Substrate module

a technology of substrate modules and substrates, applied in non-linear optics, instruments, optics, etc., can solve problems such as unfavorable reliability of liquid crystal display panels, and achieve the effect of enhancing the reliability of display panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

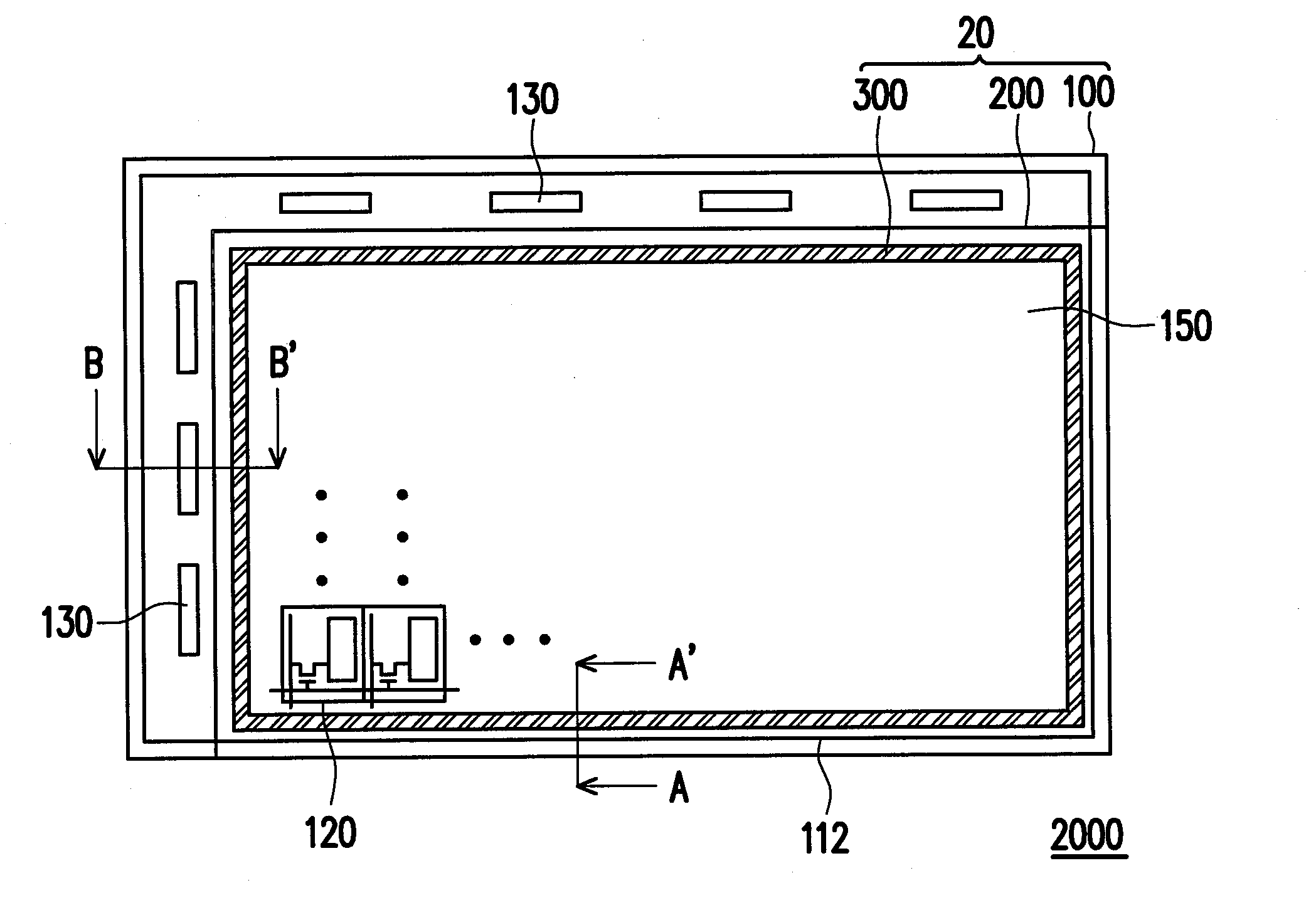

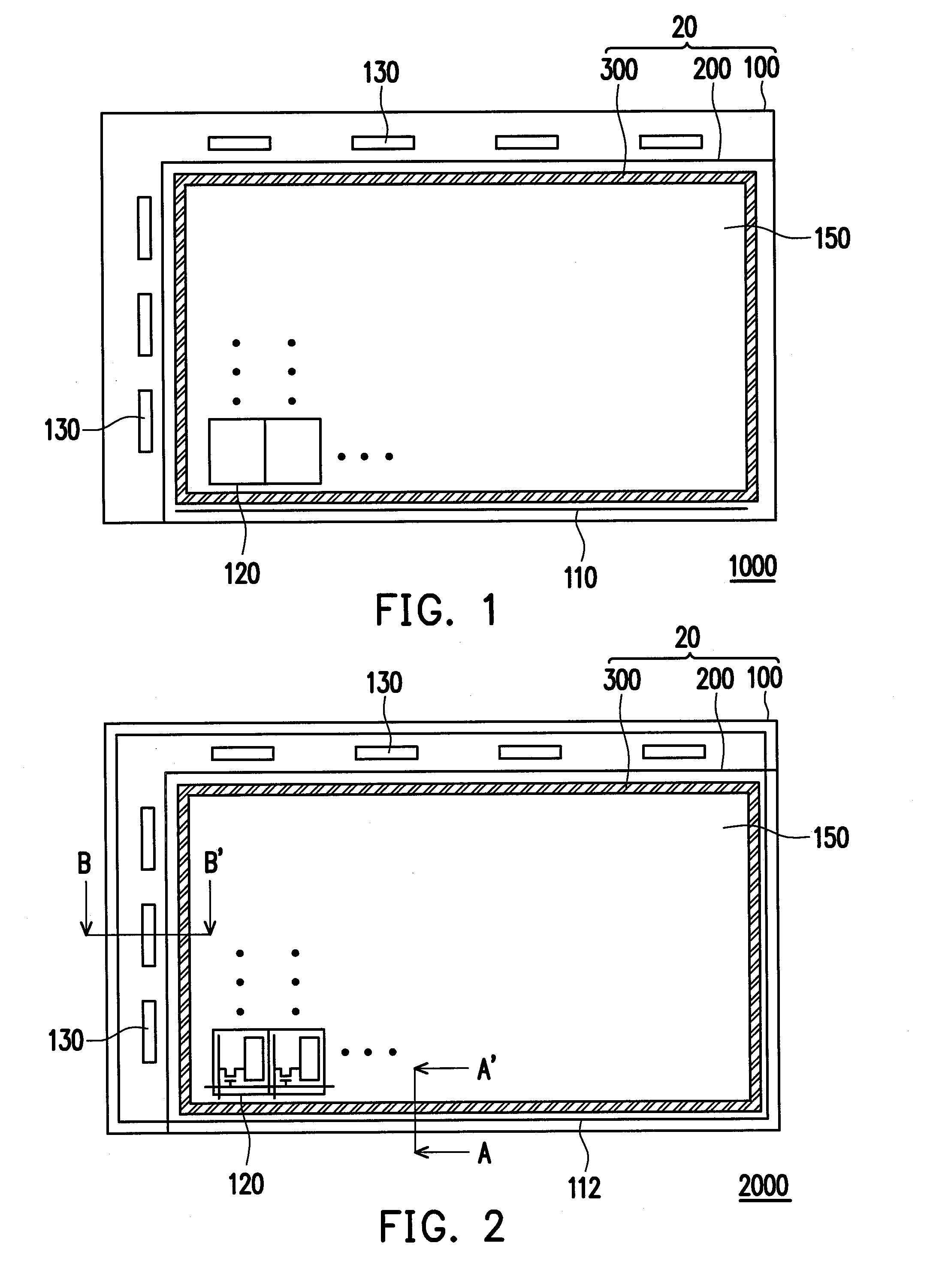

[0026]FIG. 1 schematically illustrates a display panel according to an embodiment of the invention. Referring to FIG. 1, a substrate module 10 includes an active device array substrate 100, an opposite substrate 200, and a sealant 300. The active device array substrate 100 has a groove 110. The opposite substrate 200 and the active device array substrate 100 are disposed opposite to each other so that the opposite substrate 200 and the active device array substrate 100 are overlapped in FIG. 1. The active device array substrate 100 and the opposite substrate 200 are assembled through the sealant 300. That is, the sealant 300 is disposed between the active device array substrate 100 and the opposite substrate 200. In addition, the groove 110 is located between the sealant 300 and the border of the active device array substrate 100.

[0027]In specific, the substrate module 10 is suitable for being filled with a display medium 150 so as to form a display panel 1000, wherein the display m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparent | aaaaa | aaaaa |

| conductive | aaaaa | aaaaa |

| stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com