A method for increasing the via slope angle of the via layer

A technology of slope angle and via hole, which is applied in the direction of electrical components, circuits, semiconductor/solid-state device manufacturing, etc., to achieve the effects of reducing key dimension distortion, improving circuit quality, and good lapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. The values of the following components are only preferred embodiments, and do not constitute limitations on the scope of protection of the present invention.

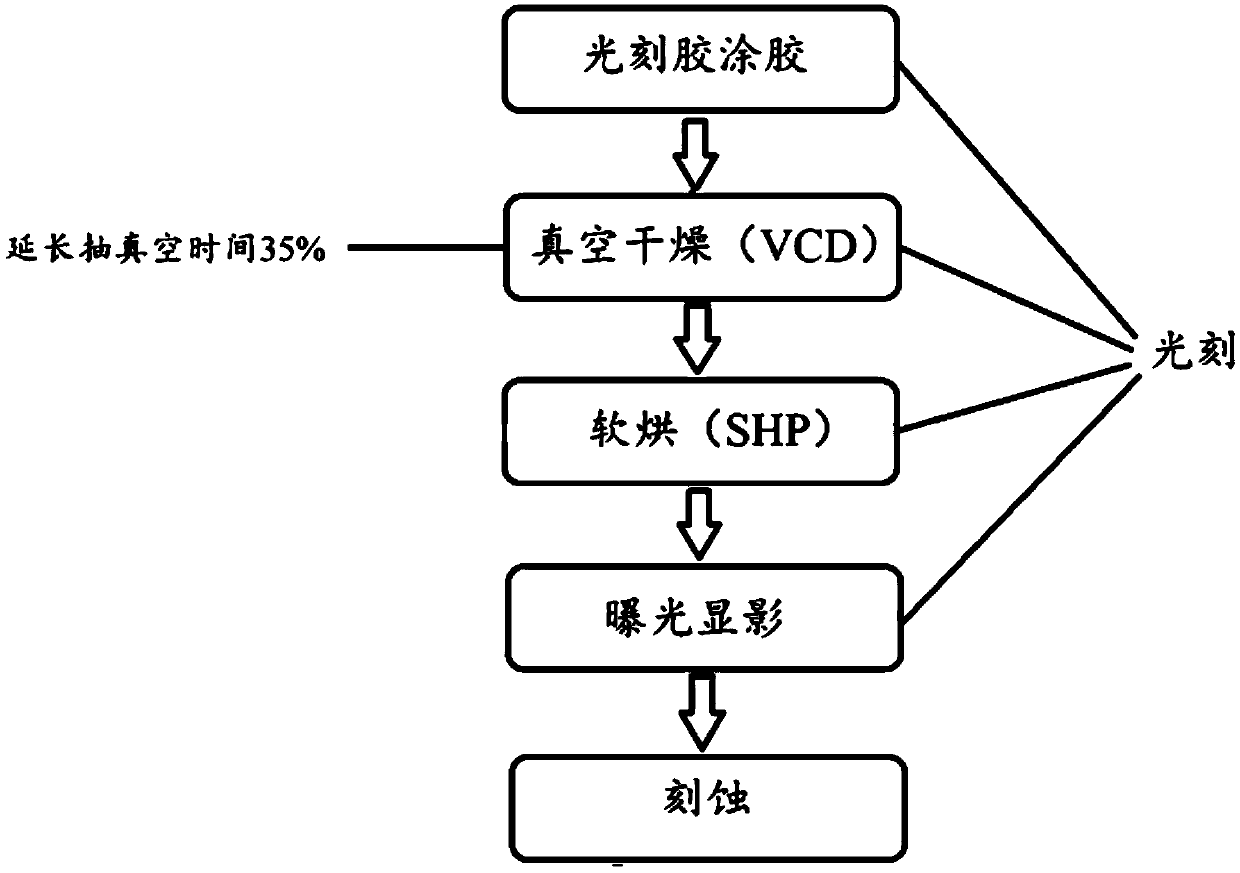

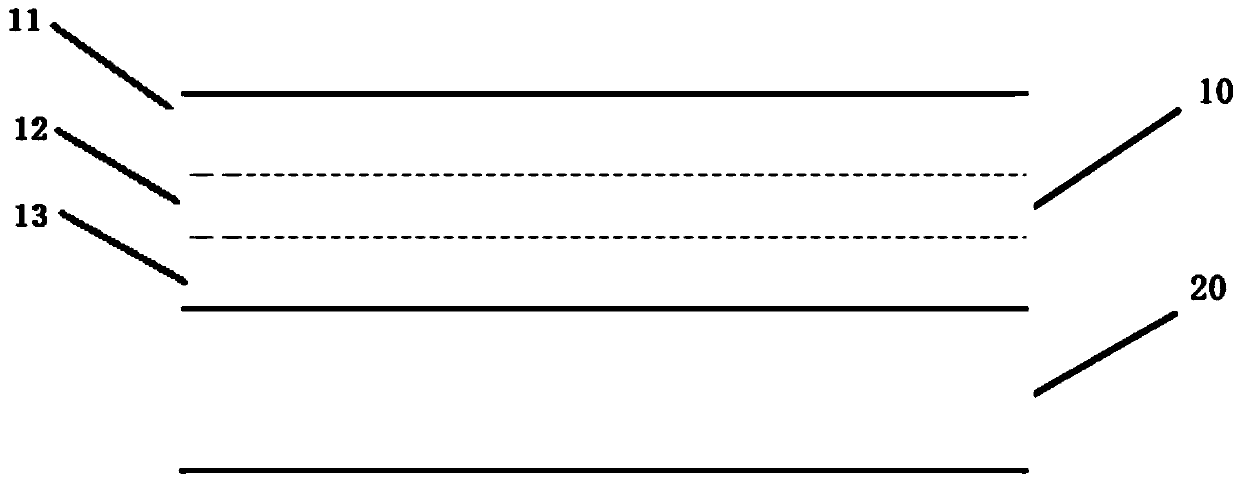

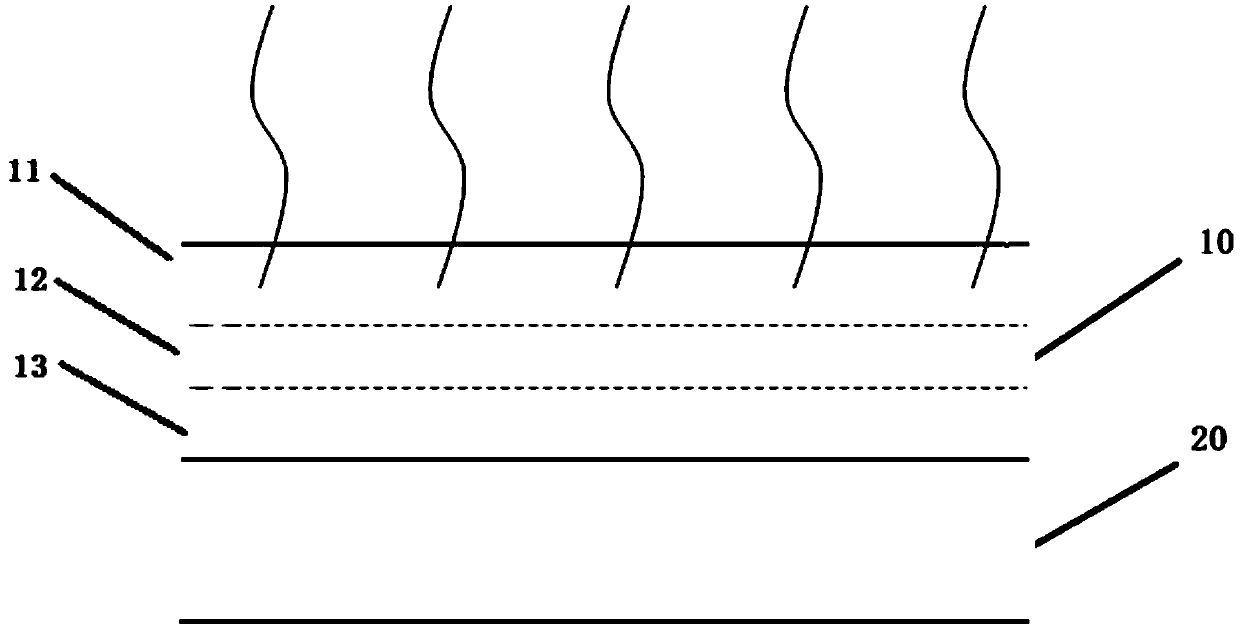

[0021] see figure 1 , is a fabrication flowchart of a method for increasing the via hole slope angle of the via layer provided by an embodiment of the present invention. In this embodiment, the method for increasing the via hole slope angle of the via layer includes a photolithography step and an etching step, and the photolithography step includes a photoresist coating step and a vacuum drying (VCD) step , soft baking (SHP) step, exposure and development step; In the photoresist coating step, the photoresist 10 is coated on the film layer 20, as figure 2 , is a schematic structural view of the via layer (the substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com