Flat welding strip pre-welding rotary table welding device

A technology of welding device and welding strip, which is applied in the field of flat welding strip pre-welding turntable welding device, can solve the problems of insufficient production capacity, achieve convenient and stable operation, good welding strip lapping effect, and improve efficiency and production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

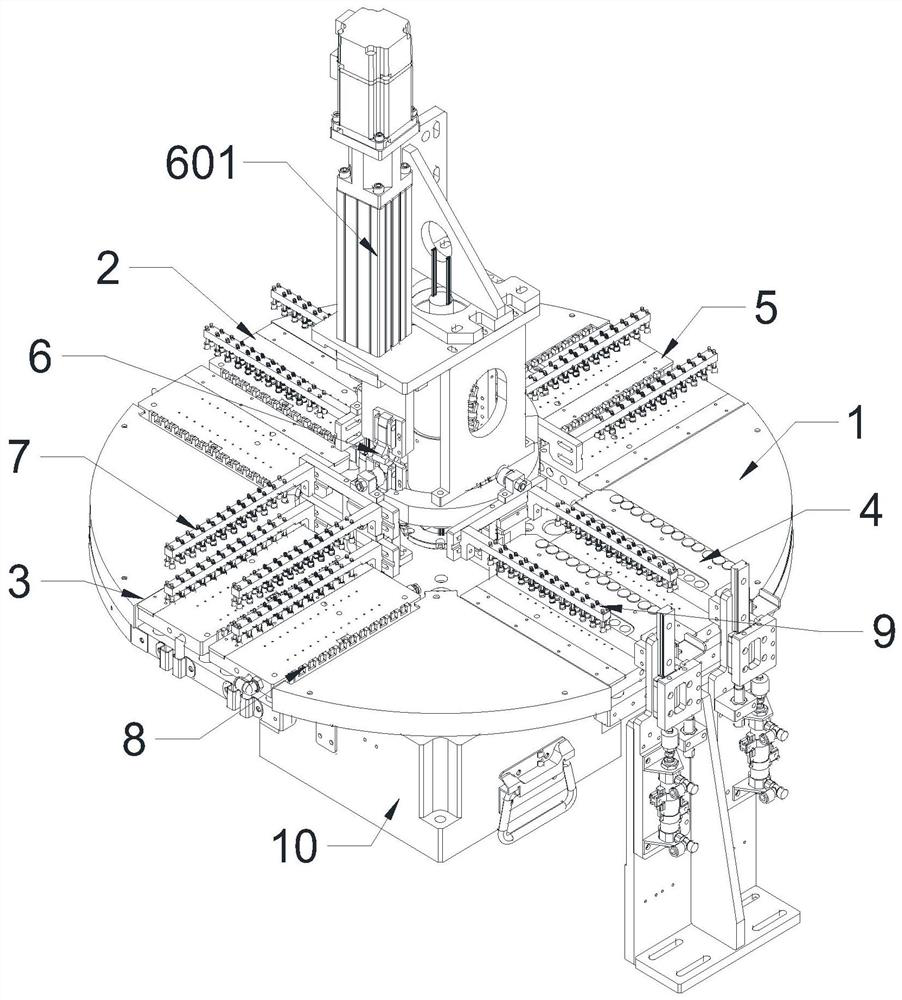

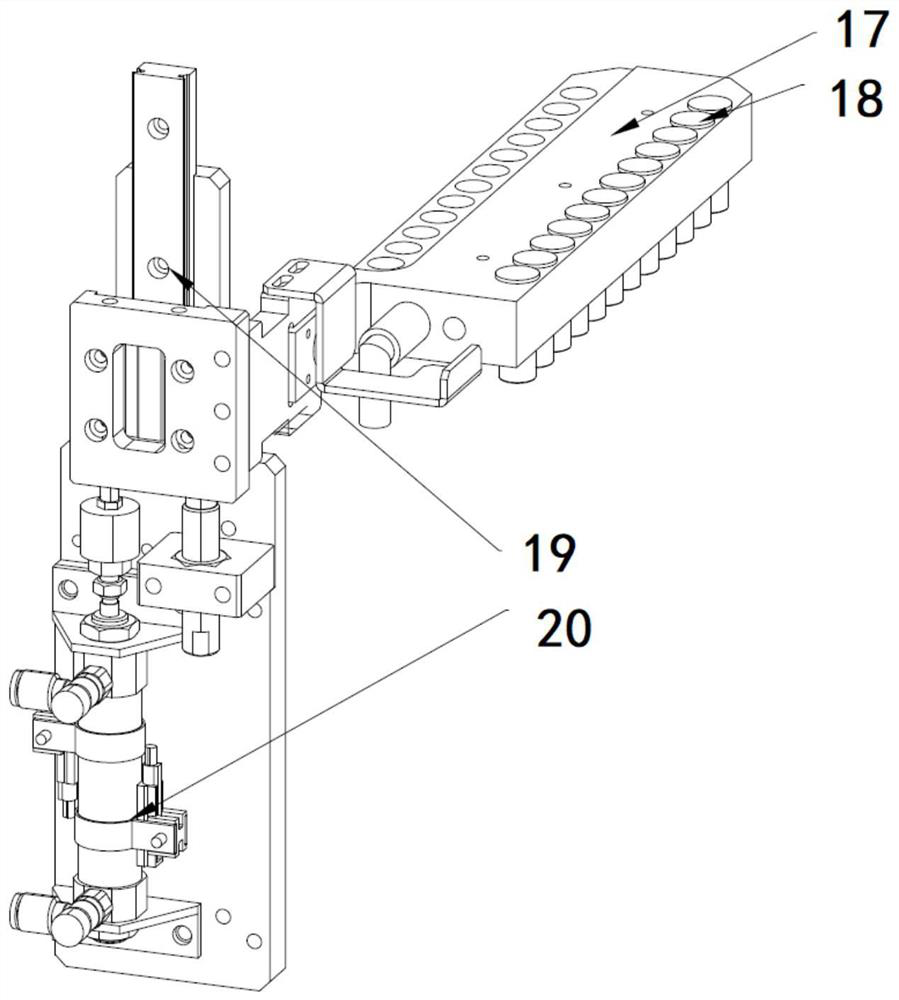

[0036] combined with Figure 1-4 , flat welding belt pre-welding turntable welding device, including a turntable 1, a first station 2, a second station 3, a third station 4, a fourth station 5, a pressing mechanism 6, a welding strip positioning structure 7 and Ribbon pre-welding mechanism 9.

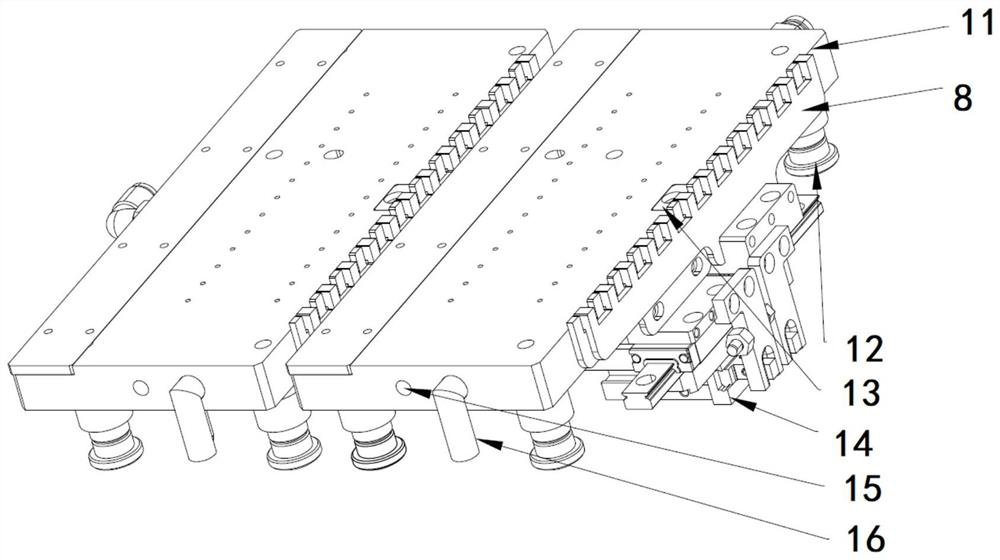

[0037] The turntable 1 is used to control the conversion of the soldering station 11, and includes a rotating shaft and a driving structure, and the rotating table 1 is connected to the driving structure through the rotating shaft. The turntable 1 and the soldering station 11 on it can be rotated, and rotate in steps of 90° to match the position of the station. The first station 2, the second station 3, the third station 4 and the fourth station 5 are evenly distributed on the turntable 1, and the turntable 1 of all stations is provided with a soldering station 11, a positioning clamp 8 and a positioning block 13. The positioning clip 8 and the positioning block 13 are used to positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com