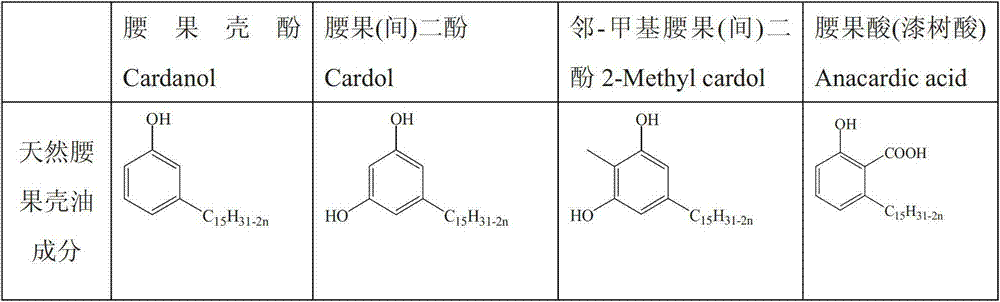

Cashew oil modified alkyl phenol-phenol formaldehyde tackifying resin, preparation method and application thereof

A technology of tackifying resin and cashew nut oil, applied in the field of rubber industry, can solve the problems of increasing the dynamic mechanical loss of rubber and increasing the friction effect of rubber molecular segments, so as to reduce dynamic heat generation, improve self-adhesion, and increase compatibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

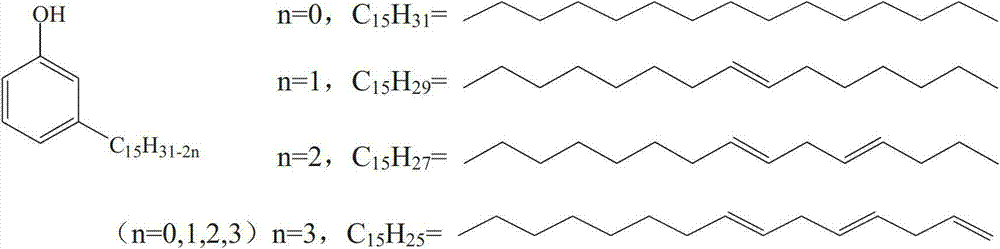

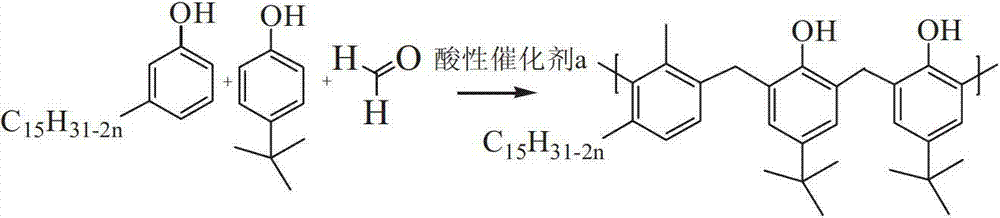

Method used

Image

Examples

Embodiment 1

[0042] On the 1000ml four-neck reaction flask, install stirring, thermometer, reflux condenser and addition funnel. Drop into p-tert-butylphenol 180g, cashew nut oil 240g, 37% formaldehyde aqueous solution 215g, triethylamine catalyst 5g. The temperature was raised to 100°C. The reaction was refluxed for 2 hours. Normal pressure dehydration. The temperature was raised to 190°C and kept at this temperature for 2 hours, then drained into a stainless steel pan and cooled to room temperature. The obtained resin of the present invention has a softening point of 120°C and is dark red.

Embodiment 2

[0044] On the 1000ml four-neck reaction flask, install stirring, thermometer, reflux condenser and addition funnel. Add 285 g of p-tert-butylphenol, 30 g of cashew nut oil, 195 g of 37% formaldehyde solution, and 4 g of triethylamine catalyst. Raise the temperature to 80°C and react for 5 hours. Normal pressure dehydration. The temperature was raised to 190°C and kept at this temperature for 2 hours, then drained into a stainless steel pan and cooled to room temperature. Obtain the resin of the present invention, the product is transparent, softening point 128 ℃, dark red.

Embodiment 3

[0046] On the 1000ml four-neck reaction flask, install stirring, thermometer, reflux condenser and addition funnel. Drop into p-tert-butylphenol 240g, cashew nut oil 120g, p-toluenesulfonic acid catalyst 3g. Heat up to 100°C to melt, add 200 g of 37% formaldehyde solution dropwise, complete the dropwise addition within 30 minutes, and reflux for 2 hours. Normal pressure dehydration. When the temperature rises to 180°C, add 3.2g of sodium hydroxide 20% aqueous solution to neutralize. The temperature was raised to 190°C and kept at this temperature for 2 hours, then drained into a stainless steel pan and cooled to room temperature. The obtained resin of the present invention has a softening point of 126°C and is dark red.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com