Novel hollow slab funnel hinge joint structure and construction method thereof

A construction method and technology of hollow slabs, which are applied to bridge parts, erection/assembly bridges, bridges, etc., can solve problems such as low tensile capacity, veneer stress, and bottom mortar falling off, so as to improve shear strength and bending resistance ability, improve shear strength, and enhance the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

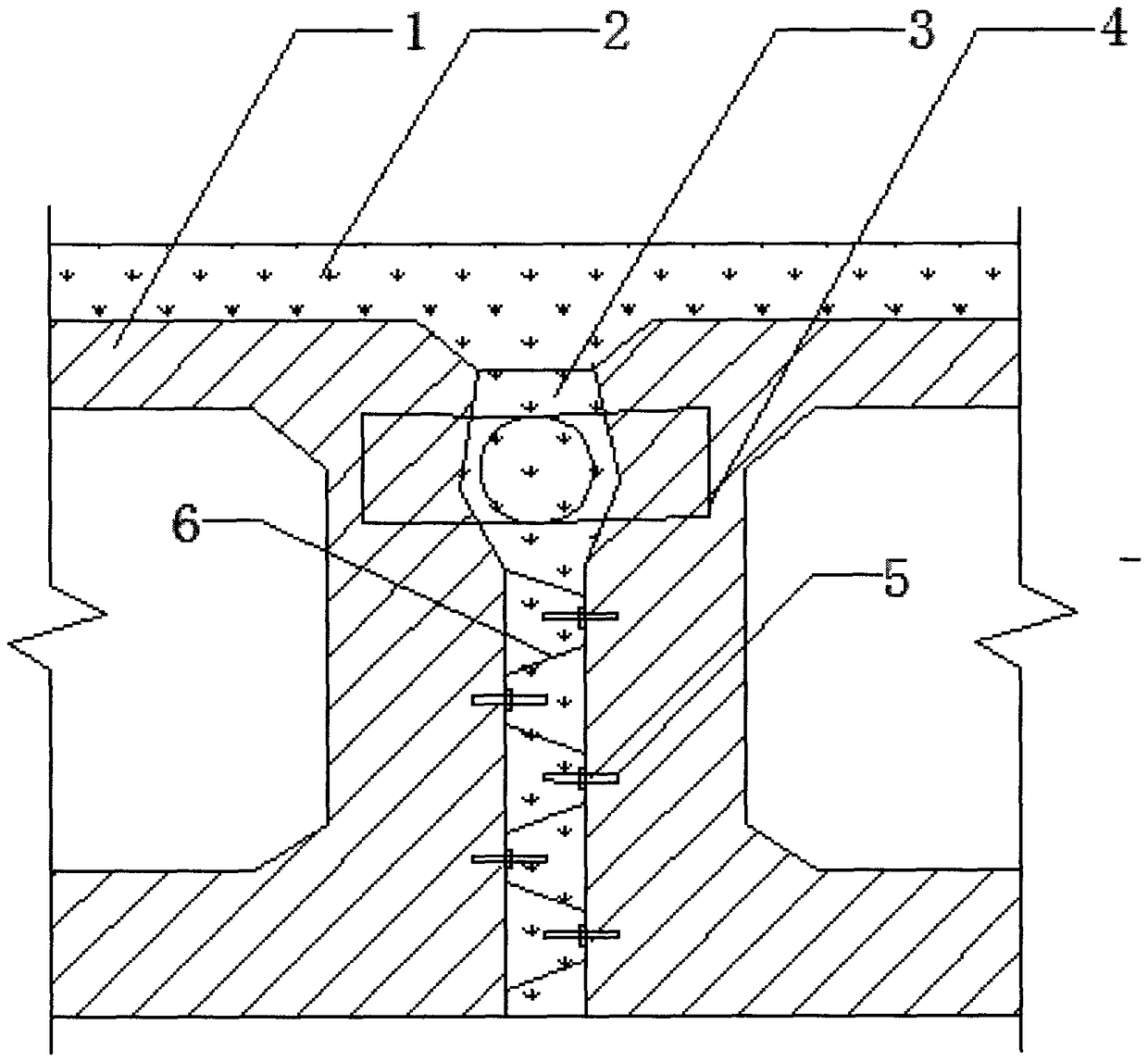

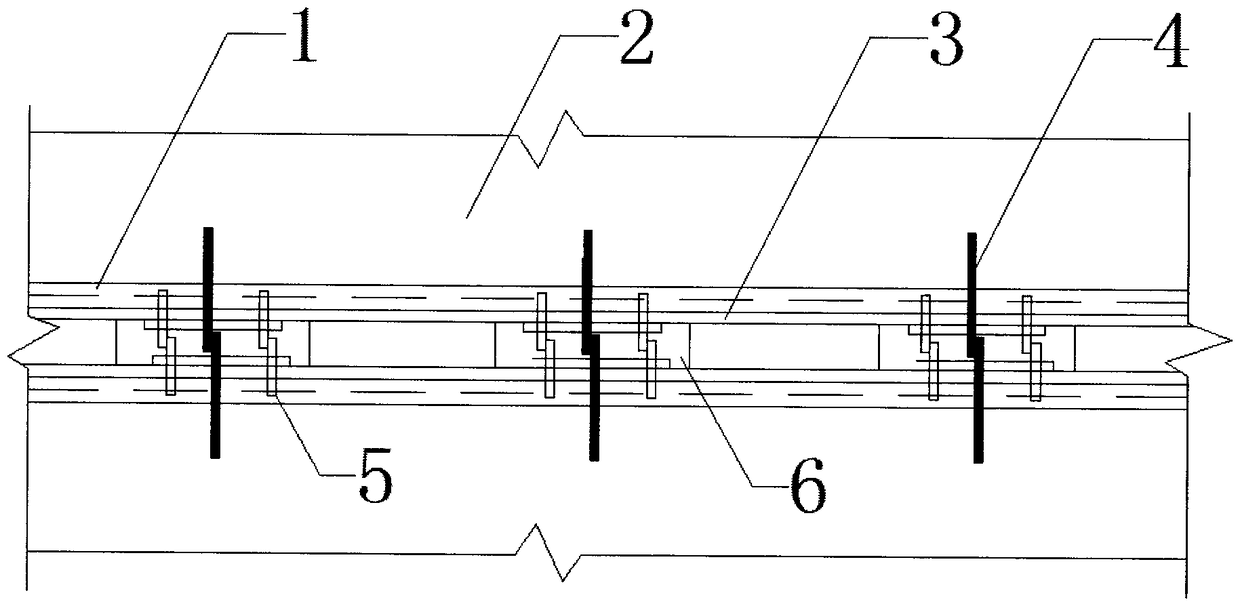

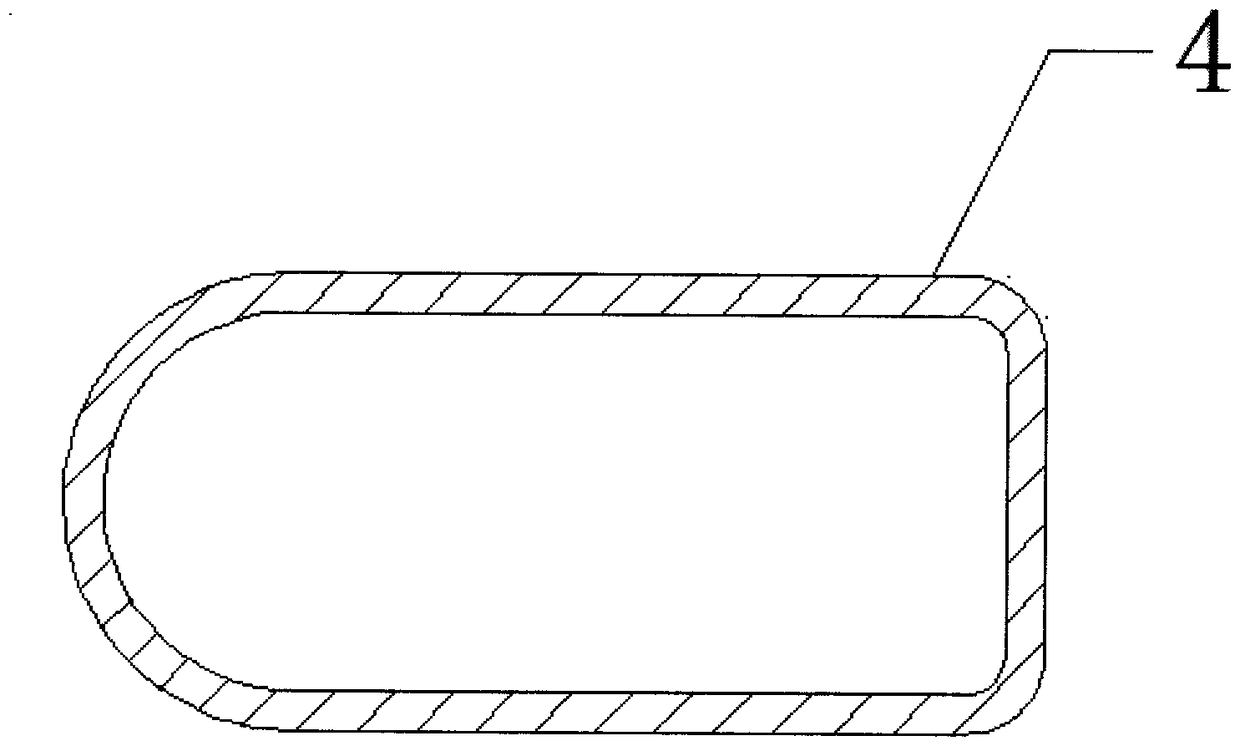

[0023] Example: such as Figure 1-3 As shown, a novel hollow slab funnel hinge joint structure, the structural system is mainly composed of prefabricated hollow slabs (1) spliced longitudinally on the same plane, and funnel hinge joints (3) are formed between the prefabricated hollow slabs (1), The prefabricated hollow slab (1) and hinged joints (3) are poured with concrete pavement (2), the prefabricated hollow slab (1) is pre-embedded with closed U-shaped steel bars (4), and the adjacent prefabricated hollow The closed U-shaped steel bar (4) pre-buried in the plate (1) extends into the upper part of the funnel hinge (3) and overlaps each other. Corrugated steel connectors. The corrugated steel plate connector comprises a corrugated steel plate (6) and a connecting bolt (5), the corrugated steel plate (6) is respectively connected with the prefabricated hollow plate (1) through the connecting bolt (5), and the straight plate sections on both sides of the corrugated steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com