Soft and hard rubber lap joint structure for recycling-prevention partition board

A joint structure and recycling technology, which is applied in the field of soft and hard glue lap joint structure of anti-recycling partitions, can solve the problems of easy cracking at the lap joint of butt forming, and achieve good lap joint effect and bonding strength of soft and hard glue. Solid, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

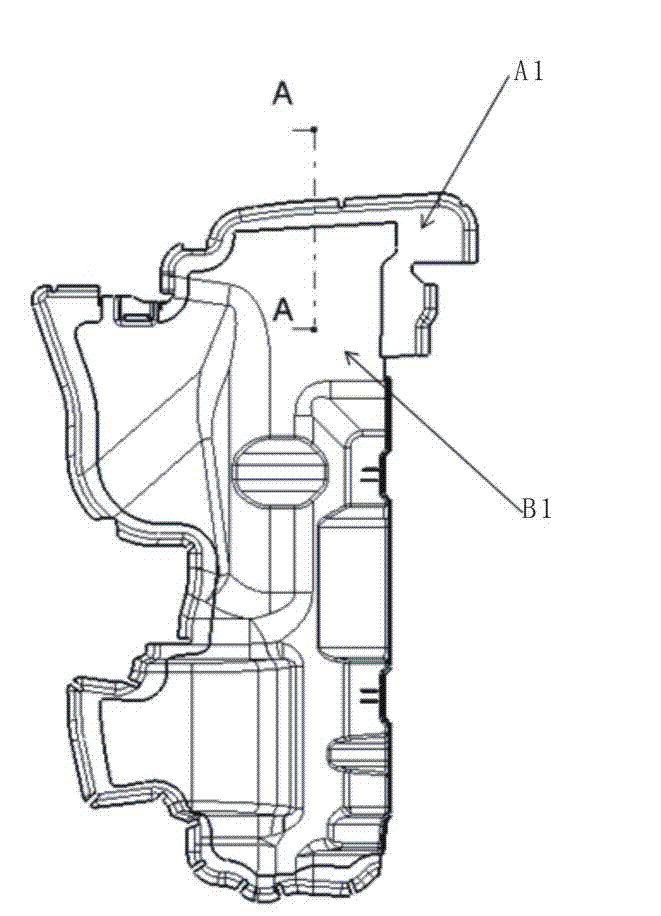

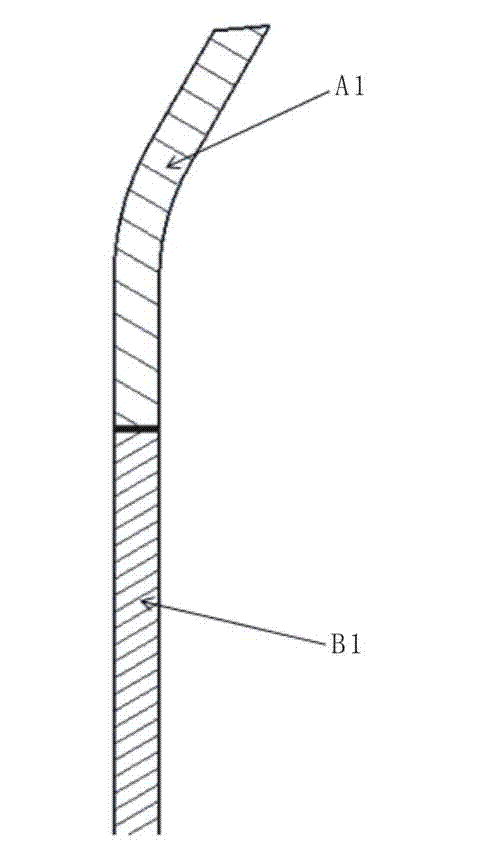

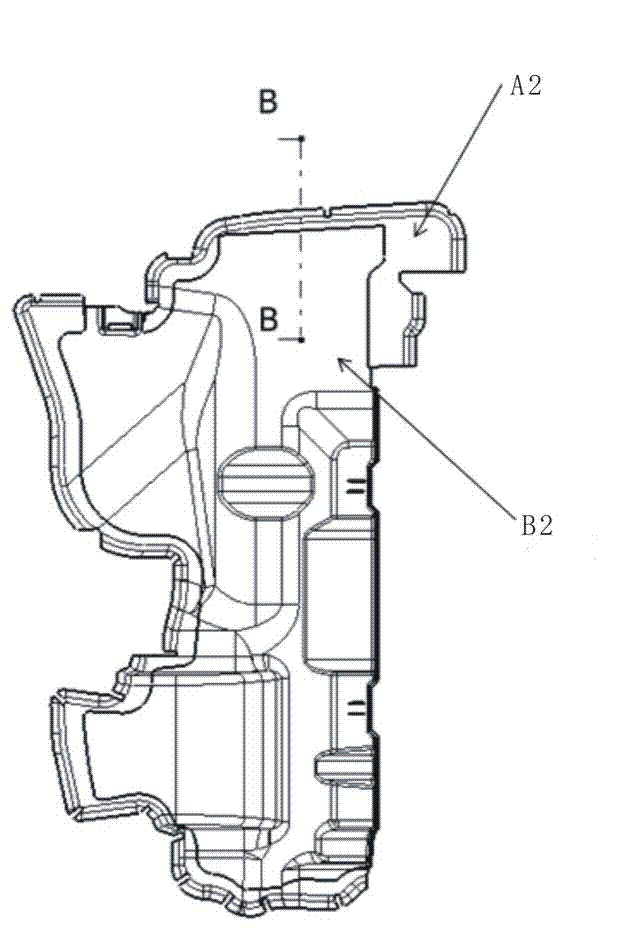

[0015] -Such as image 3 and Figure 4 As shown, the soft and hard rubber lap structure of the anti-recirculation partition of the present invention, the soft rubber A2 and the hard rubber B2 are each fixedly installed with a lap structure at the junction, and the thickness of the lap structure of the hard rubber B2 is W1 is 1 mm. The thickness W2 of the overlapping structure of the soft rubber A2 is 1mm. The overlapping amount L of the bonding structure of the soft rubber A2 and the hard rubber B2 is 5mm. In this way, the mold forming of the part itself is easy, the effect of the overlapping of soft and hard rubber is good, and it is difficult to break at the overlapping of soft and hard rubber. At the same time, this is more beneficial to the injection molding of parts and saves costs.

[0016] Although the specific implementation m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com