Display substrate, manufacturing method thereof and display device

A display substrate and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as poor lap joints, affecting product yield, and output electrodes are easily over-etched, achieving Good lap performance and the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

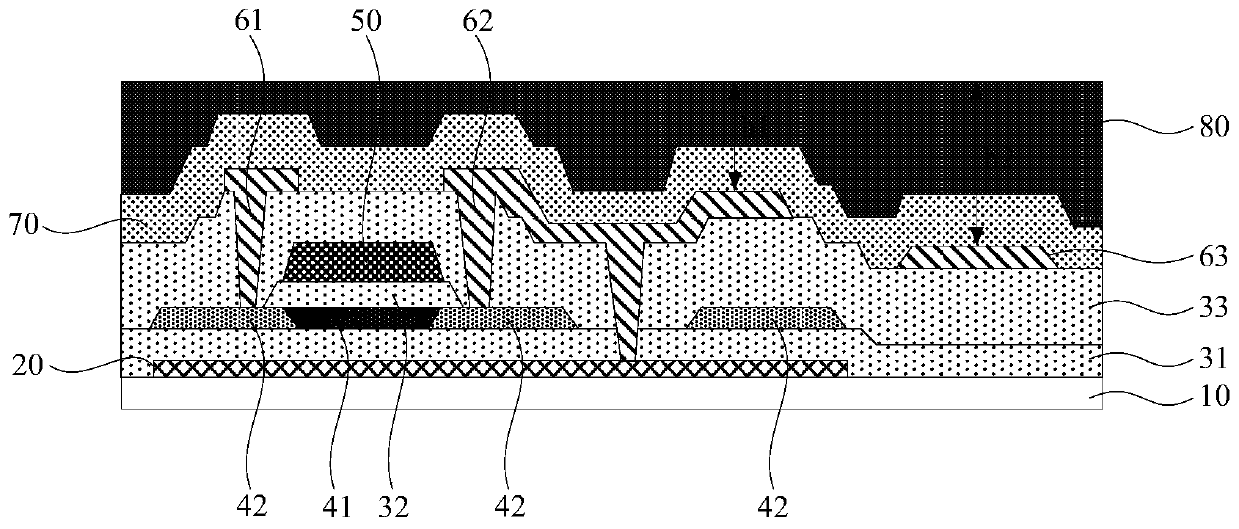

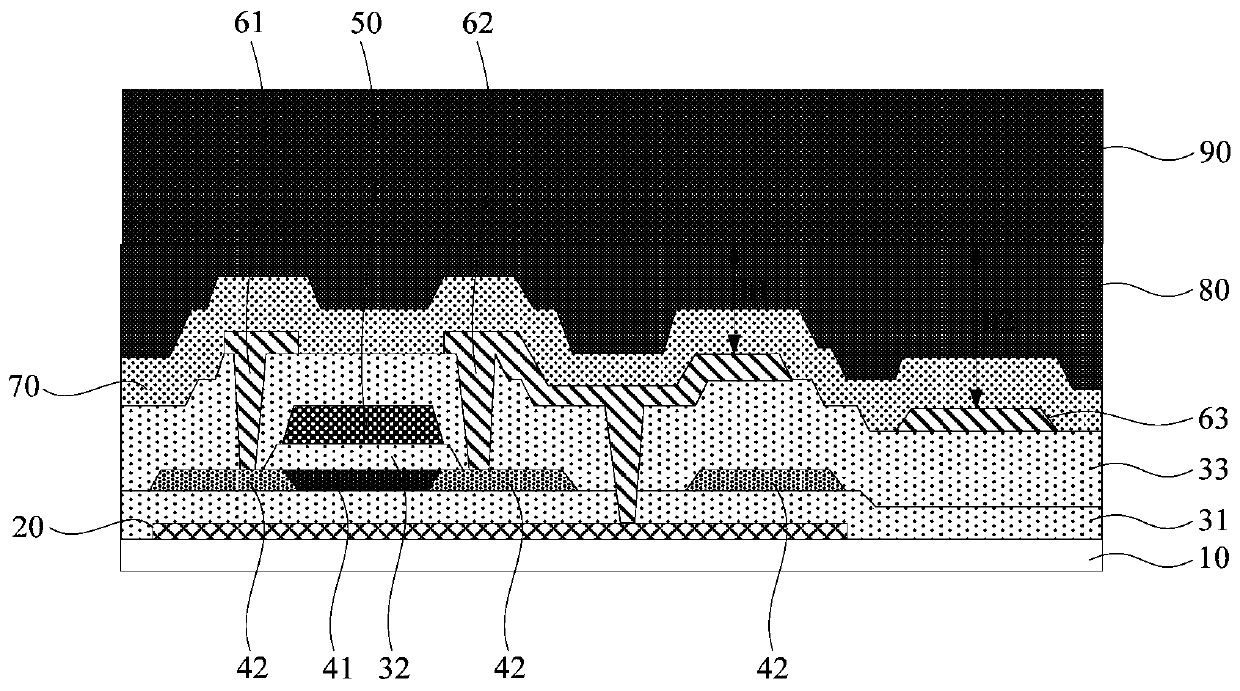

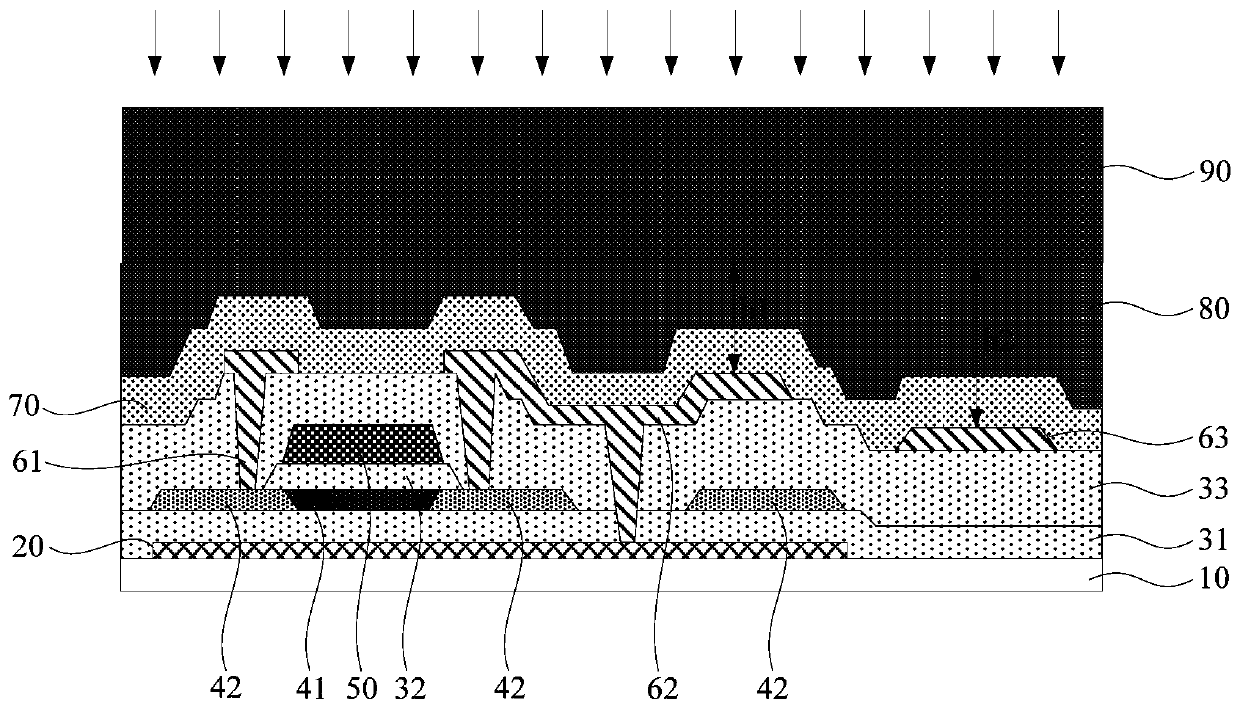

[0059] In order to further illustrate the display substrate, the manufacturing method thereof, and the display device provided by the embodiments of the present invention, a detailed description will be given below in conjunction with the accompanying drawings.

[0060] Taking OLED display substrates with top emission structure as an example, such as figure 1 with Figure 2f As shown, the first transistor for outputting the driving signal includes: a semiconductor active layer 41, a conductive connection structure 42 located on both sides of the semiconductor active layer 41 and coupled with the semiconductor active layer 41, and a gate insulating layer 32 , the gate 50, the first insulating layer 33, the input electrode 61 and the output electrode 62. A light-shielding layer 20 and a conductive connection structure 42 are arranged between the output electrode 62 of the first transistor and the substrate 10, so that in the direction perpendicular to the substrate 10, the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com