motor

A technology of motors and engaging parts, applied in the field of motors, can solve problems such as low dimensional accuracy, difficulty in overlapping bearing parts and end plates, and inability to insert engaging parts into openings, etc., to achieve the effect of reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0033] the whole frame

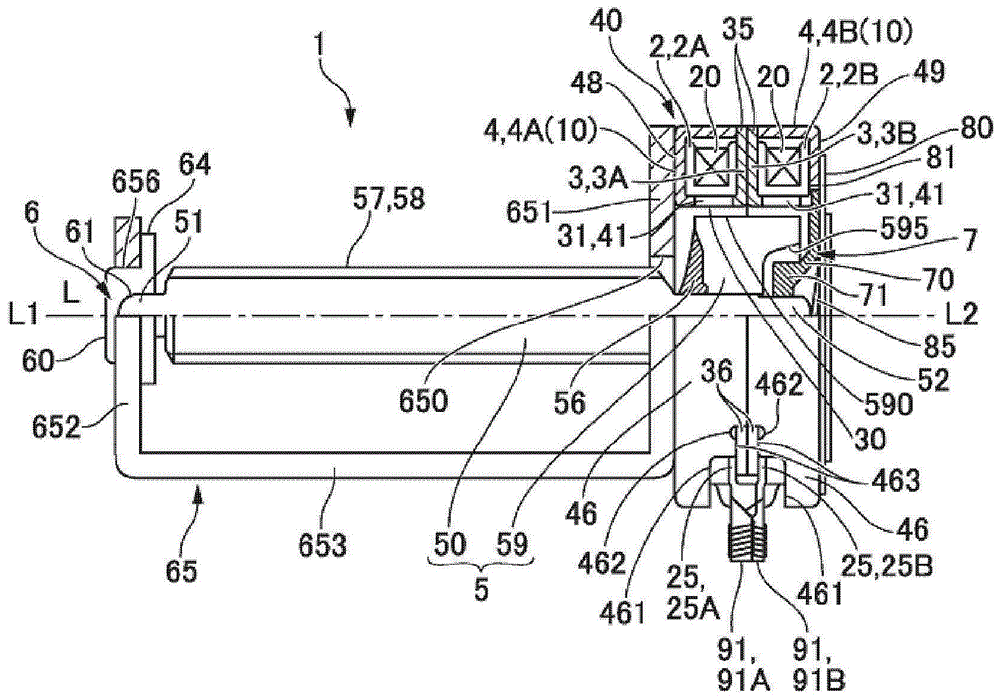

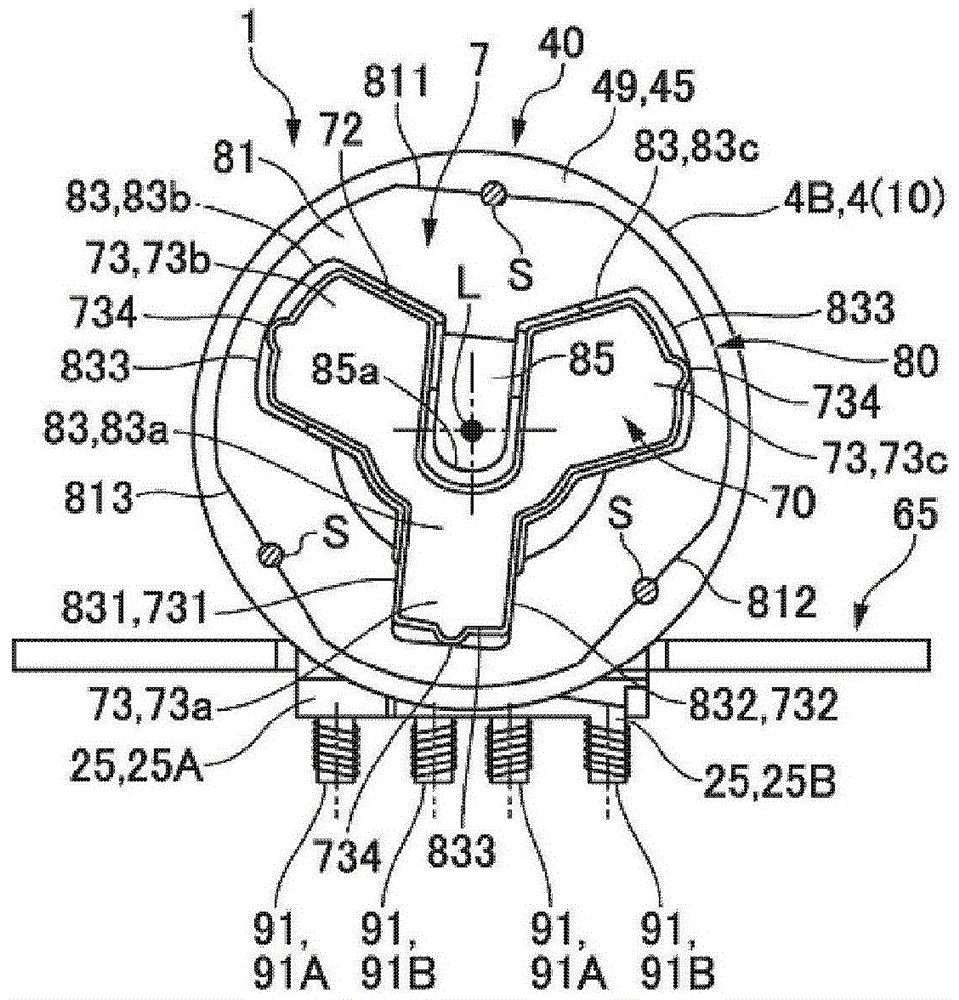

[0034] Fig. 1(a) and Fig. 1(b) are a half sectional view of the motor and a rear view of the motor seen from the side opposite to the output.

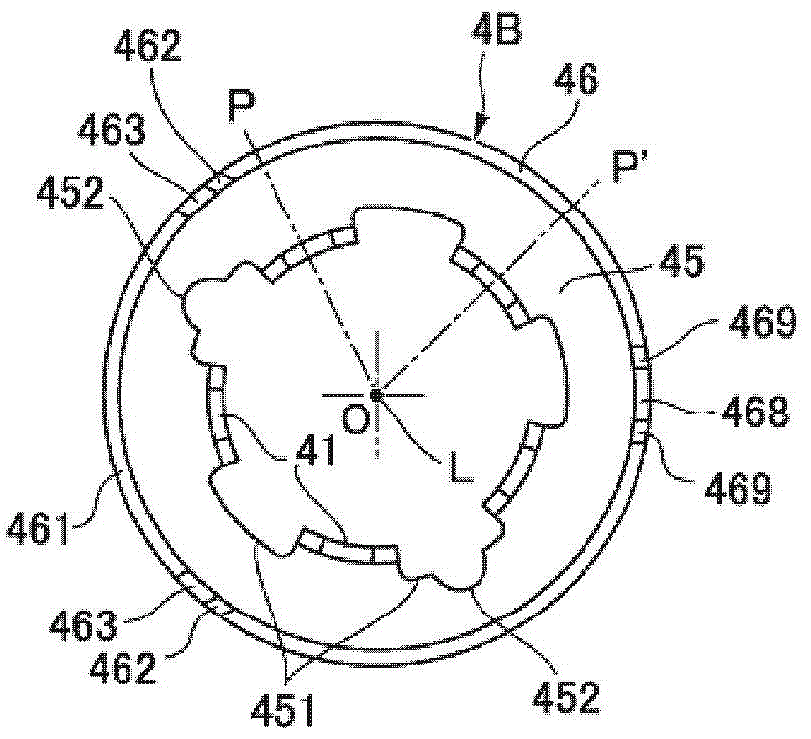

[0035]The motor 1 shown in FIG. 1( a ) and FIG. 1( b ) is a stepping motor used for driving an optical head in optical disc drive devices such as DVD and Blu-ray disc, and has a cylindrical stator 40 . The stator 40 has a structure in which an A-phase stator and a B-phase stator are arranged to overlap each other in the motor axis direction L. As shown in FIG. Therefore, in the stator 40, two annular bobbins 2 (the first bobbin 2A and the second bobbin 2B) around which the coil wire 20 is wound are overlapped in the motor axis direction L, and the bobbins 2 are respectively The inner stator core 3 and the outer stator core 4 are arranged overlappingly. More specifically, in the first bobbin 2A, an annular inner stator core 3A and an outer stator core 4A with a U-shaped cross-section are stacked on both sides ...

Embodiment approach 2

[0096] Figure 6 It is an explanatory diagram of a state where the end plate 80 is stacked on the bearing member 70 in the motor 1 according to Embodiment 2 of the present invention. In addition, in Figure 6 In , oblique lines directed downward to the right are indicated on the end plate 80 . In addition, since the basic configuration of this embodiment is the same as that of Embodiment 1, the same reference numerals are attached to the common parts and their descriptions are omitted.

[0097] In Embodiment 1, the convex portion 734 for radial positioning between the bearing member 70 and the end plate 80 is formed on the engaging portion 73 of the bearing member 70, but in this embodiment, as Figure 6 A convex portion 834 protruding toward the engaging portion 73 is formed at the end portion 833 of the opening portion 83 of the end plate 80 as shown, and the convex portion 834 has a semicircular planar shape.

[0098] Also in this configuration, as in Embodiment 1, the end ...

Embodiment approach 3

[0100] Figure 7 It is a sectional view of the end plate 80 of the motor 1 according to Embodiment 3 of the present invention. In addition, since the basic structure of this embodiment is the same as that of Embodiment 1, the same code|symbol is attached|subjected to a common part, and the description is abbreviate|omitted.

[0101] In Embodiment 1, the edge of the outer peripheral surface of the engaging portion 73 opposite to the side where the stator 40 is located forms the tapered surface 76. However, in the present embodiment, as Figure 7 In the inner peripheral surface of the opening 83 of the end plate 80 shown, the edge on the side where the stator 40 is located (the output side L1 ) forms a tapered surface 86 .

[0102] According to such a structure, since the engaging part 73 can be easily fitted into the opening part 83, the bearing member 70 and the end plate 80 can be superimposed efficiently.

[0103] In addition, when the convex portion 834 is provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com