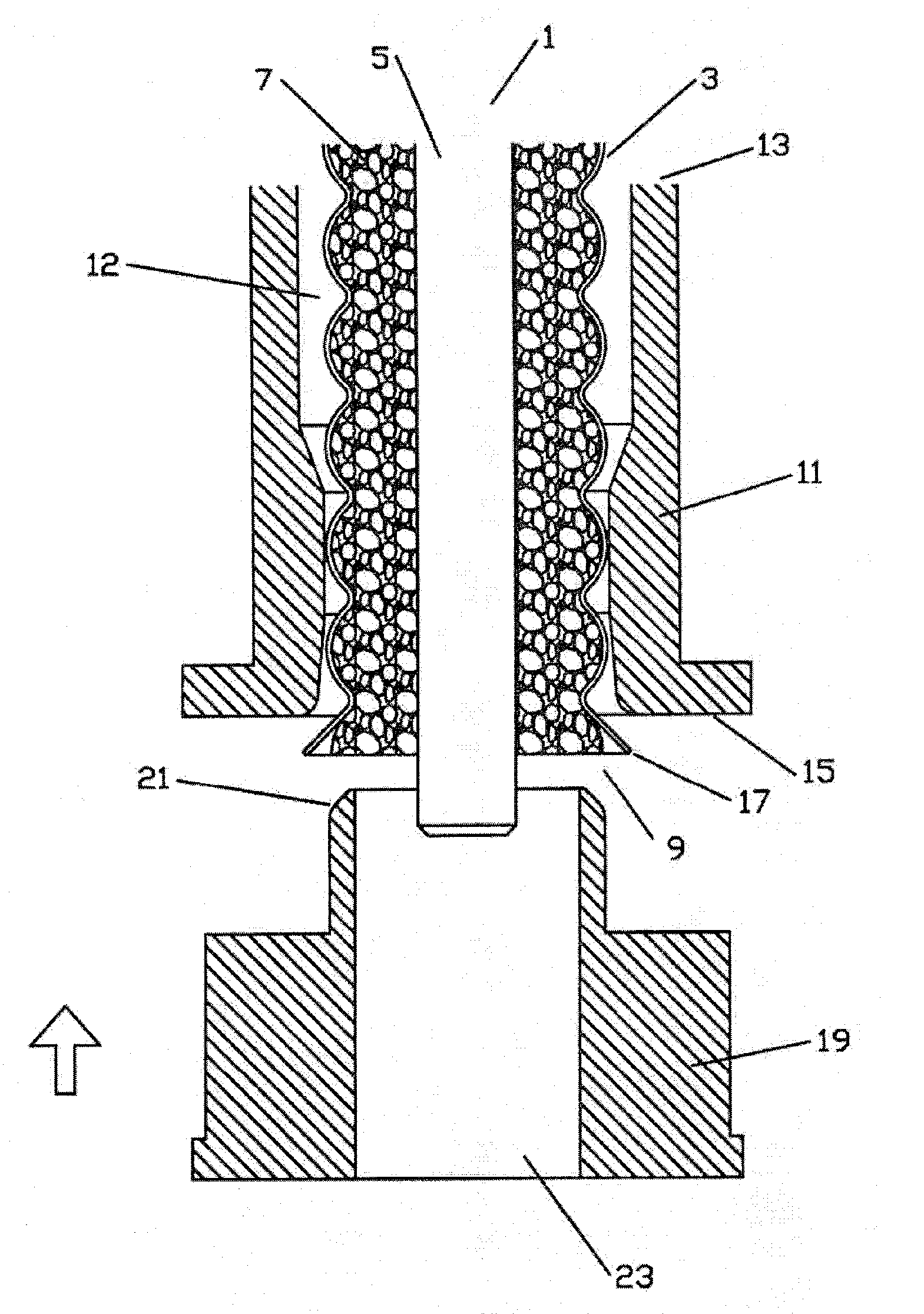

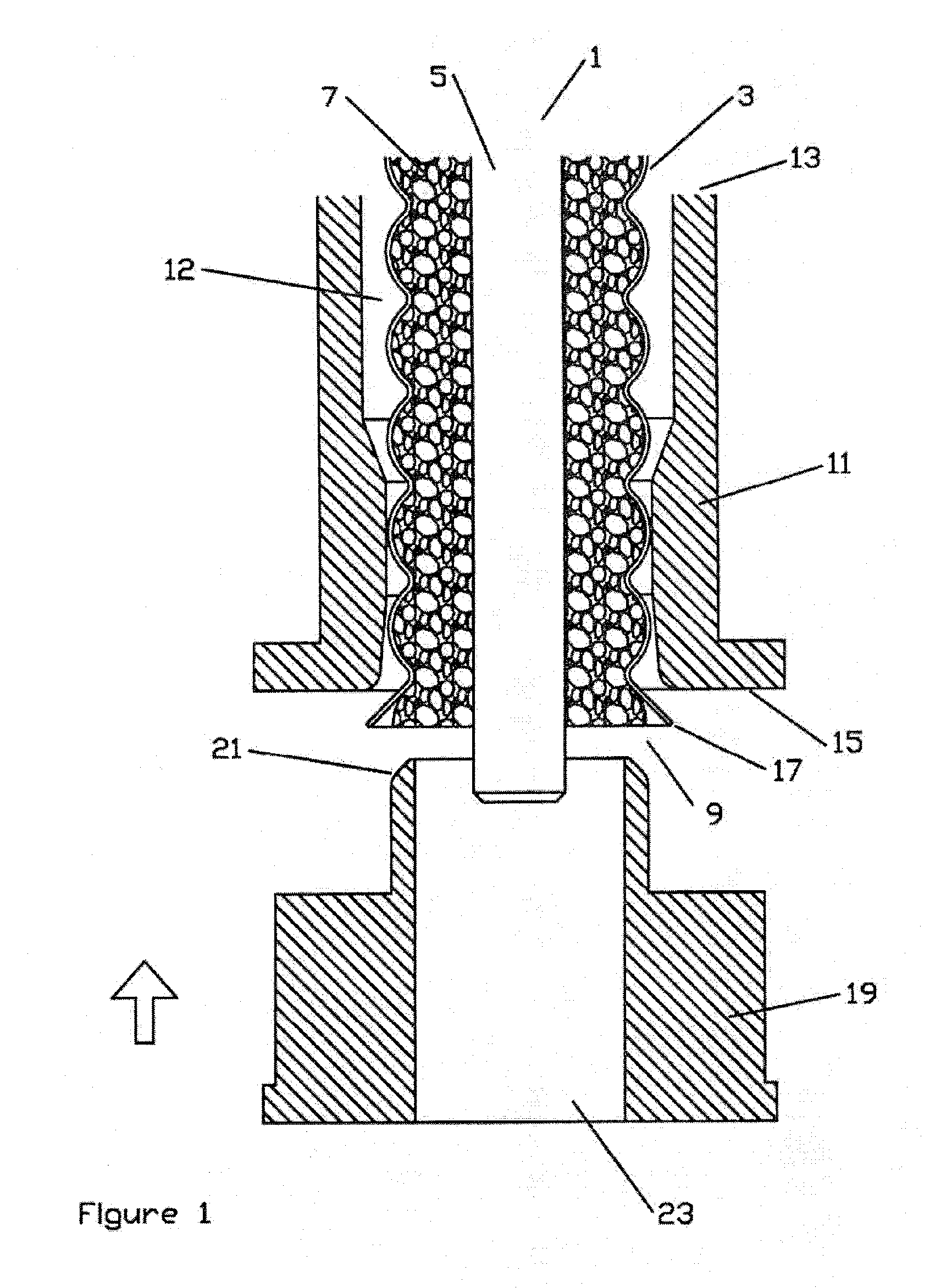

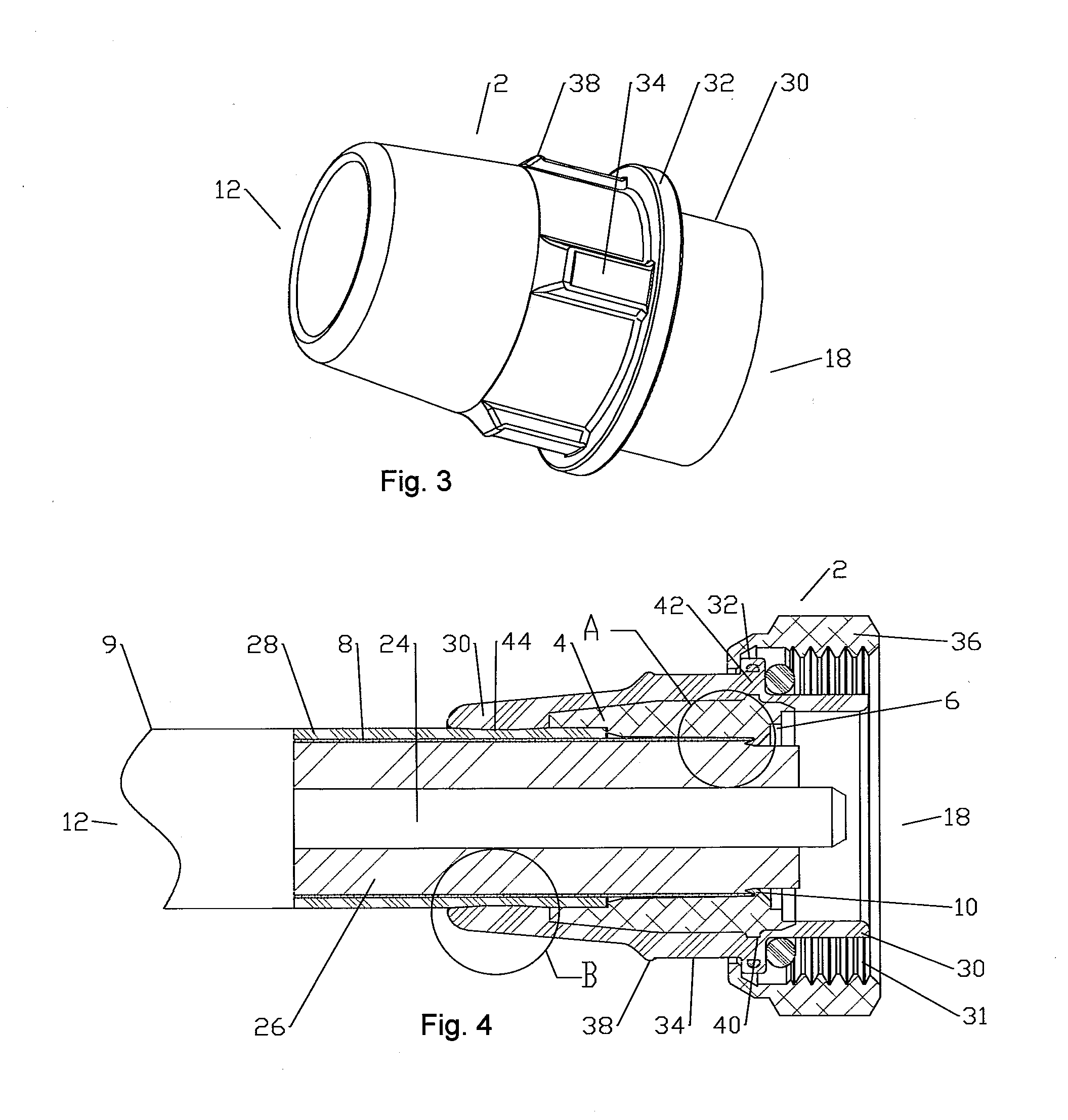

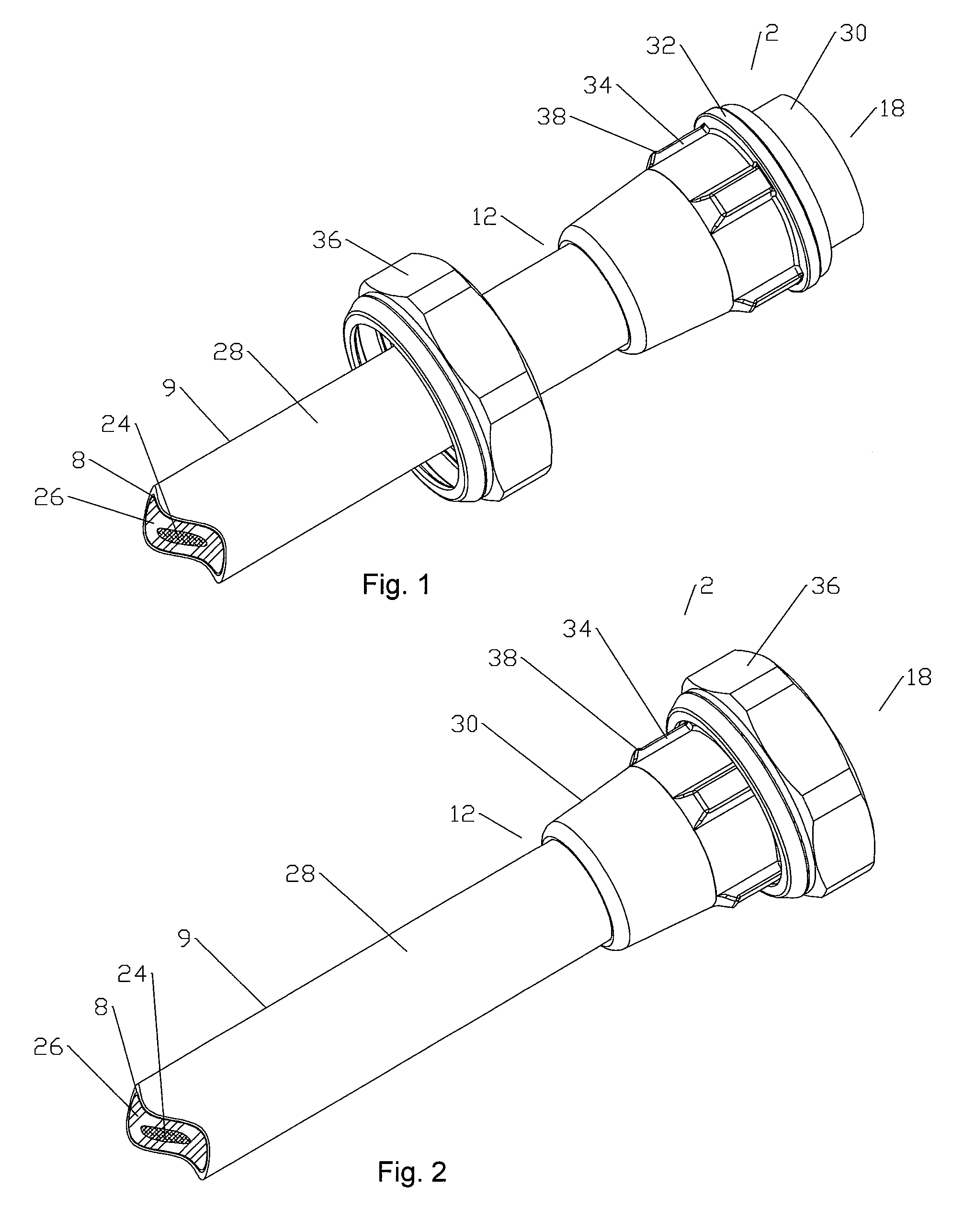

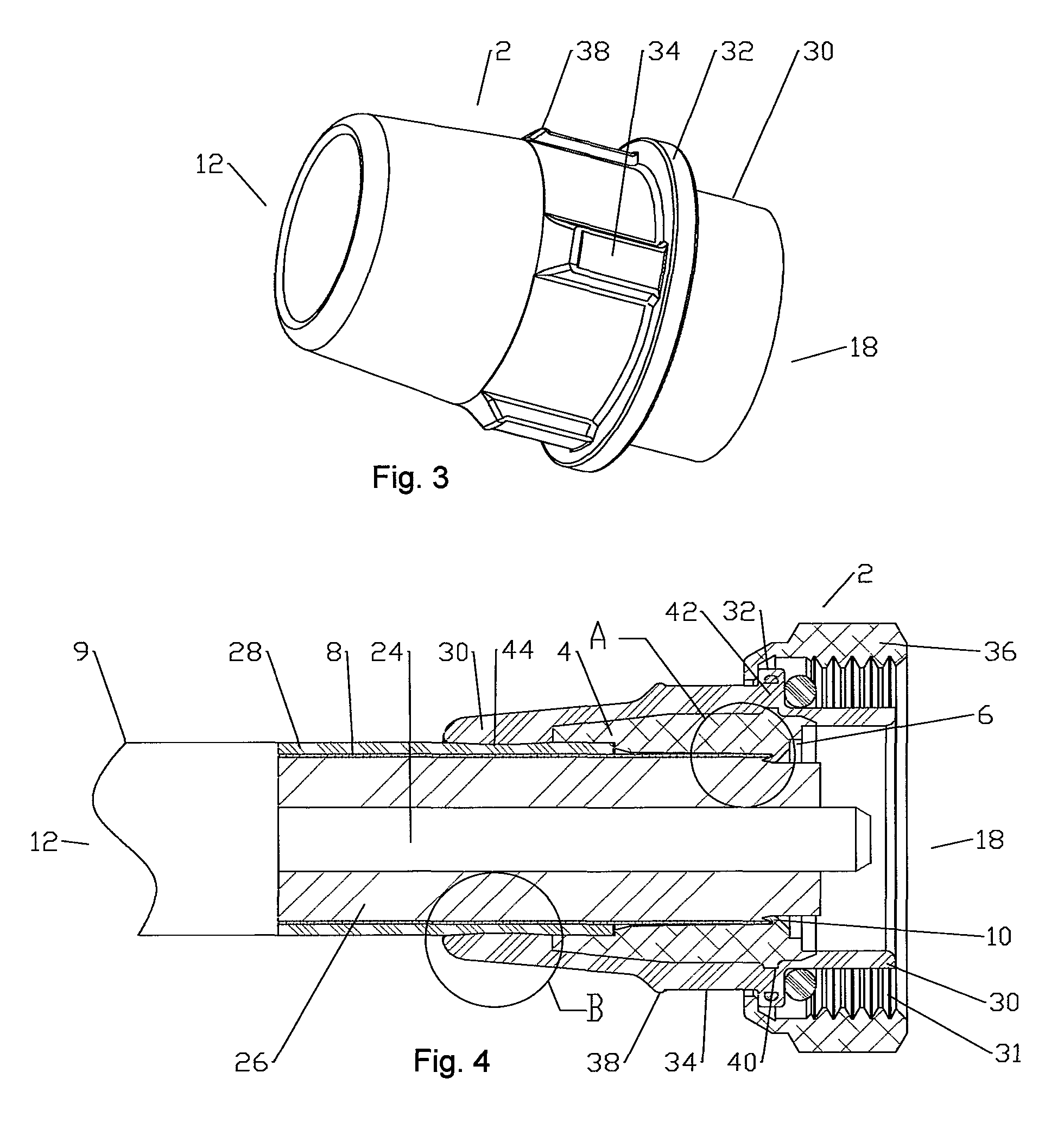

Connector and Coaxial Cable with Outer Conductor Cylindrical Section Axial Compression Connection

InactiveUS20050159044A1Improve electrical performanceReduce material costsElectrically conductive connectionsTwo pole connectionsInterference fitCoaxial cable

A connector and coaxial cable interconnectable via axial compression upon a cylindrical section of a solid outer conductor of the cable. The cylindrical section may be formed in the cable by drawing a cable end into an interference fit between a sleeve and an outer conductor seat formed in the connector body. Alternatively, the cylindrical section may be formed in the outer conductor during cable manufacture and the cylindrical section retained between the outer conductor seat and a crimp ring radially deformed by an angled die face during axial compression. To increase flexibility of a straight walled cable, annular corrugations may be formed in the solid outer conductor with the cylindrical sections at each corrugation peak. The cylindrical section having a length of at least 3 millimeters or 4 times the corrugation depth.

Owner:ANDREW CORP

Disposable diaper

InactiveUS8212102B2Easy to placeReduced material requirementsSkirtsGirdlesEngineeringMechanical engineering

A diaper having front and rear waist regions and a waist-hole, the waist hole having a peripheral edge that is elastically stretchable in a circumferential direction and includes covering zones and elastic zones in the front and rear waist regions, which peripheral edge is adapted to be stretchable beyond lengths of the covering zones in the circumferential direction.

Owner:UNI CHARM CORP

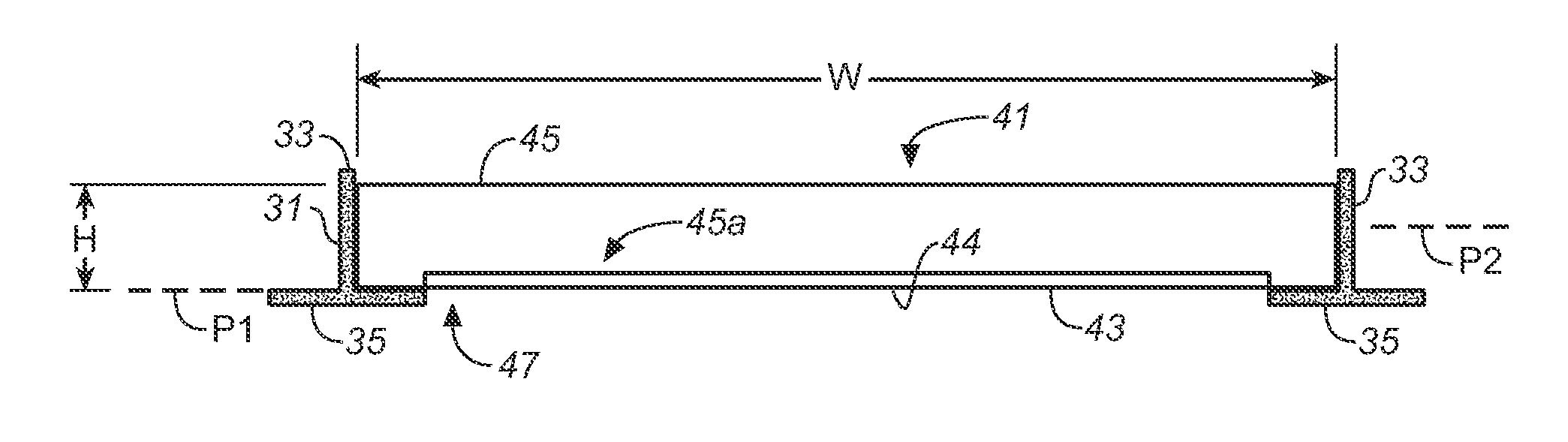

Low profile OLED luminaire for grid ceilings

ActiveUS8485700B2Low profileReduced material requirementsPlanar light sourcesCeilingsEngineeringLight-emitting diode

A low-profile luminaire has a planar light source comprised of one or more planar organic light emitting diodes (OLEDs). The OLED light source is supported by a low-profile OLED support structure that lies in a plane. The support structure has a maximum height (H) of about two inches and preferably a height of about one inch or less. It also has perimeter dimensions that allow the luminaire to fit within and to be supported by the T-bar grid of a grid ceiling system. Electrical components for driving and controlling the OLED light source can be provided within the support structure or externally of this structure.

Owner:ABL IP HLDG

Axial Compression Electrical Connector for Annular Corrugated Coaxial Cable

InactiveUS20070224880A1Reduced material requirementsReduce weightElectrically conductive connectionsTwo pole connectionsInterference fitCoaxial cable

An electrical connector having a longitudinal axis with interface and cable ends for coaxial cable having an annular corrugated solid outer conductor. The connector having a body and an interface joined in an interference fit along the longitudinal axis of the connector. A spring finger ring within a bore of the body is rigidly connected to the body. The spring finger ring having a plurality of spring fingers extending towards an connector end; the spring fingers having an inward projecting bead at the connector end. The spring fingers positioned opposite an outer conductor groove open to the cable end, the outer conductor groove proximate the cable end of the interface.

Owner:ANDREW LLC

Method for preparation of anion exchange resins

InactiveUS20030018091A1Promote recoveryLow costCation exchanger materialsIon-exchanger regenerationIon-exchange resinRaw material

An improved process for preparing anion exchange resins based on the use of a non-agitated plug-flow quench procedure followed by recycle of a portion of the recovered chloromethylation reaction fluids into subsequent chloromethylation reactions is disclosed. The combination of plug-flow hydration, providing highly concentrated recovered sulfuric acid, together with the recycle or reuse of the recovered concentrated sulfuric acid, allows for reduced raw material requirements during anion exchange resin manufacture and reduces the environmental impact of waste sulfuric acid processing.

Owner:ROHM & HAAS CO

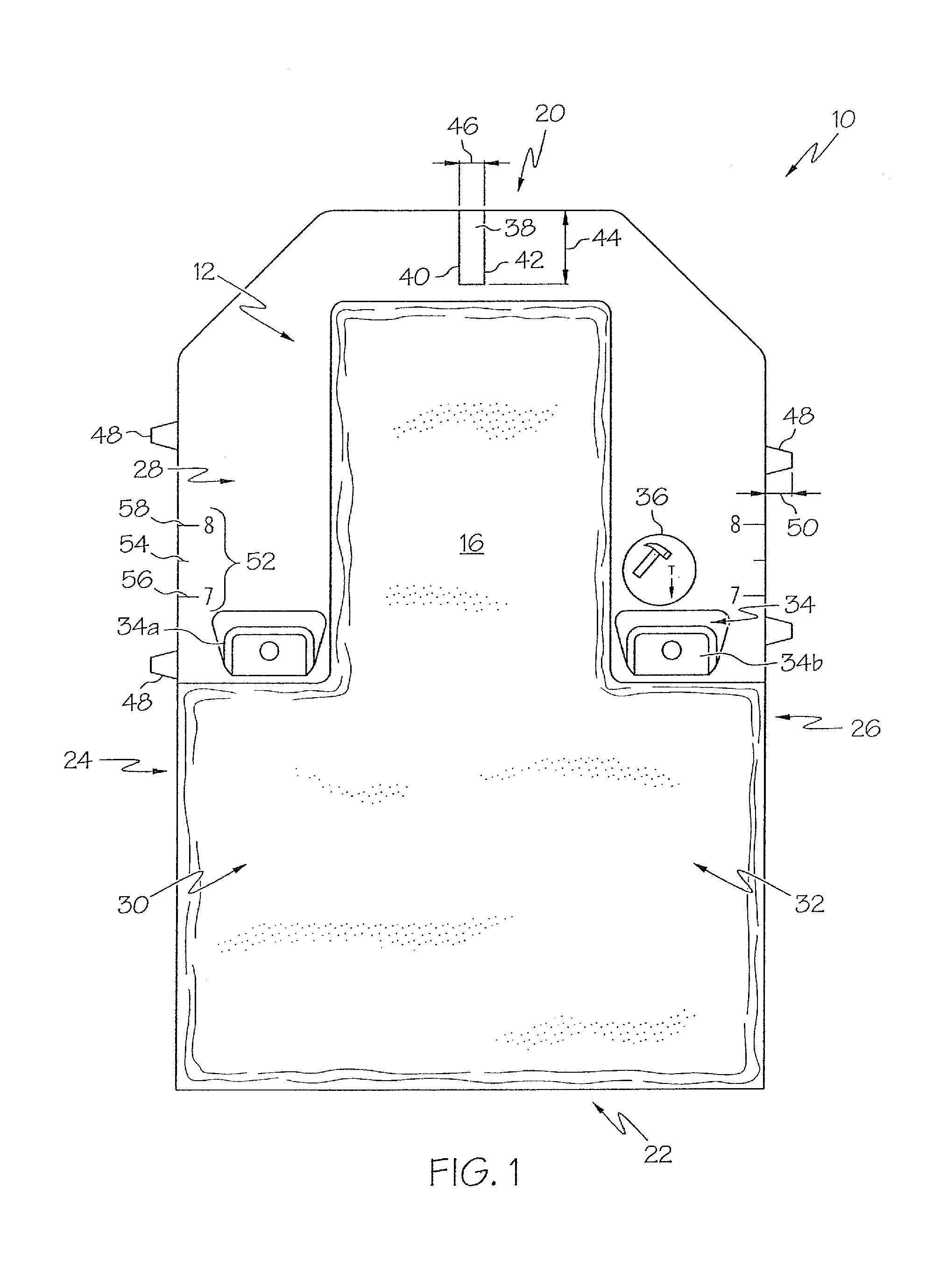

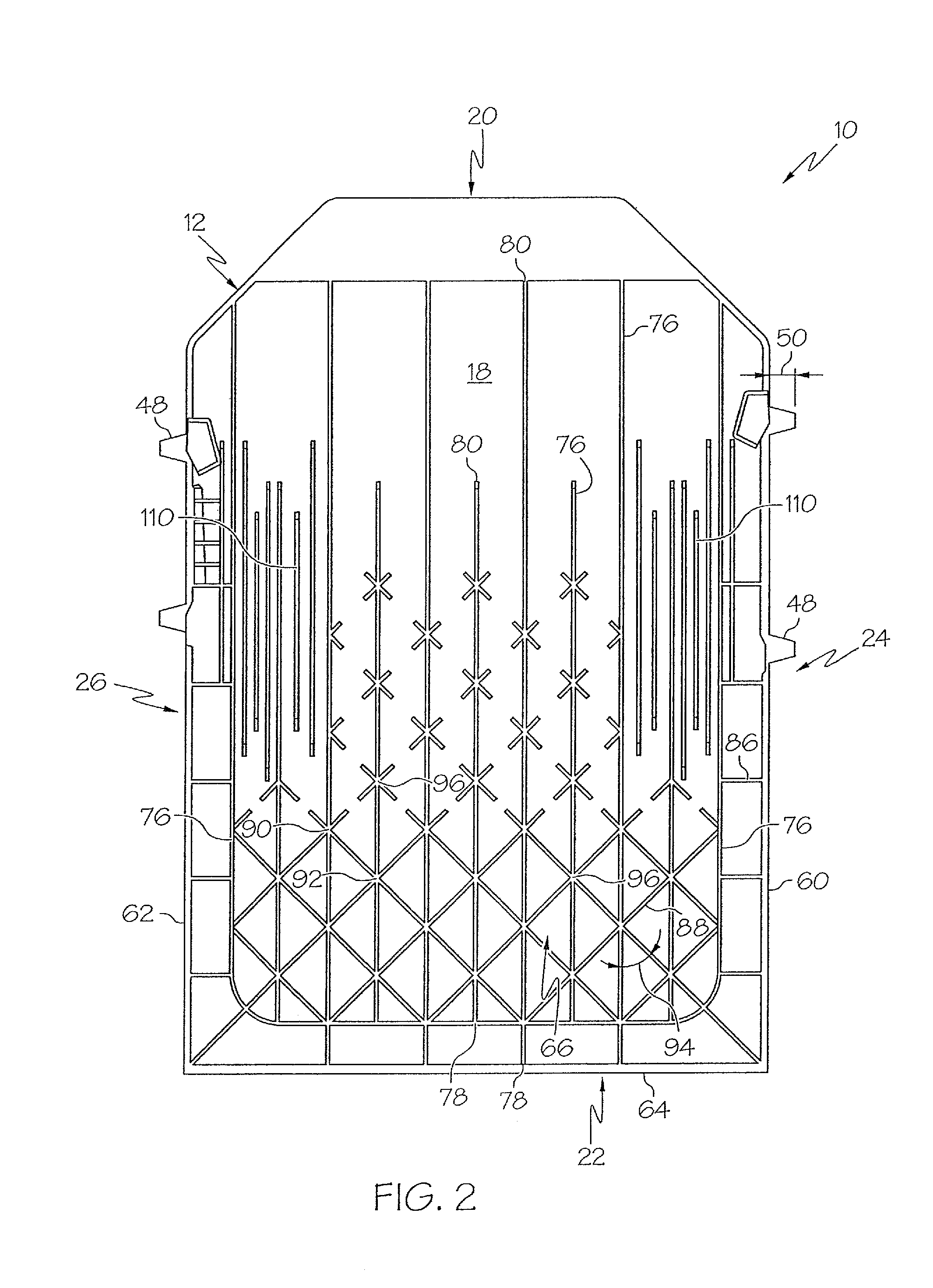

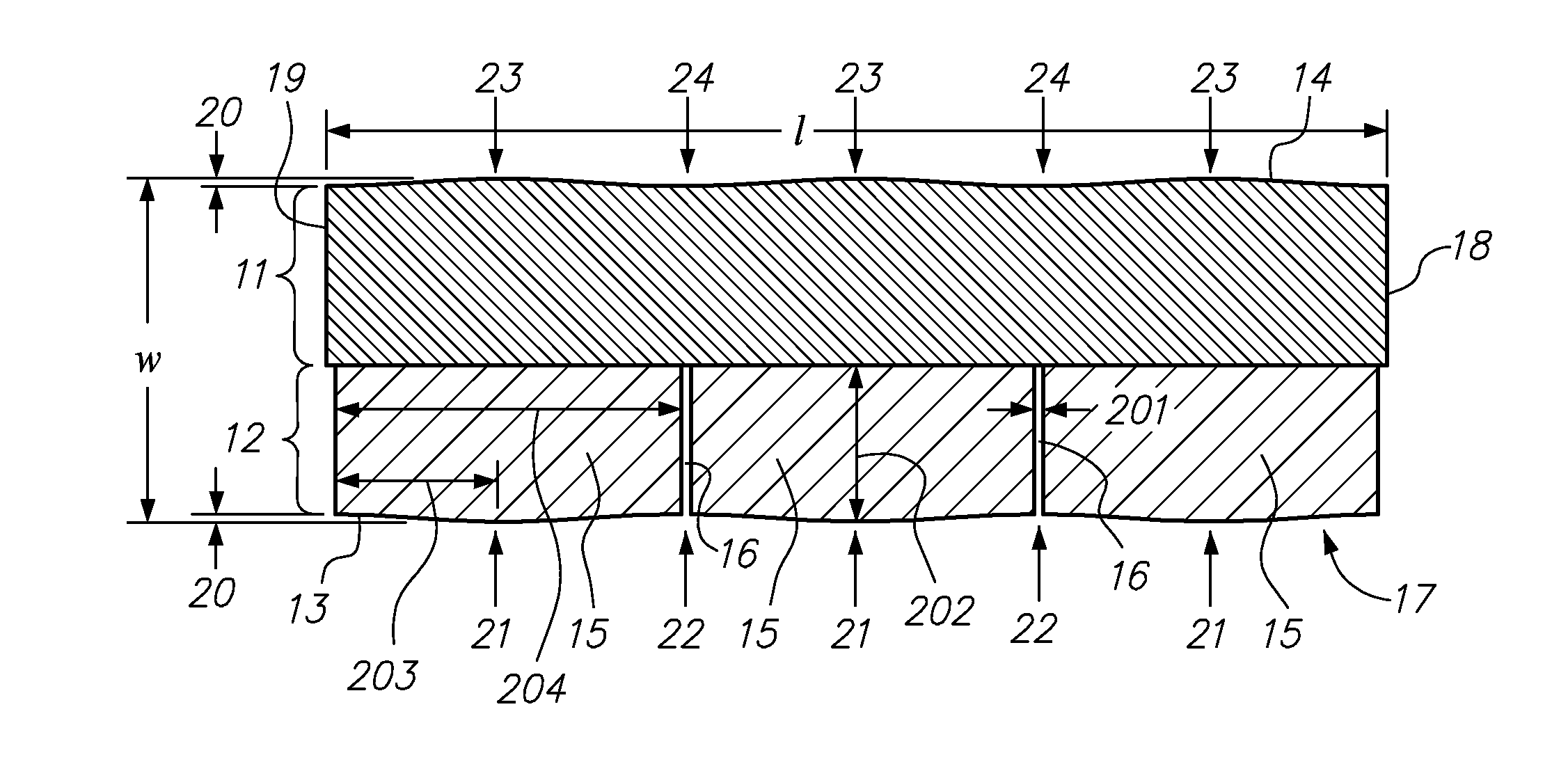

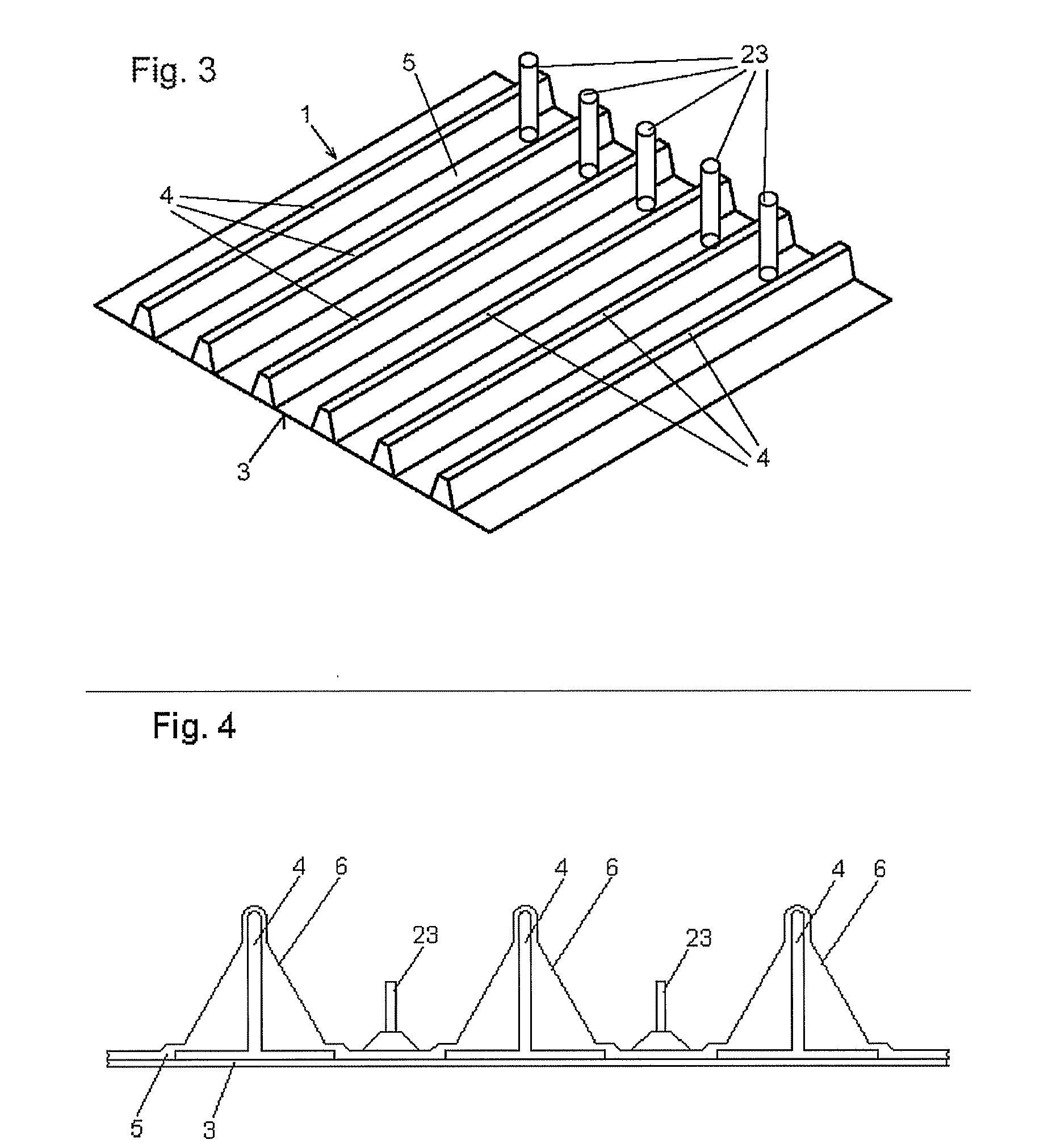

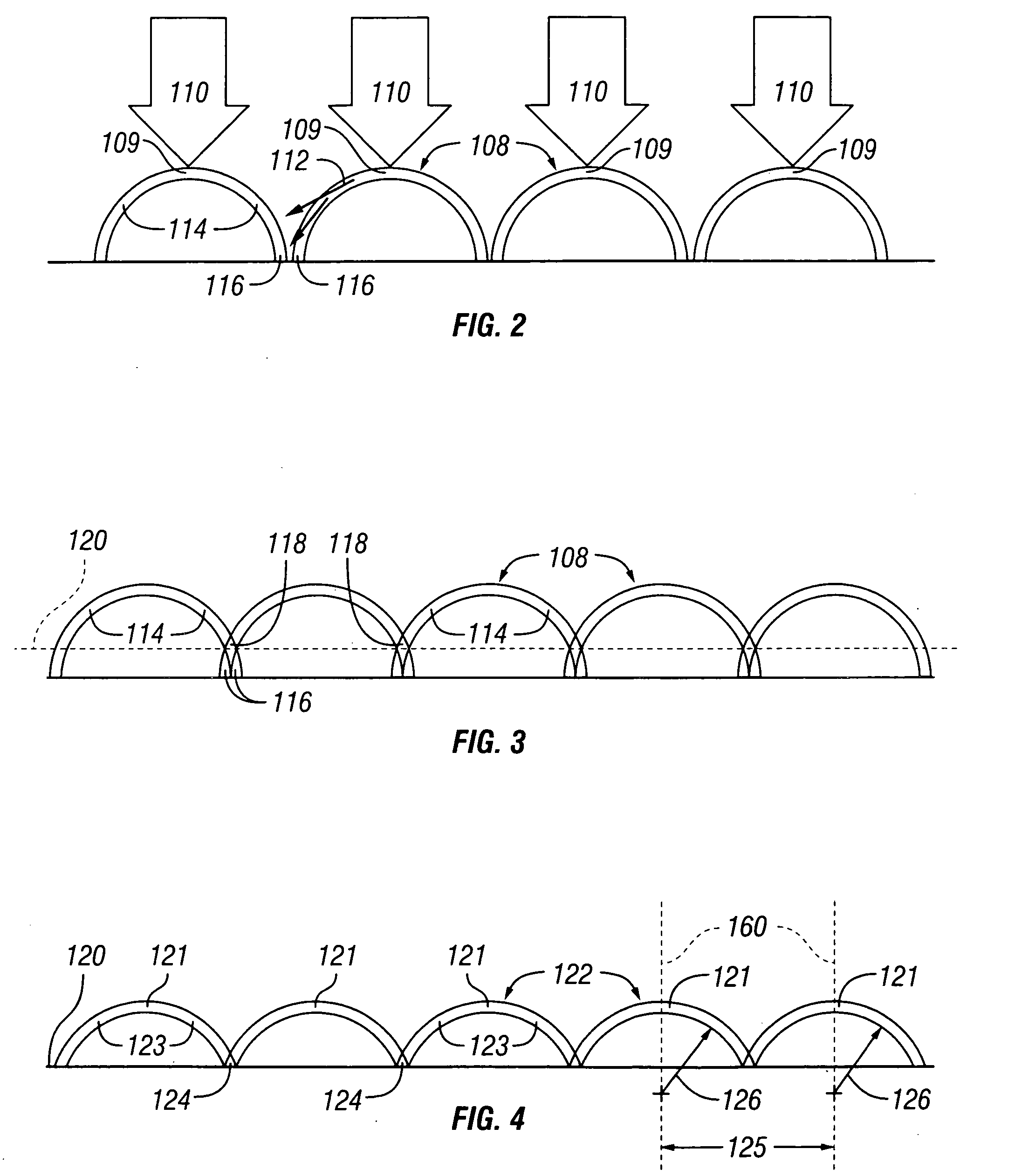

Composite shingle

InactiveUS8136322B2Reduce material usageSmall depthRoof covering using tiles/slatesBuilding repairsEngineeringBuilding construction

A composite shingle having unitary construction is presented that includes a body shell, a plurality of longitudinal ribs, and a plurality of rib stiffeners. The present composite shingle may also include transverse ribs, a depressed nailing zone, nailing zone ribs, and / or at least one alignment aid. The plurality of rib stiffeners may include a material saving profile. Further, the dimensions of the composite shingle more closely resemble true slate and shake shingles and at least a portion of the outside face of composite shingle may be textured to resemble slate or wood shake shingles.A plurality of assembled composite shingles of the present invention is also claimed as part of this invention. Finally, a method of applying multiple courses of shingles on a roof including the composite shingle of the present invention is presented.

Owner:TAMKO BUILDING PRODS

Connector and Coaxial Cable with Outer Conductor Cylindrical Section Axial Compression Connection

InactiveUS20050159043A1Improve electrical performanceReduce material costsContact member manufacturingElectrically conductive connectionsInterference fitCoaxial cable

A connector and coaxial cable interconnectable via axial compression upon a cylindrical section of a solid outer conductor of the cable. The cylindrical section may be formed in the cable by drawing a cable end into an interference fit between a sleeve and an outer conductor seat formed in the connector body. Alternatively, the cylindrical section may be formed in the outer conductor during cable manufacture and the cylindrical section retained between the outer conductor seat and a crimp ring radially deformed by an angled die face during axial compression. To increase flexibility of a straight walled cable, annular corrugations may be formed in the solid outer conductor with the cylindrical sections at each corrugation peak. The cylindrical section having a length of at least 3 millimeters or 4 times the corrugation depth.

Owner:ANDREW LLC

Low profile luminaire for grid ceilings

InactiveUS20130301249A1Low profileReduced material requirementsPlanar light sourcesCeilingsLight sourceLight fixture

A low-profile luminaire has a light source comprised of one or more organic light emitting diodes (OLEDs), LEDs or other area light sources. The one or more area light sources are supported by a low-profile support structure that lies in a plane. The support structure, which supports the area light source substantially in the plane of the support structure, preferably has a maximum height of about two inches and more preferably a height of about one inch or less. It also has perimeter dimensions that allow the luminaire to fit within and to be supported by the T-bar grid openings of a grid ceiling system. Electrical components for driving and controlling the light source can be provided within the support structure or externally of this structure.

Owner:ABL IP HLDG

Roofing shingle system and shingles for use therein

ActiveUS20130160389A1Reduce material usageReduce the amount requiredRoof covering using tiles/slatesMetal working apparatusEngineeringMechanical engineering

A roofing shingle is disclosed comprising a headlap portion with a non-straight longitudinal edge and a buttlap portion with a plurality of tabs with a non-straight longitudinal edge and spaced apart by openings, wherein the non-straight longitudinal edges do not shadow each other laterally across the shingle. A roofing system is disclosed wherein at least a portion of the headlap portion of such shingle from a subsequently installed course overlaps at least a portion of the headlap portion of a shingle from a previously installed course. The maximum headlap overlap dimension is beneath the subsequently installed shingle laterally proximate the openings in the buttlap portion of the subsequently installed shingle. A method for making the shingle is disclosed comprising cutting a sheet of roofing material longitudinally along non-straight lines wherein at least a portion of each formed shingle has a width of about twelve inches.

Owner:BMIC LLC

System and Method for Converting Electromagnetic Radiation to Electrical Energy

InactiveUS20130146117A1Reduced material requirementsLow costThermoelectric device manufacture/treatmentCircuit arrangementsEngineeringImpedance matching

An nanoantenna comprising a resonant structure element is tuned to capture energy, for example heat or light, radiated at a resonant frequency and to transfer structure to convert the captured energy to electrical energy. A co-planar strip can be used to provide impedance matching between the resonant structure element and the transfer structure. An array of nanoantennae form a nanoantenna array to provide electrical energy output from a plurality of nanoantennae. The nanoantenna array can be coupled to a device or apparatus as a power source.

Owner:REDWAVE ENERGY

Combination Cell Phone and Eyeglass Dedicated Case

InactiveUS20110210018A1Reduced material requirementsMinimizes cost to transportTravelling carriersHoldersEyewearEngineering

A trim, compact combination case dedicated to storing a cell phone (or PDA or other small electronic device) and an accessible pair of eyeglasses is disclosed. The combination cell phone and eyeglass case includes a phone housing compartment and an adjacent eyeglass housing compartment, which are configured to hold the juxtaposed cell phone and eyeglasses. The phone housing compartment and the eyeglass housing compartment are permanently attached by a joining mechanism. An optional eyeglass-housing cap and an optional swivel belt clip are also disclosed. The compact design allows the combination case to be easily carried in a bag, purse, briefcase or pocket. The combination case advantageously positions the eyeglasses oriented and located for quick retrieval when needed to view the phone screen or buttons.

Owner:FRIEDMAN MILTON +1

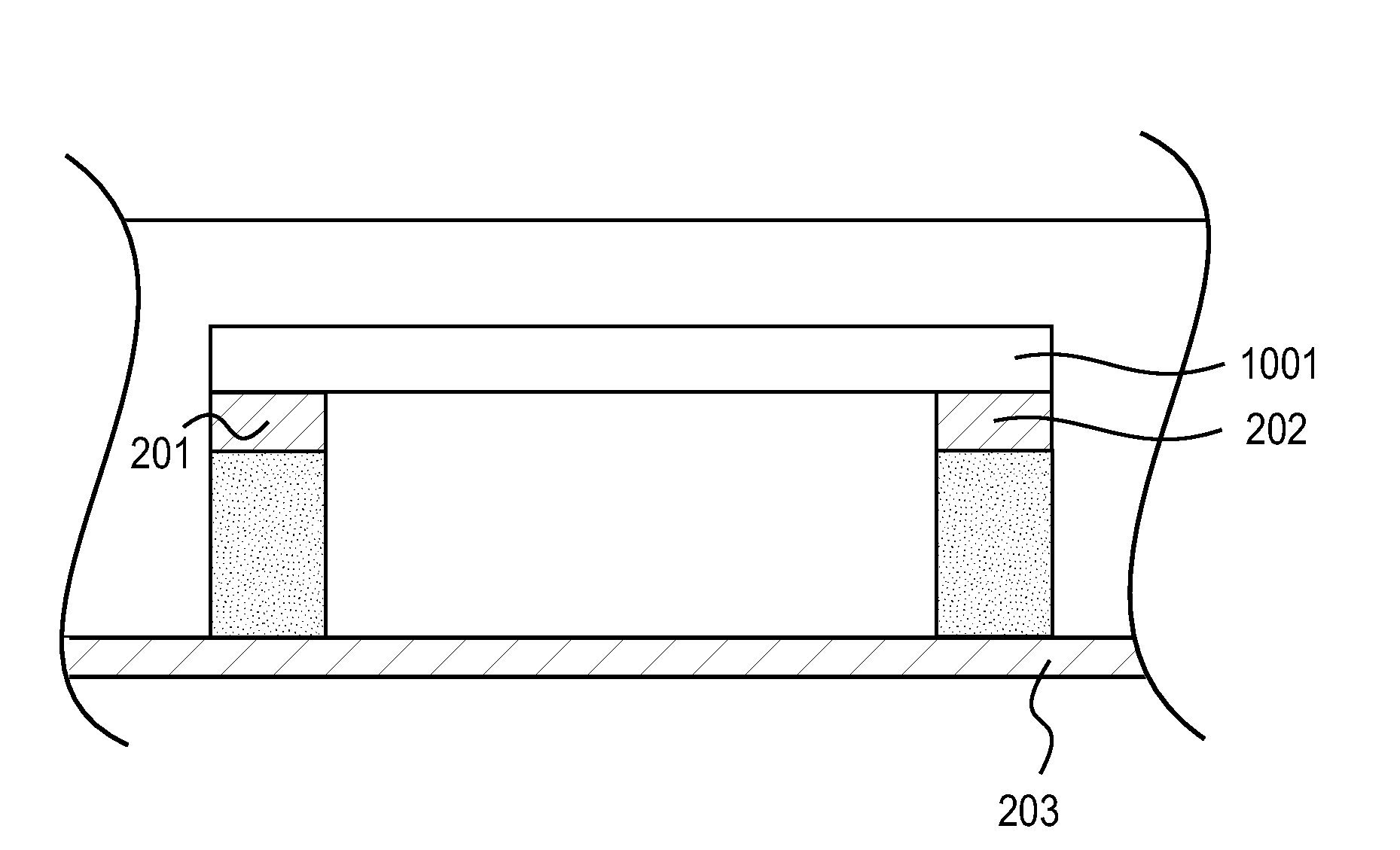

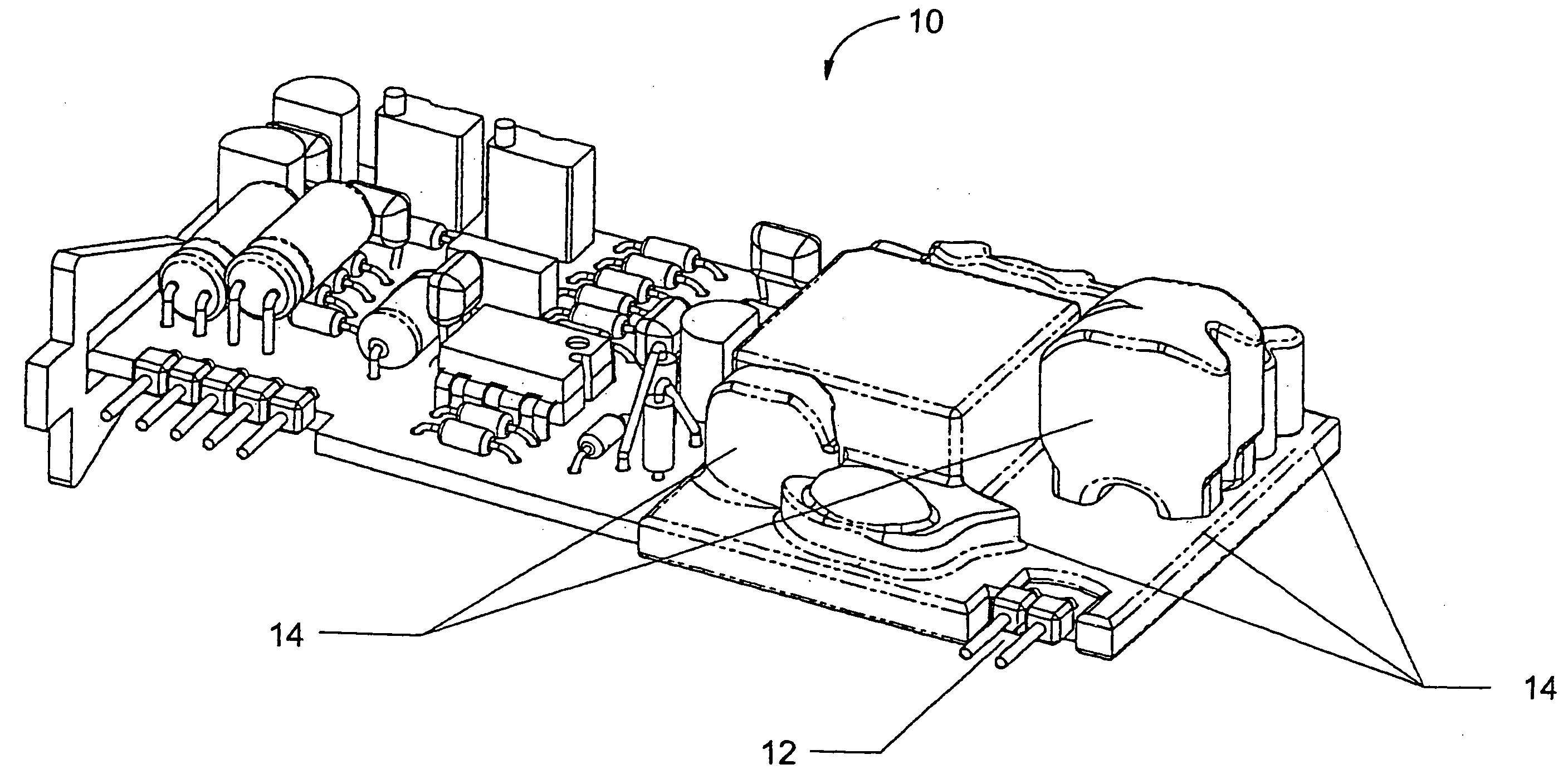

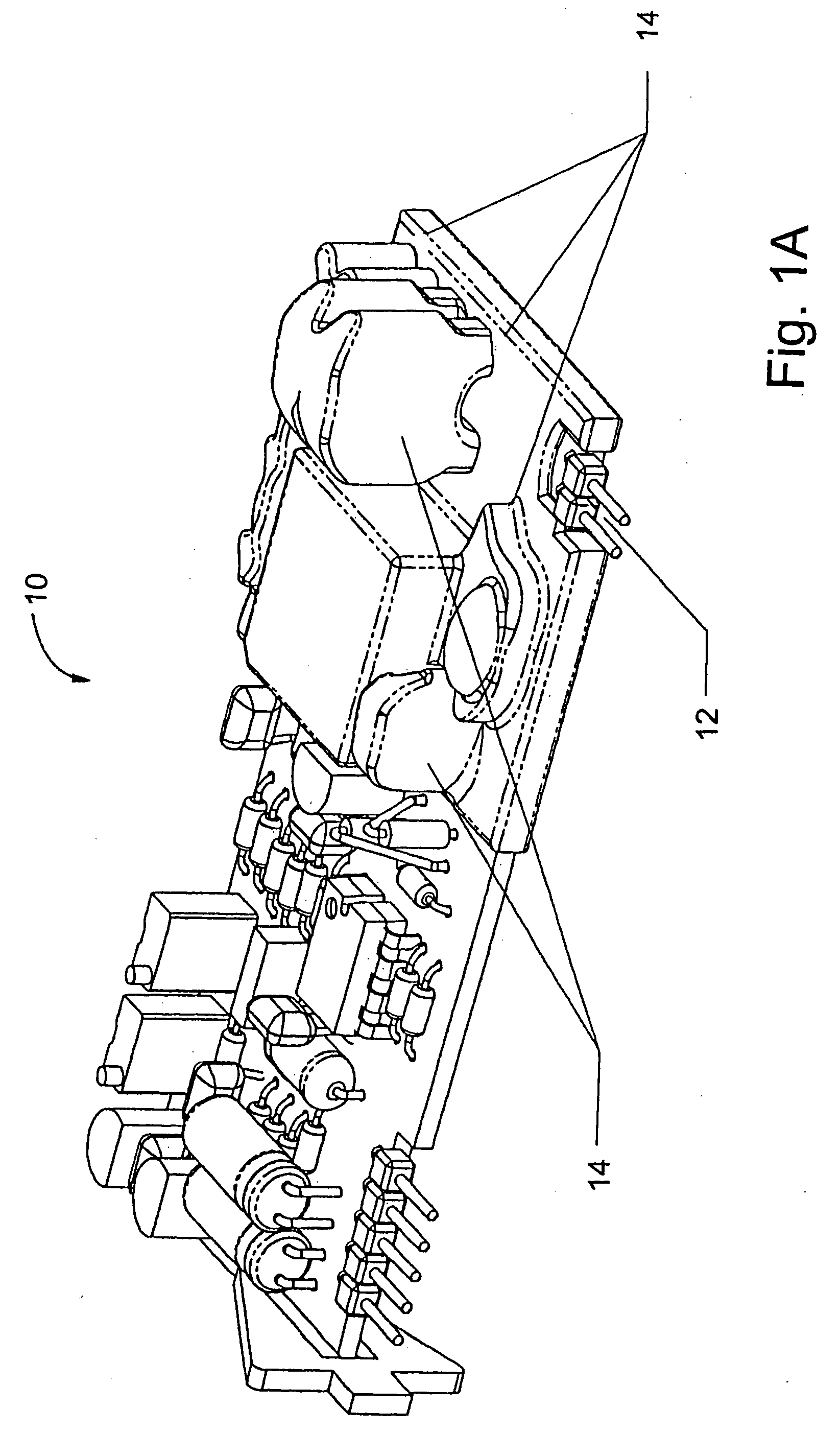

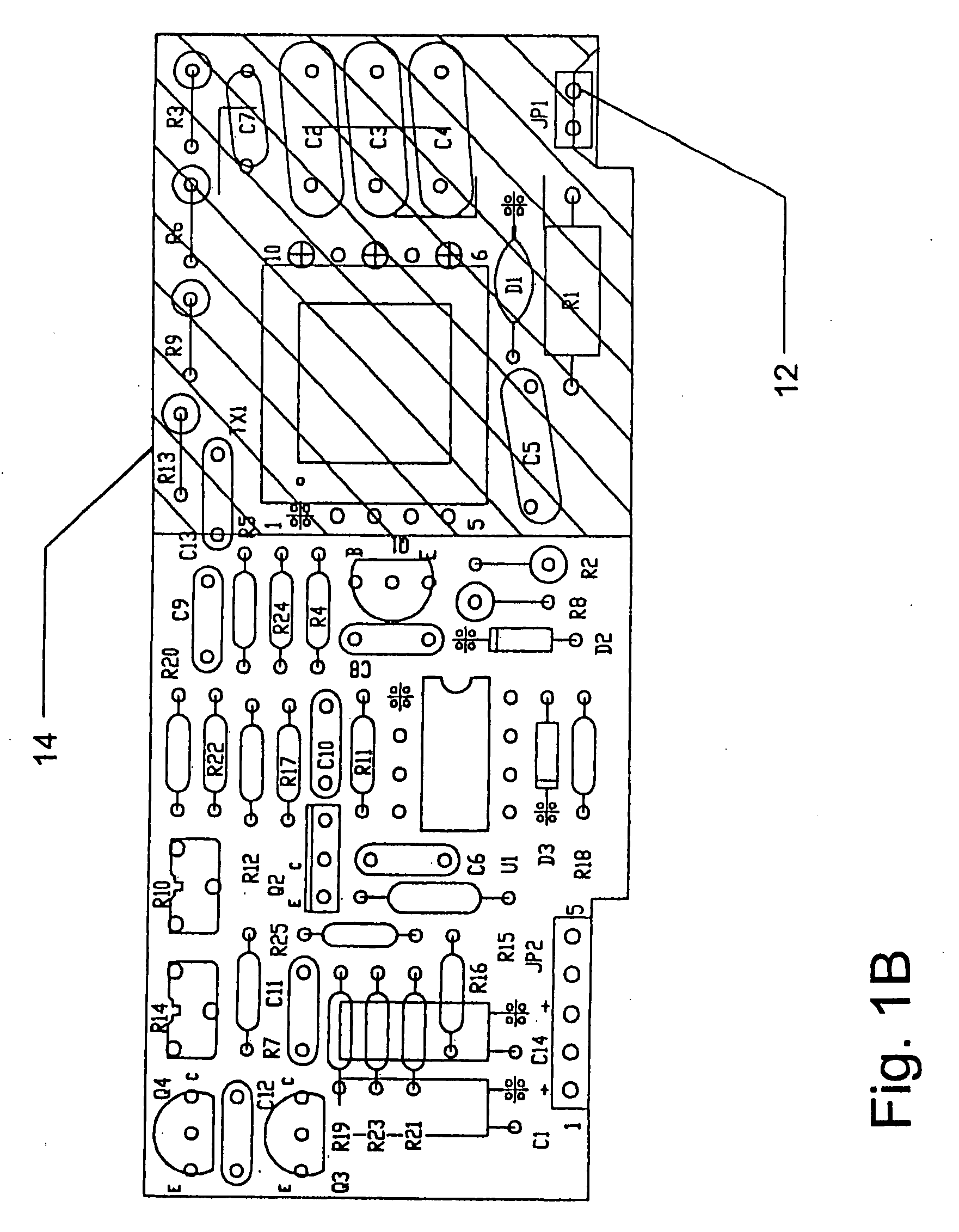

Selective Encapsulation of Electronic Components

InactiveUS20070289129A1Reduce processing timeReduced material requirementsPrinted circuit assemblingLine/current collector detailsRoom temperatureEngineering

A method for the selective encapsulation of electronic components on a printed circuit board comprising, in one embodiment, the steps of delivering the printed circuit board to an encapsulating nest at room temperature; damming the target areas with a dam resin having a latent curing agent and deposited in the shape of walls of predetermined heights, according to the desired fill heights; dispensing a fill resin to fill the dammed areas; and curing the dam and fill resins for a suitable amount of time. In a different embodiment, the invention comprises the additional steps of laying resin beads, each in a position corresponding to the footprint of each target component; and of positioning the target components over the beads and soldering the components.

Owner:LHV POWER

Friction weld coaxial connector and interconnection method

ActiveUS20120129389A1Cost-effectiveSmall sizeElectrically conductive connectionsContact member assembly/disassemblyFriction weldingElectrical conductor

A coaxial connector for interconnection with a coaxial cable with a solid outer conductor by friction welding is provided with a monolithic connector body with a bore. A sidewall of the bore is provided with an inward annular projection angled toward a cable end of the bore. A sidewall of the inward annular projection and the sidewall of the bore form an annular friction groove open to a cable end of the bore. The annular friction groove is dimensioned with a taper at a connector end of the friction groove less than a thickness of a leading end of the outer conductor. The taper provides an annular material chamber between the leading end of the outer conductor, when seated in the friction groove, and the connector end of the friction groove.

Owner:COMMSCOPE TECH LLC

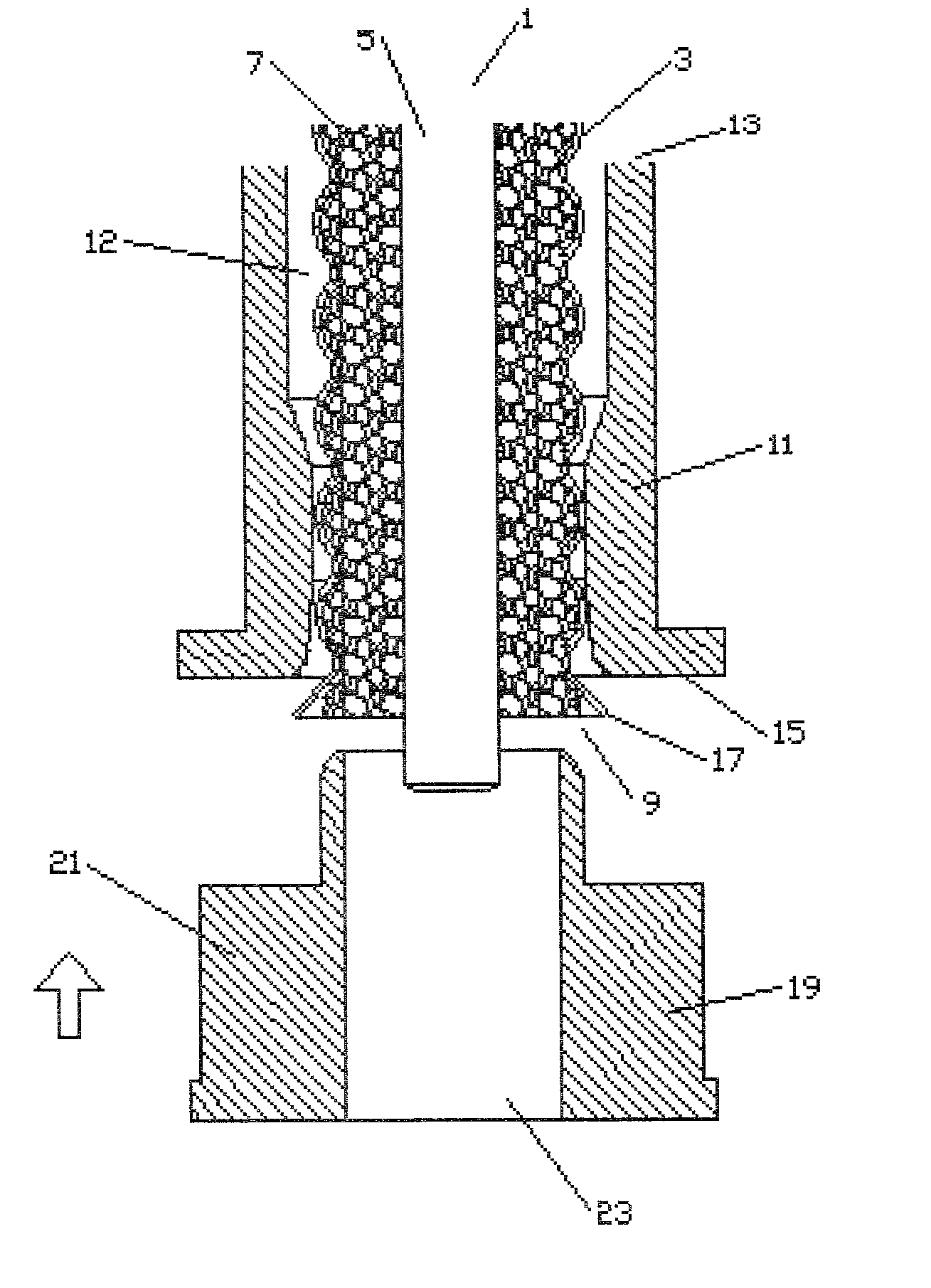

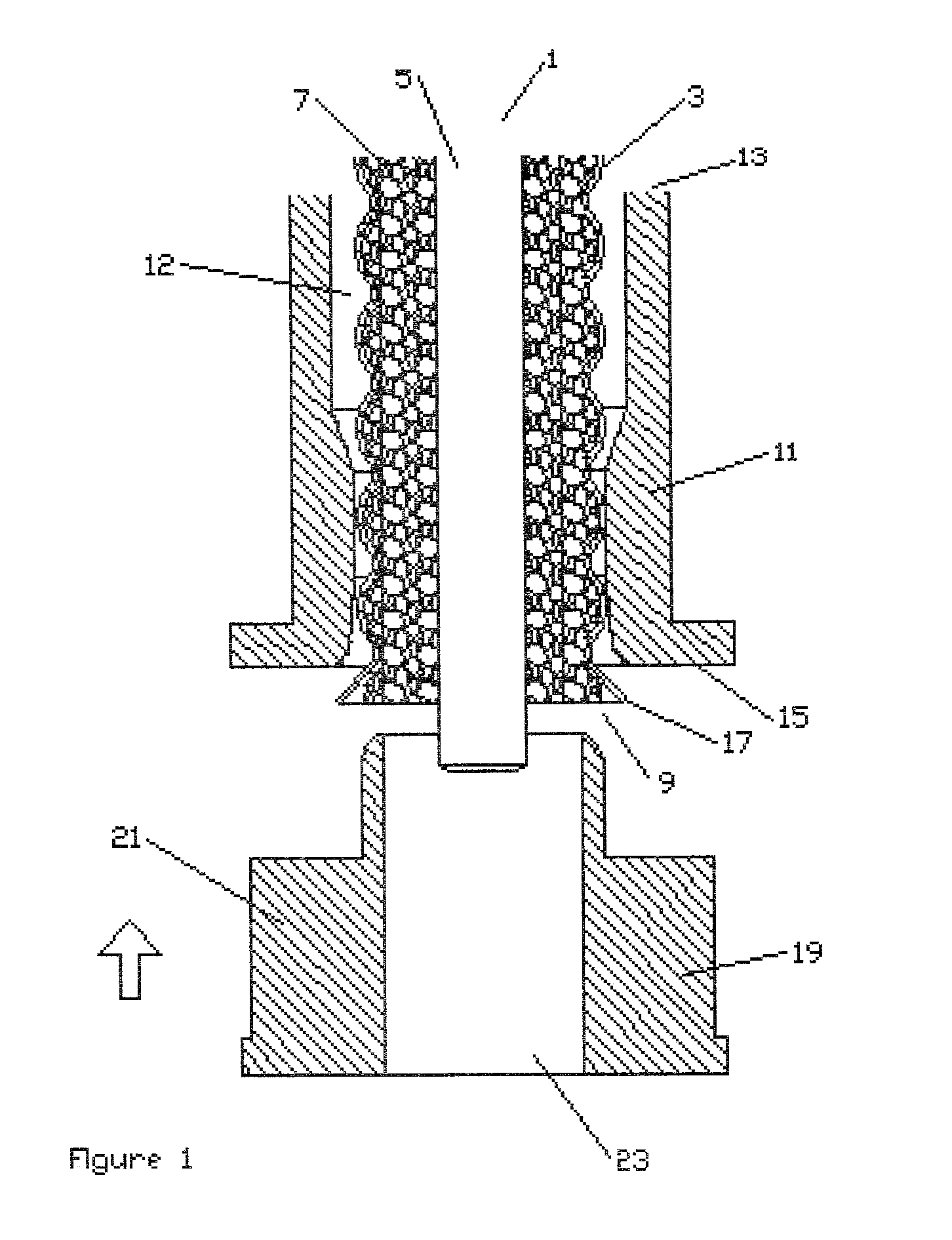

Method for reinforcing a fibre composite component and a vacuum mat and arrangement for producing a reinforced fibre composite component

InactiveUS20100314042A1Overcome disadvantagesReduce probabilityElectric discharge heatingLaminationEngineeringFibrous composites

In a method for reinforcing a fibre composite component for aviation and space flight, a vacuum mat is configured with at least one receiving portion for reproducibly receiving at least one reinforcing element. The at least one reinforcing element is introduced into the at least one receiving portion of the vacuum mat. The vacuum mat with at least one introduced reinforcing element is applied reproducibly in a sealed manner to the fibre composite component to be reinforced to form a mould portion and at least the formed mould portion is cured to connect the at least one reinforcing element to the fibre composite component. The vacuum mat is then removed from the reinforced fibre composite component so that the vacuum mat can be reused.

Owner:AIRBUS OPERATIONS GMBH

Panel antenna with variable phase shifter

ActiveUS7298233B2Low costSmall sizeDelay linesAntenna feed intermediatesPhase shiftedComputer module

A panel antenna having a variable phase shifter module with at least one main-PCB having an input trace coupled to a wiper junction. An arcuate trace on the main-PCB extending between a first output trace and a second output trace, the arcuate trace having an arc center proximate the wiper junction. A wiper-PCB having a linking trace thereon; the wiper-PCB rotatably coupled to the main-PCB proximate the wiper junction with the linking trace facing the first main-PCB. Because the linking trace faces the main-PCB, the wiper-PCB may be formed from inexpensive and structurally resilient substrate material. The linking trace coupling the wiper junction with the arcuate trace. Multiple arcuate traces may be linked to further output traces to add additional outputs, each having variable phase shift between them, depending upon the position of the wiper-PCB. Multiple main-PCBs may be stacked upon each other and the wiper-PCBs of each controlled by a common linkage.

Owner:COMMSCOPE TECH LLC

Composite shingle

InactiveUS20110047894A1Reduce material usageSmall depthRoof covering using tiles/slatesBuilding repairsEngineeringBuilding construction

A composite shingle having unitary construction is presented that includes a body shell, a plurality of longitudinal ribs, and a plurality of rib stiffeners. Further, the present composite shingle may also include transverse ribs, a depressed nailing zone, nailing zone ribs, and / or at least one alignment aid. The present composite shingle may also include spacing nibs. At least a portion of the outside face of composite shingle is textured to resemble slate or wood shake shingles. The butt end wall has a height that creates depth in composite shingle to more closely resemble true slate and shake shingles. The first side wall and second side wall generally taper from a greater height at the butt end to a lesser height at the top end. The longitudinal ribs extend downward from the bottom surface of the body shell to a common plane. There is a plurality of rib stiffeners that also extend downward from the bottom surface of the body shell and each rib stiffener end is integral with a longitudinal rib. The depressed nailing zone may also include nailing zone ribs. These ribs strengthen the area surrounding the nailing zone. Composite shingle may further comprise alignment aids including spacing nibs, a scale and / or a laying line. Additionally, the spacing nibs may be used in concert with a scale located on the top surface of the top surface to help the installer create offset composite shingle patterns or help make sure all the composite shingles have a uniform tab exposure.A plurality of assembled composite shingles of the present invention is also claimed as part of this invention. Finally, a method of applying multiple courses of shingles on a roof comprising the steps of providing an underlying shingle, coupling this shingle to the roof, laying an overlying shingle of the present invention on top of a least a portion of the underlying shingle and coupling the overlapping shingle to the roof is presented.

Owner:TAMKO BUILDING PRODS

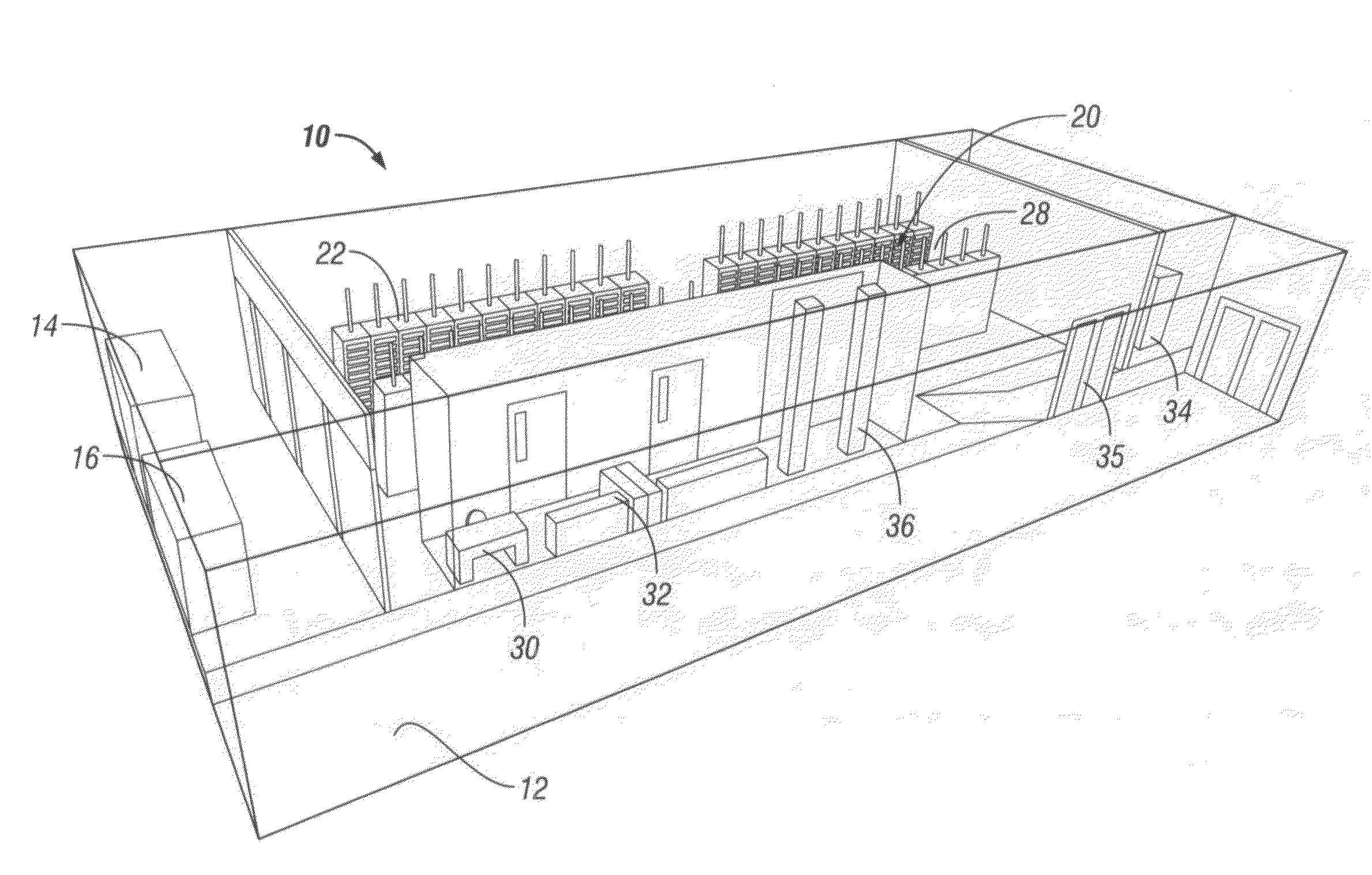

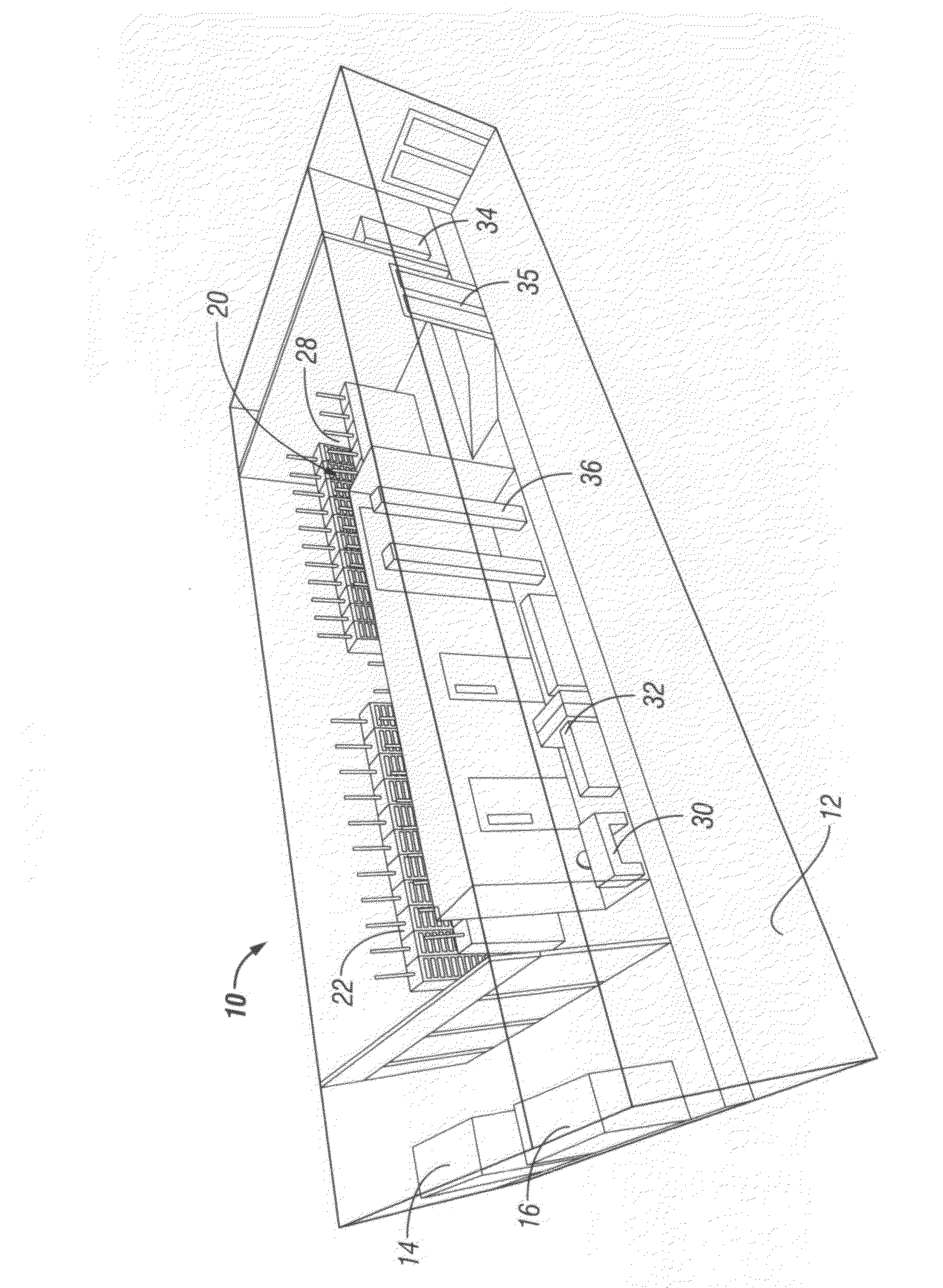

Data center facility for multi-tenant environment

InactiveUS20100223858A1Improve system reliabilityGood environmental stabilityPublic buildingsBuilding repairsData centerEngineering

A centralized common area data center for a tenant suite in large scale commercial office properties built in situ having a dedicated space, at least one computer module in the space and a self-sustaining cooling system to maintain a cooling temperature for the computer module consistent 24 / 7 / 365. This provides significant value in services and cost savings to both landlord and tenant. Each tenant can access greater levels of technology, security and energy efficiency.

Owner:DATA CENTS WORLDWIDE

Friction weld coaxial connector and interconnection method

ActiveUS8302296B2Cost-effectiveSmall sizeElectrically conductive connectionsContact member assembly/disassemblyFriction weldingElectrical conductor

Owner:COMMSCOPE TECH LLC

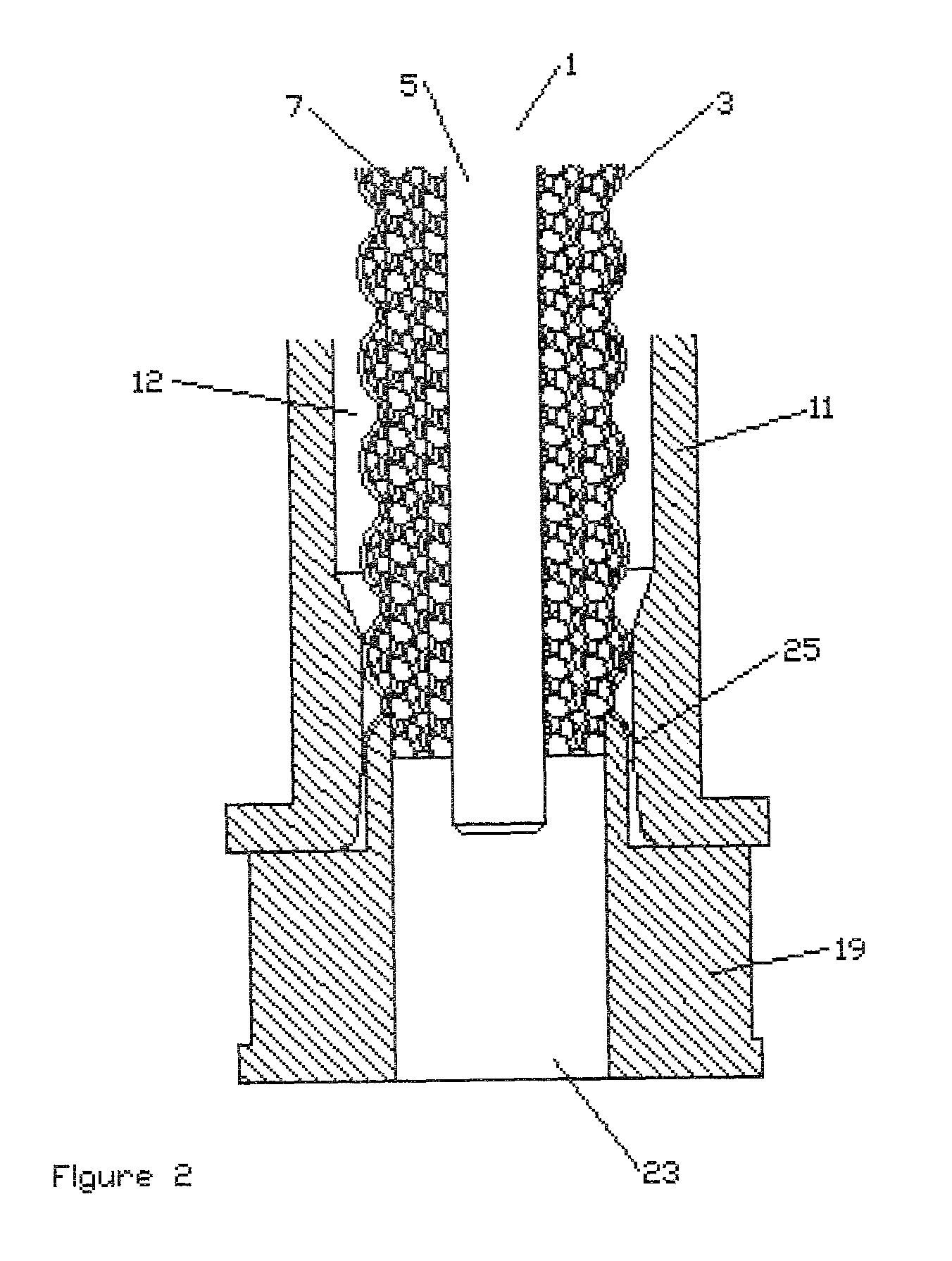

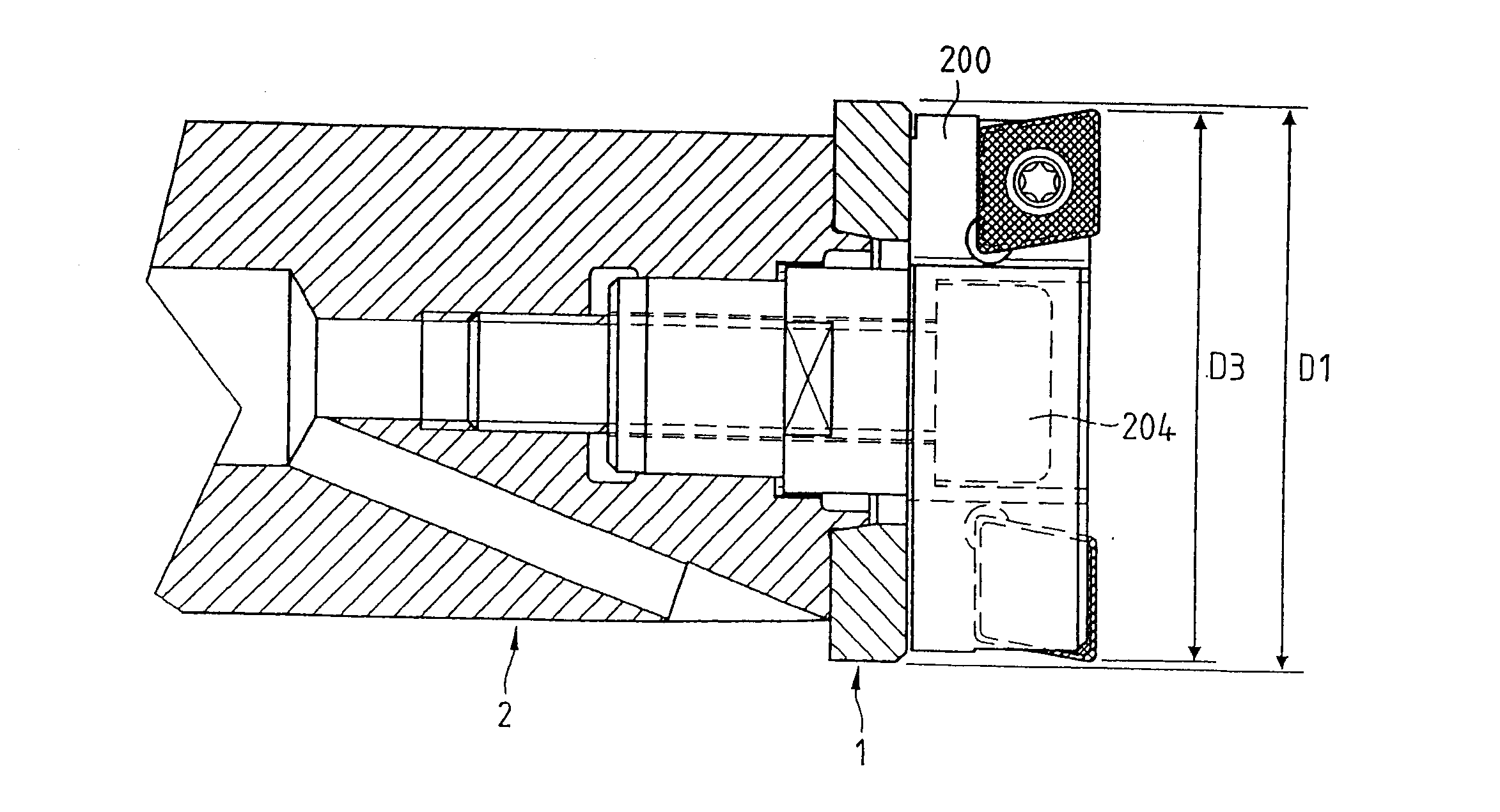

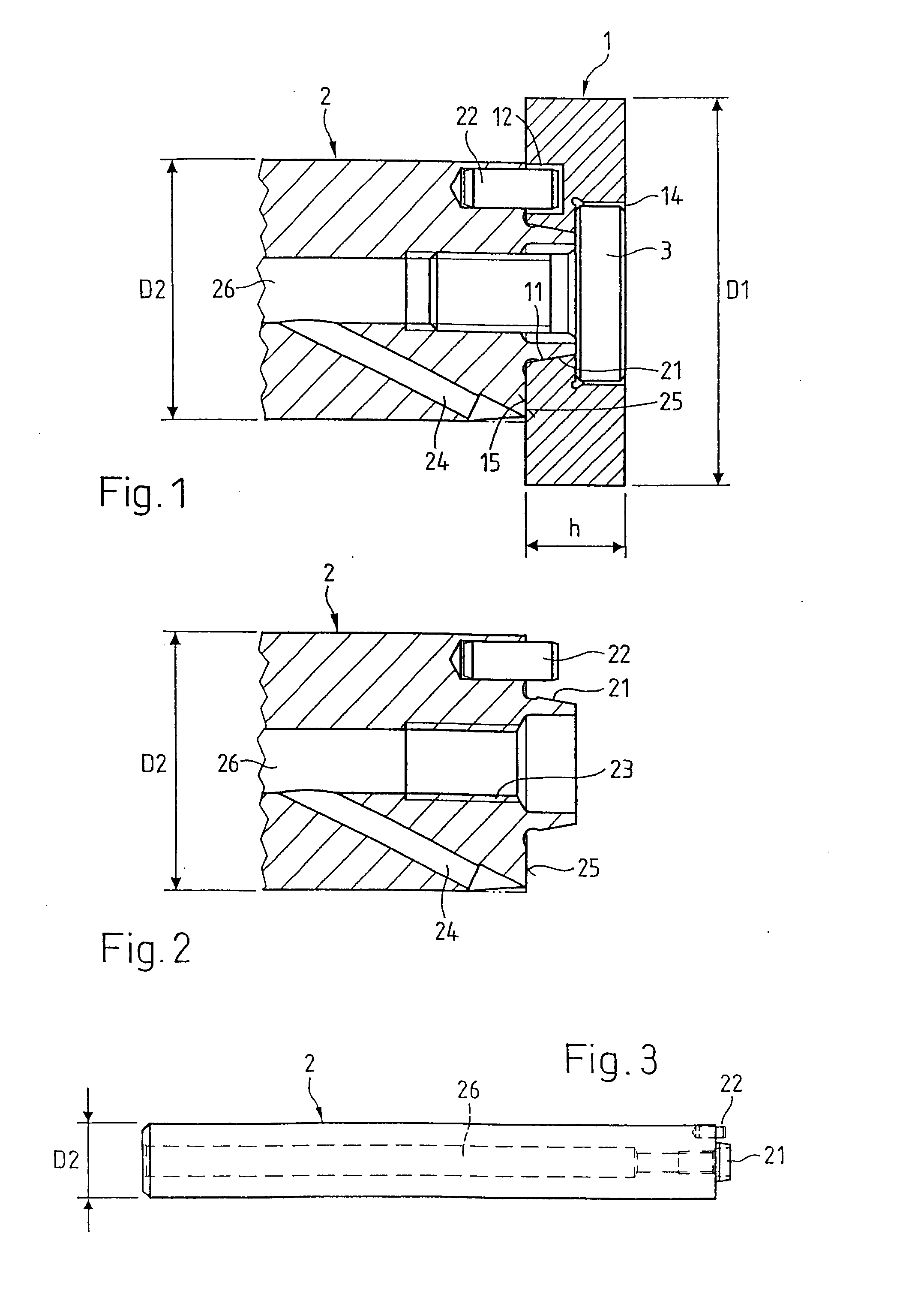

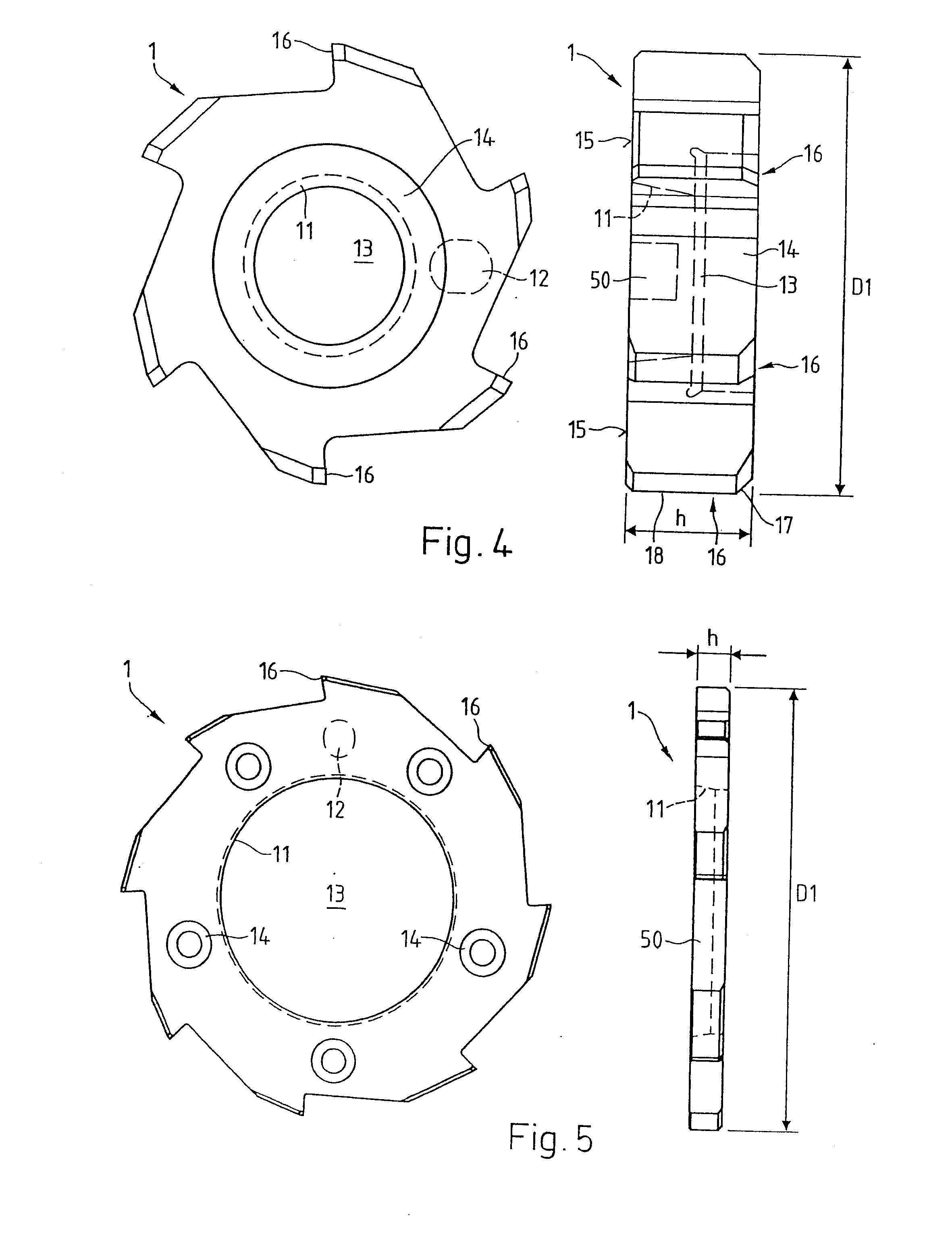

Machine friction tool, interchangeable head and shaft

ActiveUS20070067979A1Reduce manufacturing costSimple designTransportation and packagingAttachable milling devicesMaterial requirementsMillimeter

A machine reaming tool comprises a reaming head or interchangeable head (1) and a shaft (2), wherein the interchangeable head (1) is of one piece and may be exchanged, and in the axial direction and at each location, thus including means for the exchange adaptation, is thinner than a maximal thickness hmax, wherein this maximal thickness hmax is computed in millimetres from a diameter D1 of the interchangeable head in millimetres as hmax =6 mm+(1 / 10)·(D1−12 mm). On account of this, a guide portion (18) for cutters of the reaming head (1) becomes very much shorter than usual, but despite this ensures an adequate quality of machining. In a preferred embodiment of the invention, the interchangeable head (1) in a plane shaft-side end-face side end-face (15) comprises cutout (11) for the centring fastening on the shaft (2). The shaft (2) on an end-side plane surface (25) comprises a connection lug (21) which projects out of this plane surface in the axial direction and to which the cutout (11) of the interchangeable head (1) corresponds. The interchangeable head (1) thus has no axially projecting lug. The material requirement is further reduced, the manufacture of the interchangeable head (1) is simplified, and the material and manufacturing costs are reduced on account of this.

Owner:URMA

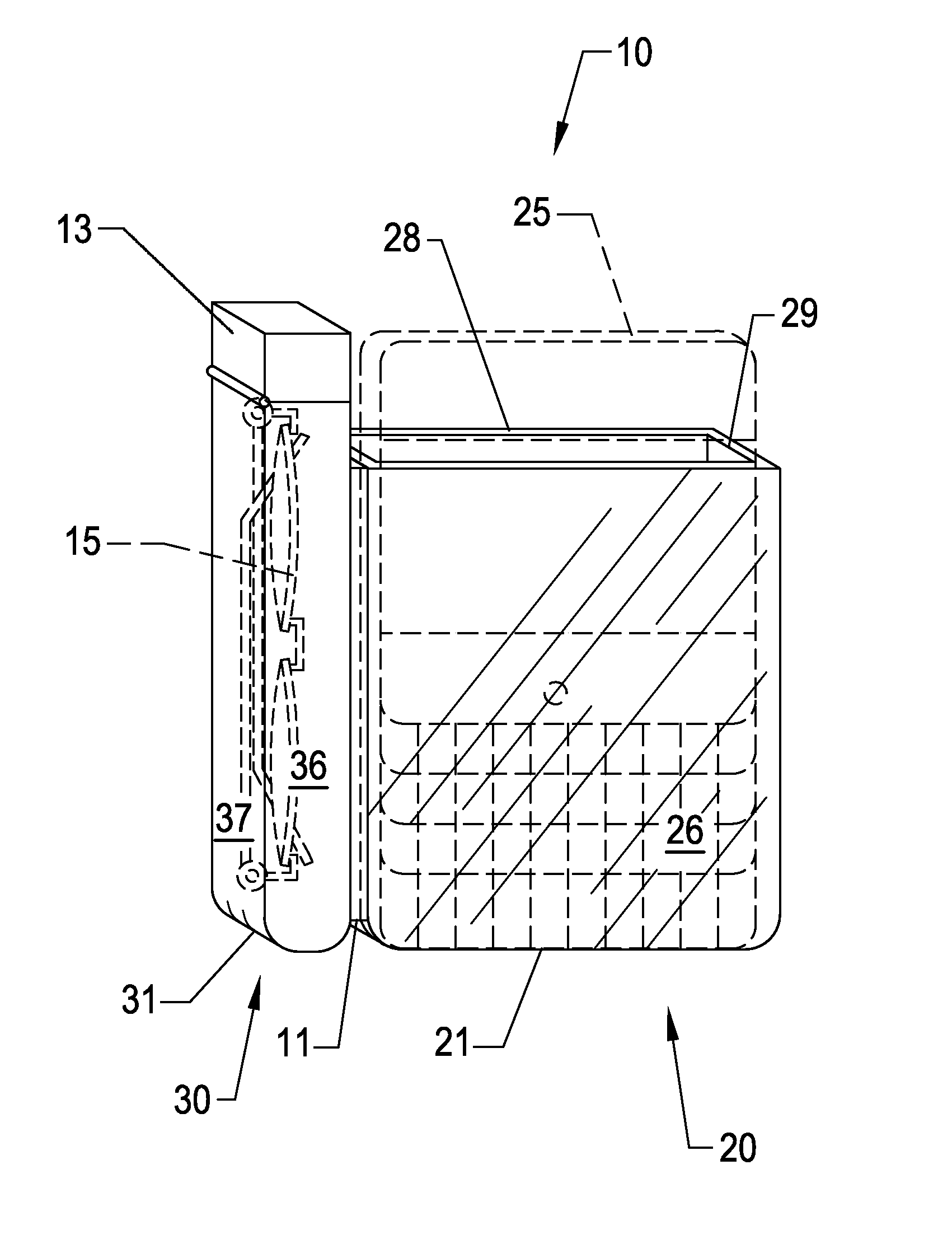

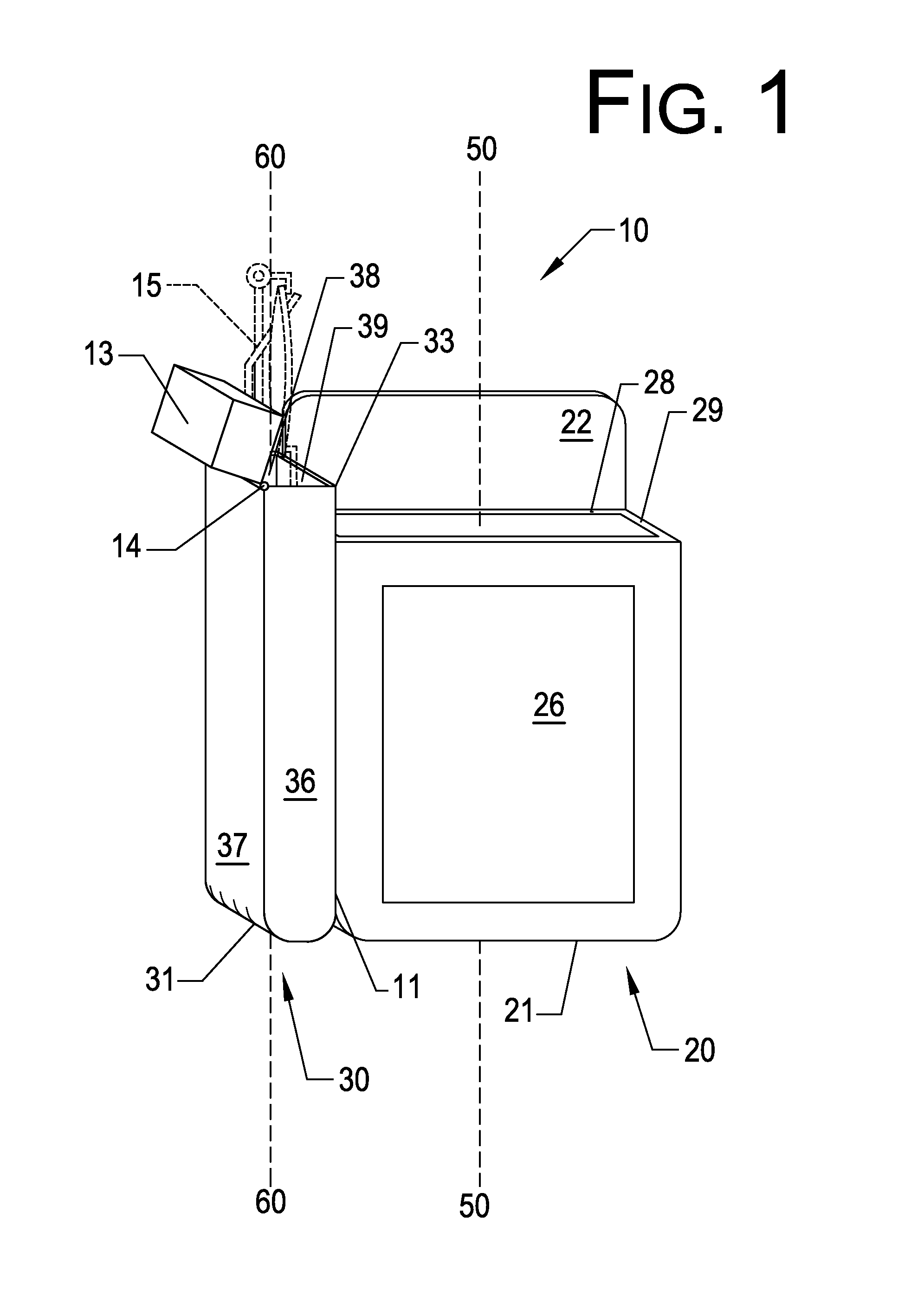

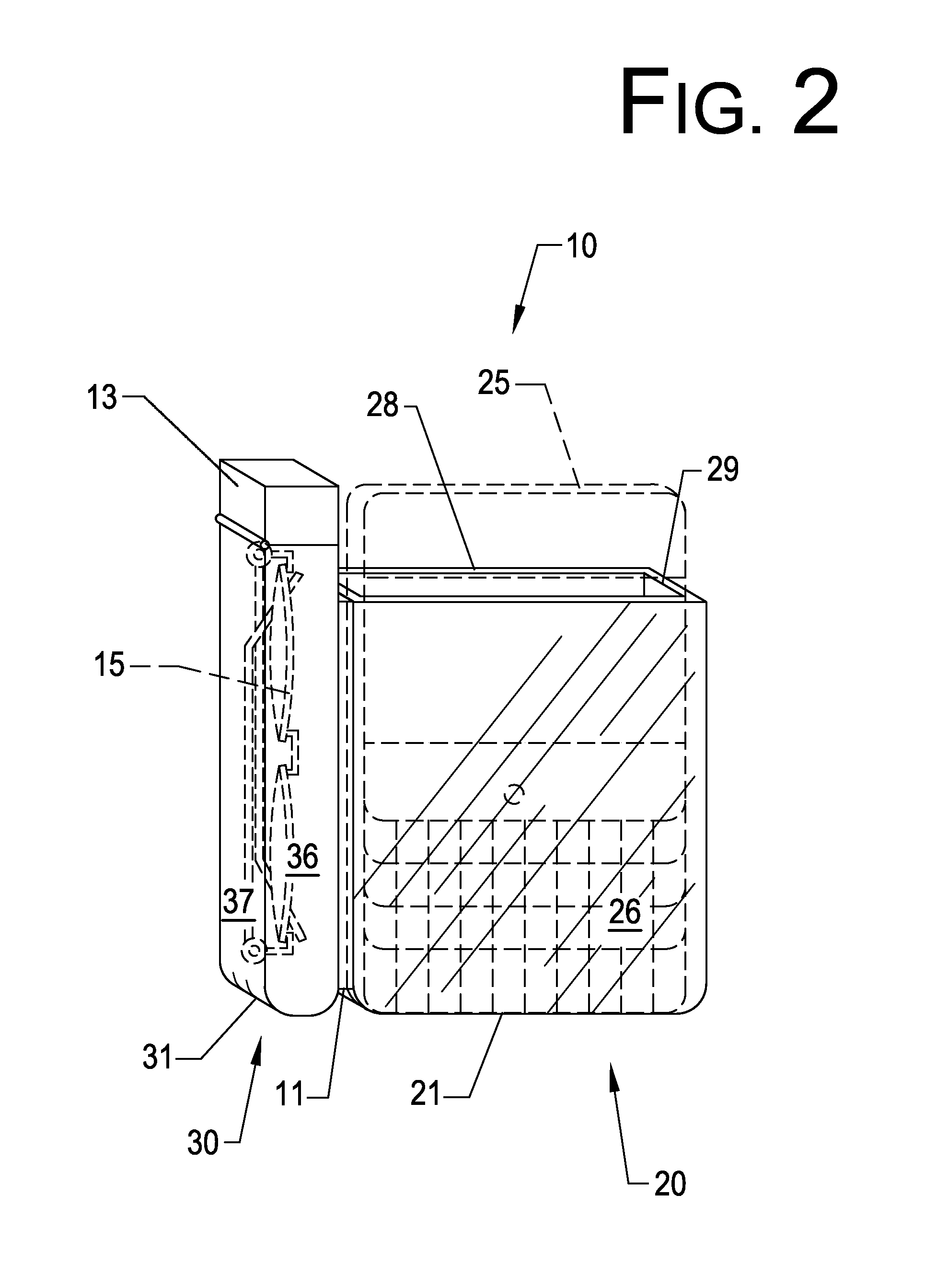

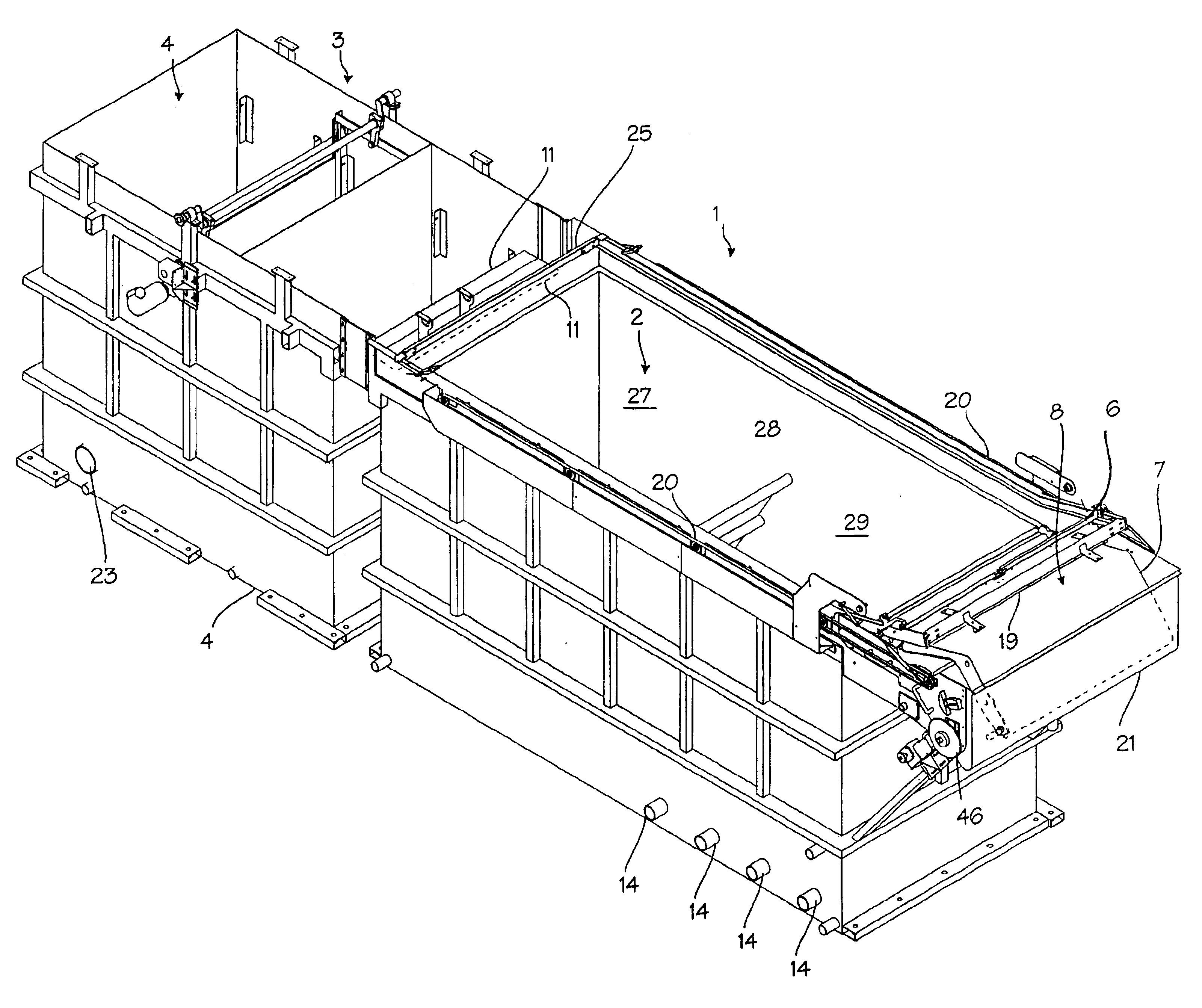

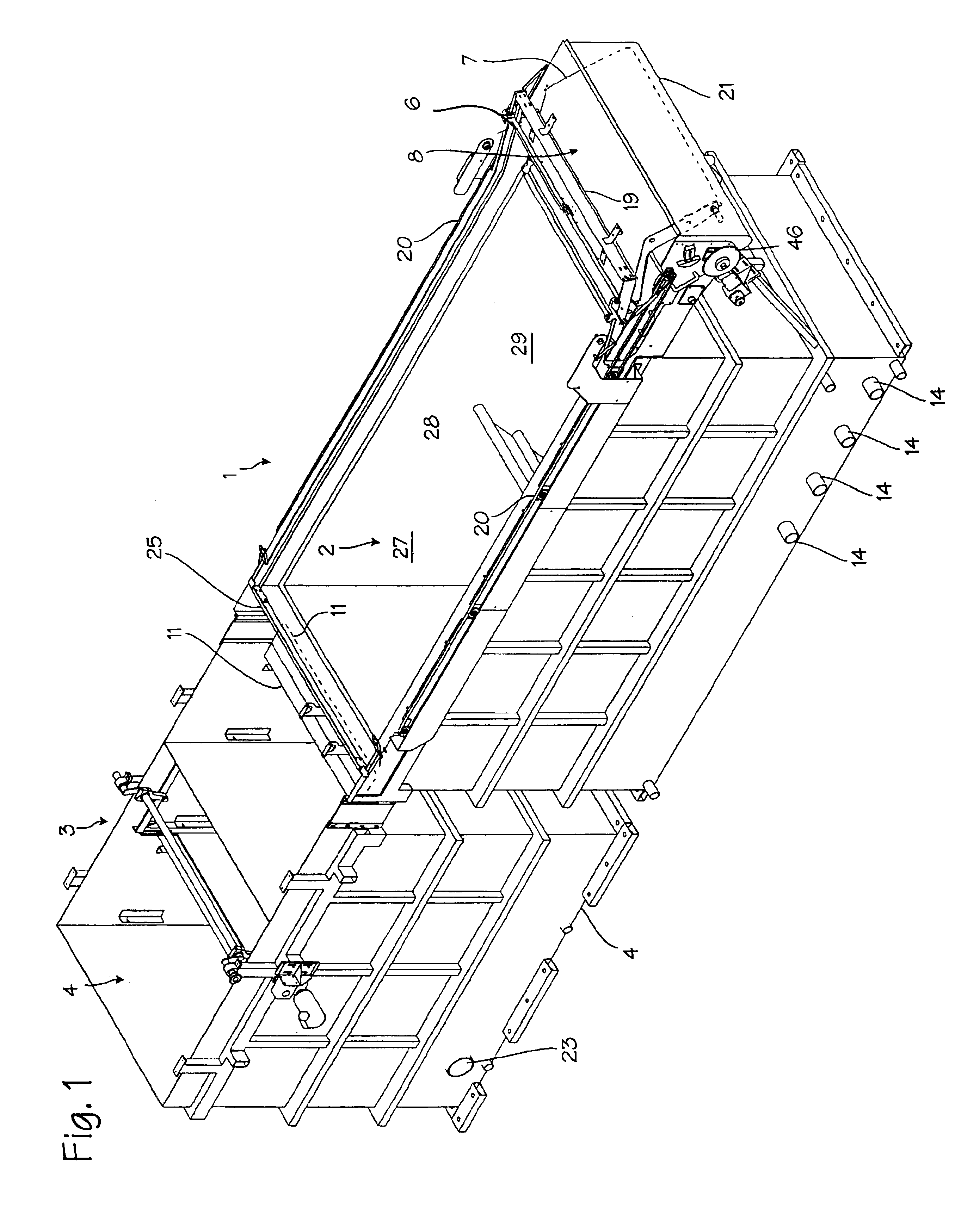

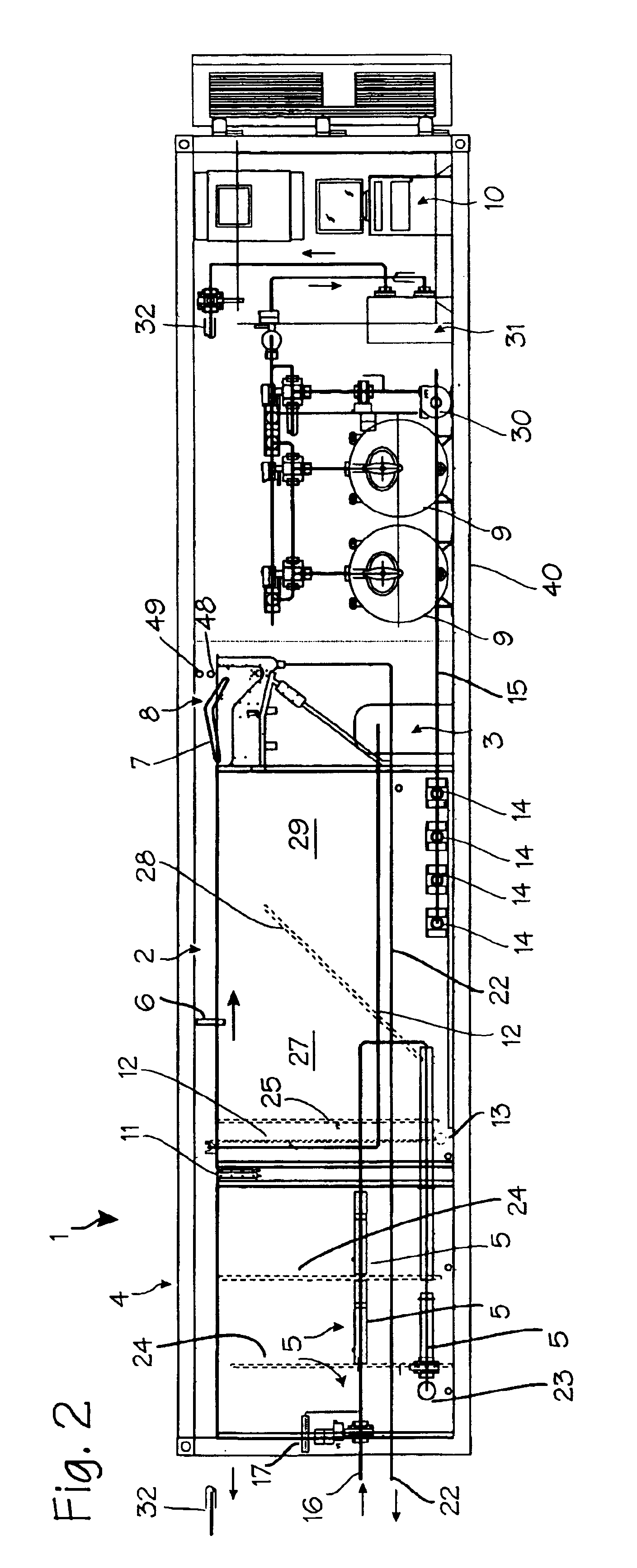

Dissolved air flotation system

InactiveUS6921478B2Continuous operationEasy disposalIon-exchanger regenerationSolid sorbent liquid separationFresh waterClean water

A dissolved air flotation system and method for purifying fresh water. The system is self-contained within a standard shipping container, with all components disposed in-line within the shipping container. Float is removed from the flotation tank with a skimmer that drives float downstream onto a conveyor belt, and the conveyor belt conveys float away from the flotation tank, in the downstream direction, and deposits the float in a collection tank. Clean water may be drawn from the flotation tank continuously, while float may be removed periodically.

Owner:SIONIX CORP

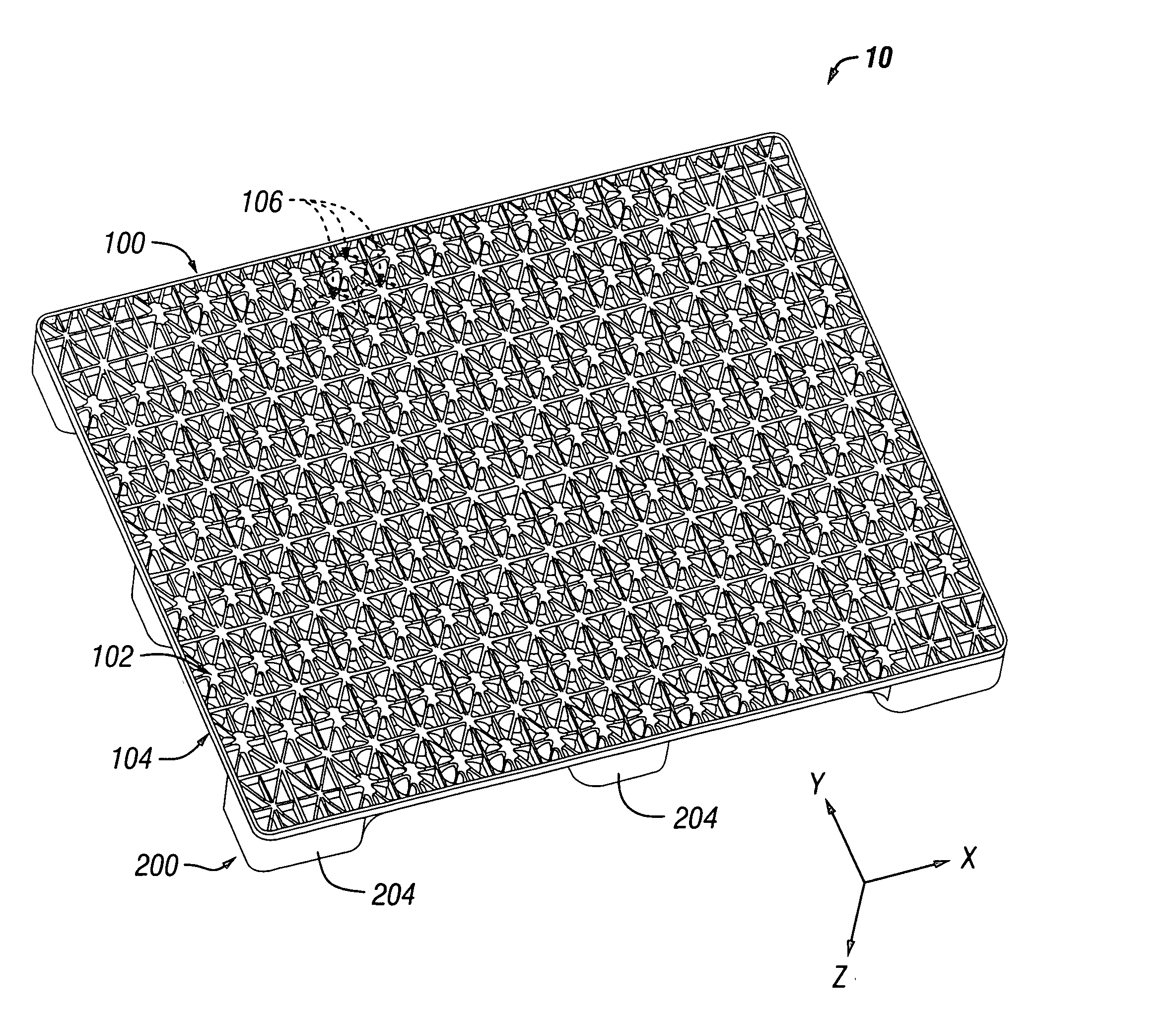

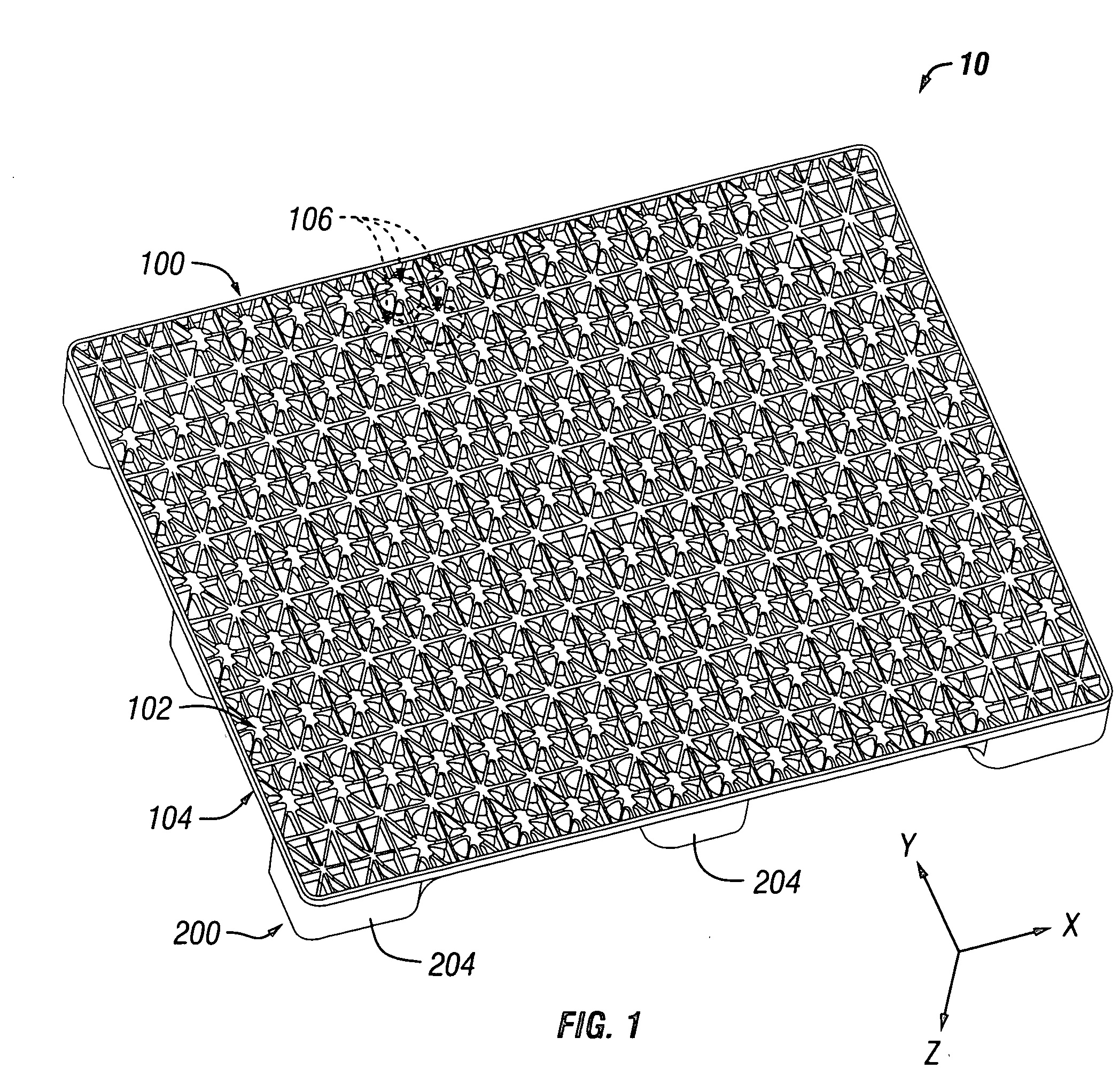

Rackable composite shipping pallet for transporting and storing loads

InactiveUS20050193927A1Improve rigidityHigh stiffnessBuilding componentsRigid containersRemote controlEngineering

A rackable pallet is disclosed that has a load bearing deck, a plurality of cross beams, and a plurality of removable base supports connected approximately perpendicular to the cross beams, and is made of a polymer. One disclosed pallet is open from the bottom and particularly suited for use in large automated warehouses, where machinery lifts and moves pallets by remote control. In one embodiment the pallet comprises a support structure that comprises a plurality of cross beams and a plurality of base supports connected to the cross beams. The deck and the cross beams typically define a single, injection-molded piece of polymer material. The base supports may be removable for repair or replacement. In one embodiment the load bearing deck has a plurality of domes in an array that provide high strength, stiffness, and rigidity.

Owner:HERRING CONRAD C +1

Roofing shingle system and shingles for use therein

ActiveUS8978332B2Reduced material requirementsReduce material usageRoof covering using tiles/slatesMetal working apparatusEngineeringMechanical engineering

A roofing shingle is disclosed comprising a headlap portion with a non-straight longitudinal edge and a buttlap portion with a plurality of tabs with a non-straight longitudinal edge and spaced apart by openings, wherein the non-straight longitudinal edges do not shadow each other laterally across the shingle. A roofing system is disclosed wherein at least a portion of the headlap portion of such shingle from a subsequently installed course overlaps at least a portion of the headlap portion of a shingle from a previously installed course. The maximum headlap overlap dimension is beneath the subsequently installed shingle laterally proximate the openings in the buttlap portion of the subsequently installed shingle. A method for making the shingle is disclosed comprising cutting a sheet of roofing material longitudinally along non-straight lines wherein at least a portion of each formed shingle has a width of about twelve inches.

Owner:BMIC LLC

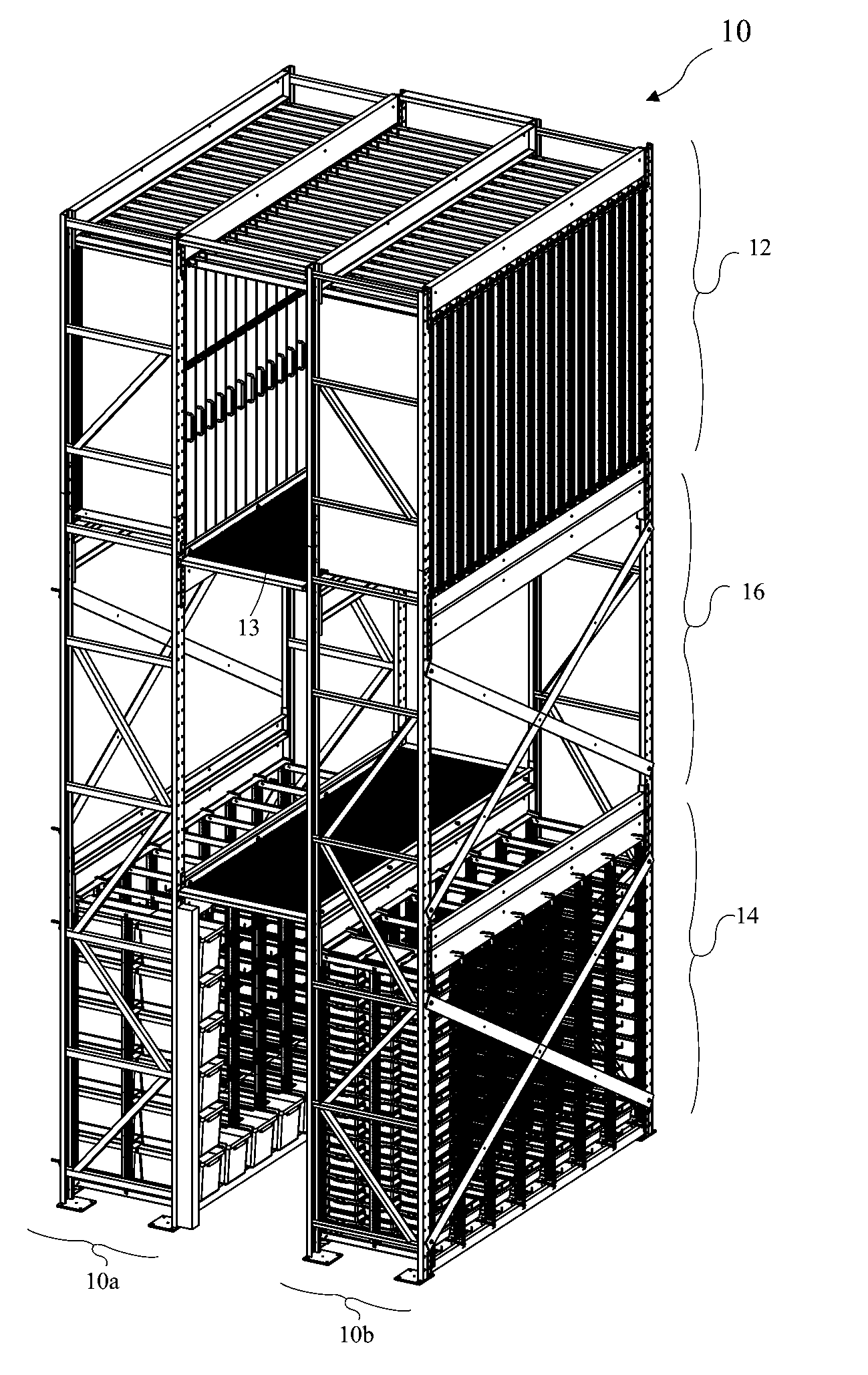

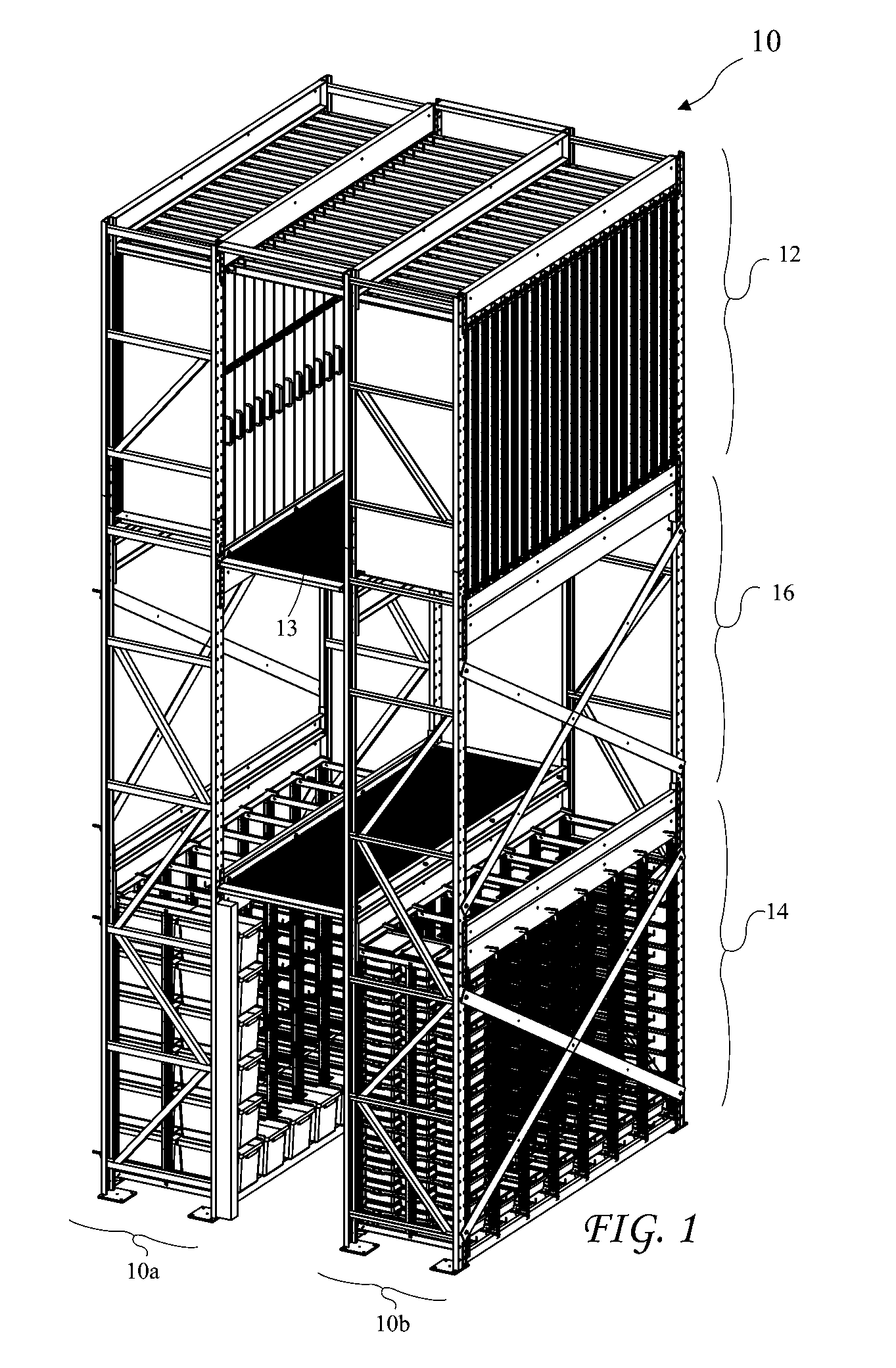

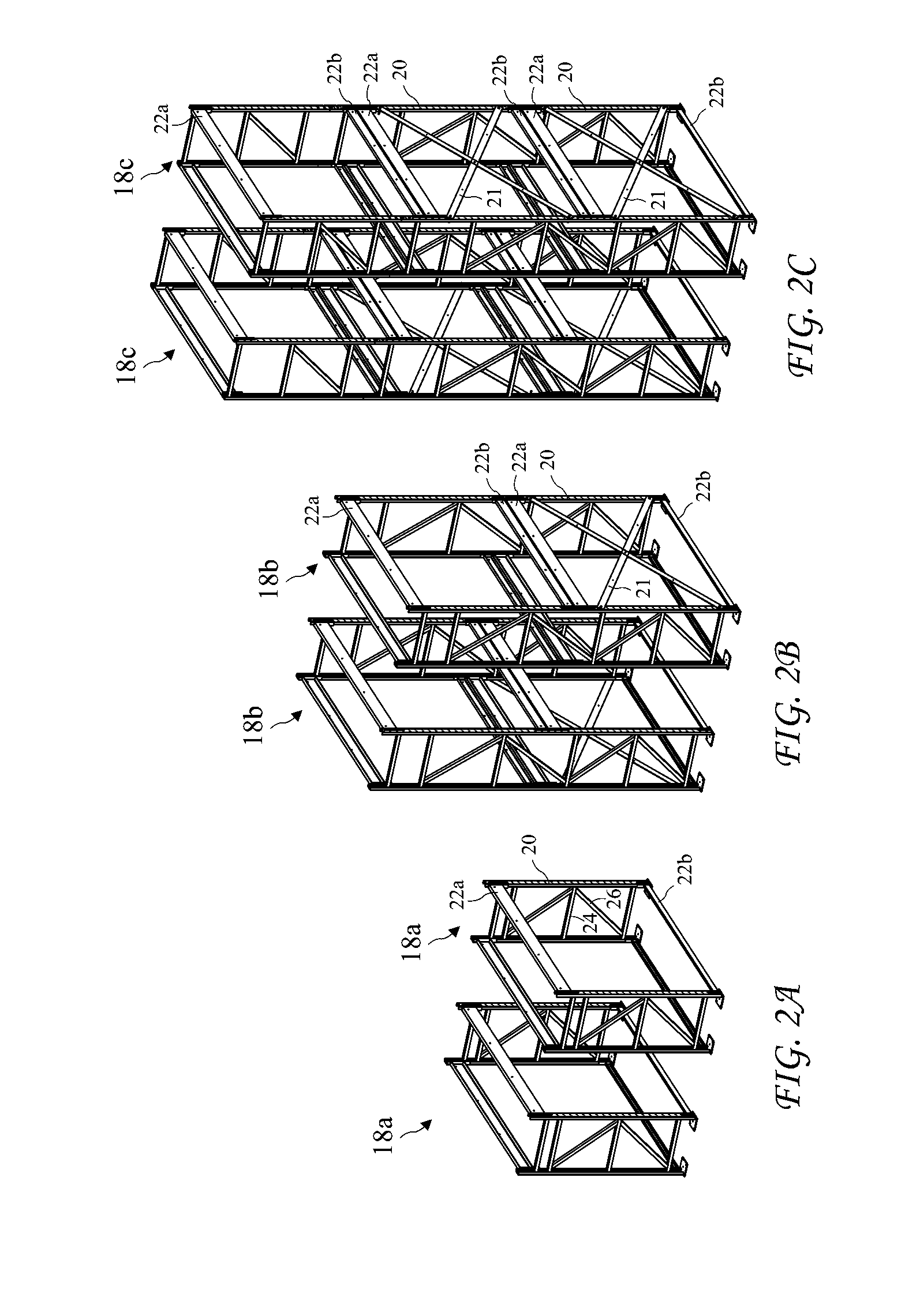

Convertible storage rack system

InactiveUS20100078399A1Minimizes strengthMinimizes material requirementKitchen equipmentDomestic articlesMagnetic tapeEngineering

A convertible media and document storage system uses elements of common pallet rack framing and is convertible between open slot and container storage. The container storage includes pilasters hanging from horizontal beam elements of the framing, and vertically spaced apart pairs of adjustable wireform racks engage the pilasters and provide horizontal ledges for supporting containers of various sizes. The use of hanging pilasters minimizes strength and material requirements. The open slot storage includes tall vertical drawers riding on overhead rails attachable to the same horizontal beam elements and individually horizontally drawn for access to the stored material such as data tape and disk media. The storage system optimizes utilization of space and allows large facilities to reconfigure storage between open slot and container storage when demands change.

Owner:HIGUEROA BERNARD A +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com