Strengthening structure for integrated bolting with bar and wire mesh

A technology for strengthening structures and anchor beam nets, which is applied in the installation of anchor rods, mining equipment, earthwork drilling and mining, etc., can solve the problems of aggravated net pockets, low strength at the joints of metal nets, and off-grid, so as to improve the overall strength and reliability. Sexuality, preventing net bag phenomenon, increasing the effect of diffusion range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further explained below in conjunction with the accompanying drawings.

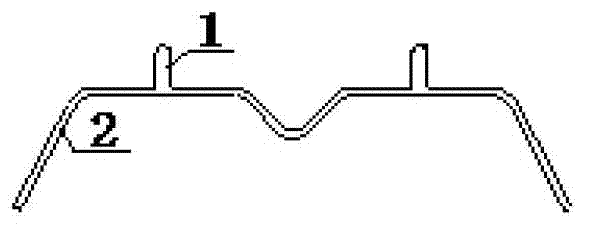

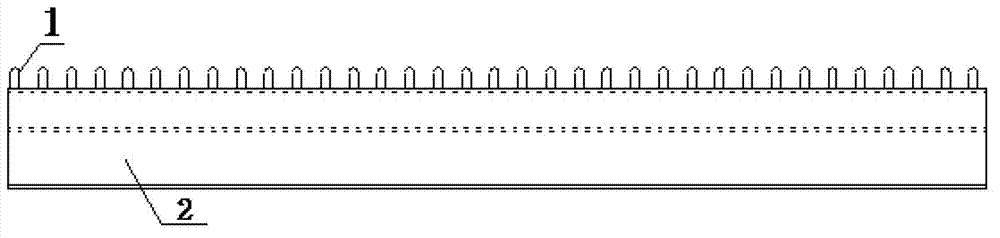

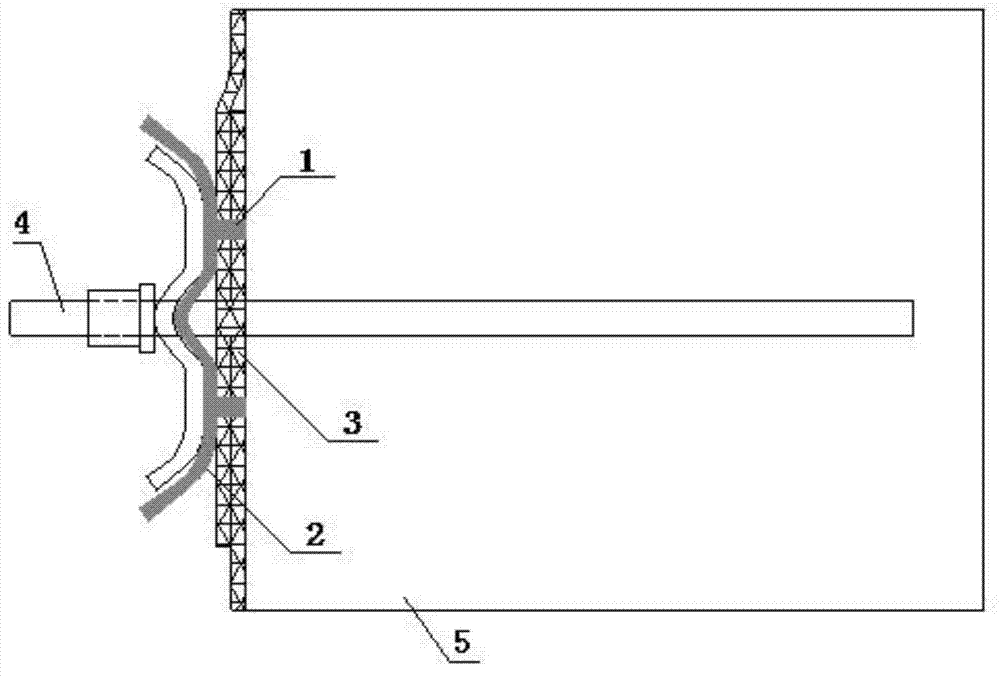

[0028] Such as Figures 1 to 3 As shown, the strengthening structure of the anchor-beam-net integrated support of the present invention is arranged on the M-shaped steel belt 2 at the overlap of the metal mesh 3 of the anchor-beam-net integrated support. Set and symmetrically distribute two rows of connecting nails 1 on both sides of the upper surface groove of the M-shaped steel strip 2, the shear strength of the connecting nails 1 is 2 to 2.5 times the tensile strength of the wire mesh 3, and the connecting nails 1 The lower end is fixed to the upper surface of the M-shaped steel strip 2, and the upper end of the connecting nail 1 is inserted into the metal mesh mesh hole at the overlap of the metal mesh 3. In order to facilitate the installation of the M-shaped steel strip 2, the spacing of the connecting nails 1 is equal to the grid spacing of the metal mesh 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com