Field machining device and method for small diameter explosive coil

A technology for on-site processing and processing devices, which is applied to ammunition, offensive equipment, weapon accessories, etc., can solve the problems of inconvenient access to small-diameter emulsion explosive rolls, and achieve the effects of high processing efficiency, simple use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

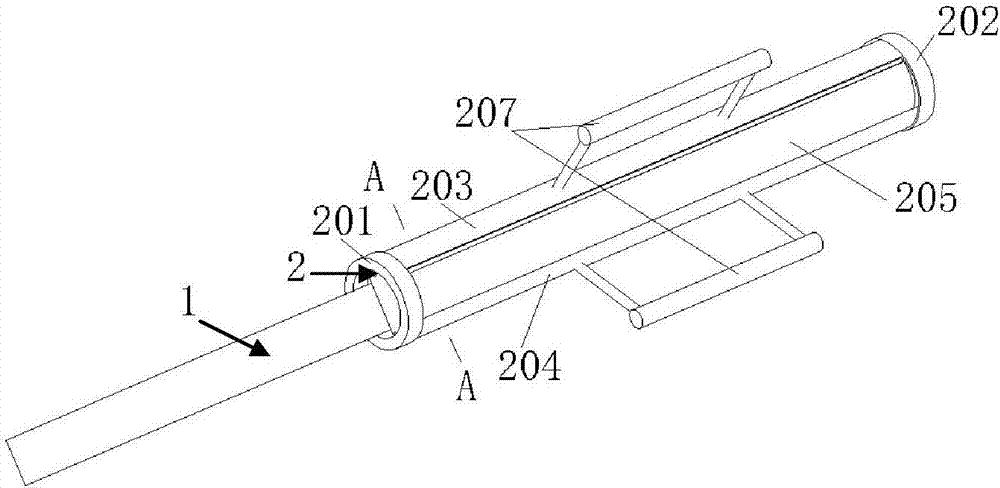

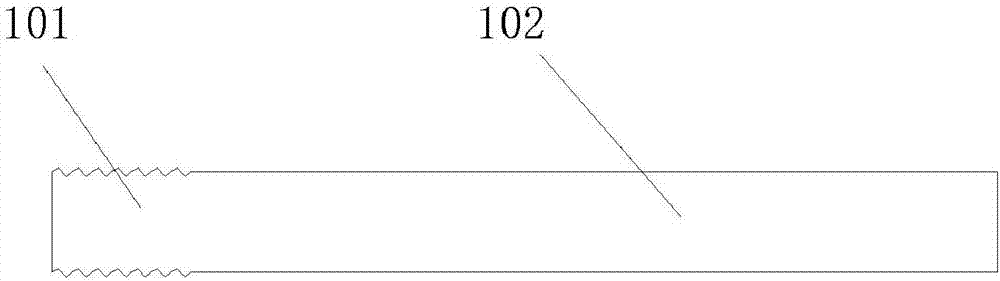

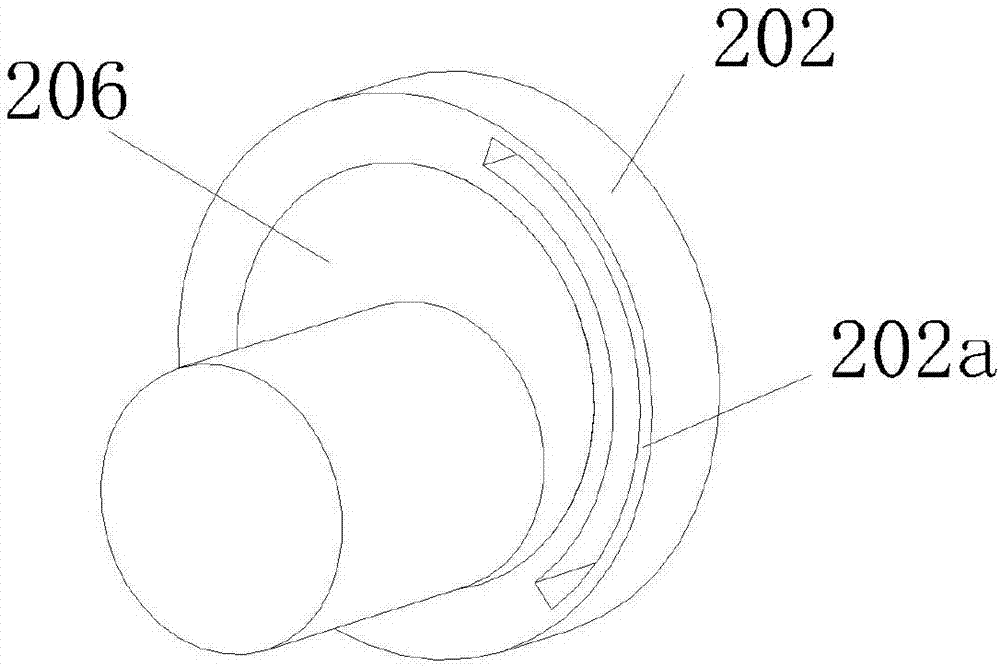

[0030] Such as Figure 1-6 As shown, an on-site processing device for small-diameter explosive rolls can be used for processing finished emulsion explosive rolls with diameters of 32mm and 35mm. The device comprises a cylindrical plastic bag 1 and a reel 2 with a variable diameter. The cylindrical plastic bag 1 is mainly composed of a non-elastic bag body section 102 and an elastic opening end 101; The fixed collars at both ends of the cylinder, one end is a hollow collar 201, and the other end is a closed collar 202; the inner diameter of the hollow collar 201 is greater than the diameter of the cylindrical plastic bag 1, and the bottom of the hollow collar 201 and the closed collar 202 ring wall have Arc chute 201a, 202a; Closed collar 202 is provided with a rotating body 206 that can rotate around the side wall of the closed collar, and the end of rotating body 206 facing the inside of reel 2 is provided with a cylinder mold 206a, and the cylinder mold 206a The diameter is...

Embodiment 2

[0044] A method for on-site processing of small-diameter explosive coils, comprising the following steps:

[0045] Step 1, cutting the seal at one end of the pre-processed finished emulsion explosive roll with a diameter of 32mm or 35mm;

[0046] Step 2: Select a cylindrical plastic bag with a diameter of 25mm of suitable length according to the model of the pre-processed finished emulsion explosive roll, and put the elastic opening end of the cylindrical plastic bag with better telescopic deformation performance on the cut end of the finished emulsion explosive roll , and the incision end extends into the body of the inelastic bag close to the cylindrical plastic bag with poor stretchability;

[0047] Step 3, from the hollow collar, put the finished emulsion explosive roll covered with a cylindrical plastic bag into the reel, and the cylindrical mold connected with the rotating body in the reel is a cylindrical mold with a diameter of 25mm;

[0048] Step 4: Close the arc-sha...

Embodiment 3

[0050] A tunnel project adopts the drilling and blasting scheme for construction, and purchased a batch of emulsion explosive rolls with a diameter of 32mm. The specifications are that the length of a single section is 300mm, and the weight of a single section is 300g. Contour blasting technology is used for pre-splitting blasting. In order to ensure a better pre-splitting effect, the pre-splitting hole needs to use 25mm small-diameter explosive coils. Due to the lack of explosive coils of this specification, and the procurement is faced with problems such as complicated approval procedures, the present invention is now used for on-site blasting. Medicine volume processing, the specific implementation method is as follows:

[0051] Step 1: Cut off the seal of one end of the finished 32mm emulsified drug roll;

[0052] Step 2: Select a cylindrical plastic bag with a diameter of 25 mm and a suitable length according to the type of medicine roll to be processed; in this project, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com