A construction method of lapping bentonite waterproof blanket by using photocuring technology

A technology of bentonite waterproof blanket and construction method, which is applied to building components, building insulation materials, etc., and can solve problems such as leakage at the acupuncture point and rupture of the waterproof blanket, and achieve the effects of not easy to leak, low cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

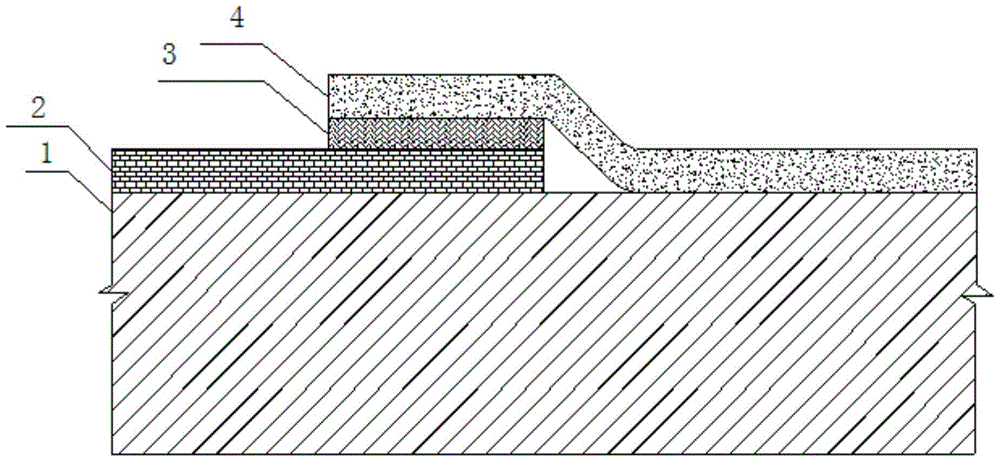

Image

Examples

Embodiment 1

[0027] The construction method of overlapping bentonite waterproof blanket, the specific steps are as follows:

[0028] 1) Carry out basic treatment on the base of the waterproof construction site, such as tamping, leveling, compacting, etc. The treatment method of the base layer is as follows: there should be no linear flowing water on the surface of the floor cushion concrete and the surrounding protection piles, otherwise the leakage treatment should be done first; the cushion concrete should be calendered and smoothed while pouring to avoid large bulges and unevenness Parts; the protrusions on the surface of the retaining piles should be chiseled off, and the nets should be hung with shotcrete between the piles.

[0029] 2) Lay the bentonite waterproof blanket on the base layer by manual laying or mechanical laying. First lay the bentonite waterproof blanket at the yin and yang corners, and then lay the large bentonite waterproof blanket; the bentonite waterproof blanket ...

Embodiment 2

[0036] The construction method of overlapping bentonite waterproof blanket, the specific steps are as follows:

[0037] 1) Carry out basic treatment on the base of the waterproof construction site, such as tamping, leveling, compacting, etc. The treatment method of the base layer is as follows: there should be no linear flowing water on the surface of the floor cushion concrete and the surrounding protection piles, otherwise the leakage treatment should be done first; the cushion concrete should be calendered and smoothed while pouring to avoid large bulges and unevenness Parts; the protrusions on the surface of the retaining piles should be chiseled off, and the nets should be hung with shotcrete between the piles.

[0038] 2) Lay the bentonite waterproof blanket on the base layer by manual laying or mechanical laying. First lay the bentonite waterproof blanket at the yin and yang corners, and then lay the large bentonite waterproof blanket; the bentonite waterproof blanket ...

Embodiment 3

[0045]The construction method of overlapping bentonite waterproof blanket, the specific steps are as follows:

[0046] 1) Carry out basic treatment on the base of the waterproof construction site, such as tamping, leveling, compacting, etc. The treatment method of the base layer is as follows: there should be no linear flowing water on the surface of the floor cushion concrete and the surrounding protection piles, otherwise the leakage treatment should be done first; the cushion concrete should be calendered and smoothed while pouring to avoid large bulges and unevenness Parts; the protrusions on the surface of the retaining piles should be chiseled off, and the nets should be hung with shotcrete between the piles.

[0047] 2) Lay the bentonite waterproof blanket on the base layer by manual laying or mechanical laying. First lay the bentonite waterproof blanket at the yin and yang corners, and then lay the large bentonite waterproof blanket; the bentonite waterproof blanket i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| swell index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com