Rackable composite shipping pallet for transporting and storing loads

a composite and shipping pallet technology, applied in the field of shipping pallets, can solve the problems of heavy wood pallets, high cost, and affecting the performance of conventional shipping pallets, and achieve the effects of reducing the cost of wood pallets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

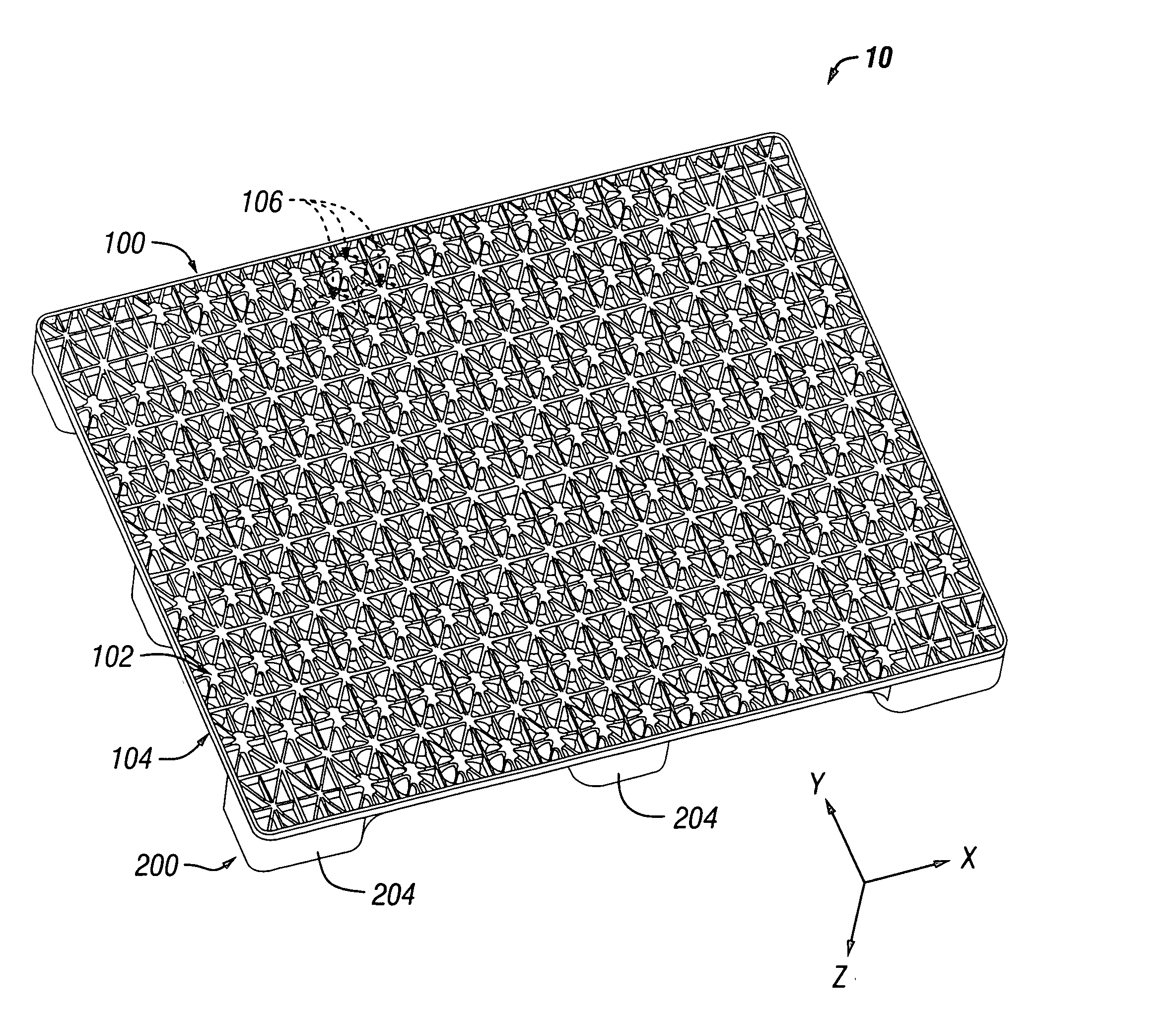

Image

Examples

Embodiment Construction

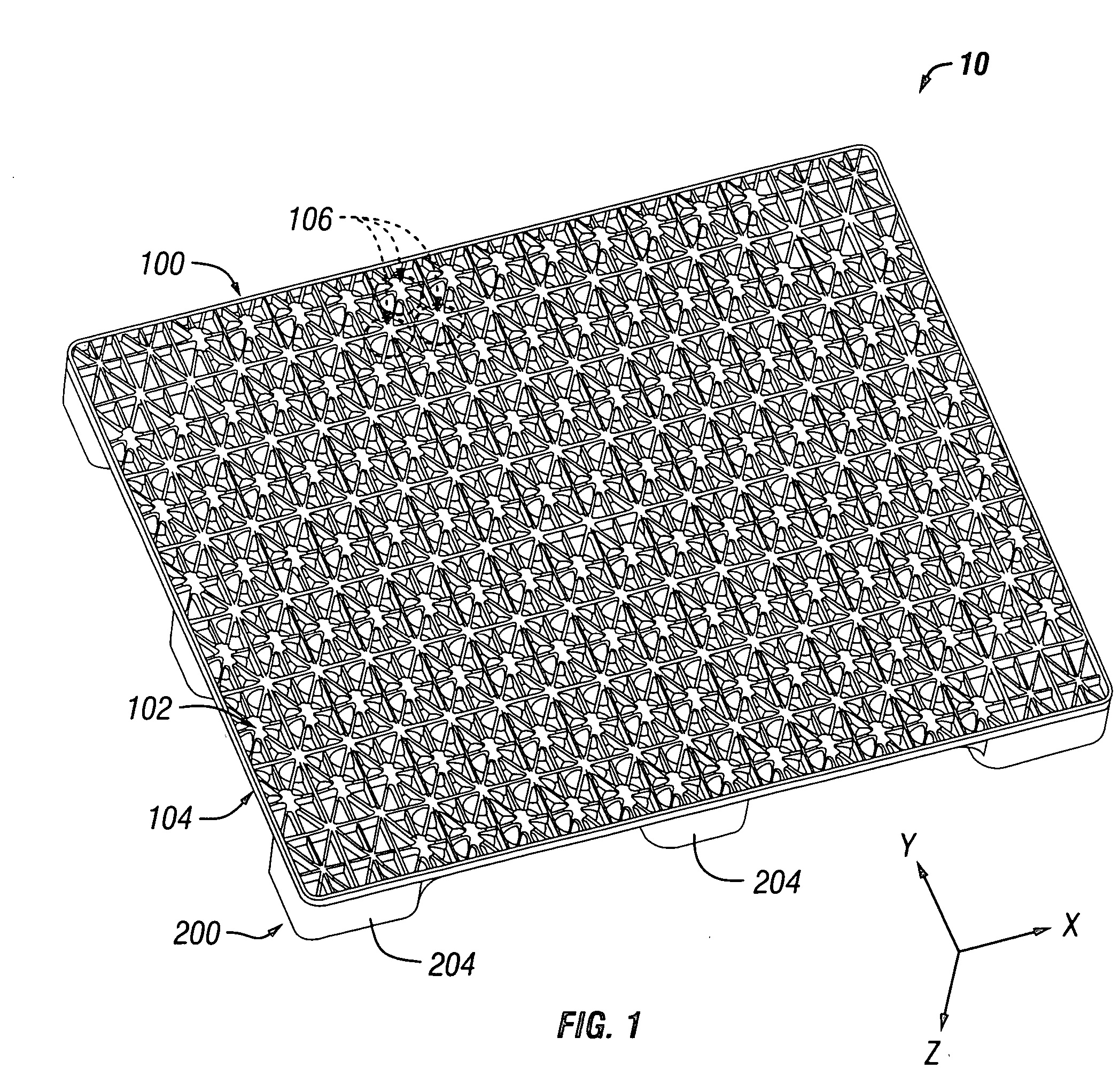

[0048] This invention is described in the following description with reference to the figures, in which like numbers represent the same or similar elements.

GLOSSARY OF TERMS AND ACRONYMS

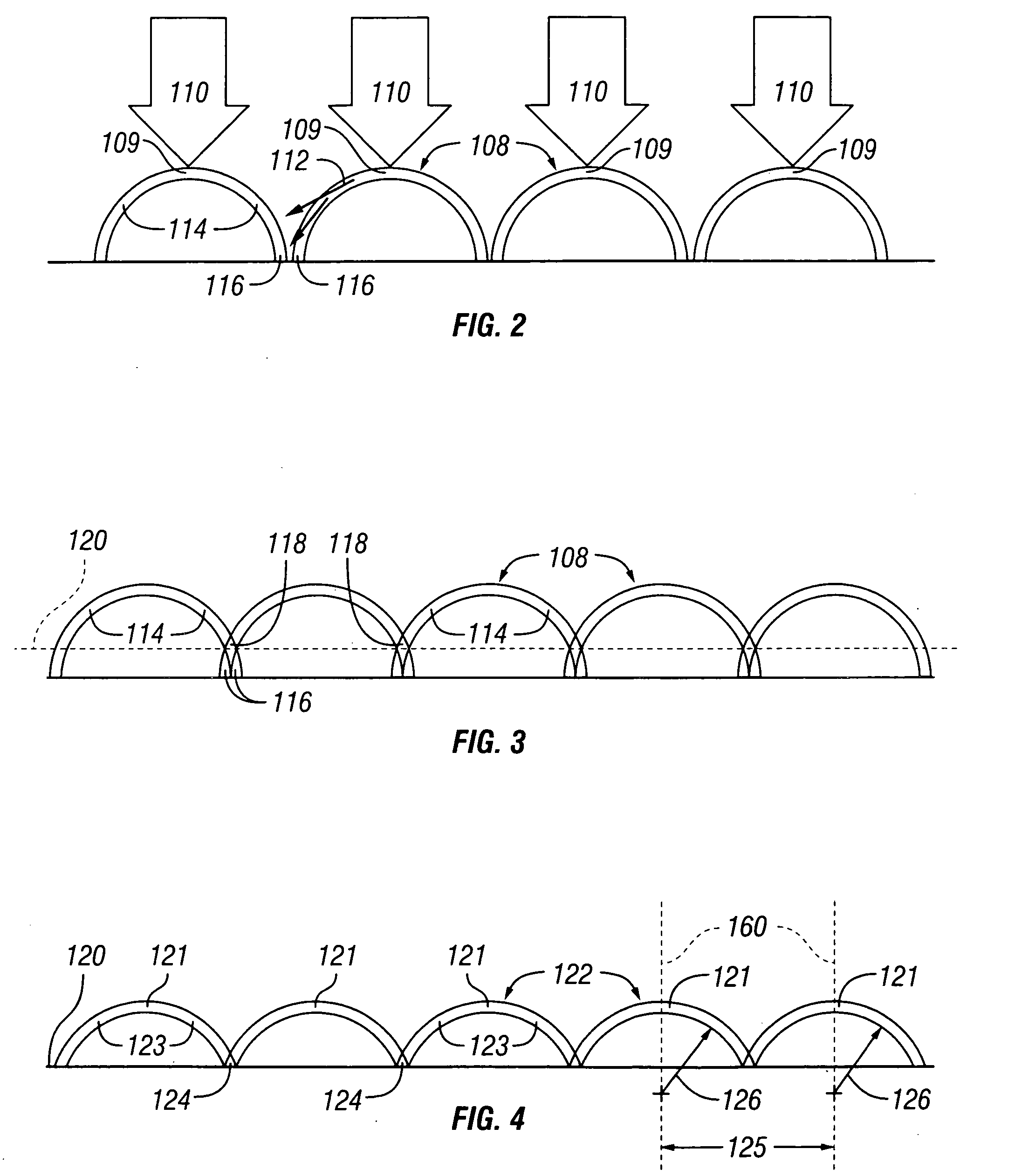

[0049] The following terms are used throughout the detailed description: [0050] arch A structure that begins at an apex has two legs that extend downwardly from the apex toward their lower ends. An arch transmits an applied load in two directions substantially laterally through the legs of the arch. A “full” arch extends fully from the apex through to a point wherein both legs are substantially vertically oriented at their lower ends. A “partial” arch has legs that have been truncated short of a full arch, such that the legs are non-vertically oriented at their lower ends. [0051] arch row A row comprising a plurality of arches. [0052] dome A three-dimensional element defined by a plurality of arches angularly arranged at varying degrees about a vertical axis extending through the apex of the arches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com