High-performance flame-retardant silicone rubber self-adhesive tape and preparation process therefor

A silicone rubber and flame-retardant technology, which is applied in the field of high-performance flame-retardant silicone rubber self-adhesive tape and its preparation, can solve the problems of short shelf life, poor self-adhesiveness, high electrical breakdown, etc., and achieve high tensile strength, Excellent electrical properties and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

[0027] Embodiment 1~10 and comparative example 1~2

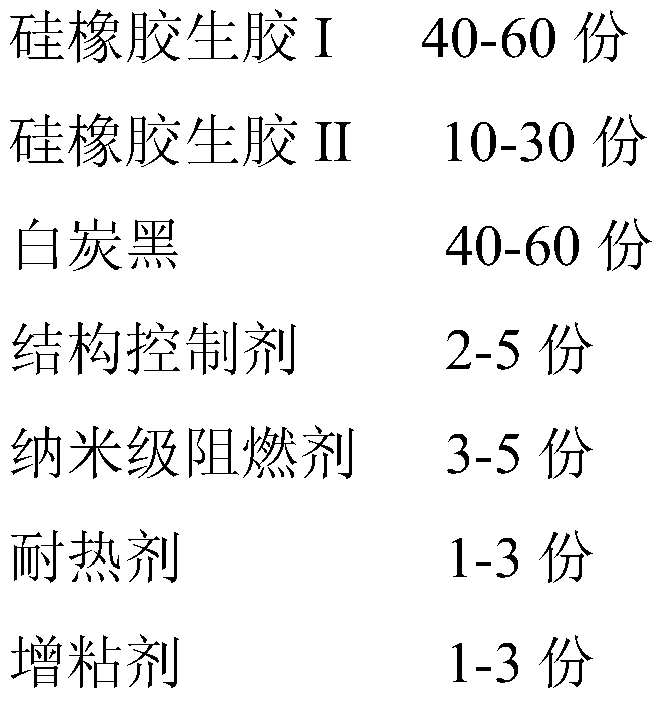

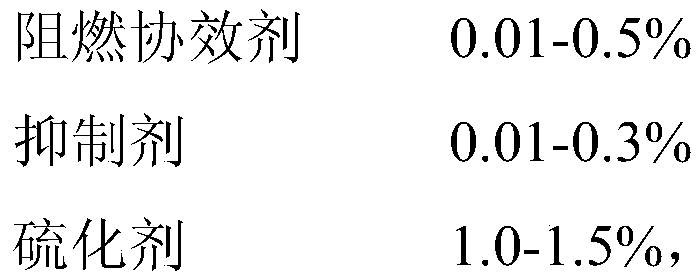

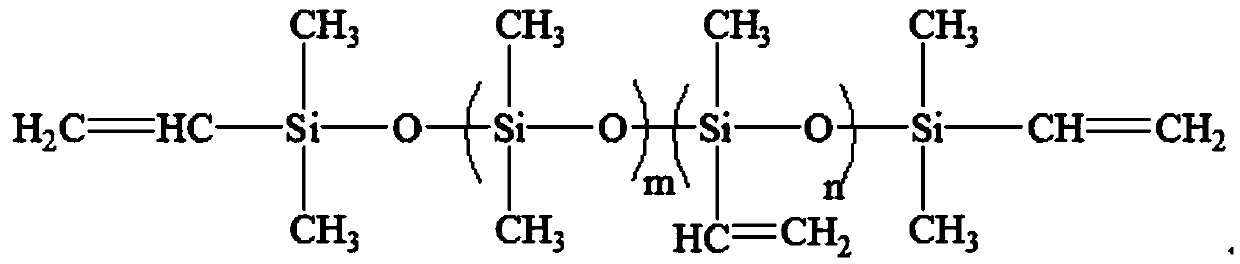

[0028] According to the formula quantity in table 1, take raw material, silicone rubber raw rubber I (adopt the composition with following structural formula ), silicone rubber raw rubber II (using the composition with the following structural formula ), white carbon black (fumed white carbon black, the specific surface area is 180m 2 / g), structure control agent (hydroxyl silicone oil, viscosity is 35-40cps, hydroxyl content is 4%), nanoscale flame retardant (embodiment 1- / 10 is nanoscale rutile type titanium dioxide, particle diameter D50=0.12 μ m , comparative example 1 is a nitrogen-phosphorus flame retardant, and comparative example 2 is an aluminum hydroxide flame retardant) and a heat-resistant agent (nano-scale iron oxide red, which is gamma crystalline iron oxide, particle size D50=20nm) into the kneader Stir evenly at room temperature for 1 hour, heat to 150-160°C and stir for 3 hours and vacuumize, then add a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com