A method for repairing inorganic thermal insulation mortar system

A technology of inorganic thermal insulation mortar and repair method, applied in the field of building wall thermal insulation, can solve the problems such as inability to find effectively, difficult maintenance of the inorganic thermal insulation mortar system, falling off, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

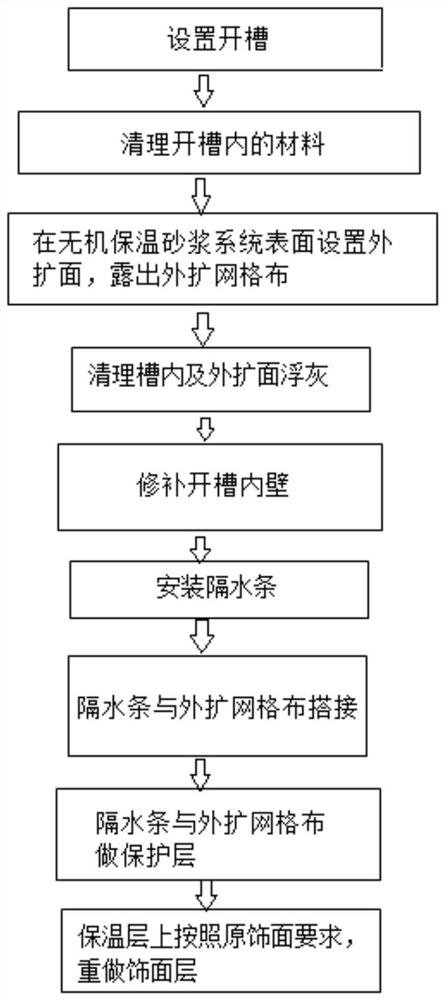

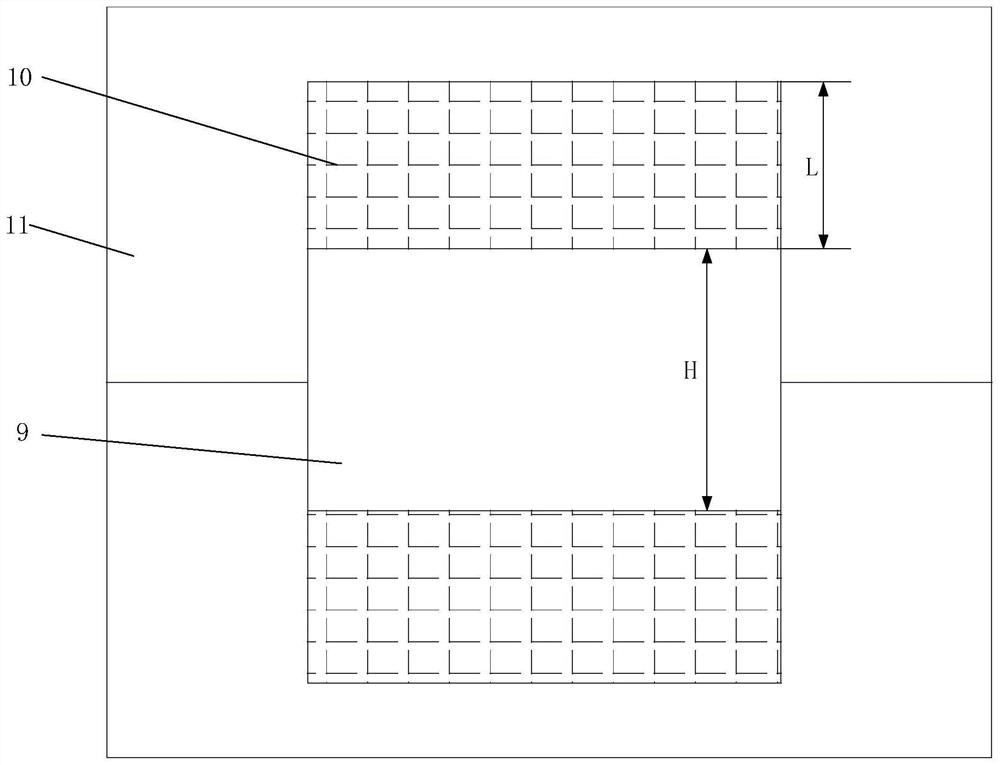

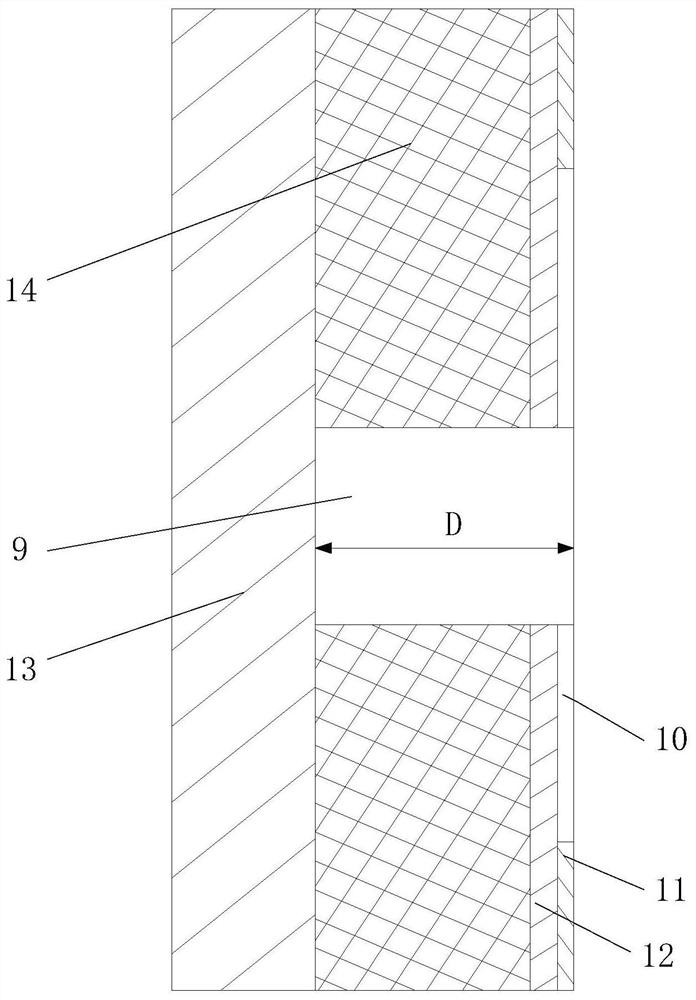

[0061] Such as Figure 1 to Figure 4 As shown, the present invention provides a method for repairing the inorganic thermal insulation mortar system. The inorganic thermal insulation mortar system is arranged on the surface of the base wall 13, and the thermal insulation layer 14, the plastering mortar layer 12 and the veneer layer 11 are sequentially arranged from the inside to the outside. , the plastering glue layer 12 is provided with grid cloth, and the repair method comprises:

[0062] Step 1. Set the slot 9 that runs through the inorganic thermal insulation mortar system, and the bottom of the slot 9 is the base wall 13;

[0063] Step 2. Expand the surface of the inorganic thermal insulation mortar system to the top and bottom of the slot 9 respectively to form an outer expansion surface 10, remove the outer expansion surface 10 to the plastering mortar layer 12, and expose the grid cloth, that is, the outer expansion surface 10 Expanded grid cloth;

[0064] Step 3. In...

Embodiment 2

[0082] Such as Figure 5 As shown, the difference between the inorganic thermal insulation mortar system repair method according to embodiment 2 and embodiment 1 is that,

[0083] In this embodiment, the water-separating strip is a bridge-broken water-separating strip, and the bridge-broken water-separating strip includes a first thermal insulation board 5, a second water guide bridge 6, a second thermal insulation board 7 and a second grid cloth 8, The second insulation board 7 is a door-shaped structure, and the door-shaped structure includes a long side, a short side and a horizontal side connecting the long side and the short side, and the first insulation board 5 is arranged above the short side, and the long side is fixedly connected;

[0084] The second grid cloth 8 is attached to the other side of the first insulation board 5 and the outside of the short side respectively, and the second water guide bridge 6 is arranged between the short side and the first insulation b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com