Method for manufacturing a solid aluminum alloy structure through wire filling type additive

A technology of additive manufacturing and aluminum alloy, which is applied in the field of wire-filled additive manufacturing of solid aluminum alloy structures, can solve the problems of reduced production cost, production cycle, reduced forming efficiency, large deformation of formed parts, etc., and achieves optimal lap joint effect , Forming efficiency improvement, arc stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

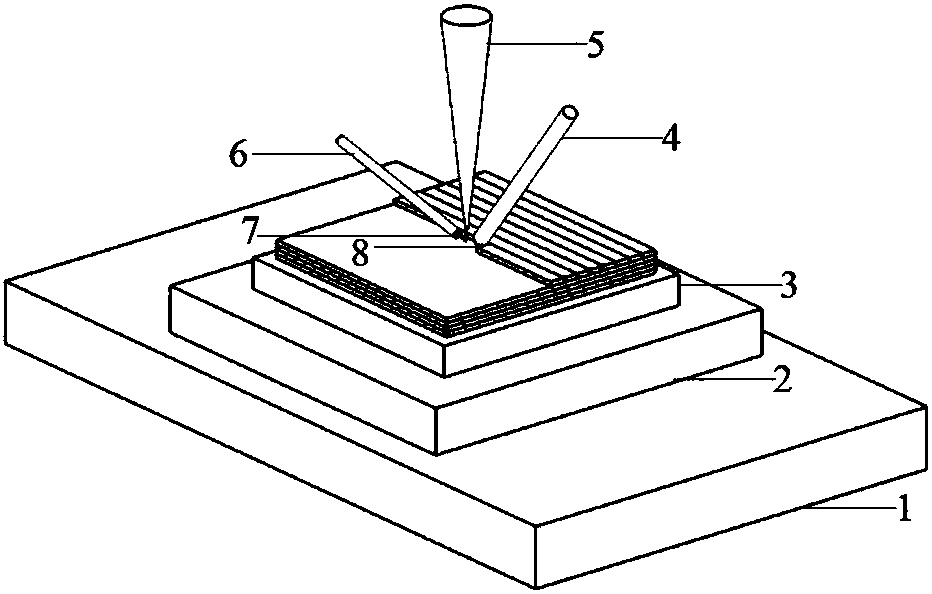

[0018] A method for wire-filling additive manufacturing of a solid aluminum alloy structure. The manufacturing method is realized based on the following structure. A 6061 aluminum alloy substrate 3 with a thickness of 15 mm is used, which is mechanically polished and cleaned with absolute ethanol; The heating device 2 is fixed above the CNC system workbench 1, and the substrate 3 is fixed above the preheating device 2, the laser is deflected by 5°, the defocus is -1.0mm, the angle between the axis of the TIG welding torch 4 and the horizontal plane is 50°, The height of the end of the tungsten needle 8 is 2.0 mm, the angle between the axis of the wire feed nozzle 6 and the horizontal plane is 10°, and the welding wire 7 is ER4043. Proceed as follows:

[0019] Step 1: Adopt laser-TIG composite heat source and pre-wire feeding method, laser spo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com