Earth rock cofferdam anti-seepage construction method combining high-pressure jet grouting and clay core wall

A technology of earth-rock cofferdam and clay core wall, which is applied in the direction of basic structure engineering, construction, etc., to achieve the effects of shortening the construction period, increasing the contact area, and improving the anti-seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

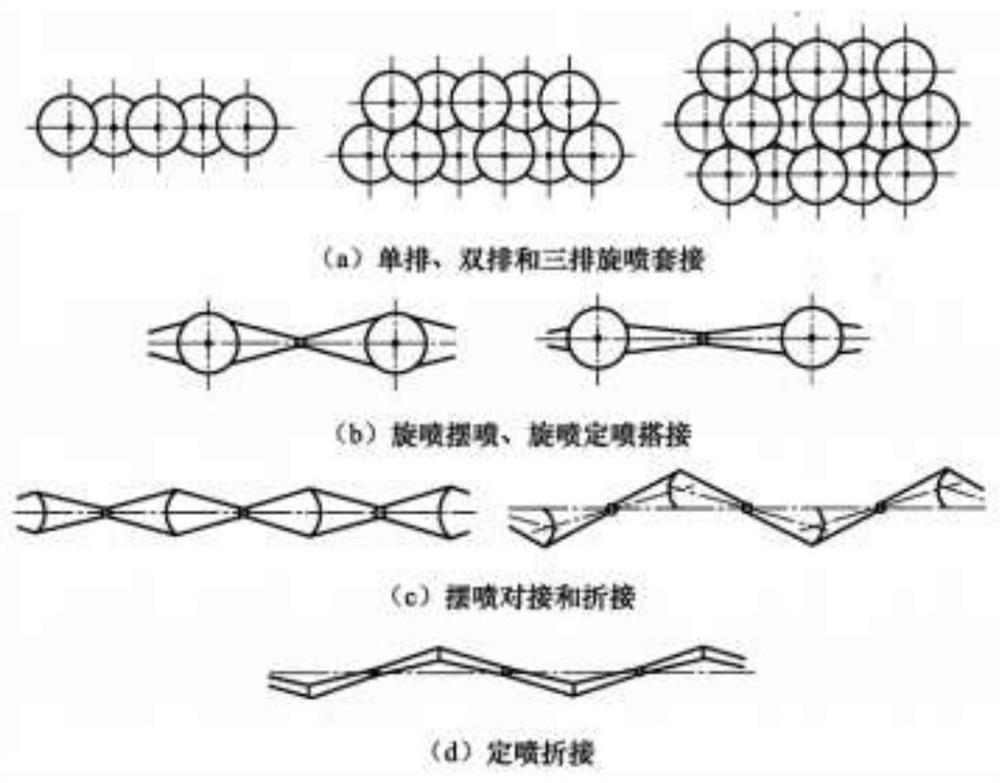

Method used

Image

Examples

Embodiment 1

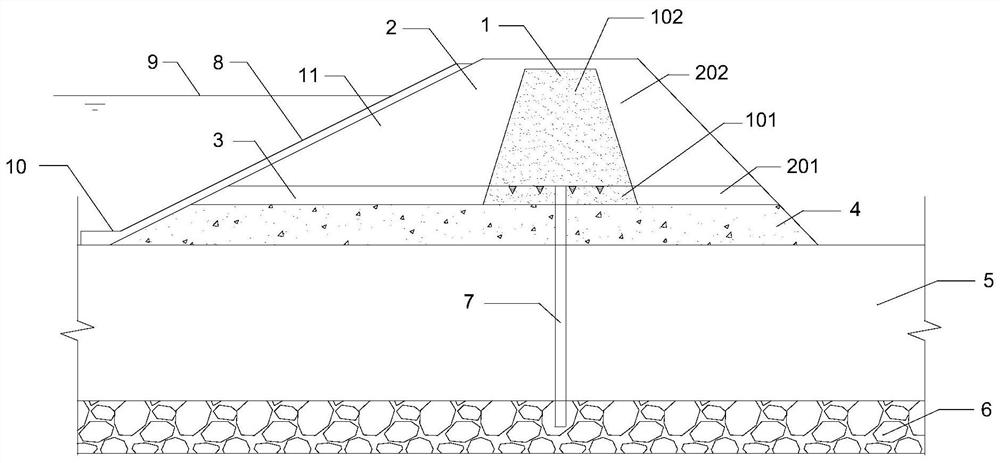

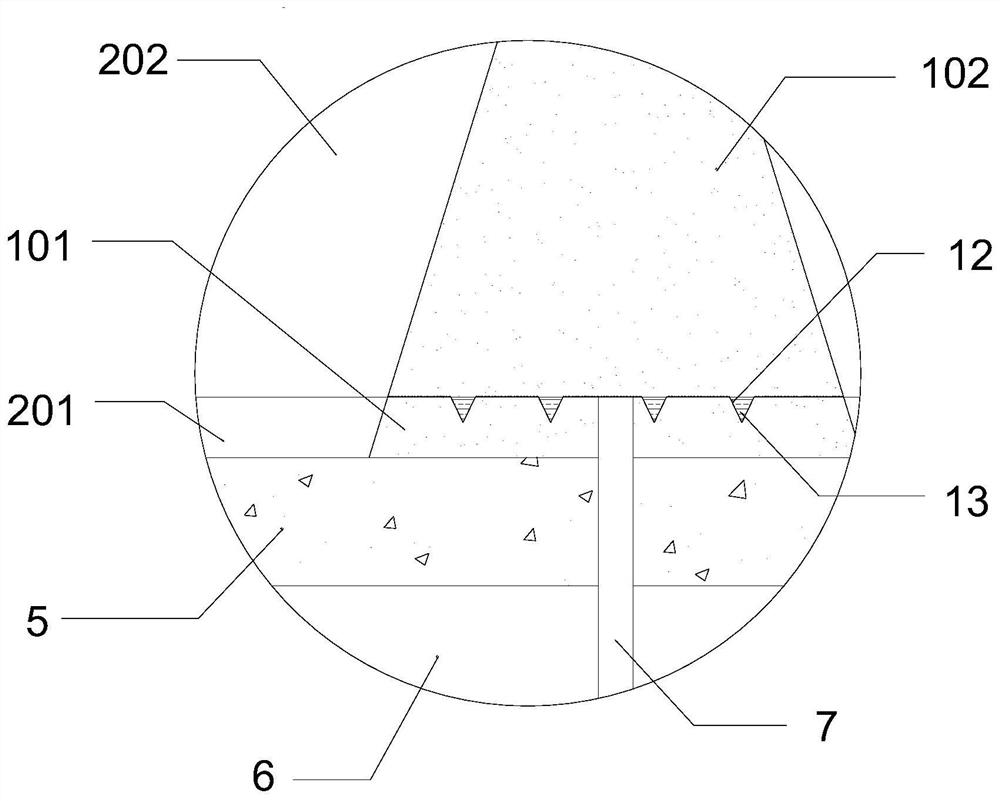

[0032] Seepage prevention construction method of earth-rock cofferdam with high-spray anti-seepage combined with clay core wall, please refer to figure 1 , which includes the following steps:

[0033] 1) Dike filling

[0034] The filling method is adopted to fill the embankment 4; the embankment method includes a double embankment construction method that throws and fills directly into the water from both ends of the river channel to the middle, and a single embankment construction method that enters from one end to the other end;

[0035] 2) Elevation of the embankment

[0036] After the embankment 4 is closed, the lower cofferdam 201 is filled with sand and pebbles from both sides of the embankment 4, and then the lower clay core wall 101 is filled in the middle to form the underlying structure of the earth-rock cofferdam with a thickness of 0.5-2m. 3. Heighten the embankment 4;

[0037] 3) High pressure jet grouting construction

[0038] After the embankment 4 is height...

Embodiment 2

[0055] In order to better understand the present invention, more specific examples are given below. In the anti-seepage construction method of the earth-rock cofferdam with high-spray anti-seepage combined with clay core wall in this embodiment, the width of the cofferdam crest is 5m, the maximum weir height is about 14m, the slope ratio of the upstream side is 1:2, and the slope ratio of the backside is 1:2. 1:1.5, the filling of the weir body is river bed sand and pebbles, and the anti-seepage of the cofferdam adopts the combination of high-spray grouting and clay core wall; 11m; see figure 1 , the specific construction steps of this embodiment are as follows:

[0056] 1) Dike filling

[0057] For the filling construction of the cofferdam, the underwater part is constructed by throwing the filling method, and the filling is directly thrown into the water from both ends to the middle, and the filling of the embankment 4 is carried out; the material is loaded by a backhoe ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com