Sol mixing-fine grinding-pressure method to improve the strength of mullite porous material

A porous material, mullite technology, applied in the field of new structural materials, porous materials, bioengineering, can solve the problems of uncontrollable porosity, narrow application range, low phase porosity, etc., to increase contact points and overlap , easy to operate, and the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

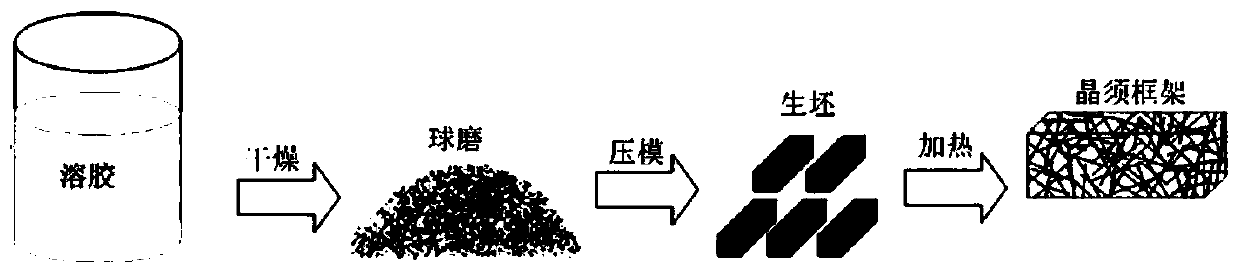

[0025] Steps such as figure 1 Shown, step 1, take water as dispersion medium, according to the Al in polyaluminum chloride sol 2 o 3 and SiO in acidic silica sol 2 The molar ratio is 1:1.5 to obtain a mixed sol, which is magnetically stirred at a speed of 250r / min. At the same time, hydrofluoric acid with a mass concentration of 35% is slowly added dropwise at a speed of 80 drops / min as a catalyst, and the addition amount is aluminum oxide and 45% of the sum of the mass of silicon oxide, after the dropwise addition, continue magnetic stirring for 1.5h to obtain the precursor sol, and dry it in an oven at 75°C for 48h to completely remove the dispersion medium and become a dry glue;

[0026] Step 2. Put the dry glue into the dry corundum ball mill tank, add dry alumina grinding balls, the ball-to-material ratio is 1.7:1, the grinding balls are large balls with a diameter of 8mm: medium balls with a diameter of 4mm: small balls with a diameter of 1mm The ratio of the quantity...

Embodiment 2

[0030] Step 1, using water as the dispersion medium, according to the Al in polyaluminum chloride sol 2 o 3 and SiO in acidic silica sol 2 The molar ratio is 1:1.05 to obtain a mixed sol, which is magnetically stirred at a speed of 200r / min, and at the same time, hydrofluoric acid with a mass concentration of 30% is slowly added dropwise at a speed of 60 drops / min as a catalyst, and the addition amount is aluminum oxide and 30% of the sum of the mass of silicon oxide, after the dropwise addition, continue magnetic stirring for 1 hour to obtain the precursor sol, and dry it in an oven at 70°C for 48 hours to completely remove the dispersion medium and become a dry glue;

[0031] Step 2. Put the dry glue into the dry corundum ball milling tank, add dry alumina grinding balls, the mass ratio of balls to materials is 1.5:1, the grinding balls are large balls with a diameter of 8mm: medium balls with a diameter of 4mm: small balls with a diameter of 1mm The quantity ratio of the ...

Embodiment 3

[0035] Step 1, using water as the dispersion medium, according to the Al in polyaluminum chloride sol 2 o 3 and SiO in acidic silica sol 2The molar ratio is 1:1.76 to obtain a mixed sol, which is magnetically stirred at a speed of 400r / min. At the same time, hydrofluoric acid with a mass concentration of 44% is slowly added dropwise at a speed of 100 drops / min as a catalyst, and the addition amount is aluminum oxide and 58% of the sum of the mass of silicon oxide, after the dropwise addition, continue magnetic stirring for 2 hours to obtain the precursor sol, and dry it in an oven at 80°C for 48 hours to completely remove the dispersion medium and become a dry glue;

[0036] Step 2. Put the dry glue into the dry corundum ball mill tank, add dry alumina grinding balls, the mass ratio of balls to materials is 2:1, the grinding balls are large balls with a diameter of 8mm: medium balls with a diameter of 4mm: small balls with a diameter of 1mm The quantity ratio of the balls is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com